Coating micro-drilling knife for printed circuit board machining and preparation method thereof

A printed circuit board and micro-drilling technology, which is applied in coating, metal processing, metal material coating technology, etc., can solve the problems that cannot meet the service conditions of high-speed cutting, and achieve simple operability, good adhesion, Effect of Low Coefficient of Friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

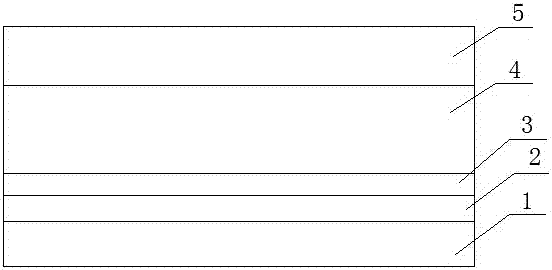

[0028] Such as figure 1 As shown, a coated micro-drill for processing printed circuit boards includes a micro-drill substrate 1, and the micro-drill substrate 1 is sequentially attached with a metallurgical bonding layer 2, a transition layer 3, and a main resistance layer from the inside to the outside. The grinding layer 4 and the self-lubricating layer 5, the metallurgical bonding layer 2 is a pure metal Cr layer, the transition layer 3 is a nano-multilayer composed of Cr and VN alternately, and the main wear-resistant layer 4 is a nano-multilayer composed of DLC and VN alternately. The lubricating layer 5 is a Cr-doped DLC layer.

[0029] The thickness of the transition layer 3 is 100-200 nm, the thickness of the main wear-resistant layer 4 is 500-1500 nm, and the thickness of the self-lubricating layer 5 is 200-500 nm.

[0030] In the transition layer 3, the thickness of a single layer of Cr is 10-20 nm, and the thickness of a single layer of VN is 5-15 nm.

[0031] In ...

Embodiment 2

[0043] A coated micro-drill for processing printed circuit boards, comprising a micro-drill substrate, on which a metallurgical bonding layer, a transition layer, a main wear-resistant layer and a self-lubricating layer are sequentially attached from the inside to the outside, The metallurgical bonding layer is a pure metal Cr layer, the transition layer is a nano-multilayer composed of Cr and VN alternately, the main wear-resistant layer is a nano-multilayer composed of DLC and VN alternately, and the self-lubricating layer is a Cr-doped DLC layer.

[0044] The thickness of the transition layer is 100nm, the thickness of the main wear-resistant layer is 500nm, and the thickness of the self-lubricating layer is 200nm. In the transition layer, the single-layer Cr thickness is 10nm, and the single-layer VN thickness is 8nm. In the main wear-resistant layer, the single-layer DLC has a thickness of 5nm, and the single-layer VN has a thickness of 10nm.

[0045] The material of the...

Embodiment 3

[0055] A coated micro-drill for processing printed circuit boards, comprising a micro-drill substrate, on which a metallurgical bonding layer, a transition layer, a main wear-resistant layer and a self-lubricating layer are sequentially attached from the inside to the outside, The metallurgical bonding layer is a pure metal Cr layer, the transition layer is a nano-multilayer composed of Cr and VN alternately, the main wear-resistant layer is a nano-multilayer composed of DLC and VN alternately, and the self-lubricating layer is a Cr-doped DLC layer.

[0056] The thickness of the transition layer is 120nm, the thickness of the main wear-resistant layer is 600nm, and the thickness of the self-lubricating layer is 300nm. In the transition layer, the single-layer Cr thickness is 12nm, and the single-layer VN thickness is 6nm. In the main wear-resistant layer, the single-layer DLC has a thickness of 6nm, and the single-layer VN has a thickness of 9nm.

[0057] The material of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com