Diamond micro-drilling grinding tool

A diamond and diamond particle technology, which is applied in the field of diamond micro-drilling abrasive tools, can solve the problems of difficulty in processing micro-holes, long processing cycle, and high tool cost, so as to improve the phenomenon of grinding head clogging and grinding layer wear, and improve the quality of micro-holes And dimensional consistency, shorten the effect of processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

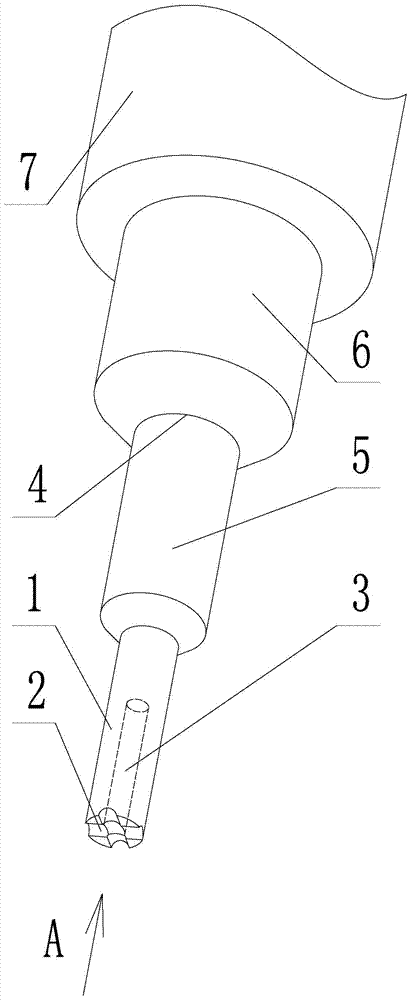

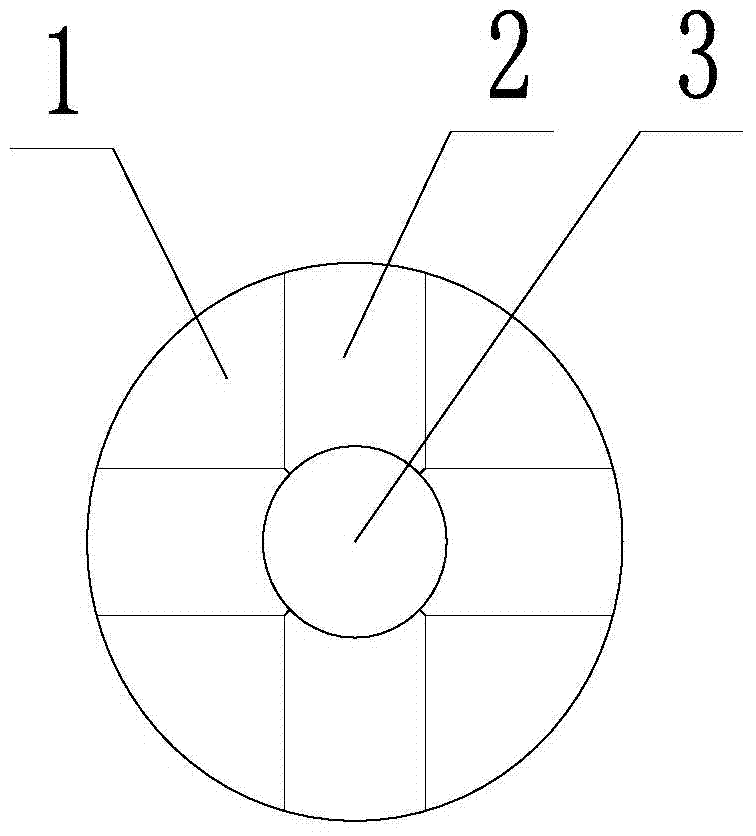

[0018] Such as figure 1 , 2 , shown in 3, a kind of diamond micro-drilling abrasive tool comprises base body 7 and grinding layer, and grinding layer is diamond particle layer, and grinding layer is plated on base body surface by electroplating mode, and described base body 7 tops are arranged as grinding head 1 , the top end surface of the grinding head 1 is a plane, a cross-shaped groove 2 is provided on the top end surface of the grinding head 1, and a central hole 3 for eliminating the low-speed grinding zone is provided in the axial center of the grinding head 1.

[0019] A stepped base 4 is provided between the grinding head 1 and the base 7 .

[0020] The stepped base 4 includes a primary reaming step 5 and a secondary reaming step 6 , the primary reaming step 5 is located on the grinding head 1 side, and the secondary reamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com