Seabed hard rock multi-point pressure-maintaining coring micro drilling machine

A multi-point, hard rock technology, applied in underwater drilling, earthwork drilling, extraction of undisturbed core devices, etc., can solve problems such as high cost efficiency, achieve simple and compact structure, ensure safety, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

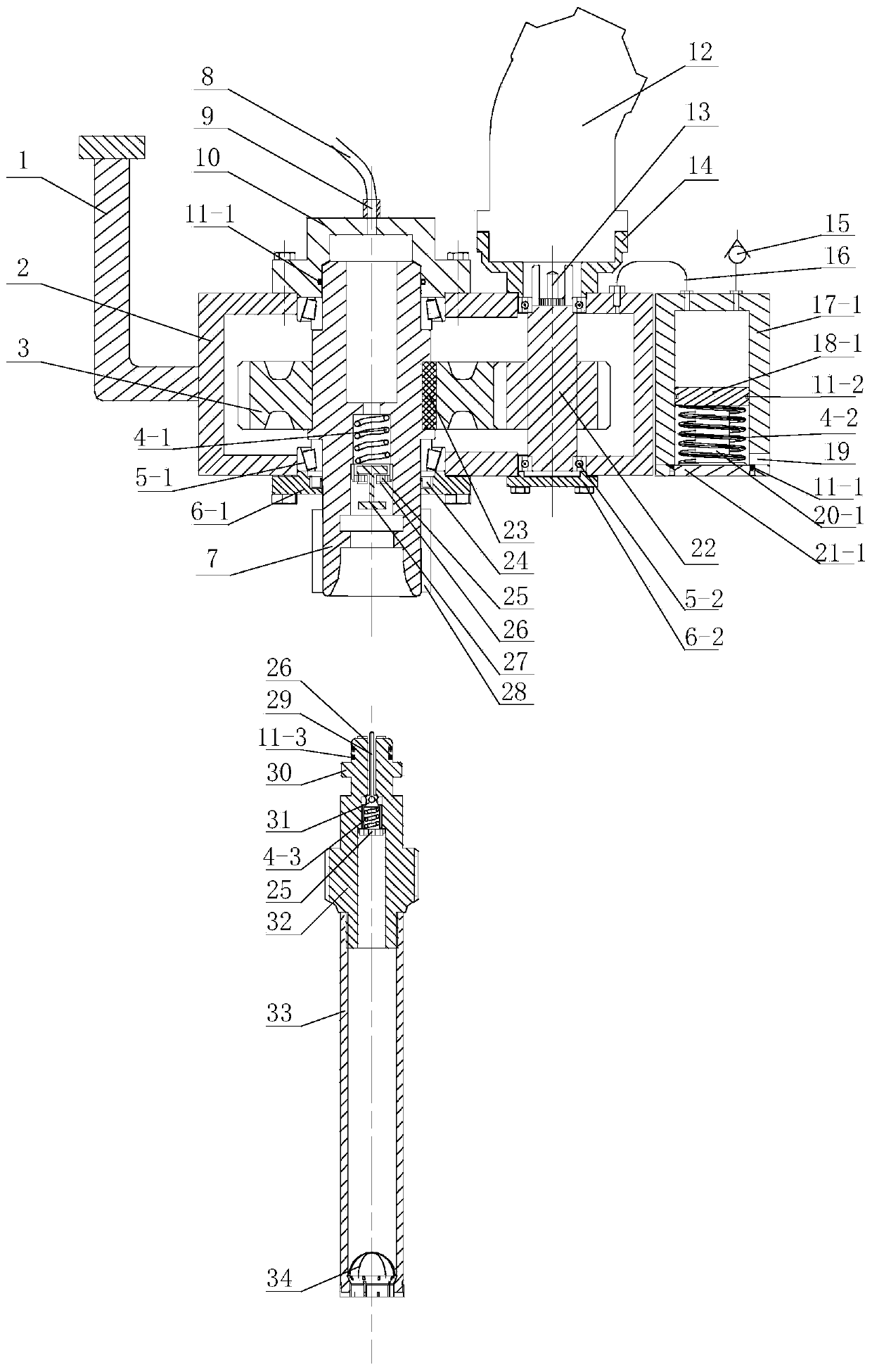

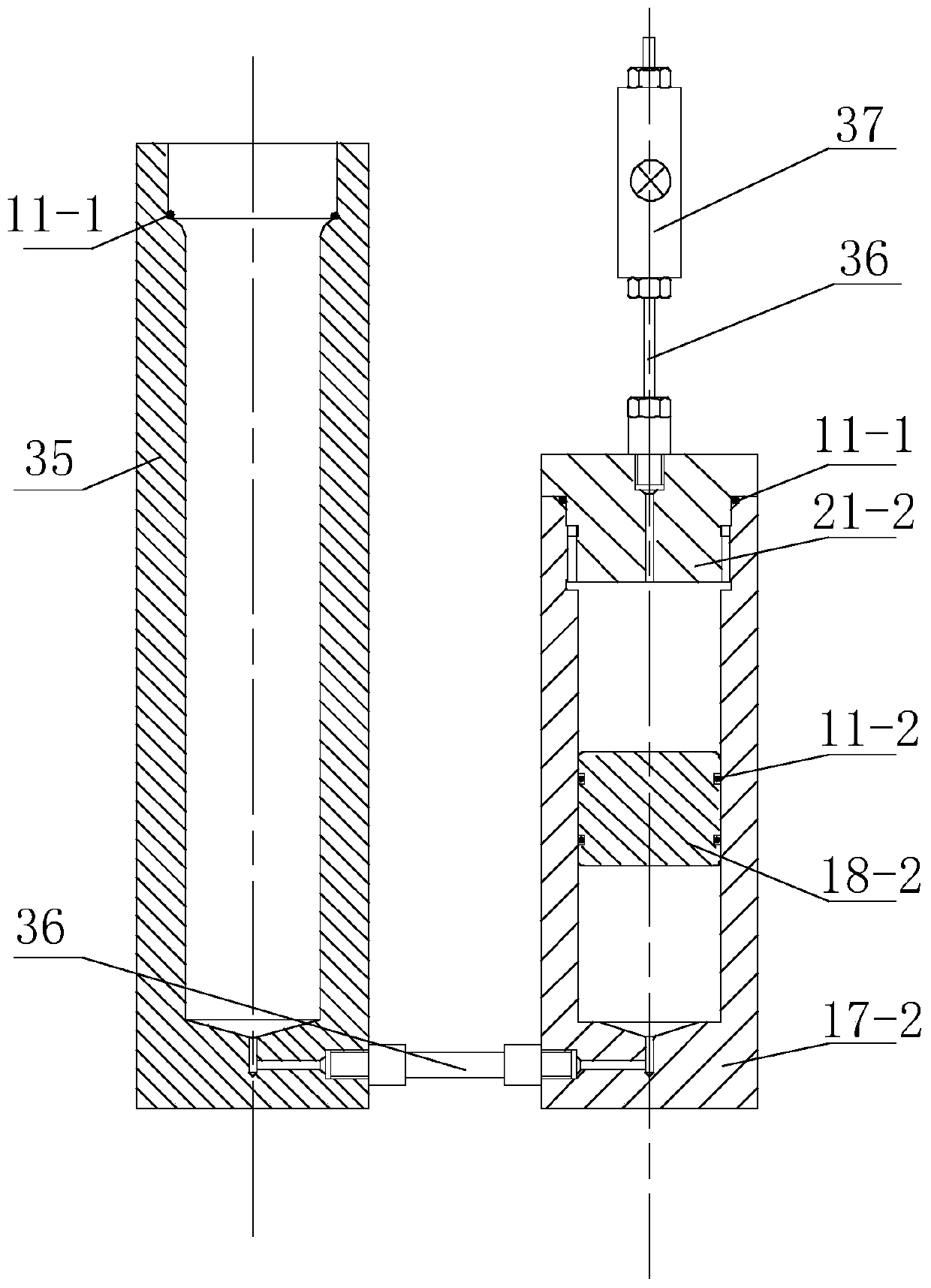

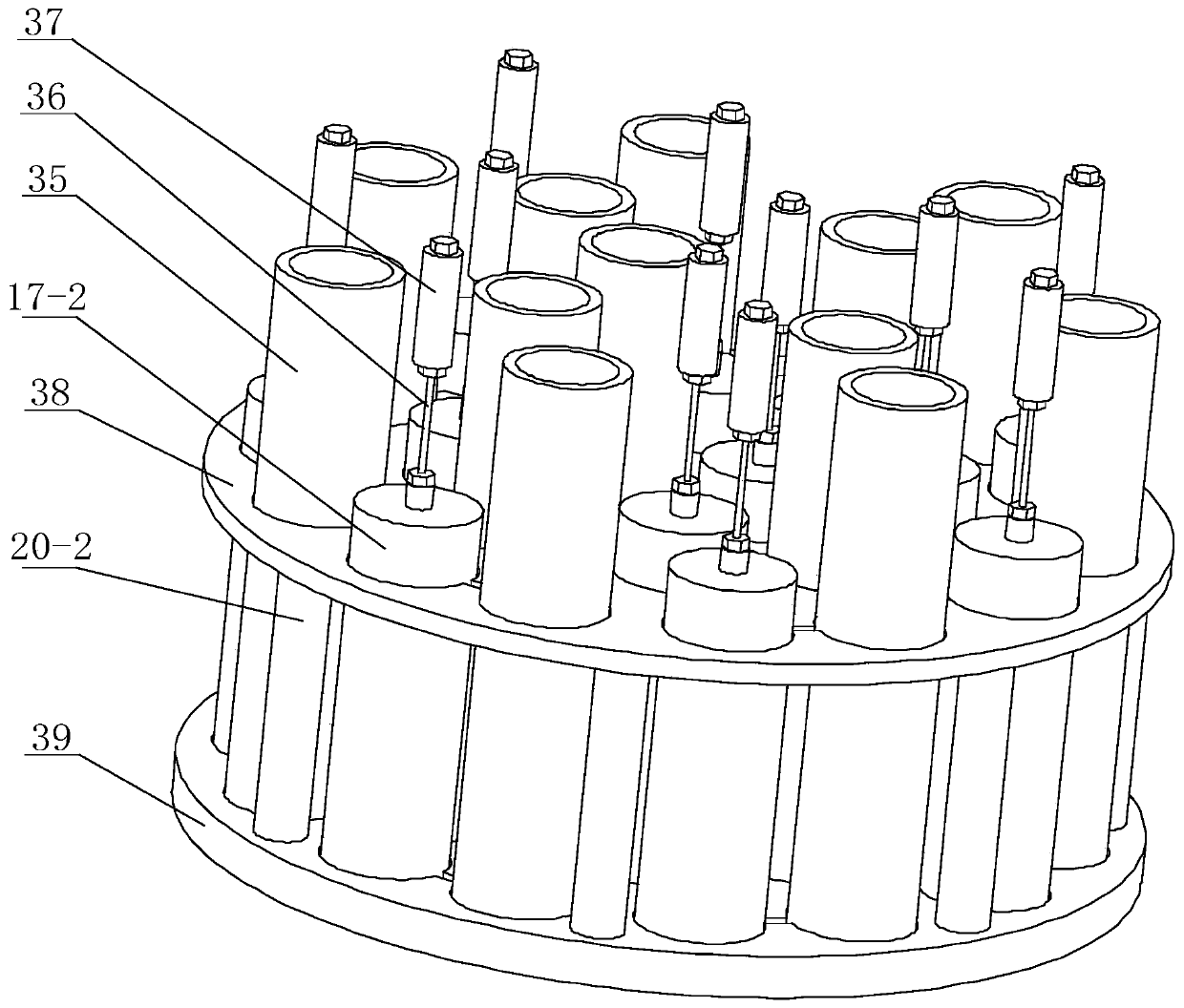

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, the present invention includes a handle 1, a power head 12, a reduction box 2, a drilling tool discarding device, a drilling tool, a pressure compensator, a core pressure maintaining device and a rock stand. The top plate of the reduction box is equipped with a water supply joint 10 and a power head 12, the power head 12 is connected with the driving gear shaft 22 (the input shaft of the gearbox 2) through the power head output shaft 13, and the driving gear shaft 22 is connected through the bearing 5- 2 is installed in the reduction box 2; the driving gear shaft 22 is provided with a driving gear; the main shaft 7 is installed in the reduction box 2 through the bearing 5-1, the main shaft 7 is parallel to the driving gear shaft 22, and the main shaft 7 (the output shaft of the gear box 2 ) is provided with a driven gear 3, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com