High-precision resin diamond micro-drilling excircle grinding wheel and application

A diamond and cylindrical grinding technology, used in abrasives, drill accessories, metal processing equipment, etc., can solve the problem of hard, brittle, wear-resistant grinding objects, and achieve good shape retention of grinding wheels and reduce fractures. Needle, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

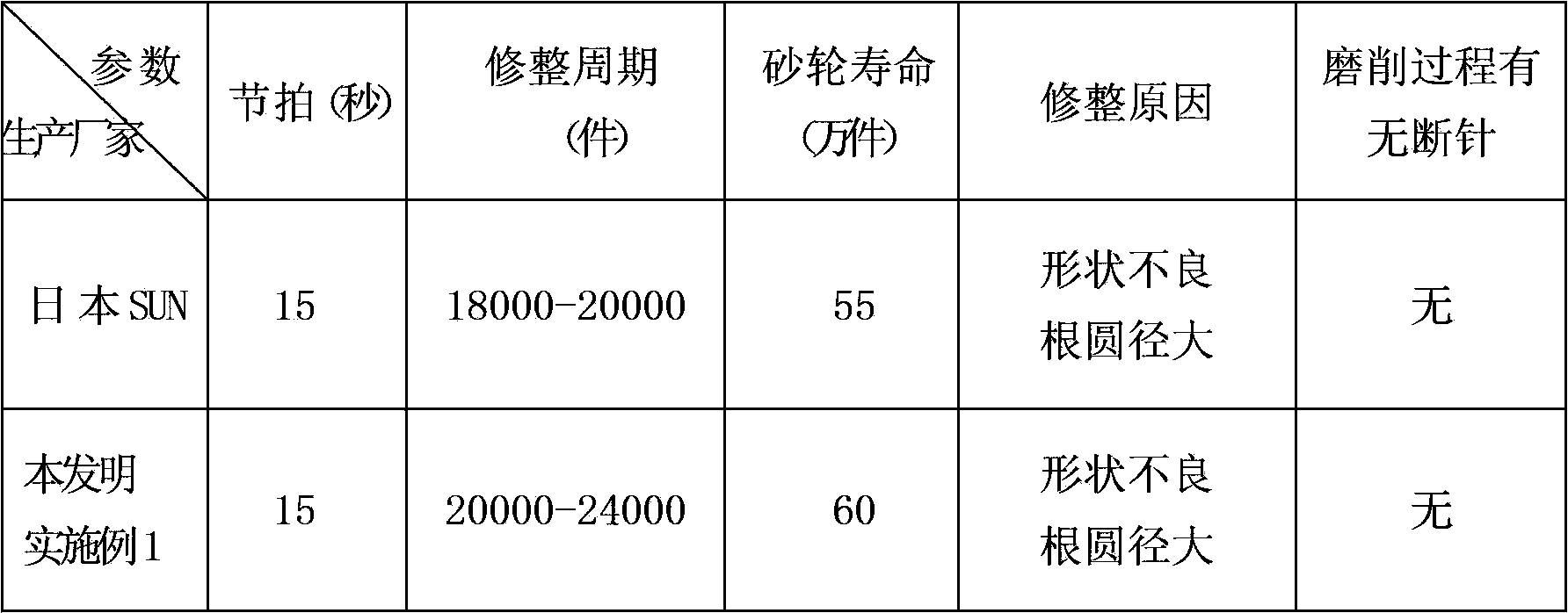

Embodiment 1

[0018] Grinding wheel manufacturing adopts the steps of the preparation process of general resin bonded diamond grinding wheel, namely: production preparation, lower abrasive formula, simultaneous rough turning of aluminum substrate with compounding materials, forming of grinding wheel blank, rough turning of grinding wheel substrate, drilling and tapping of grinding wheel substrate, fine grinding of grinding wheel substrate Car, grinding wheel outer circle dressing, dynamic balance, appearance treatment, final inspection. The composition of the working abrasive layer is by weight: resin bond 60, white corundum 10, nanometer MgO1, copper powder 5, nanometer TiO 2 4. Diamond 15, CBN5.

Embodiment 2

[0020] The preparation process steps are the same as in Example 1, except that the composition of the working abrasive layer is by weight: resin bond 50, white corundum 15, nanometer MgO2, copper powder 5, nanometer TiO 2 3. Diamond 20, CBN10.

Embodiment 3

[0022] The preparation process steps are the same as in Example 1, except that the composition of the working abrasive layer is: resin bond 70, white corundum 10, nanometer MgO1, copper powder 5, nanometer TiO21, diamond 10, CBN7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com