Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Laser interference lithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

False proof structure for driving license and its identifying method

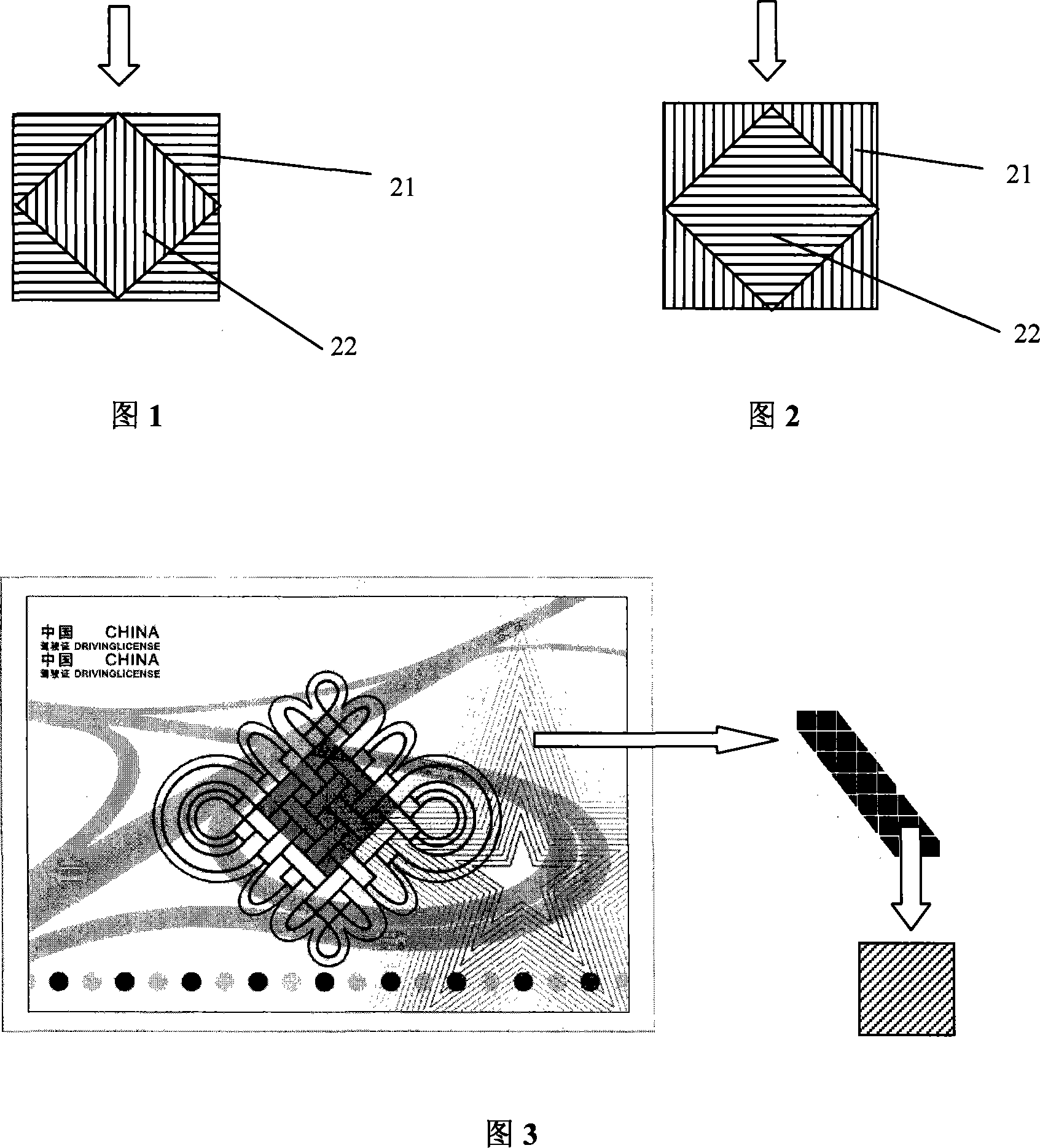

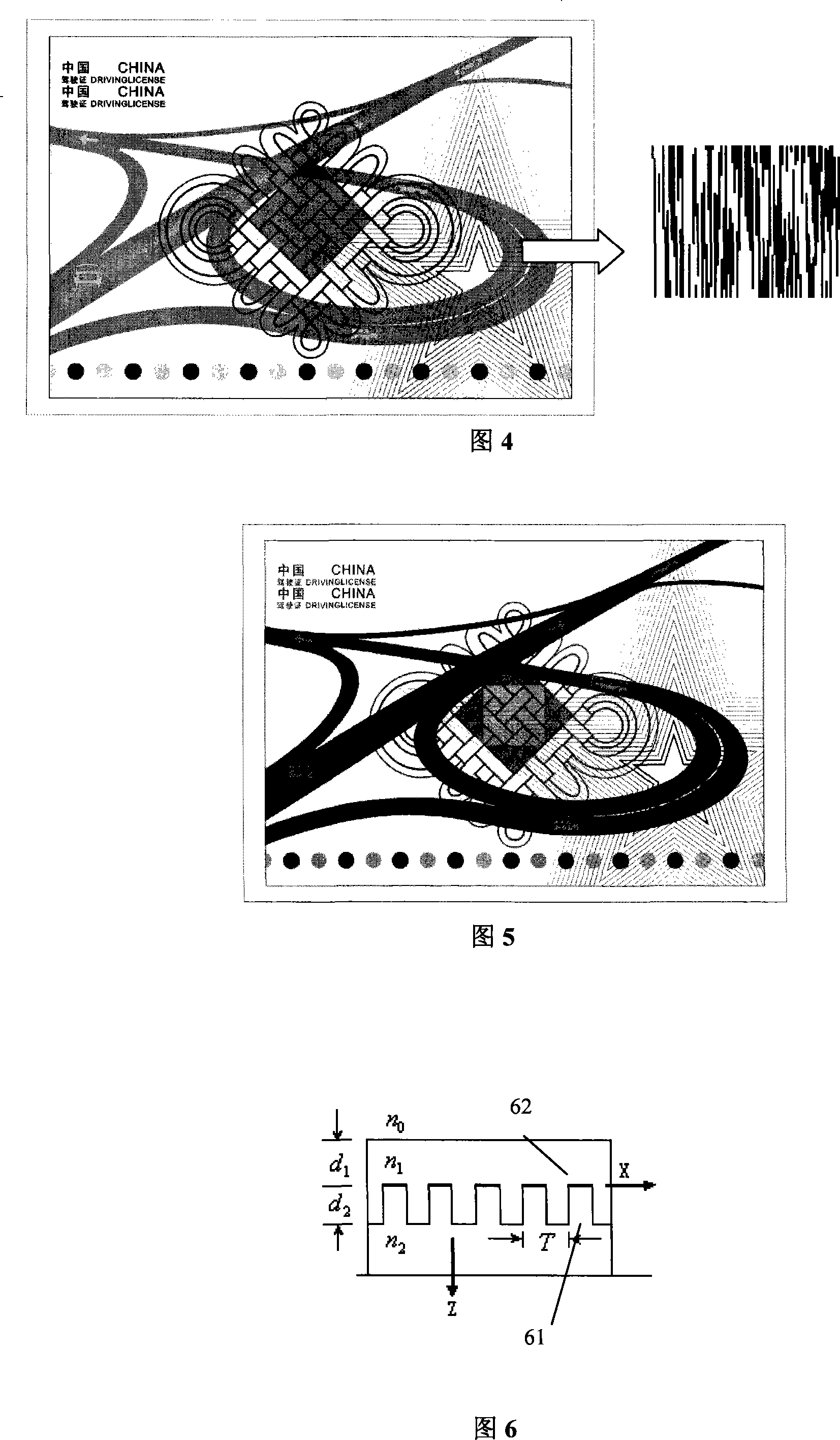

ActiveCN101161482AWith dynamic effectProminent visual featuresOther printing matterLight effect designsColor effectBody shape

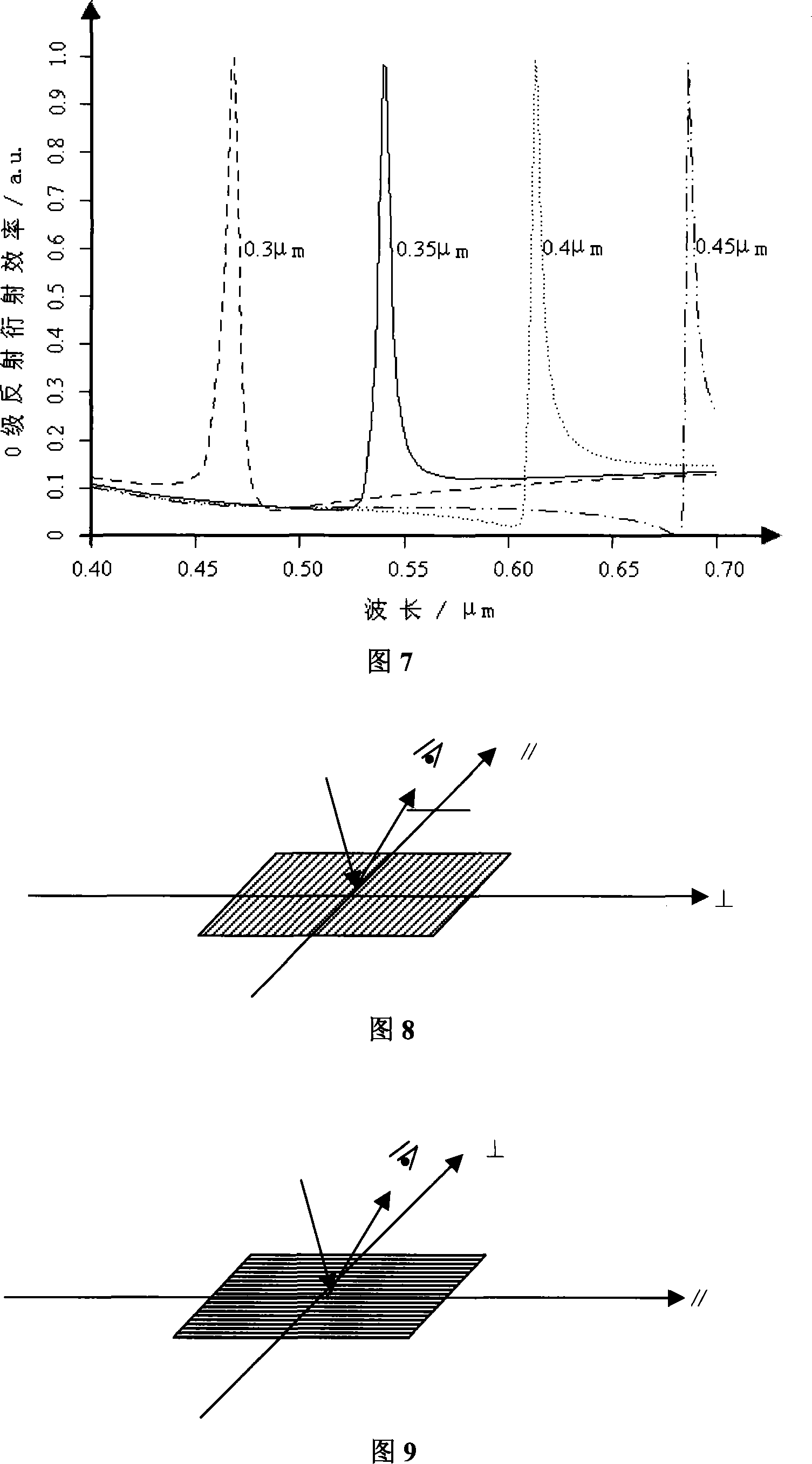

The invention discloses an anti-counterfeiting structure for driving card. The marked pattern composed of microstructure is set on the plastic packaged film of the card. The said marked pattern comprises at least three pattern area. A first pattern area is composed of sub-wavelength structure raster of orientated orthogonal structure and the double vision channel forms single color effect. A second pattern area is composed of light spot with body shape of square. The light spot shape of the pattern edge is determined by the outer outline of the pattern, with gliding property. The interference fringes are set in the light point. A third pattern area is composed of bar speckle microstructure, with oriented achromatization effect for white light reflection. The vision character of pattern is notable, easy to recognize in public places and conveniently and quickly distinguish the card. At the same time, the structure data is computed using rigid coupled wave. The said microstructure is produced using electron beam or laser interference optical lithography, and the means is advanced and the difficulty of technique is high with high safety.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY +1

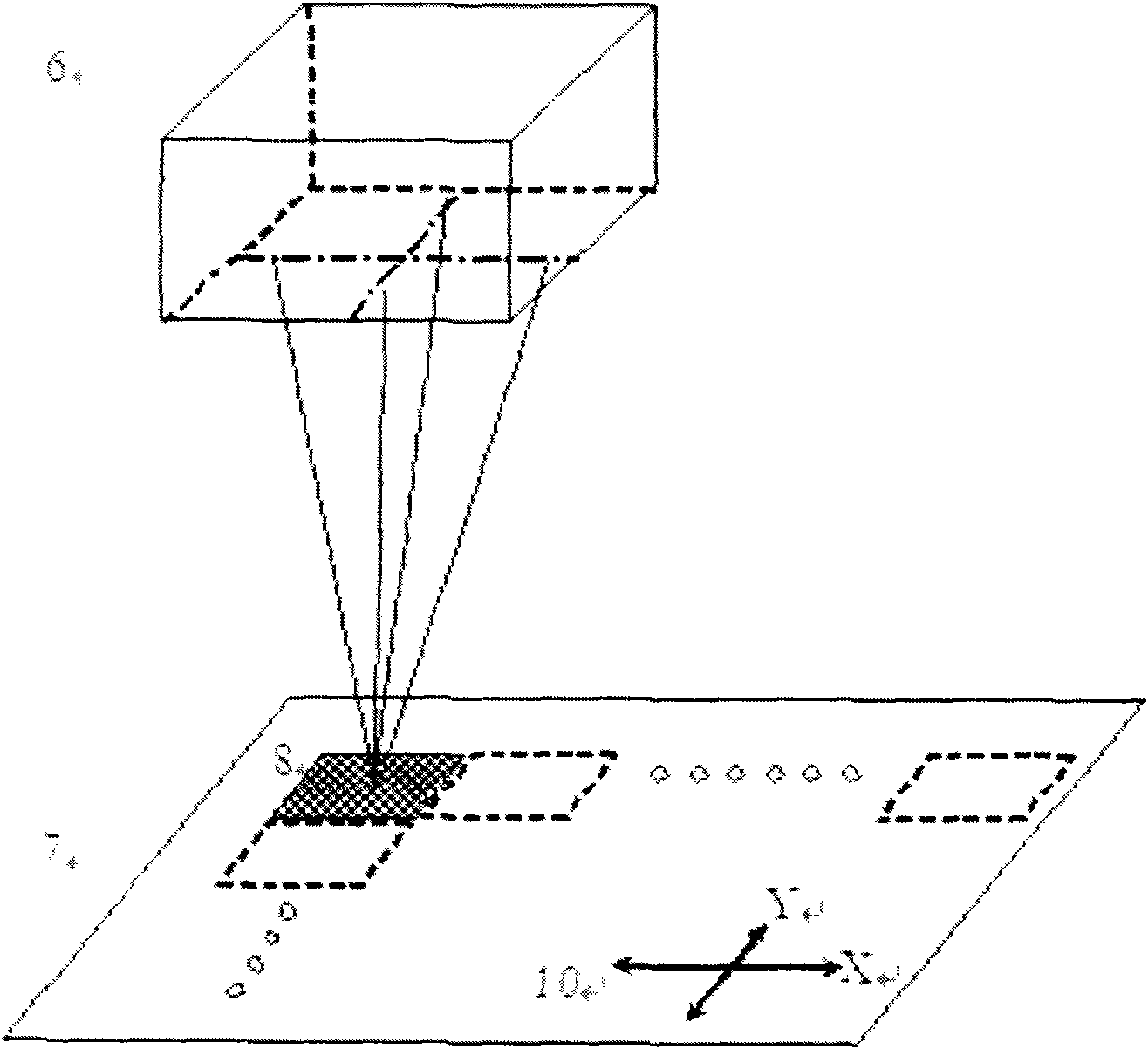

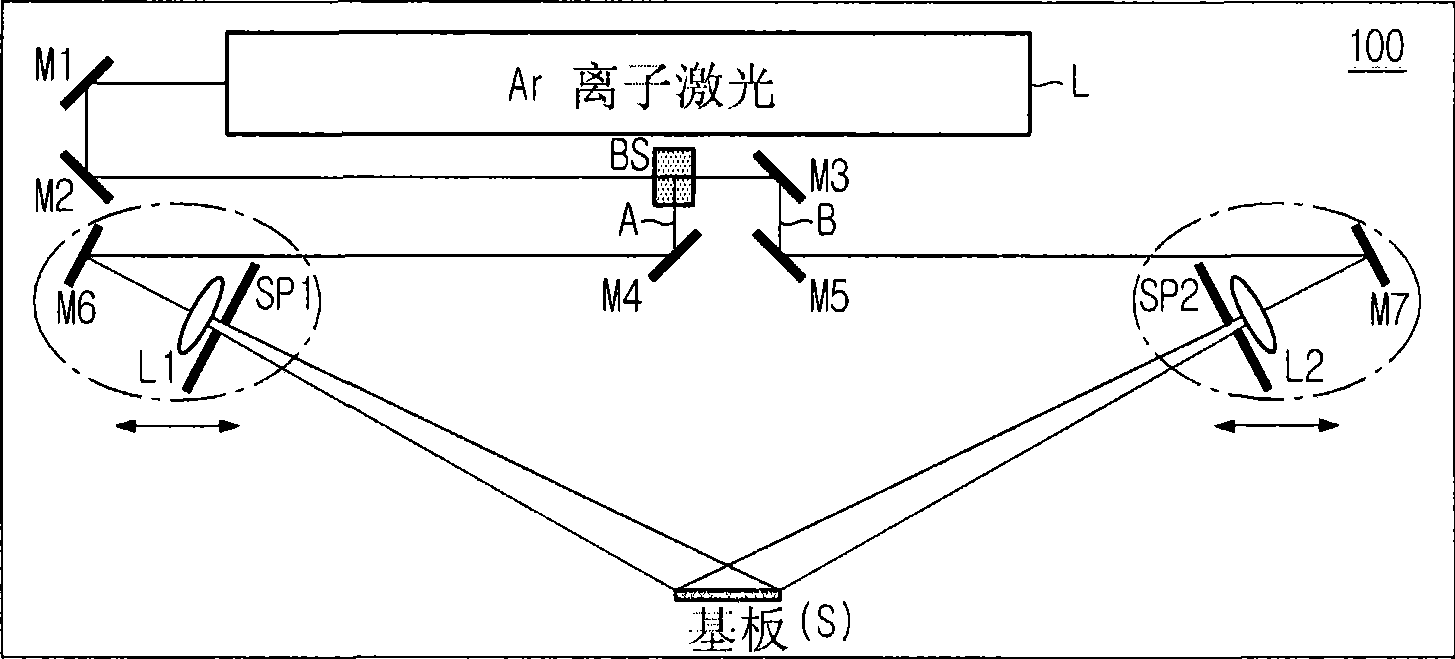

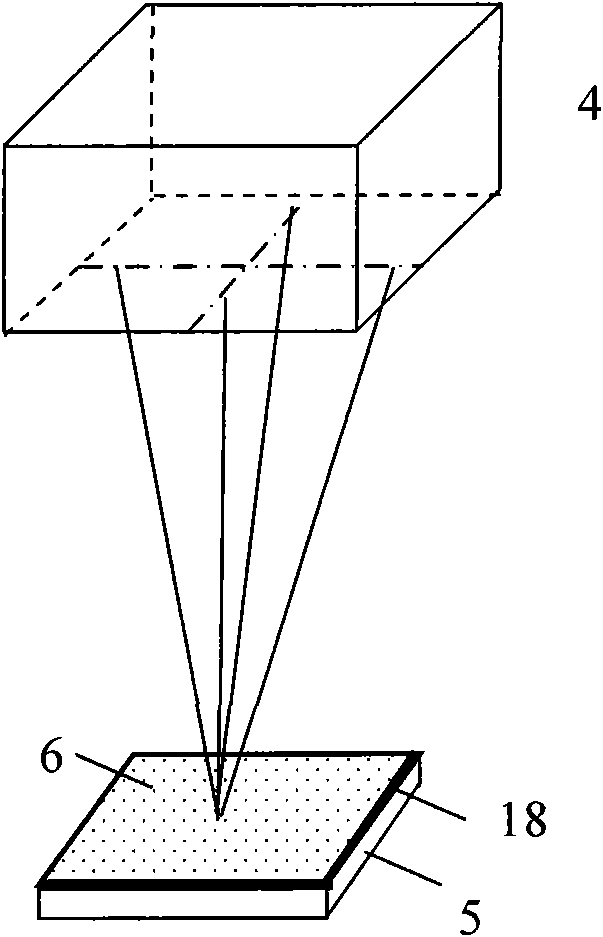

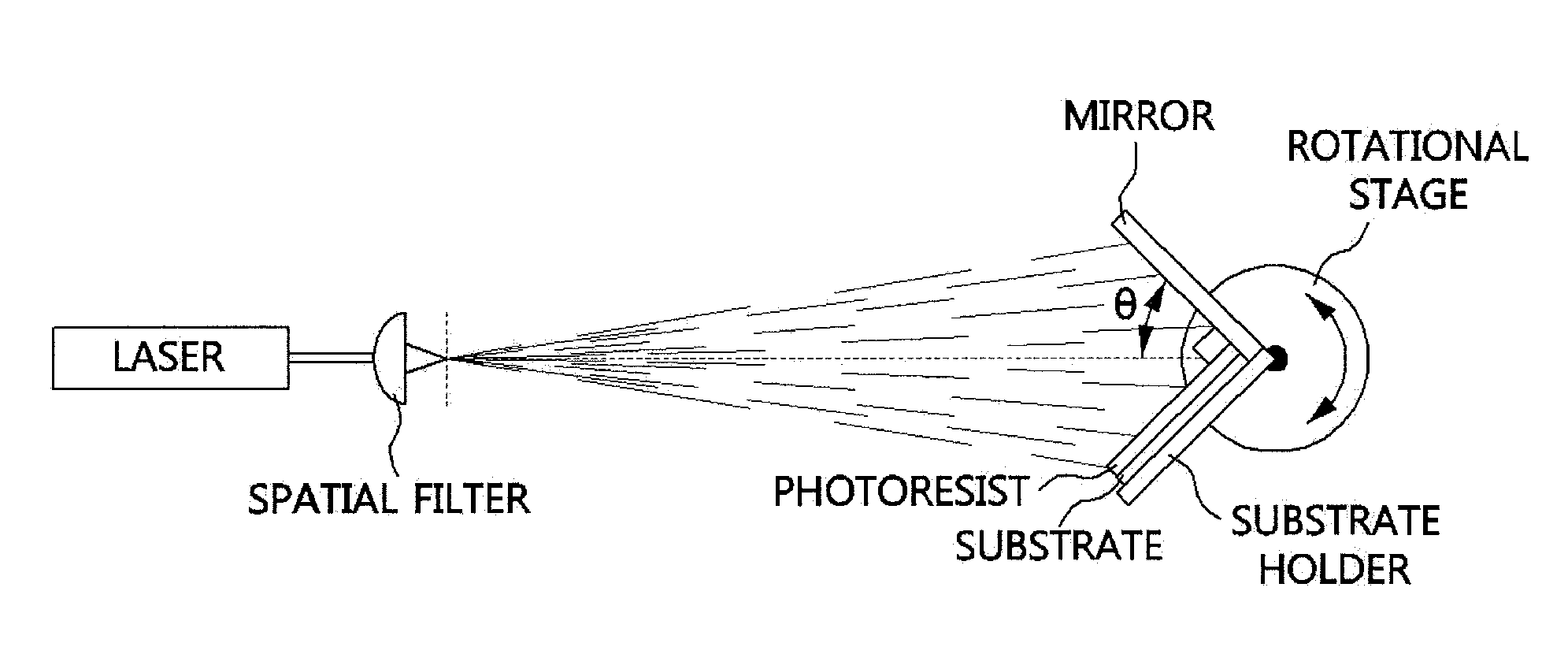

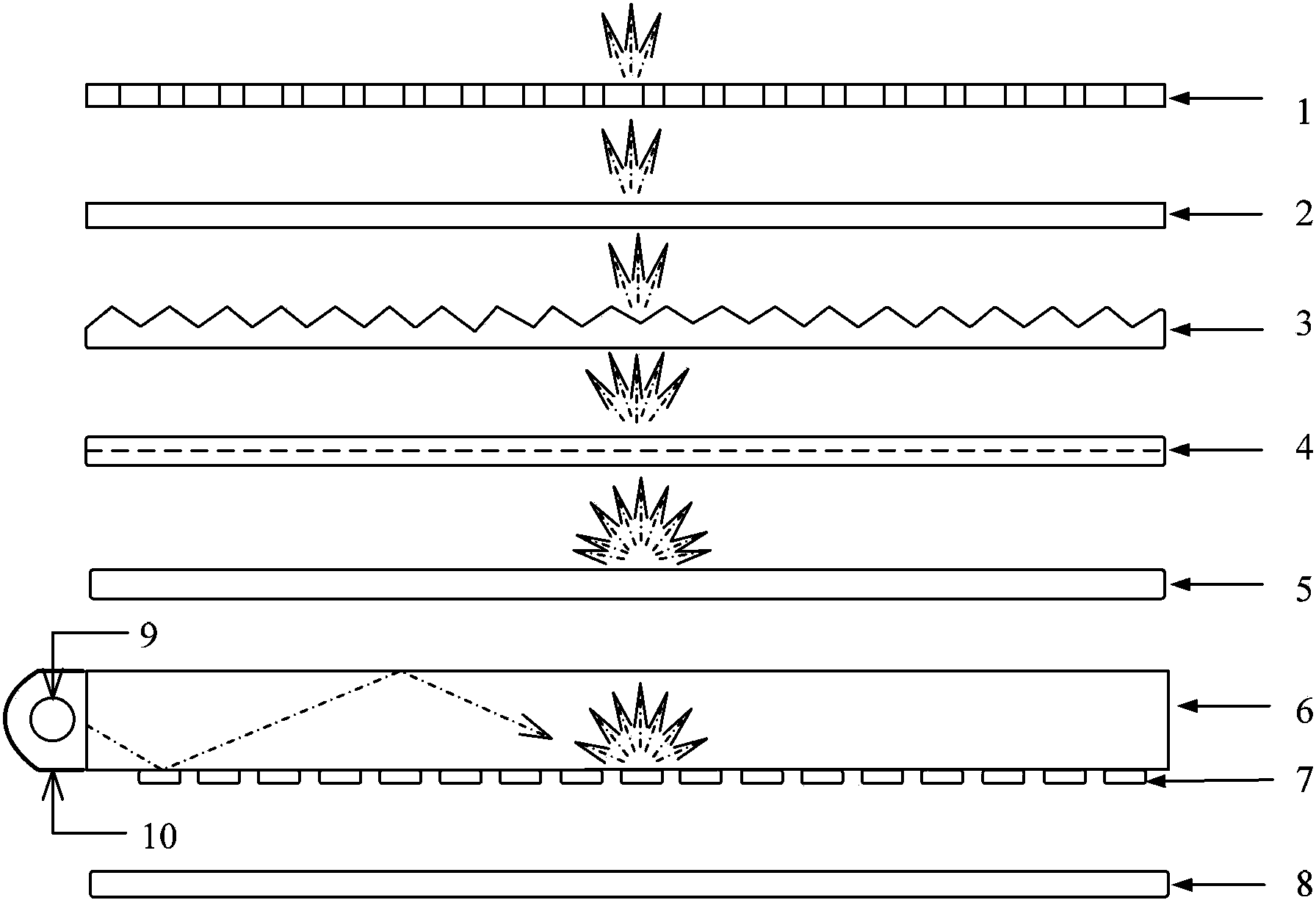

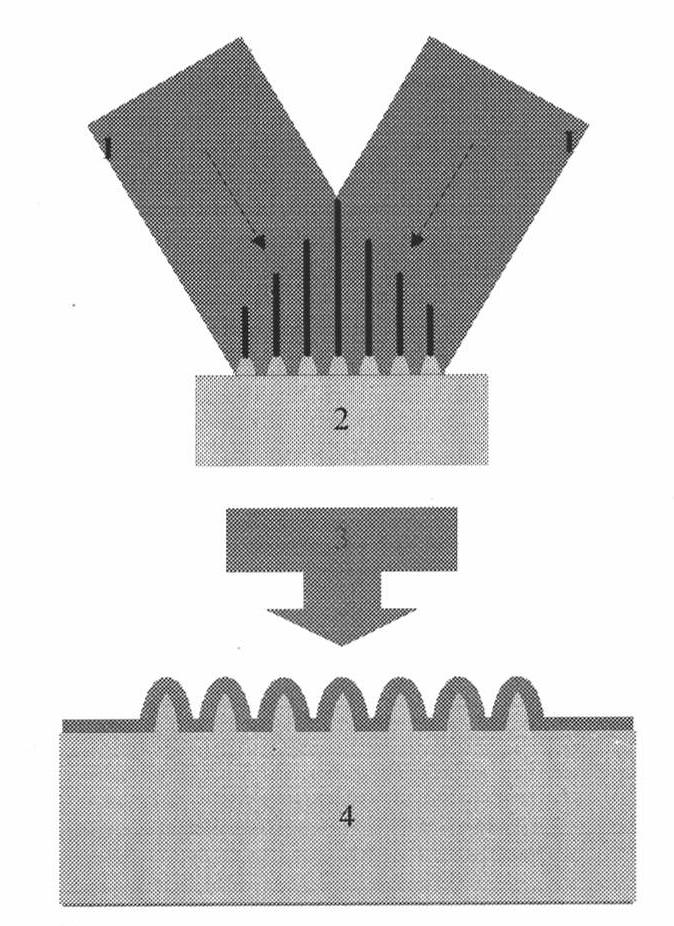

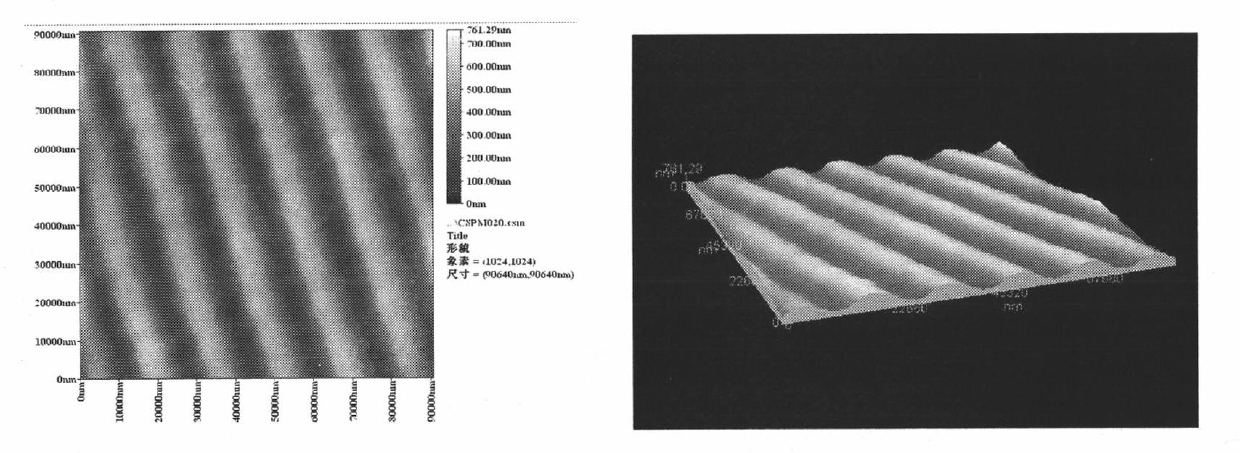

Method and system for manufacturing self-cleaning surface structure by adopting laser interference photolithography technology

InactiveCN101844272AParameters can be adjustedGood controllability of structural parametersPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoMicron scale

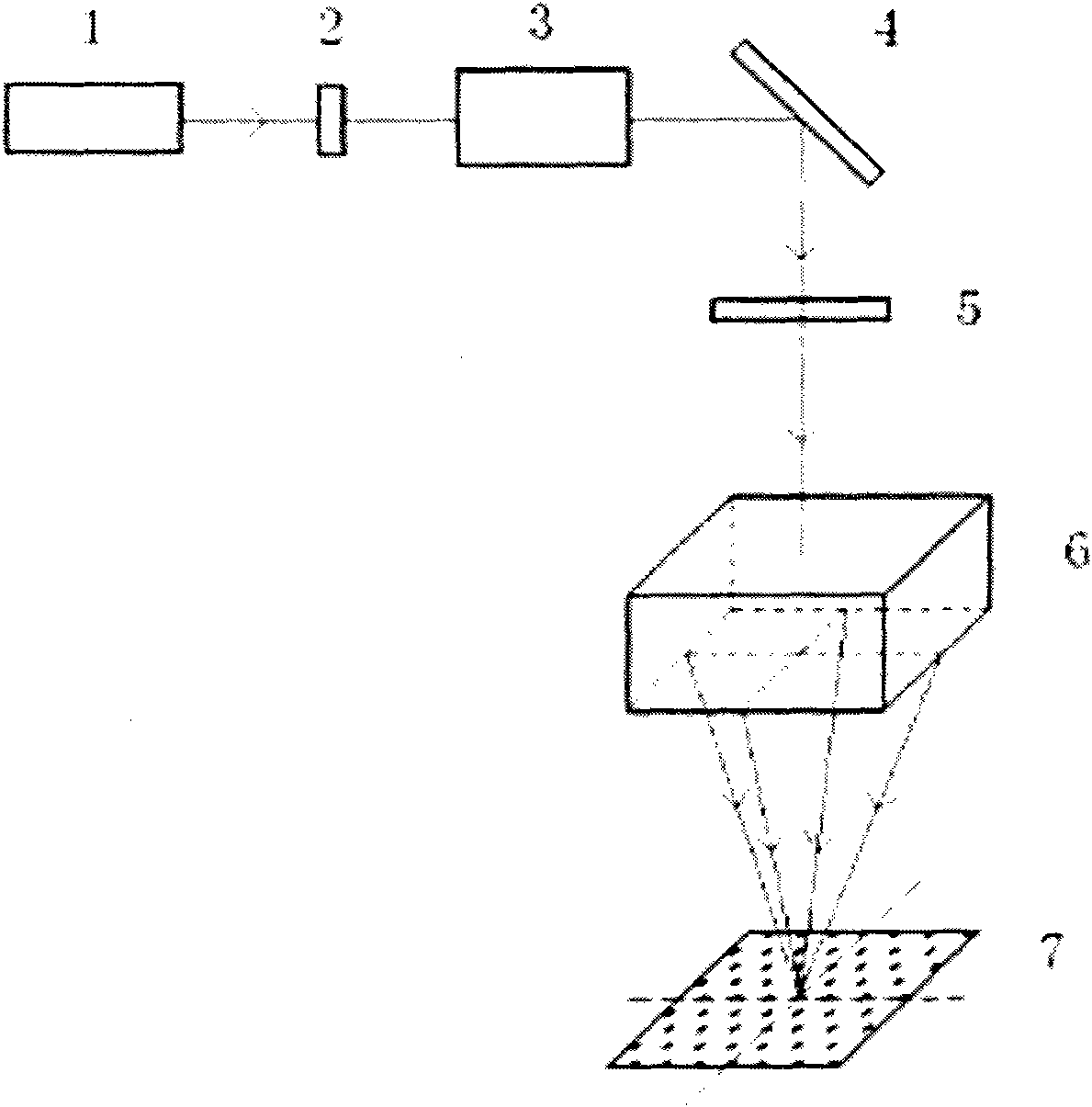

The invention relates to method and system for manufacturing a self-cleaning surface structure by adopting a laser interference photolithography technology. The method is characterized in that a plurality of coherent laser beams are combined by using a laser interference photolithography system, weakness modulation is carried out on light intensity distribution in an interference field, redistributed laser energy after modulation is used for ablating the surface of optics materials, and a micron-size or nanoscale dense cylindrical or conical anaglyph structure is generated within a large area range, thereby obtaining a super-hydrophobic film, greatly lowering the viscous phenomenon, benefiting to attachments including dusts, liquid and the like on the surface of the materials detaching from the surface of the materials and fulfilling a self-cleaning function. Without external materials, the self-cleaning fine structure generated on the surface of the materials is more stable and durable and can continuously regulate the period and the size from the nanoscale to the micron size by regulating an incidence angle of the interference photolithography system to enable dual structure of nanometer, micro and micro nanometer to become possible.

Owner:CHANGCHUN UNIV OF SCI & TECH +1

Method for preparing biomimetic colour super-hydrophobic coating by multi-beam interference photoetching technology

InactiveCN101727010AEasy to manufactureMake fastPhotomechanical coating apparatusManufacturing technologyLight beam

The invention belongs to the field of biomimetic micro-manufacturing technology and particularly relates to a method for preparing a biomimetic colour super-hydrophobic coating on a transparent polymer material by multi-beam interference photoetching technology, which comprises the following steps: building a laser multi-beam interference system, spirally coating a solidifiable or degradable material on a substrate, solidifying the solidifiable material or degrading the degradable material through laser interference photoetching and obtaining a microstructural array after developing; and then modifying a low-surface energy material on a microstructure, and obtaining the biomimetic colour super-hydrophobic coating by the multi-beam interference photoetching technology on the substrate. The method of the invention can overcome the shortcomings of the traditional preparation method, allows the surface of the material to display various colours and plays a role of very good decoration effect because the regular structure scatters and diffracts incident light, and promotes the super-hydrophobic surface to develop to a simplified and practical surface.

Owner:JILIN UNIV

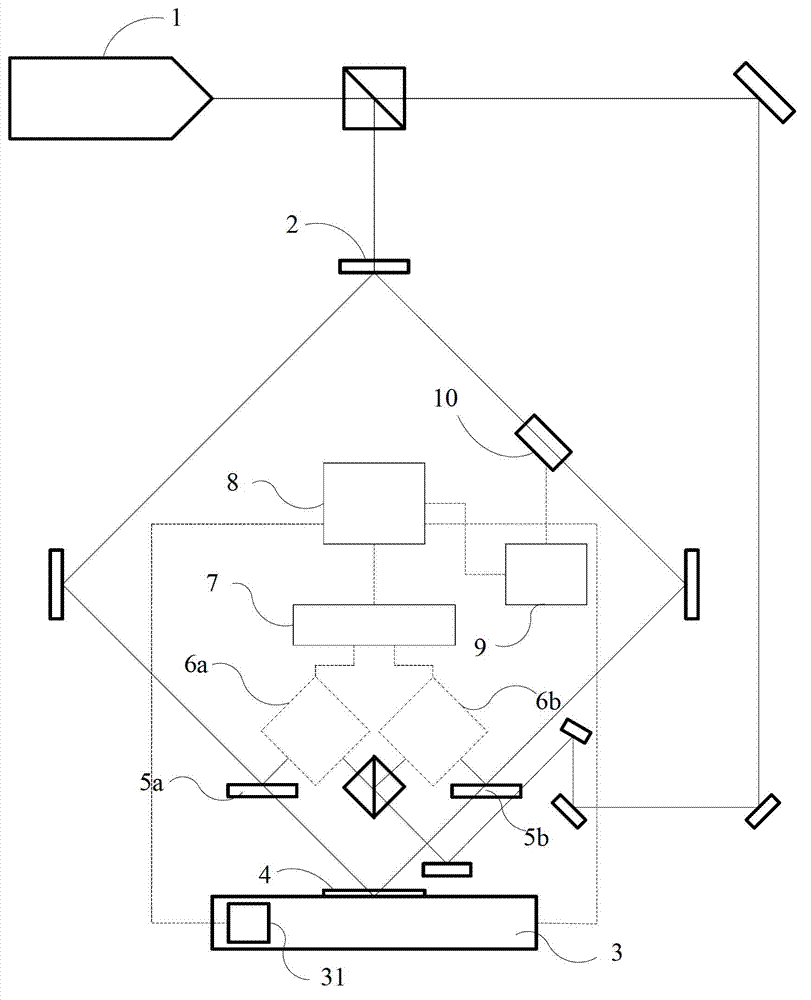

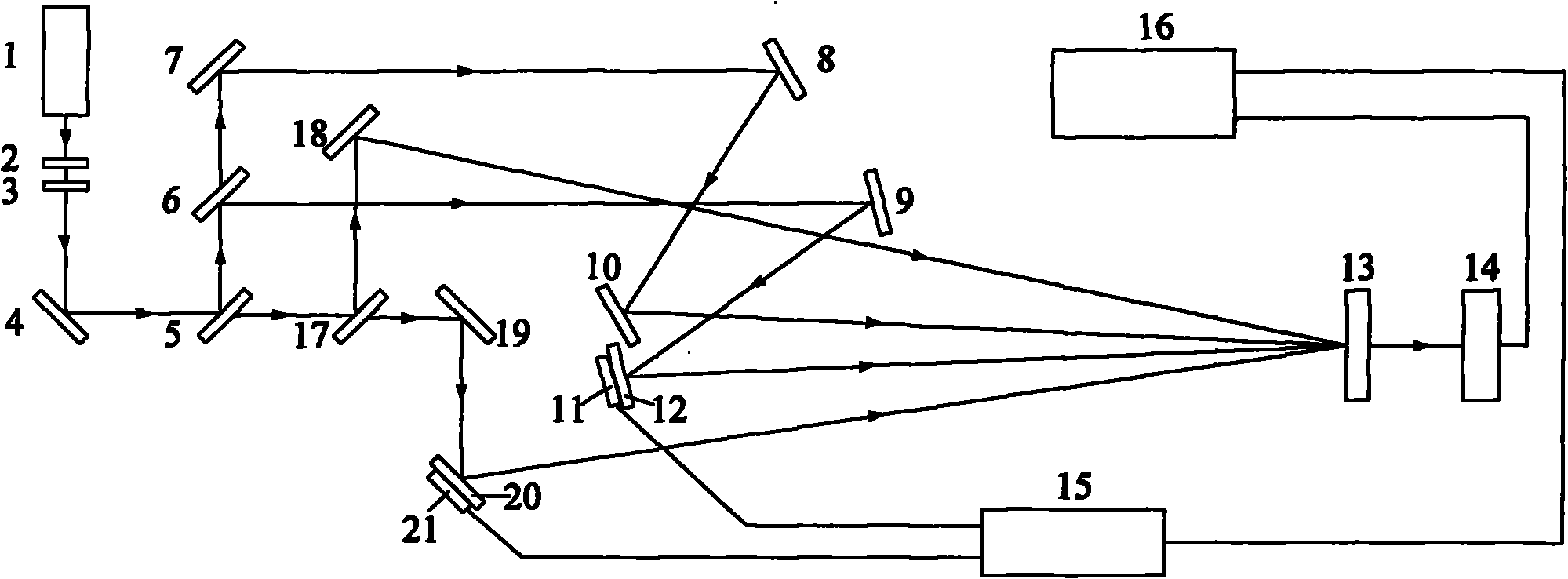

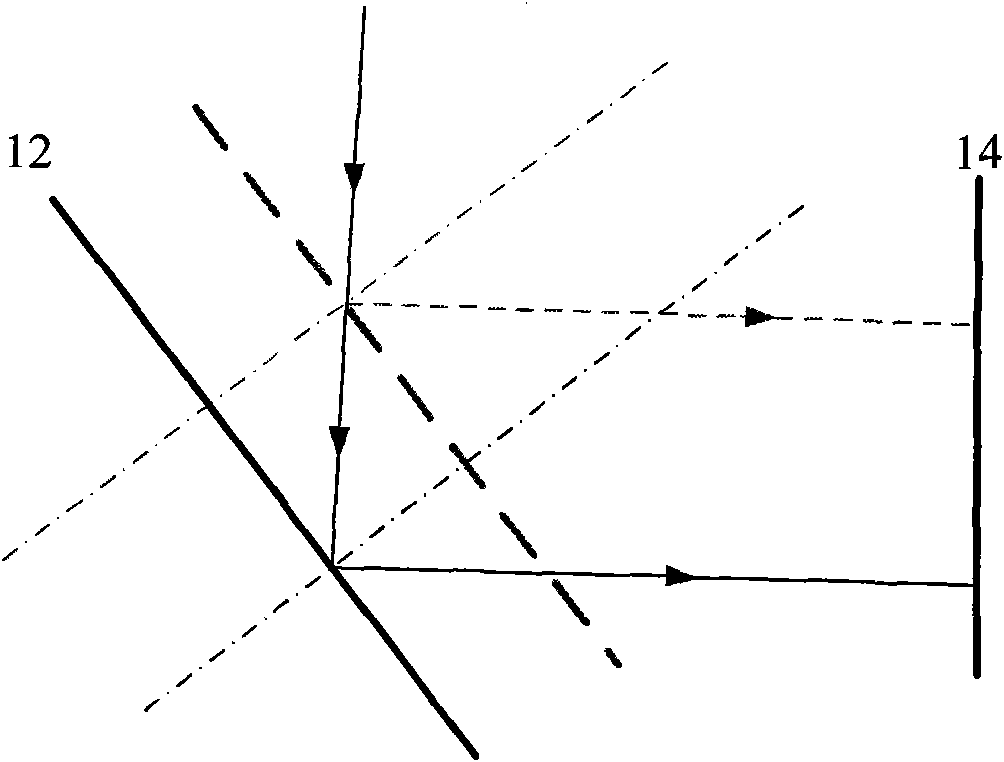

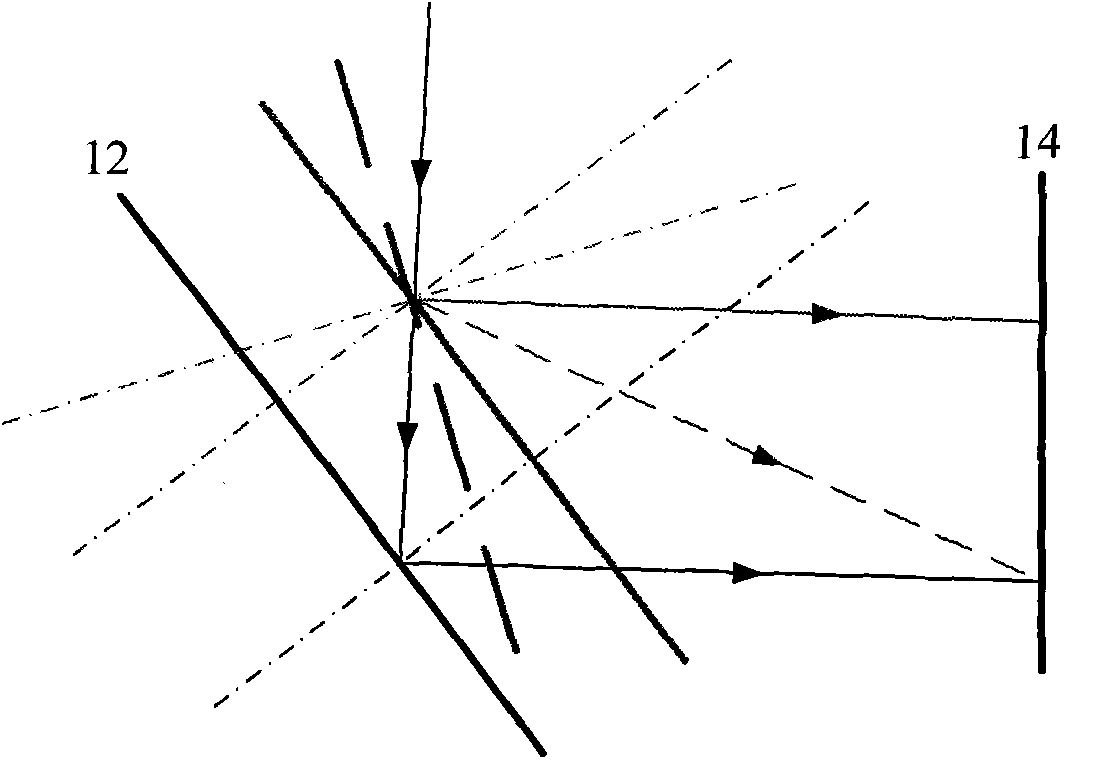

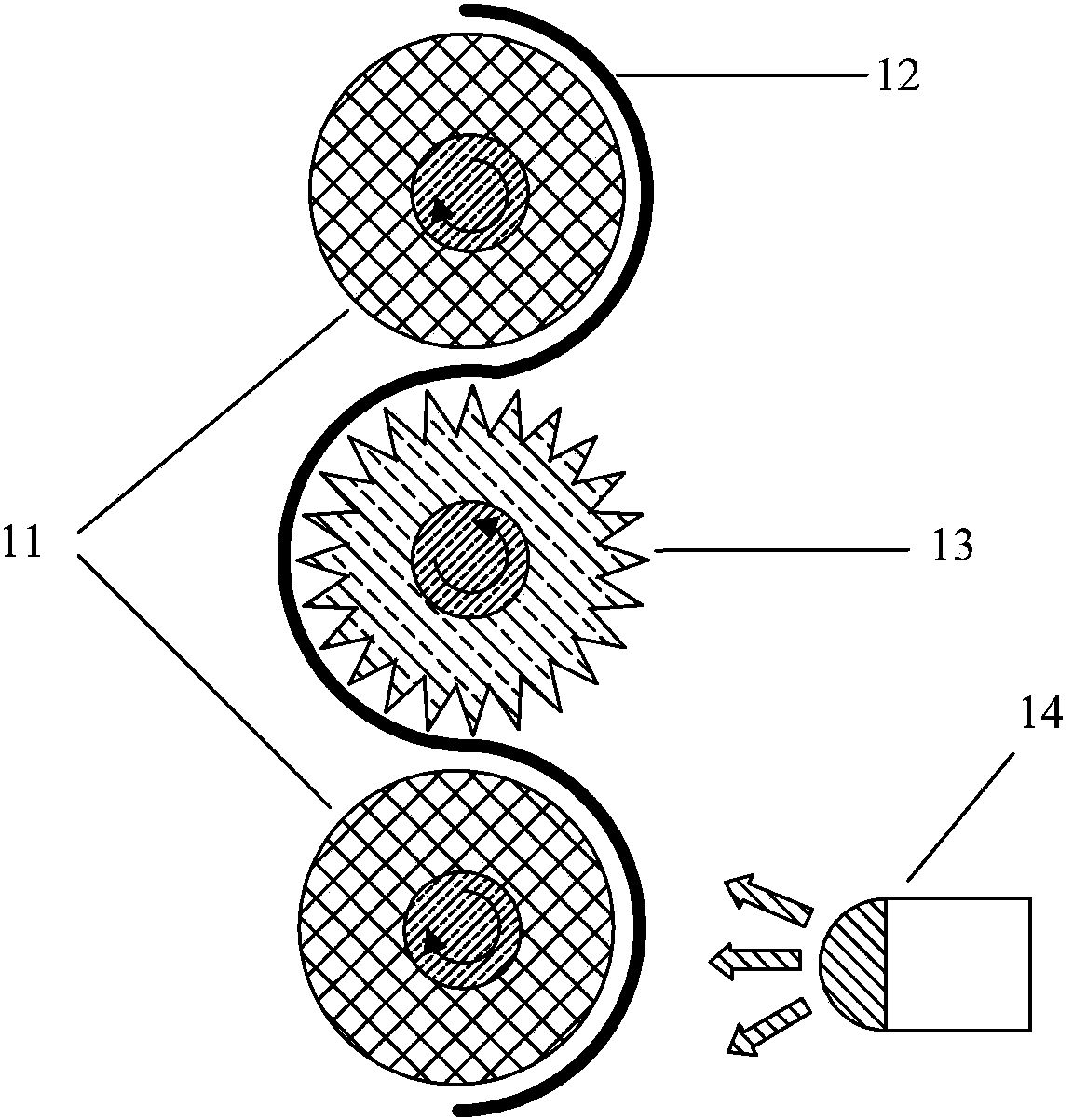

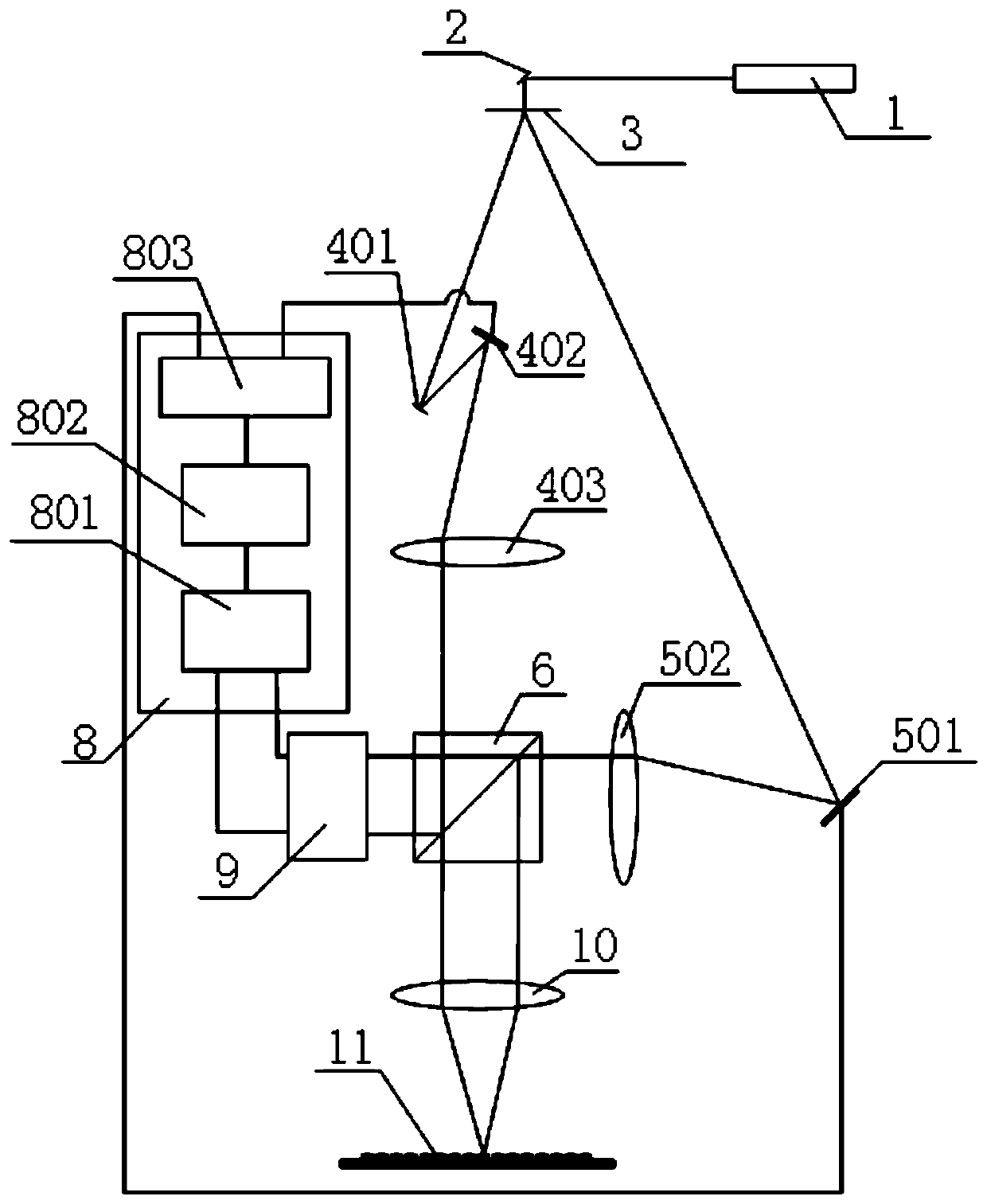

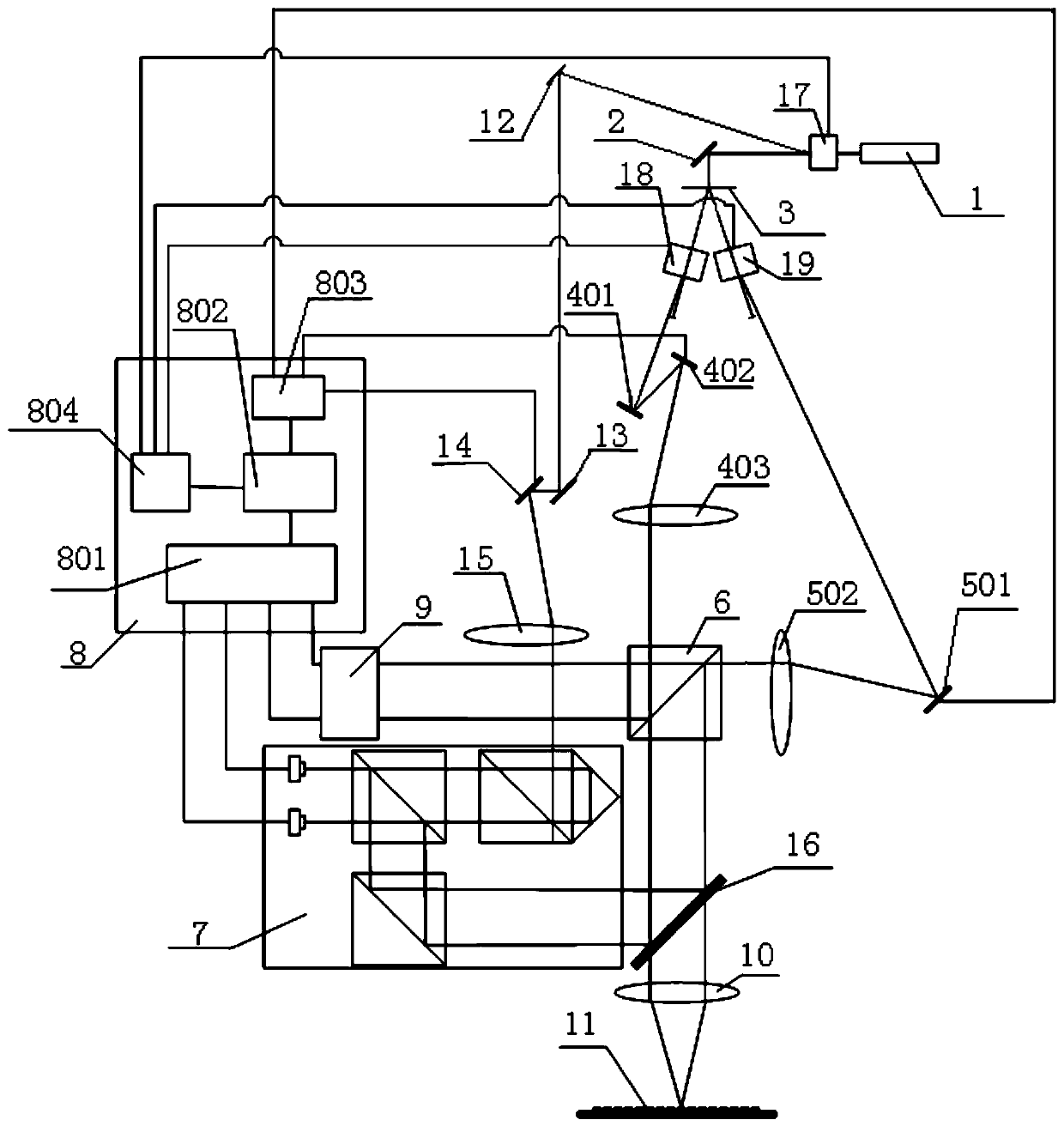

Laser interference lithography system with pattern locking function

ActiveCN103092002AWith graphics lock functionLock high speedPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingBeam splitter

A laser interference lithography system with a pattern locking function comprises a laser, a reflector, a beam splitter, a substrate stage, a substrate and a pattern locking device. A laser beam emitted by the laser is split into an exposure beam and a reference beam by a spectroscope; the exposure beam passes through the beam splitter, and is reflected to the substrate on the substrate stage by the reflector to realize interference; the interference patterns can realize pattern record transfer by exposing the substrate; and the patterns are locked by the pattern locking device to prevent pattern drift during exposure. The pattern locking device includes a null phase meter, an electronic signal processing component, a controller, a driver and a phase modulation executing, wherein the null phase meter is used for measuring pattern phase drift; the pattern phase drift is fed back to the controller through the signal processing component; and the controller controls the phase modulation executer to realize phase locking through the driver. The laser interference lithography system provided by the invention has the advantages of simple structure, high pattern locking accuracy and the like, and is a key system for realizing large-area high-accuracy grating fabrication.

Owner:TSINGHUA UNIV +1

False proof structure used for card and certificate and its identifying method

InactiveCN101100156AProminent visual featuresEasy to identifyLight effect designsCharacter and pattern recognitionGratingRefractive index

The present invention discloses anti-fake structure for cards, and the anti-fake card is provided with mark pattern comprising raster structure and features that the mark pattern includes at least two kinds of pattern areas with orthogonally arranged raster structures to constitute double visual channels. The raster structures have period of 300-500 nm, slot depth of 50-150 nm and filled transparent high refractive index dielectric layer of 20-30 nm thickness and refractive index higher than 1.6. The pattern of the present invention has obvious visual characteristic capable of being recognized easily and convenient identification of the truth. The micro anti-fake structure has structural data calculated based on strict coupled wave theory, is made by means of advanced electronic beam or laser beam interference photoetching technology, and possesses high safety.

Owner:SVG TECH GRP CO LTD +1

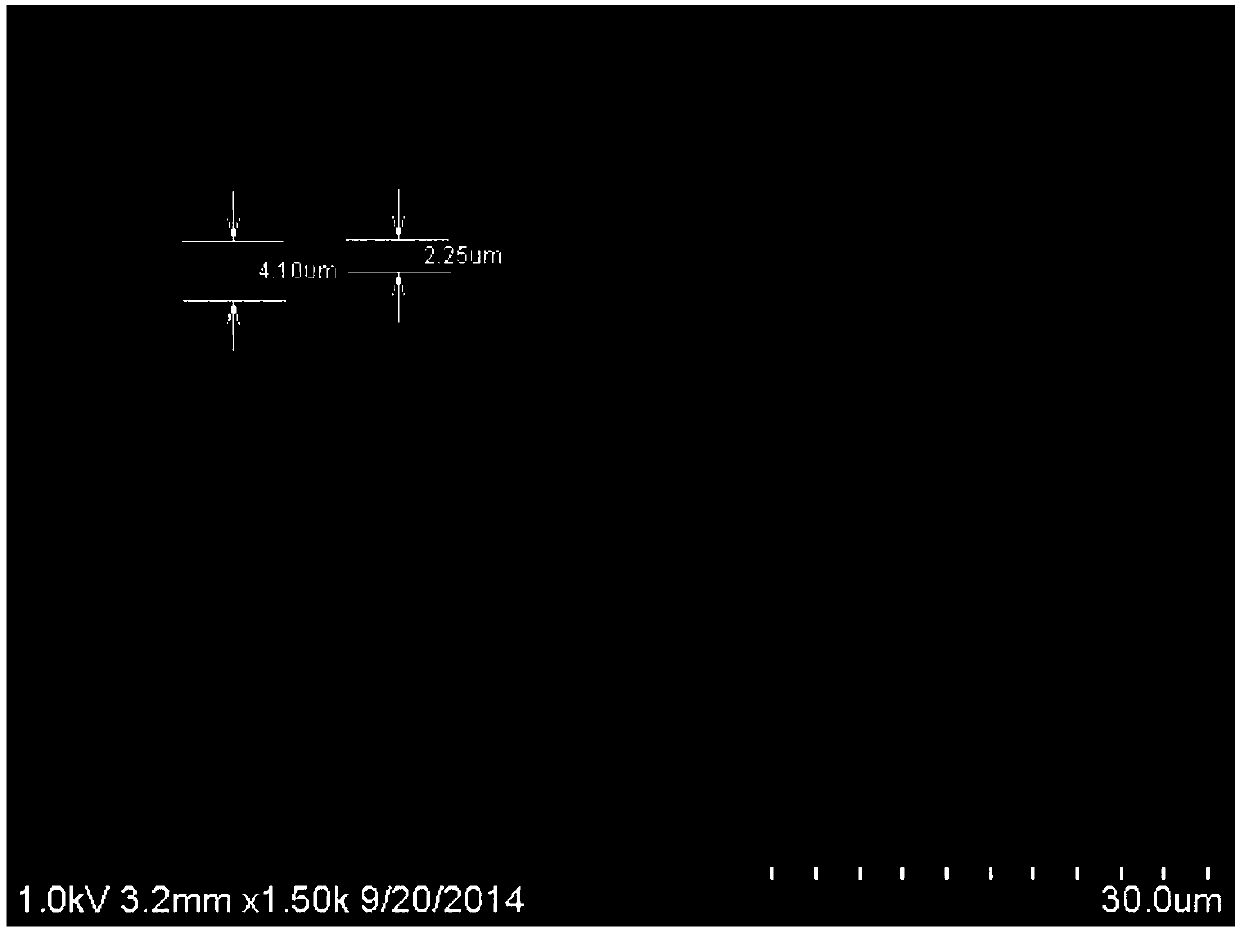

Method for preparing periodic nanostructure with high aspect ratio

InactiveCN102096317AAdd depthIncrease steepnessNanotechnologyPhotosensitive materials for photomechanical apparatusCooking & bakingGrating

The invention discloses a method for preparing a periodic nanostructure with high aspect ratio. The method is characterized by comprising the following steps of: selecting a polished substrate; coating a layer of photoresist with the thickness of greater than or equal to 300 nm on the surface of the polished substrate by a spin-coating method; depositing a SiO2 film with the thickness of 20 nm on the surface of the photoresist by a magnetron sputtering method; coating a layer of high-resolution photoresist with the thickness of 50 to 100 nm on the surface of the SiO2 film by the spin-coating method; exposing and developing the surface high-resolution photoresist by utilizing laser interference photolithography; hardening the three-layer adhesive structure in a heating plate or a baking oven; selecting a fluorine-base gas; transferring a surface photoresist pattern to the SiO2 layer by utilizing reactive ion etching; selecting and using oxygen; taking the SiO2 layer as a hard mask layer; and transferring a pattern on the SiO2 layer to the bottom photoresist by utilizing the reactive ion etching to obtain a photoresist pattern with high resolution and high aspect ratio. The method has low cost, large area of processed pattern area, and a broad application prospect in the aspects of the manufacturing and the application research of sub-wavelength gratings and photonic crystals.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Method of forming electrochromic layer pattern, method of manufacturing electrochromic device using the same, and electrochromic device including electrochromic layer pattern

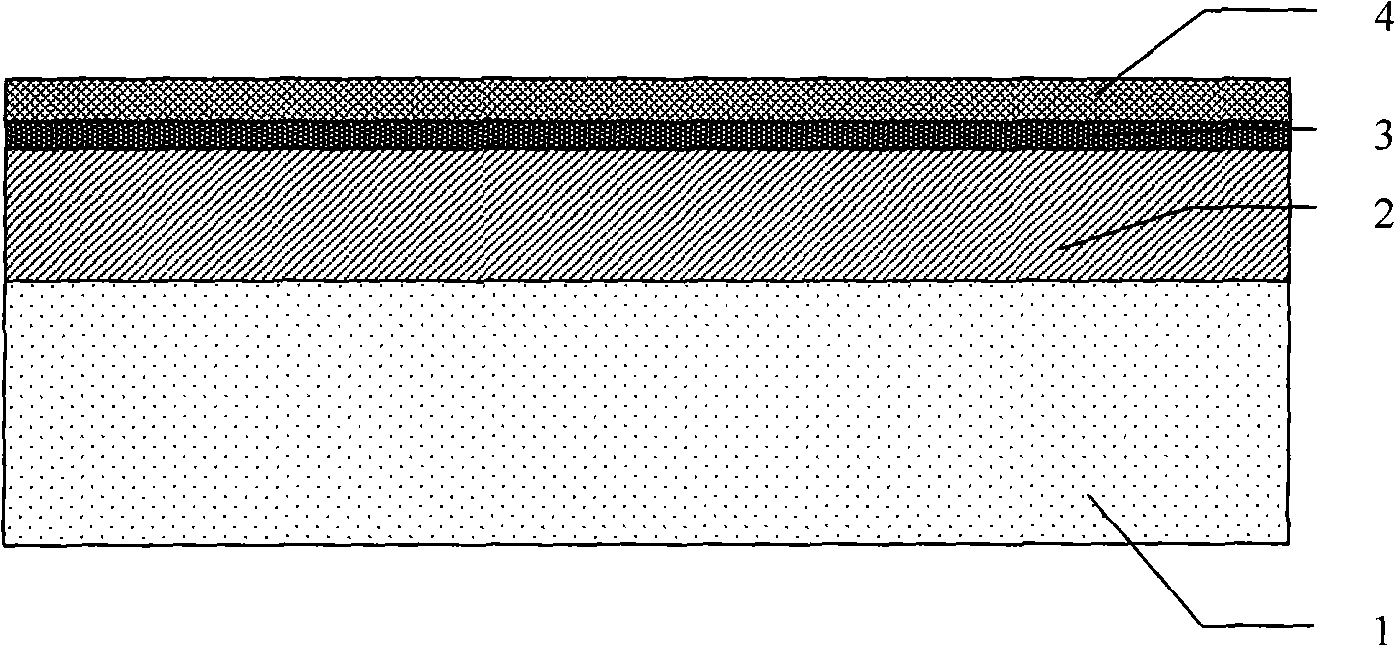

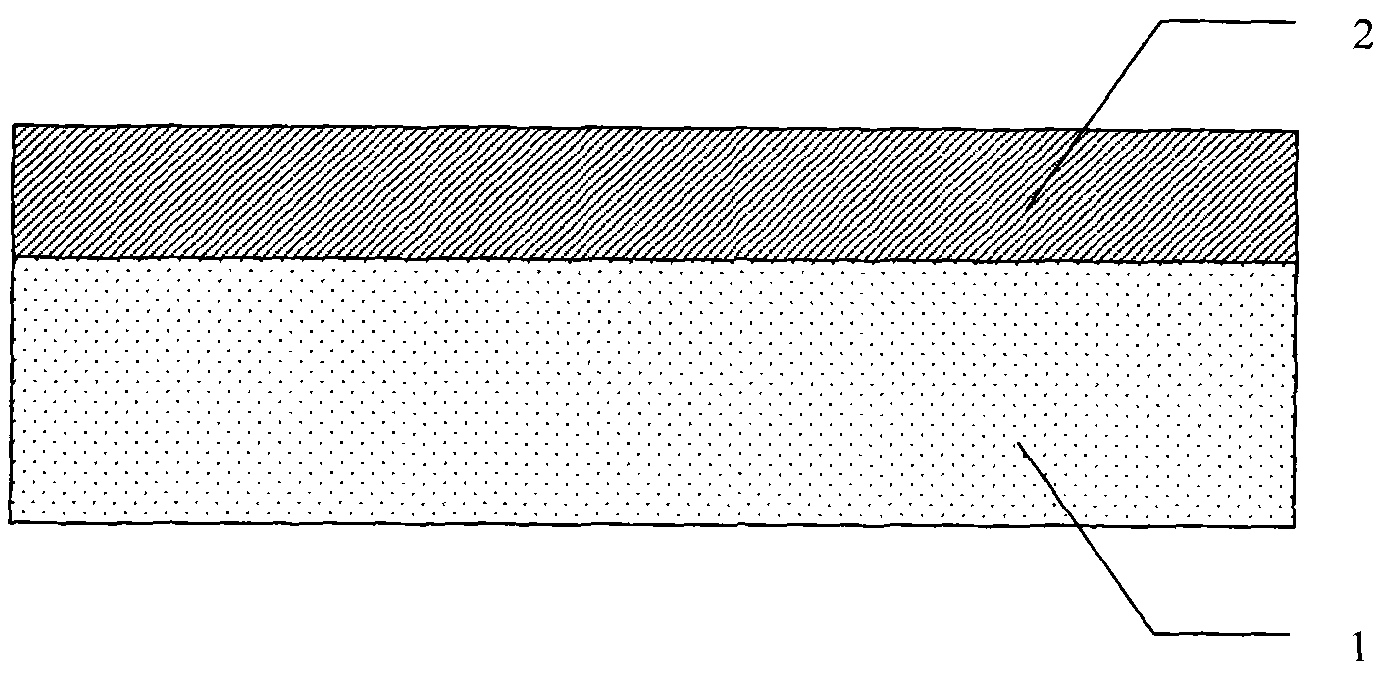

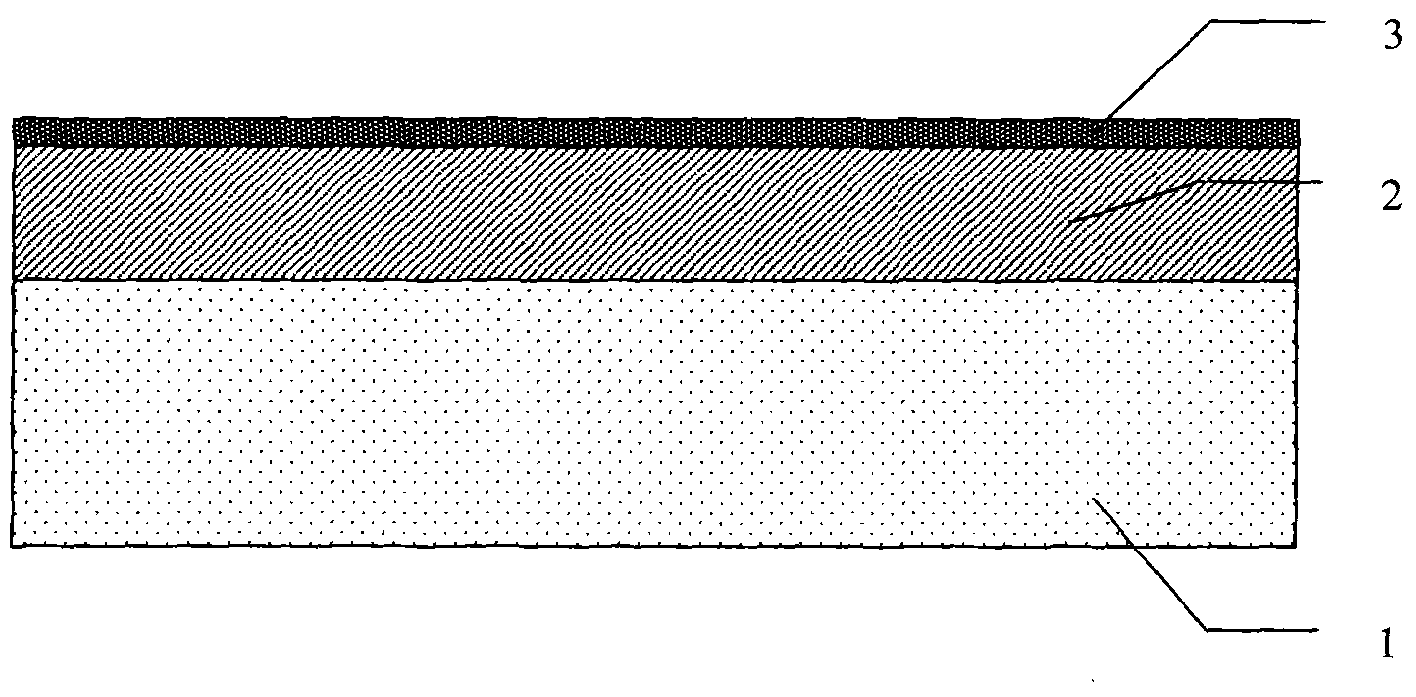

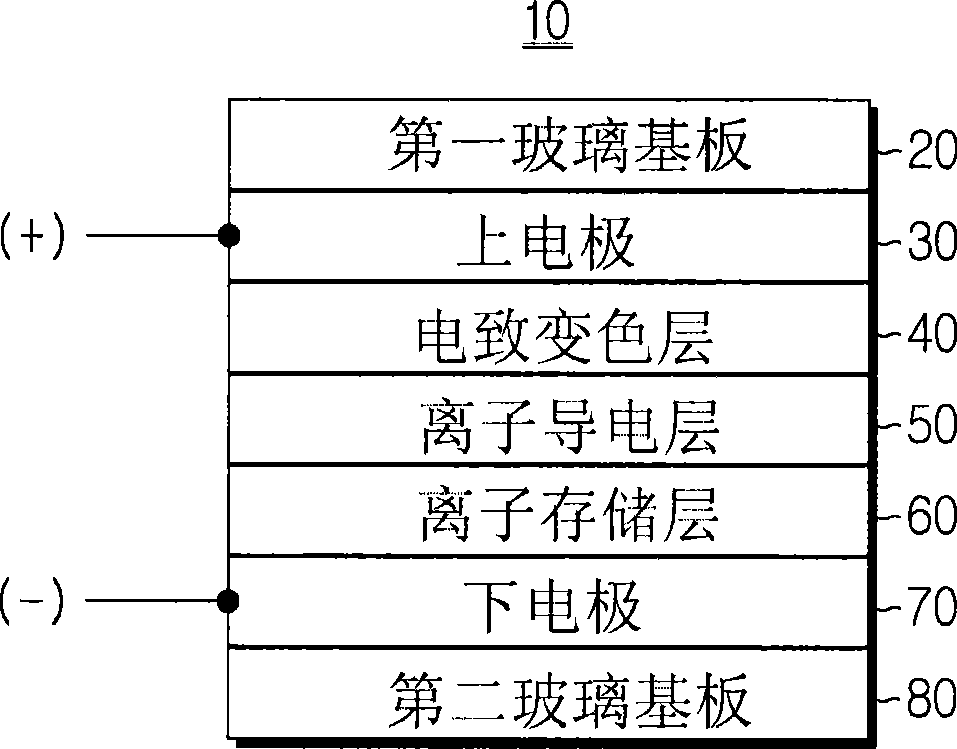

A method for forming an electrochromic layer pattern includes forming a transparent electrode layer and a photoresist layer on a transparent substrate, forming a photoresist pattern by laser interference lithography, and depositing an electrochromic layer pattern on the transparent electrode through openings defined by the photoresist pattern by depositing an electrochromic layer on a front surface of the substrate and then lifting up the photoresist pattern. An insulation layer may be further formed between the transparent layer and the photoresist layer. Here, the electrochromic layer may be formed after an insulation layer pattern is formed using the photoresist pattern as an etching mask. In this case, the electrochromic layer pattern is formed in openings defined by the insulation layer pattern. As a result, a contact surface area between the electrochromic layer pattern and the ion conductive layer is increased to ensure a rapid response speed.

Owner:LG CHEM LTD

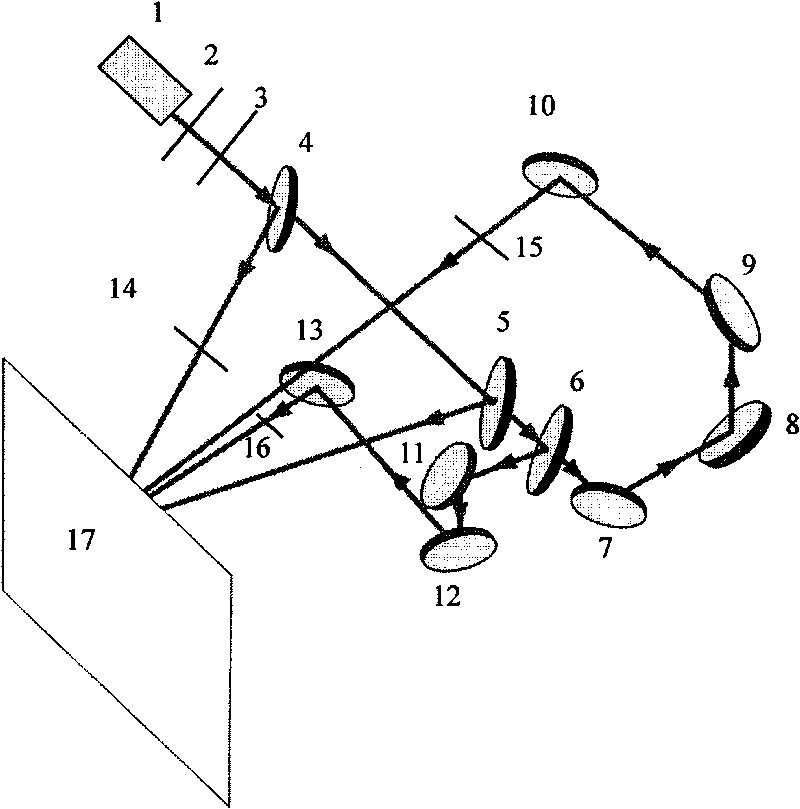

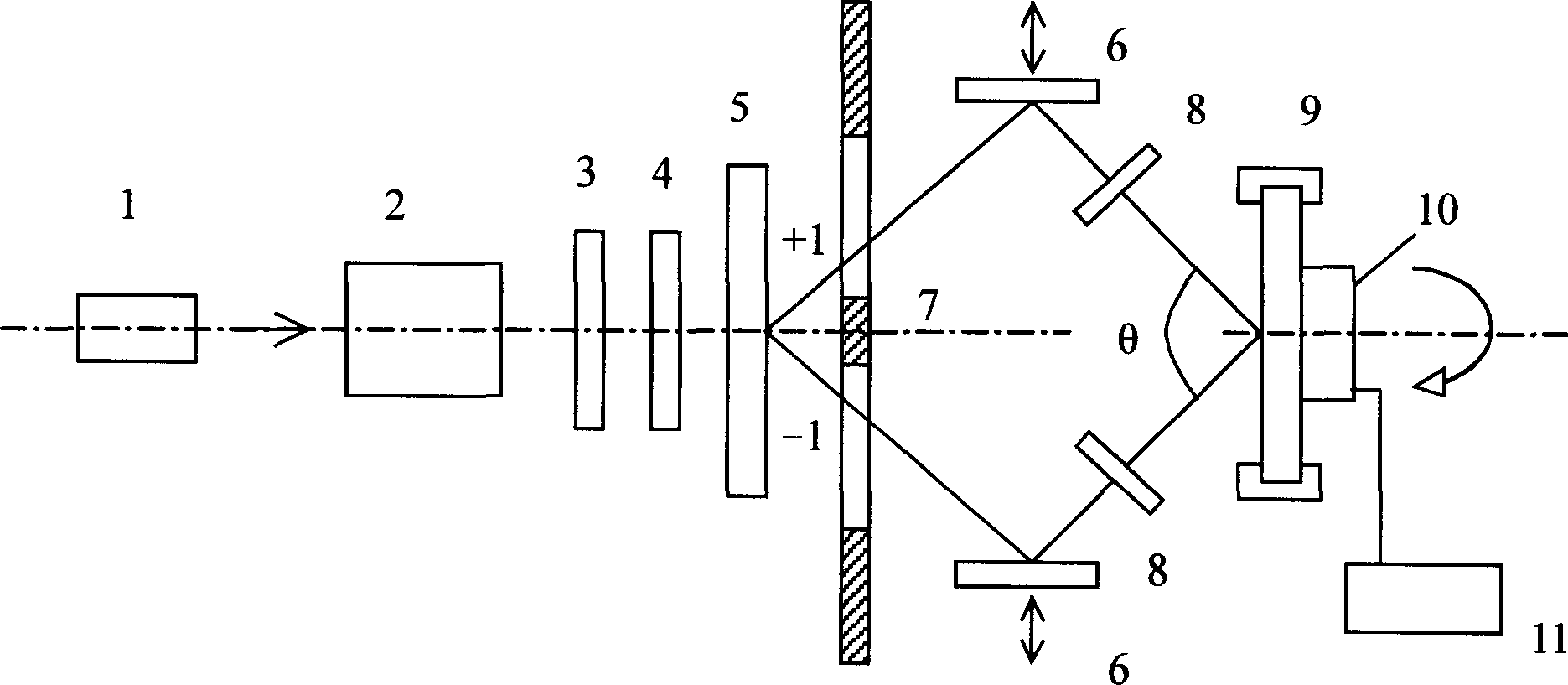

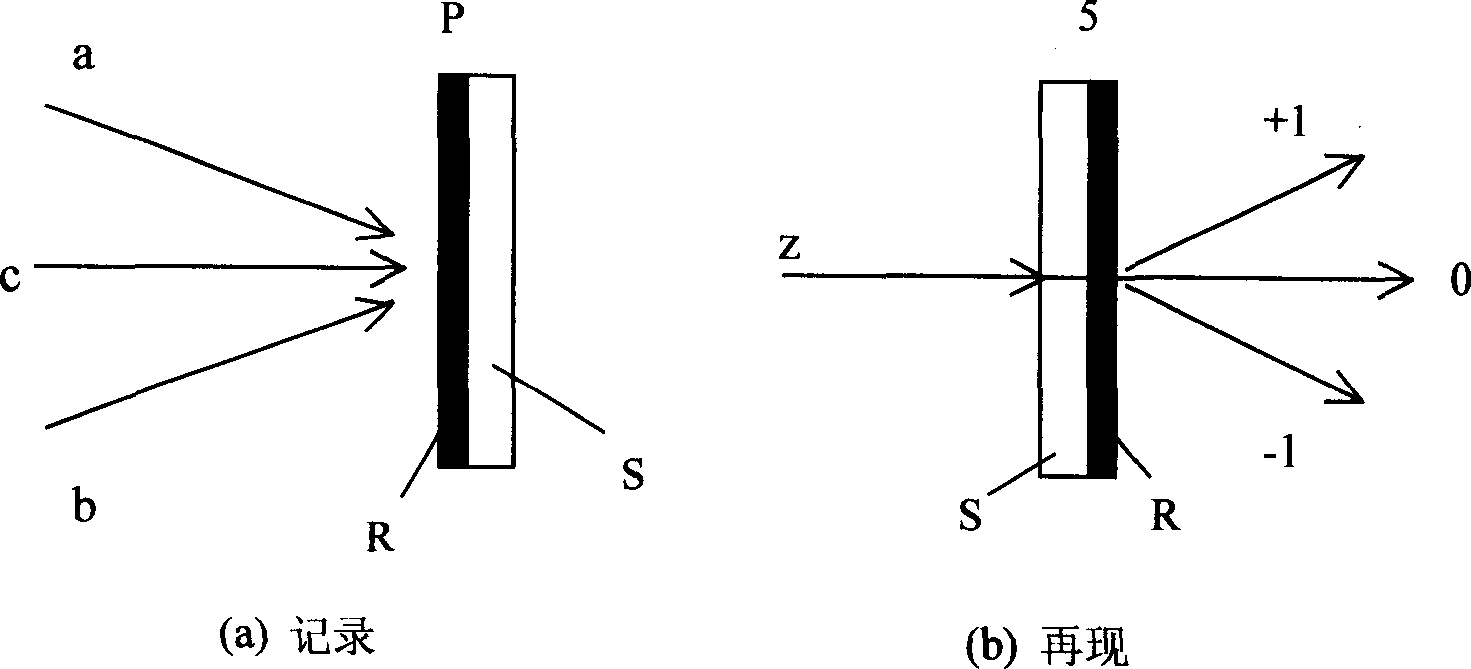

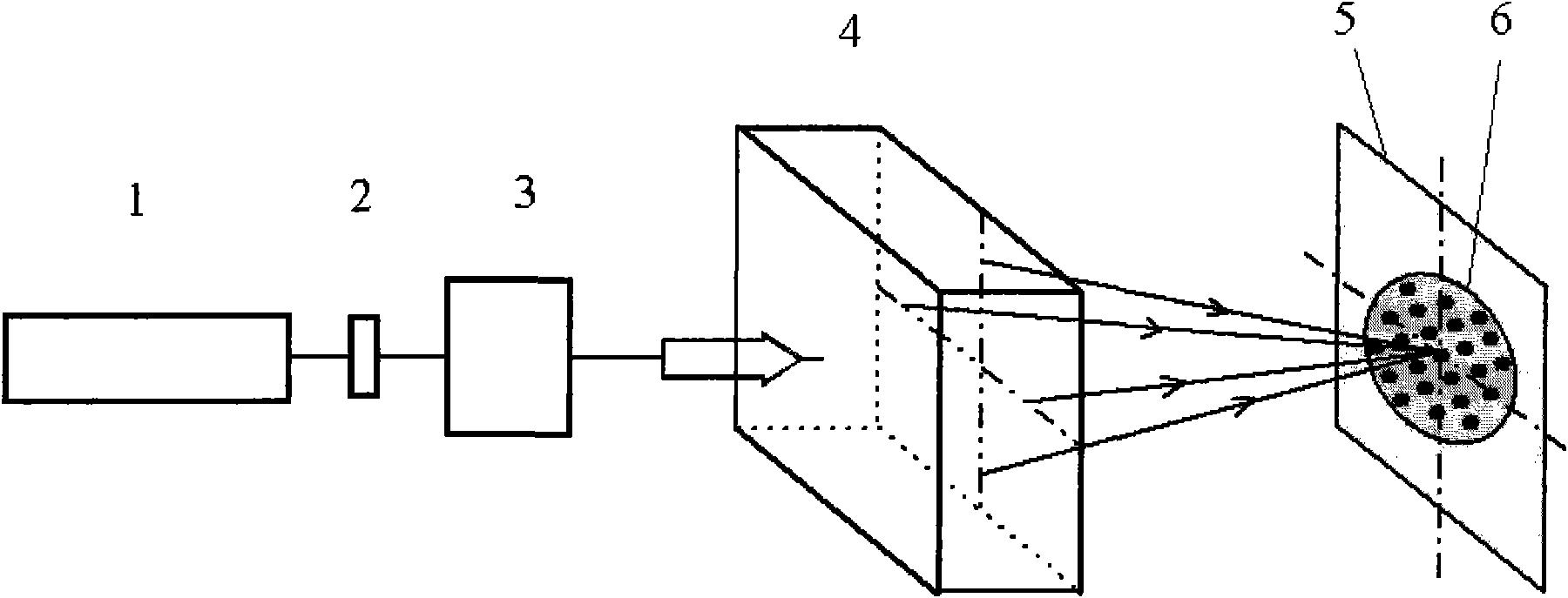

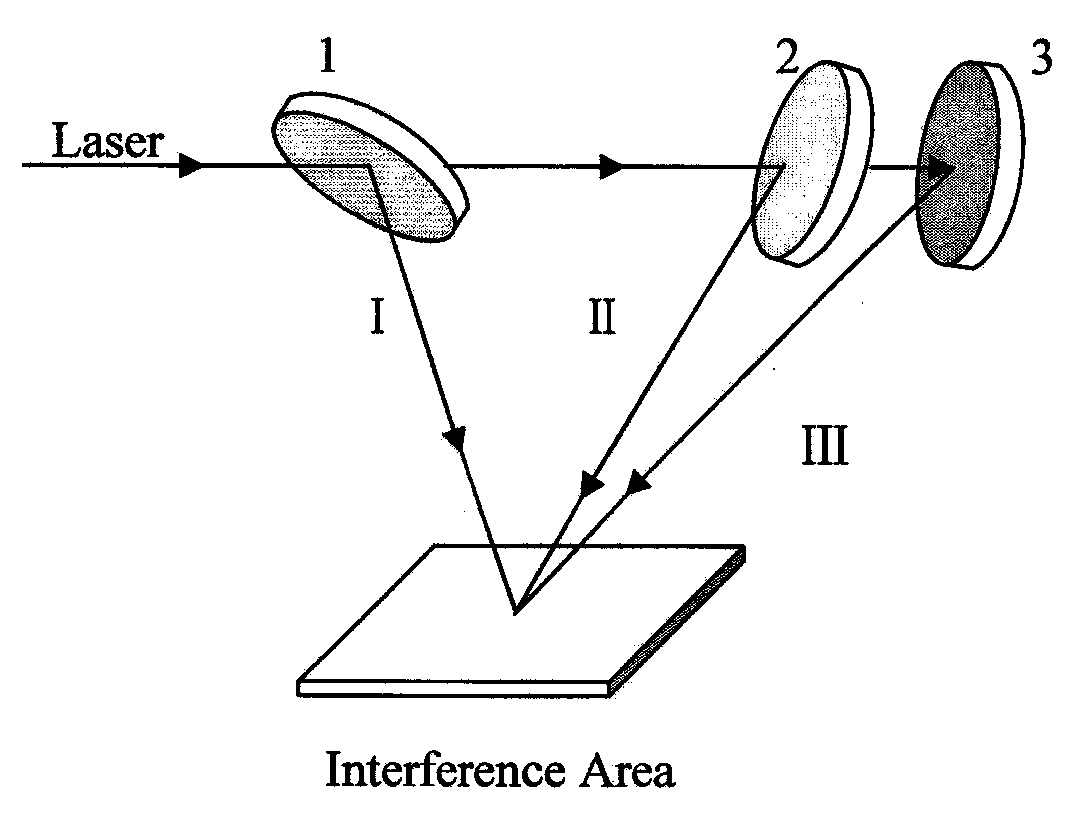

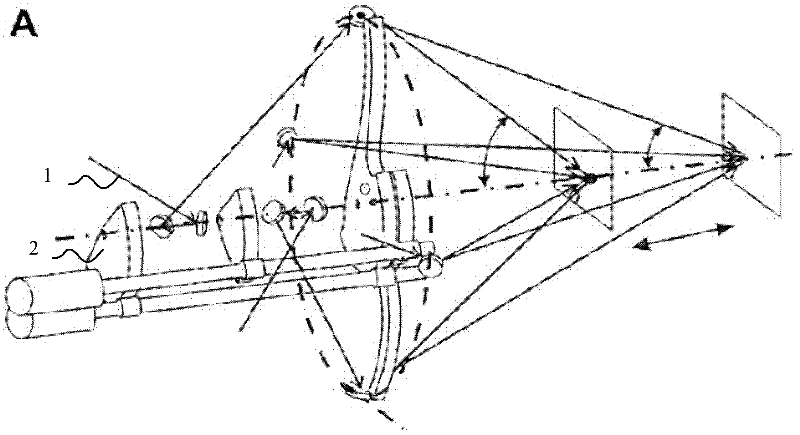

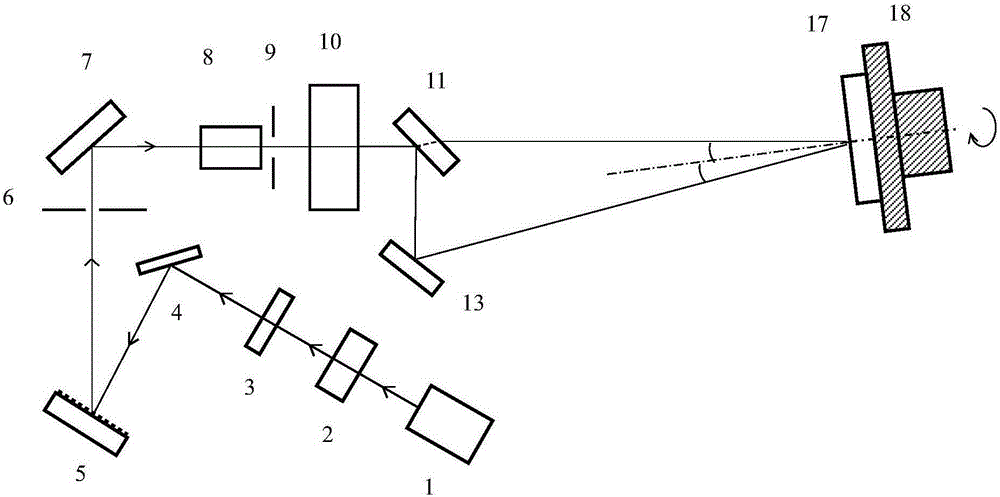

Laser interference photo etching method adopting holographic optical elements and photo etching system

InactiveCN1690857AEasy to manufactureImprove adaptabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingWavelength

The laser interference photo-etching method with holographic optical element is characterized in that: use holographic optical element as beam amplitude division element to divide the laser beam to two beams of almost equal strength and angle divided; reflect to make them intersect; on the intersect overlap area, expose the resister basal plate to produce high resolution grating, form minuteness interference image; holographic optical element is element that can produce tri-beam, quad-beam, or quint-beam, or holographic image produced by computer, or diffraction optic element; laser interference photo-etching system realized aforementioned method comprises a laser of ª™-wave, beam expand collimating device, timer shutter, variable density neutral color filter, holographic optical element, adjustable diaphragm, holophote, optical attenuator, basal plate and electric control roller. As the preparation of holographic optical element is easy, with light weight, and can made with low cost according to different angle to adjust different needs, this invention can decrease size, weight and cost of the system, of far reaching importance and application future.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Manufacture system of anti-reflection structure on surface of solar cell and manufacture method thereof

InactiveCN101924166ALithographic feature size adjustablePromote absorptionFinal product manufactureSemiconductor devicesFine structureEngineering

The invention relates to a manufacture system of an anti-reflection structure on the surface of a solar cell and a manufacture method thereof, which is characterized in that a plurality of coherent laser beams are combined by a laser interference lithography system to modulate the light intensity distribution in an interference field; the material surface of a photovoltaic cell device is ablated with redistributed laser energy after modulation; and micro or nano-stage dense hole and column relief structures are generated in a large-area range so as to reduce the reflectivity, enhance the light absorption and improve the photovoltaic conversion efficiency. Lacking of external materials, the anti-reflection fine structure generated on the substrate surface by using the method is more stableand durable, and the cycle and the size of the structure can be adjusted by adjusting the incidence angle of the interference lithography system so that the received wavelength has better pertinence and has the advantage of good working band controllability.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI +2

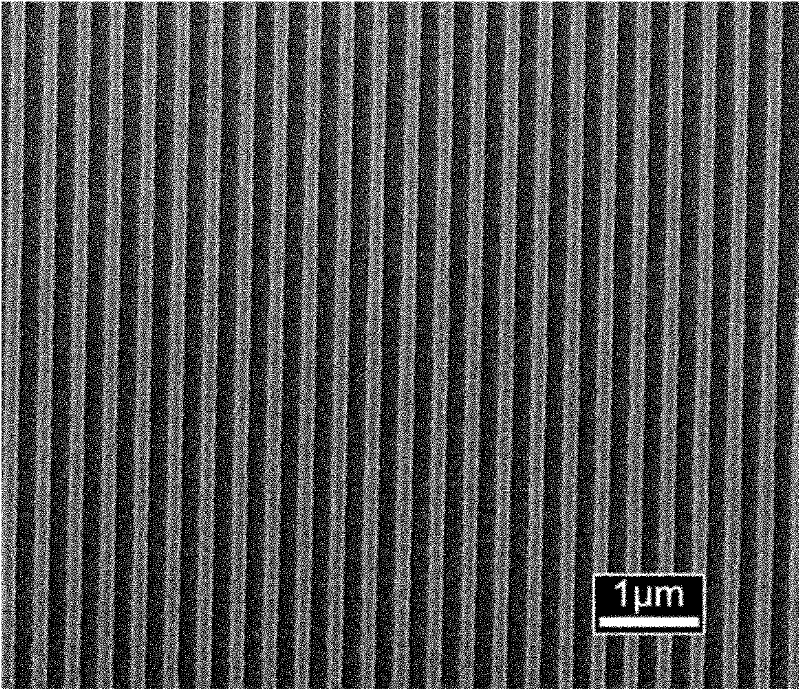

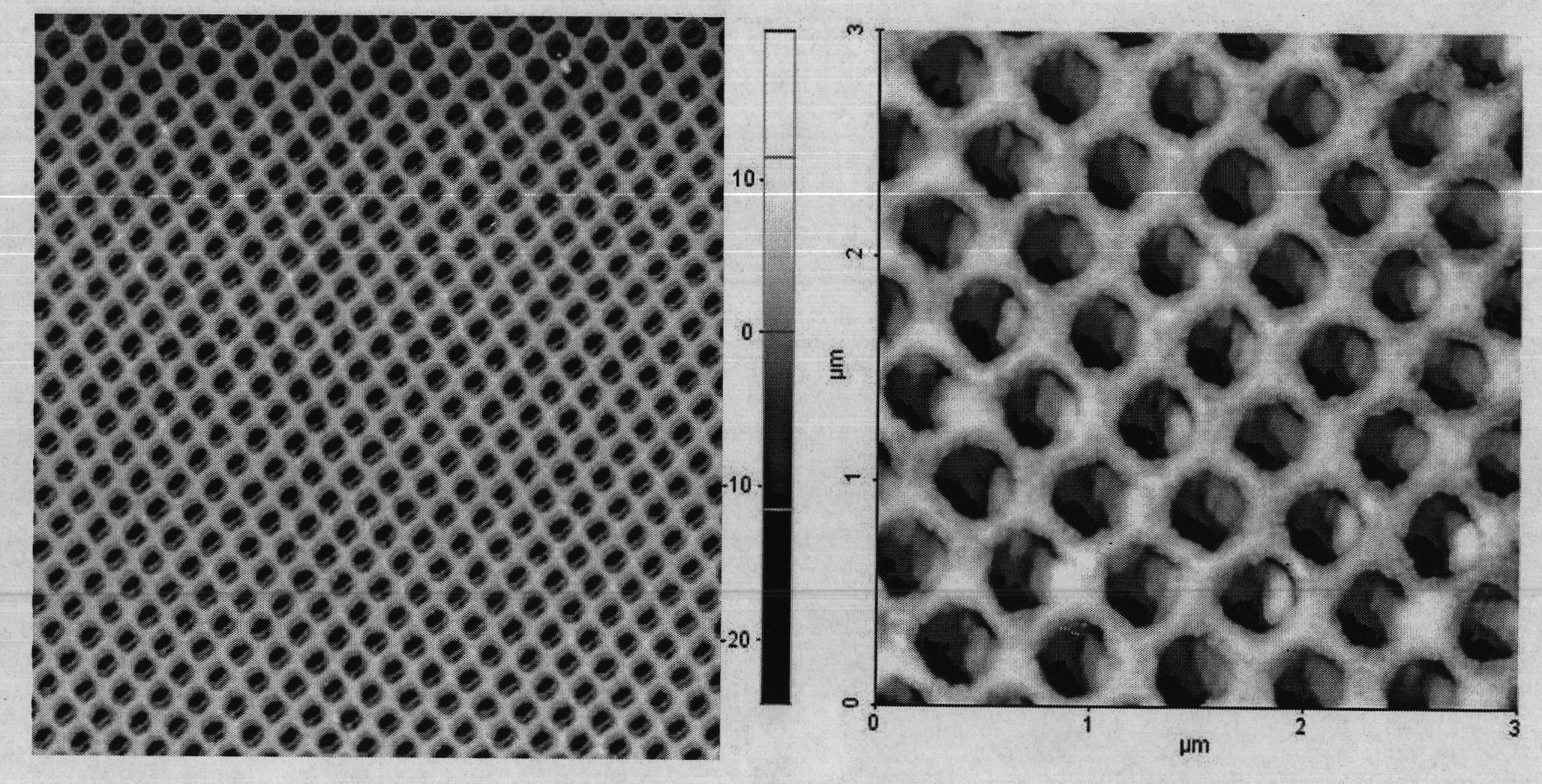

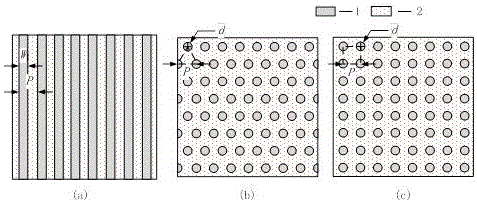

Method for preparing micro-nano structure on material surface based on laser interference photolithography

InactiveCN102838082AIncrease the areaQuality improvementDecorative surface effectsPhotomechanical exposure apparatusGratingLaser interference

The invention belongs to the technical field of electronics, and particularly relates to a method for preparing a micro-nano structure on a material surface based on laser interference photolithography. The micro-nano structure is formed on photoresist by generation of laser interference, so as to transfer the micro-nano structure on the photoresist to the material surface of a substrate with an etching method, and form the structures such as micro-nano-scale gratings, dot matrixes and linear arrays. By adoption of the method disclosed by the invention, high-quality nano structures can be produced in a large area on various material surfaces. The method disclosed by the invention is simple and convenient, is low in cost and has a great application value.

Owner:FUDAN UNIV

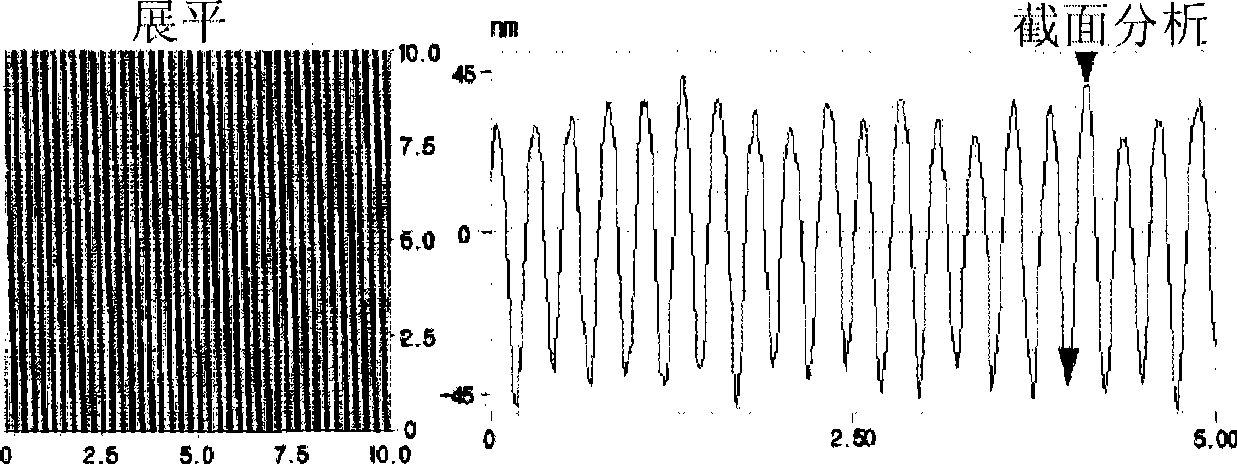

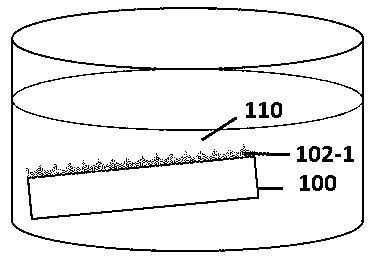

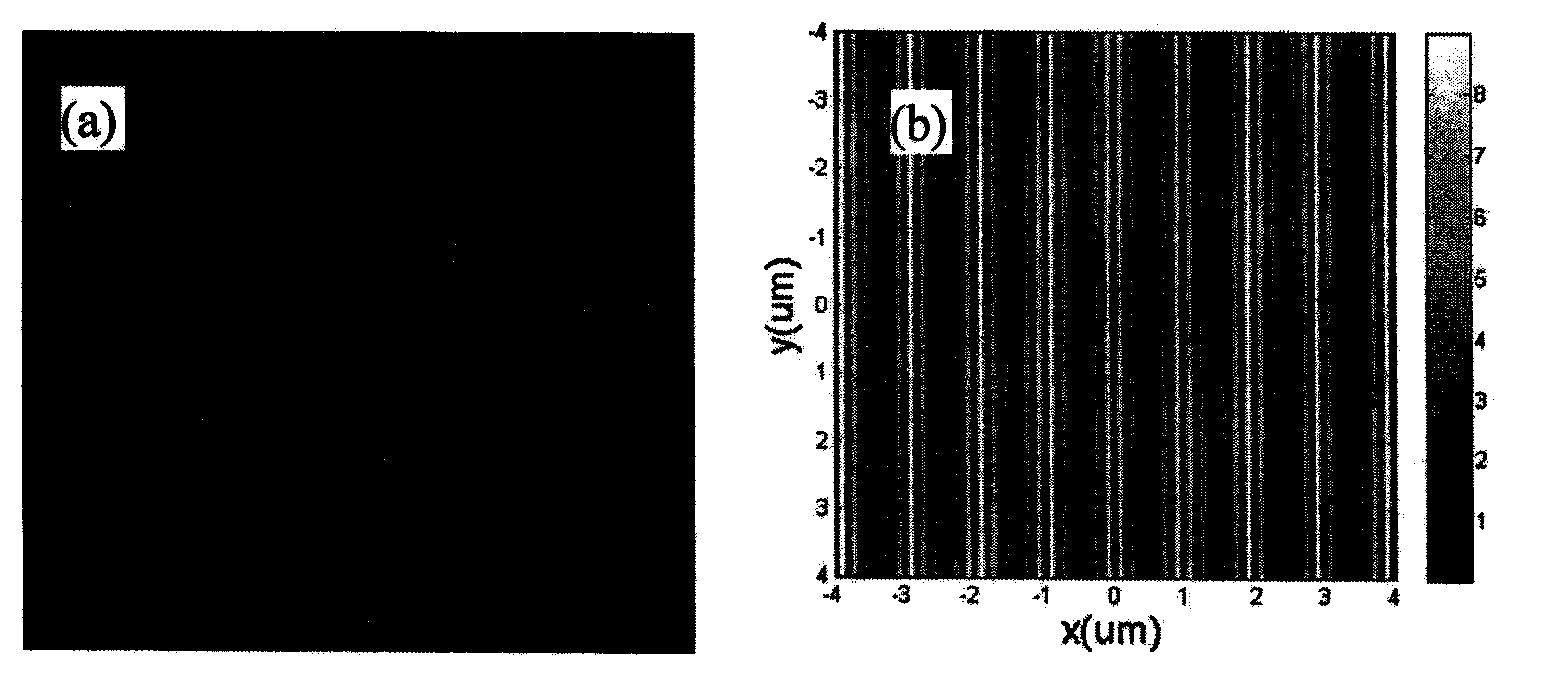

Method for preparing dual-period nanostructure through laser interference nanolithography

ActiveCN103852975AAdjust the angle of incidenceAdjust space angleNanotechnologyPhotomechanical exposure apparatusNanolithographyLithographic artist

Owner:CHANGCHUN UNIV OF SCI & TECH

Distributed feedback type organic semiconductor laser preparation method based on laser interferometer lithography

InactiveCN102651534ALow costGood repeatabilityLaser optical resonator constructionLithographic artistOrganic solvent

The invention discloses a distributed feedback type organic semiconductor laser preparation method based on laser interferometer lithography and belongs to the technical fields of nanometer photoelectron materials and devices. The preparation method comprises the following steps: 1) coating a substrate with recording medium in a spinning way, thus obtaining an uniform recording medium thin film with thickness of 50-500nm; 2) reacting a laser interference figure with the recording medium thin film, thus forming a high-quality recording medium distributed feedback type structure; 3) dissolving a fluorescence-emission organic semiconductor material in an organic solvant; 4) coating the recording medium distributed feedback type structure with the organic semiconductor solution in a spinning way, thus obtaining an organic semiconductor thin film with uniform thickness of 50-500nm. The preparation method is low in cost, excellent in repeatability and high in preparation efficiency, and can be used for preparing large-area, non-defective, one-dimensional and two-dimensional distributed feedback type organic semiconductor lasers; and the prepared two-dimensional organic semiconductor laser has a controllable structure.

Owner:BEIJING UNIV OF TECH

Method and system for realizing phase shift in laser interference lithography

ActiveCN102012561AGuaranteed accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusNanolithographyVertical plane

The invention discloses a method for shifting a phase in laser interference nano lithography. The method is characterized in that in two-beam or multi-beam laser interference lithography, two or more coherent laser beams are combined for interference, and one or more phase-shift locating systems are controlled to change the optical distance of an optical path and shift and locate the phase of interference graphics. In the method, the phase-shift locating system comprises a voltage source, a displacement driver and a reflector, and different voltages are applied to the displacement driver so that the reflector also moves along the axial direction thereof to shift and locate the phase. The phase-shift locating system can also push an optical wedge in a plane direction perpendicular to incoming light by changing the voltage of the voltage source or control an LCD (Liquid Crystal Display) in the plane direction perpendicular to the incoming light by changing the voltage of the voltage source or control the driver to draw optical fiber to shift the phase of the interference graphics by changing the voltage of the voltage source. The phase-shift method can detect the phase difference of the interference graphics, control the phase shift of the interference graphics by adopting feedback (such as phase locking) and lessen phase shift to more accurately locate the graphics.

Owner:CHANGCHUN UNIV OF SCI & TECH

Methods for manufacturing micro/nano scale pattern stamping die

ActiveCN103730339AExcellent format scaleLarge formatPhotomechanical apparatusSemiconductor/solid-state device manufacturingNano sizeLaser interference

The invention discloses methods for manufacturing a micro / nano scale pattern stamping die to solve the problems that a laser interference photo-etched die is not exquisite enough in pattern scale, the speed is too low when high-precision patterns are manufactured through electron beam photo-etching, and the electron beam photo-etching is not suitable for large-area manufacture, and belongs to stamping die finish machining methods. One of the methods sequentially includes the steps of electron beam photo-etching, primary dry etching, laser interference etching, secondary dry etching, nanometer stamping and micro-electroforming. The other method sequentially includes the steps of laser interference etching, primary dry etching, electron beam etching, secondary dry etching, nanometer stamping and micro-electroforming. The advantage that electron beam etching is exquisite in manufacture and the advantages that the laser interference etching is low in cost and large in width of a manufactured die are combined, nano scale patterns and micro scale patterns are manufactured at different positions of the stamping die, the expressive force of the manufactured patterns is far better than the expressive force of patterns manufactured through traditional laser interference etching, and the anti-counterfeiting capacity of holographic anti-counterfeiting marks and other products with stamped patterns is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Laser interference lithographic system

ActiveCN102236267AReduce lossImprove reliabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splitterOptical axis

The invention discloses a laser interference lithographic system, which comprises at least two lens groups. The lens group comprises a beam splitter, a first completely reflecting mirror and a second completely reflecting mirror. The beam splitter of the lens group is positioned on the main optical axis of incident light. Different lens groups are positioned at different positions of the main optical axis. After passing through the beam splitter of each lens group, the incident light generates reflected light and transmitted light, wherein the reflected light irradiates interference points of a sample to be lithographed after being reflected by the first and second completely reflecting mirrors of the current lens group; and the transmitted light is taken as the incident light of the lens group adjacent to the current lens group. In the laser interference lithographic system provided by the invention, angles of incident planes of interference light can be randomly adjusted about the main optical axis of the incident light so as to greatly widen the adjustment range of the angles of the incident planes of the interference light and meet the diversity of interference patterns.

Owner:SUZHOU UNIV

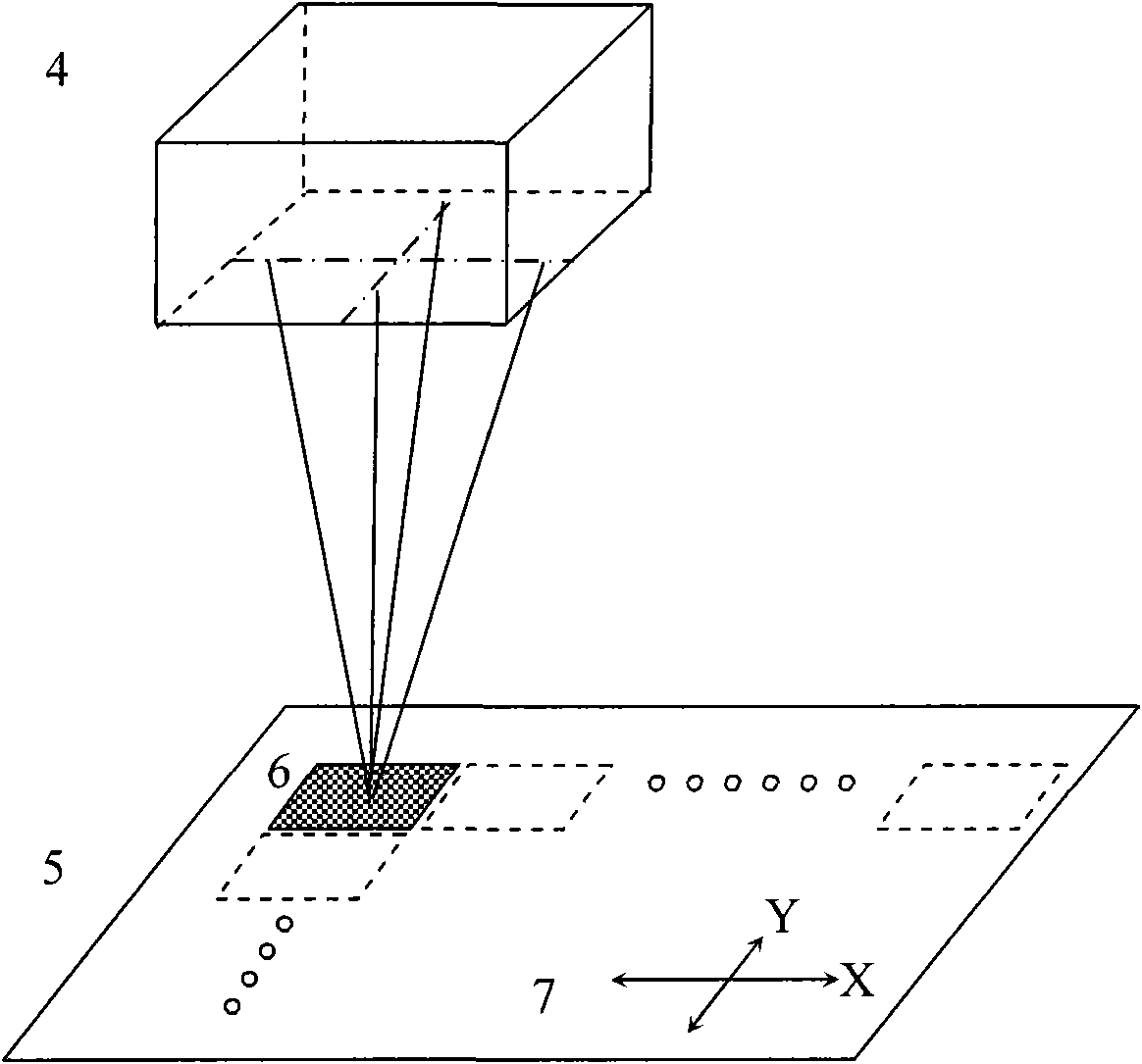

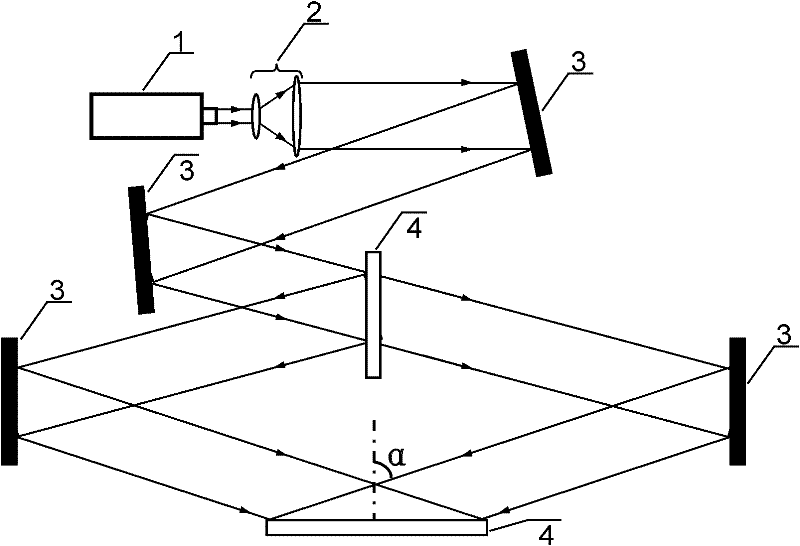

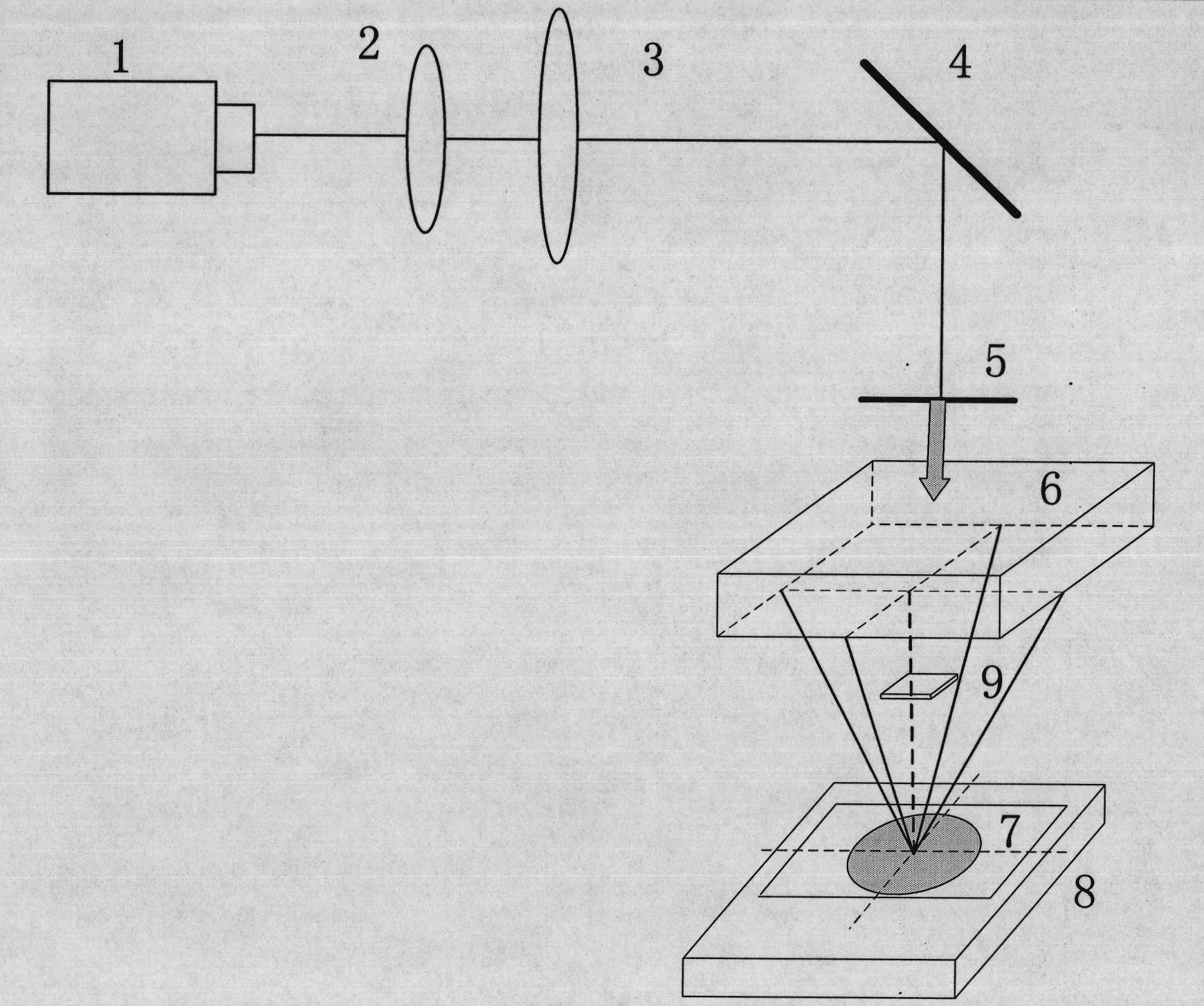

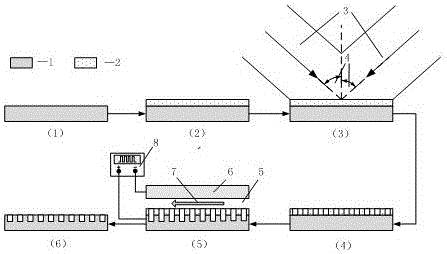

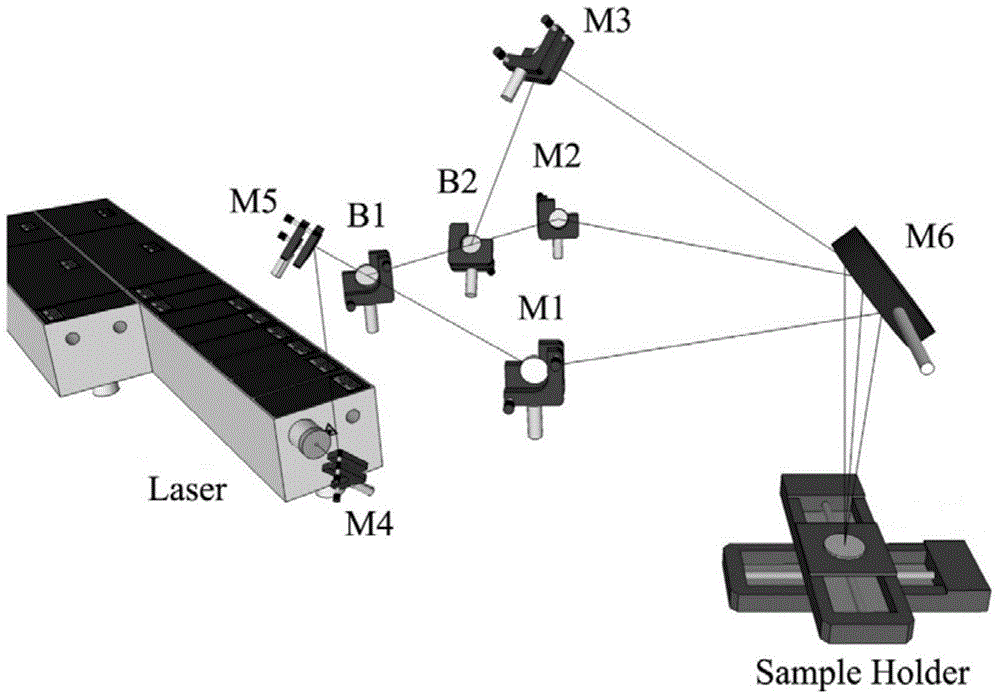

Method and system for preparing filter membrane mesh structure by laser interference photoetching technology

ActiveCN101980083AParameters can be adjustedStructural parameters are controllablePhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoBeam expander

The invention discloses a method and a system for preparing a filter membrane mesh structure by laser interference photo-etching technology. The system can generate images with different intervals by different exposure methods of the laser interference photo-etching technology. A photoetched image is generated by regulating and controlling light intensity distribution in an interference field by a specified light beam combination method, and ablating the surface of a processed material by using modulated redistributed laser energy. The system consists of a laser, a beam expander, a beam splitter, a reflecting mirror, a polaroid and a mechanism for clamping and regulating the optical elements and devices. By changing the relative arrangement position of the optical devices, an incident angle of a related light beam which is irradiated on the surface of a substrate material is changed so as to regulate parameters of a micro-mesh structure of the surface of the processed material. The system can realize adjustability of photo-etching characteristic sizes from nanometers to hundreds of microns. By optical phase shifting or mechanical shifting of a sample, repeated exposure or repeated exposure interpolation, a high-density micro-nano filter membrane mesh structure can be prepared.

Owner:CHANGCHUN UNIV OF SCI & TECH

Electrode for battery and method for manufacturing thereof

InactiveUS20130052532A1Long charge/discharge cycle characteristicLarge capacityMaterial nanotechnologyNanostructure manufactureInternal resistanceEngineering

An electrode for a battery and a method for manufacturing the same are disclosed. The electrode for a battery according to the present invention comprising silicon nanostructures integrally formed on a silicon thin film and having a period array can reduce the internal resistance, have better charge transport properties, and reduce the structural stress, thereby exhibiting high storage capacity, high efficiency charge / discharge characteristics, and long charge / discharge cycle characteristics. Moreover, the method for manufacturing the electrode for a battery according to the present invention can simply and easily form a nanopattern with nanostructures on a silicon thin film using laser interference lithography (LIL) and dry etching.

Owner:GWANGJU INST OF SCI & TECH

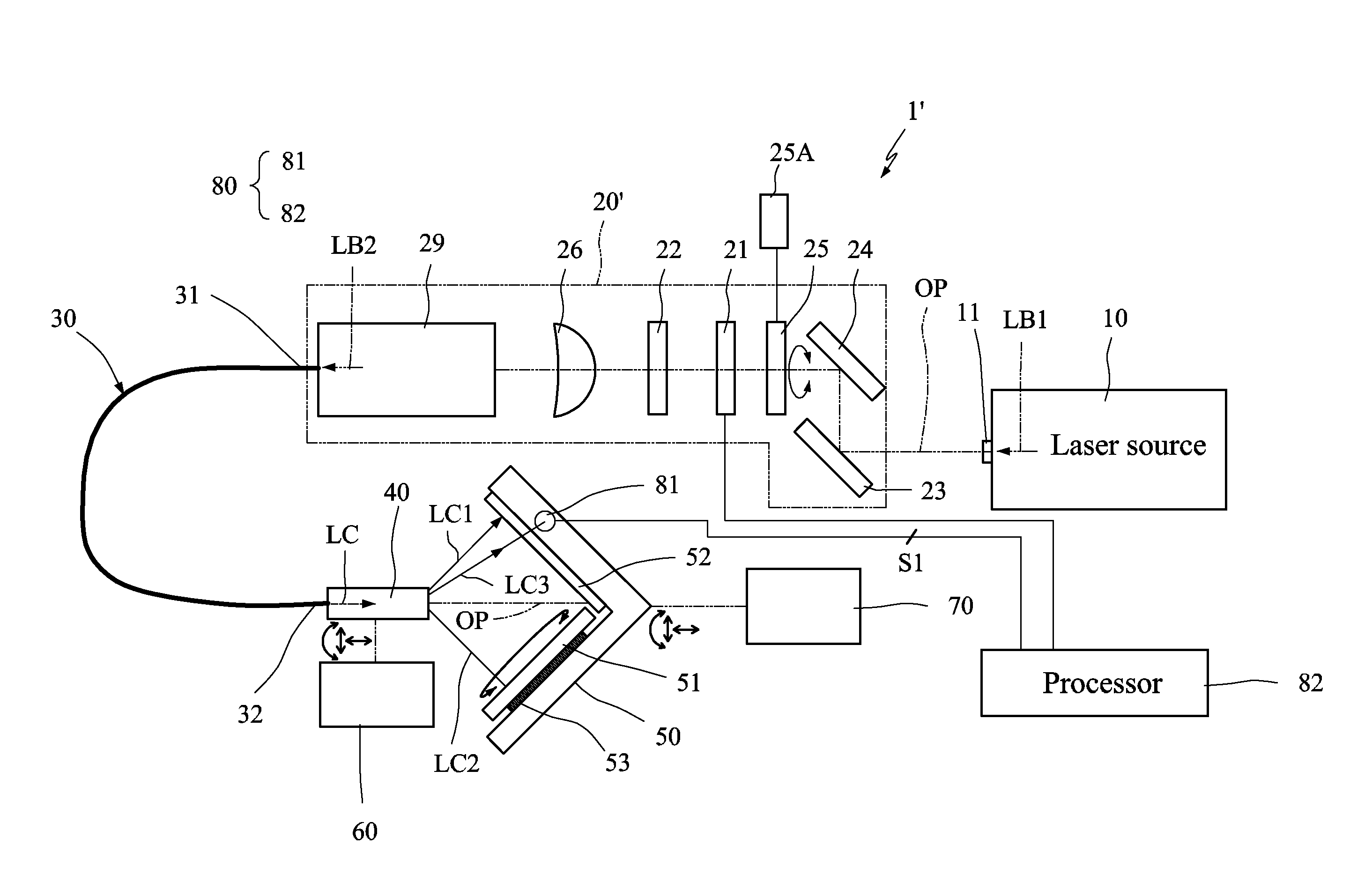

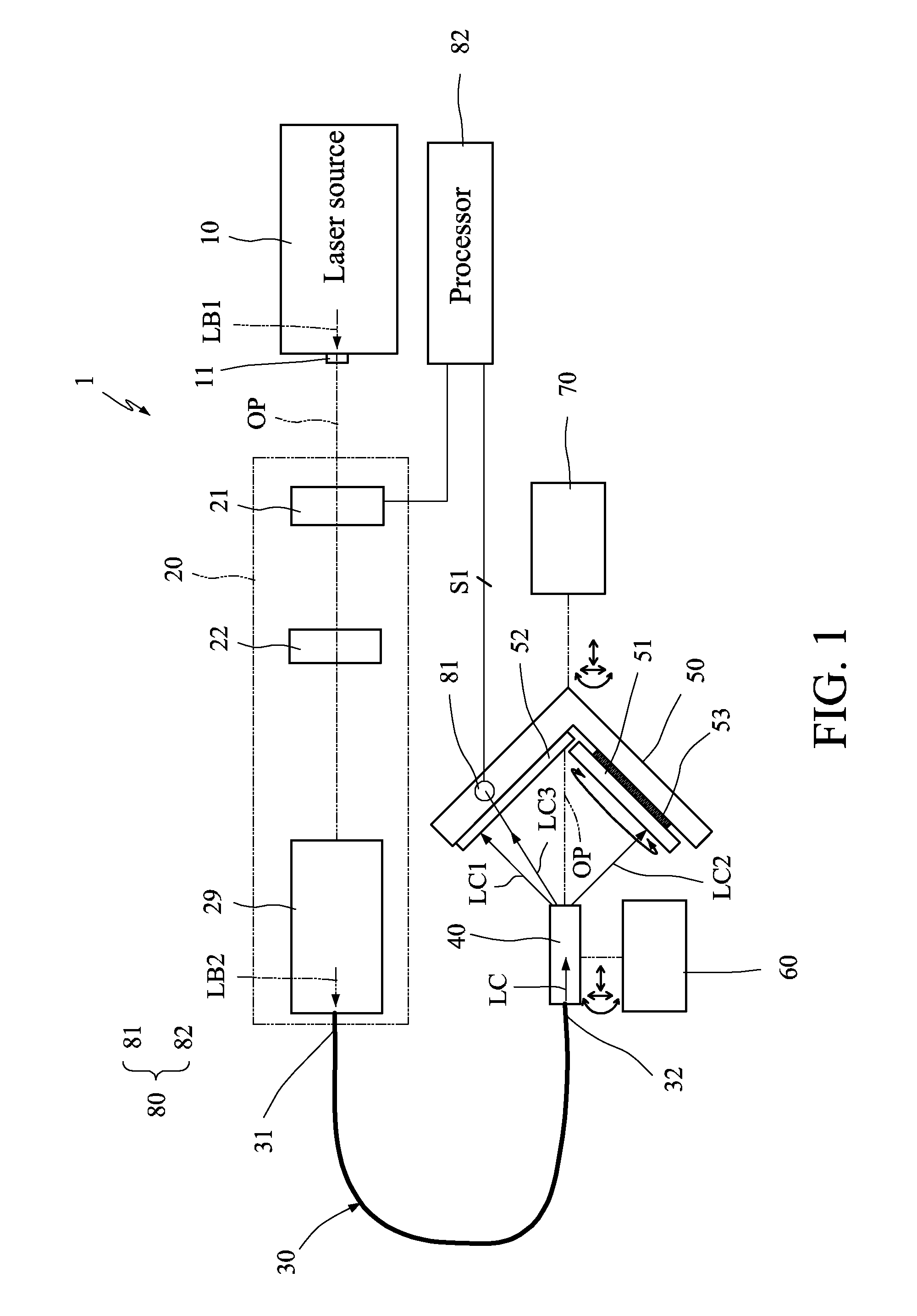

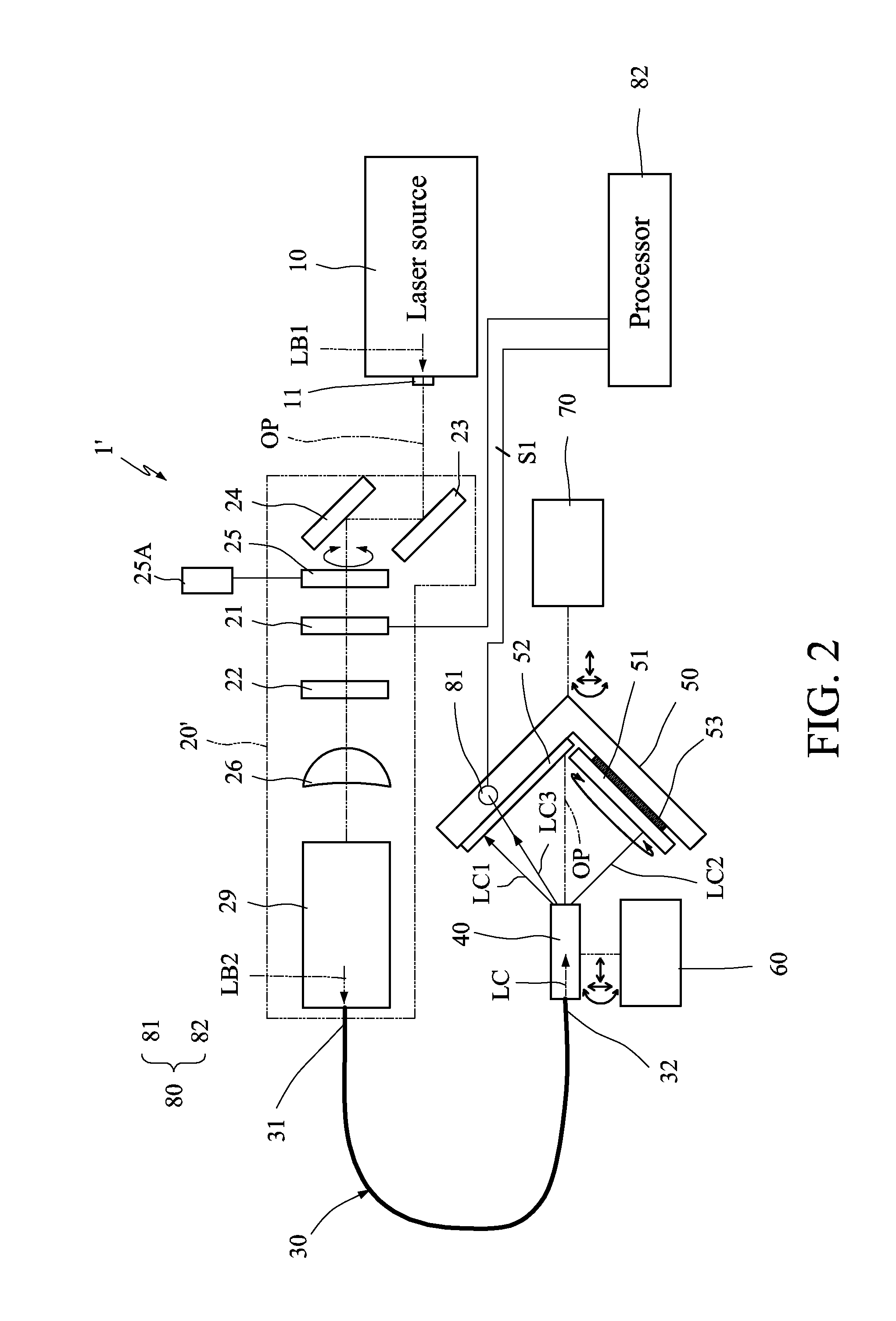

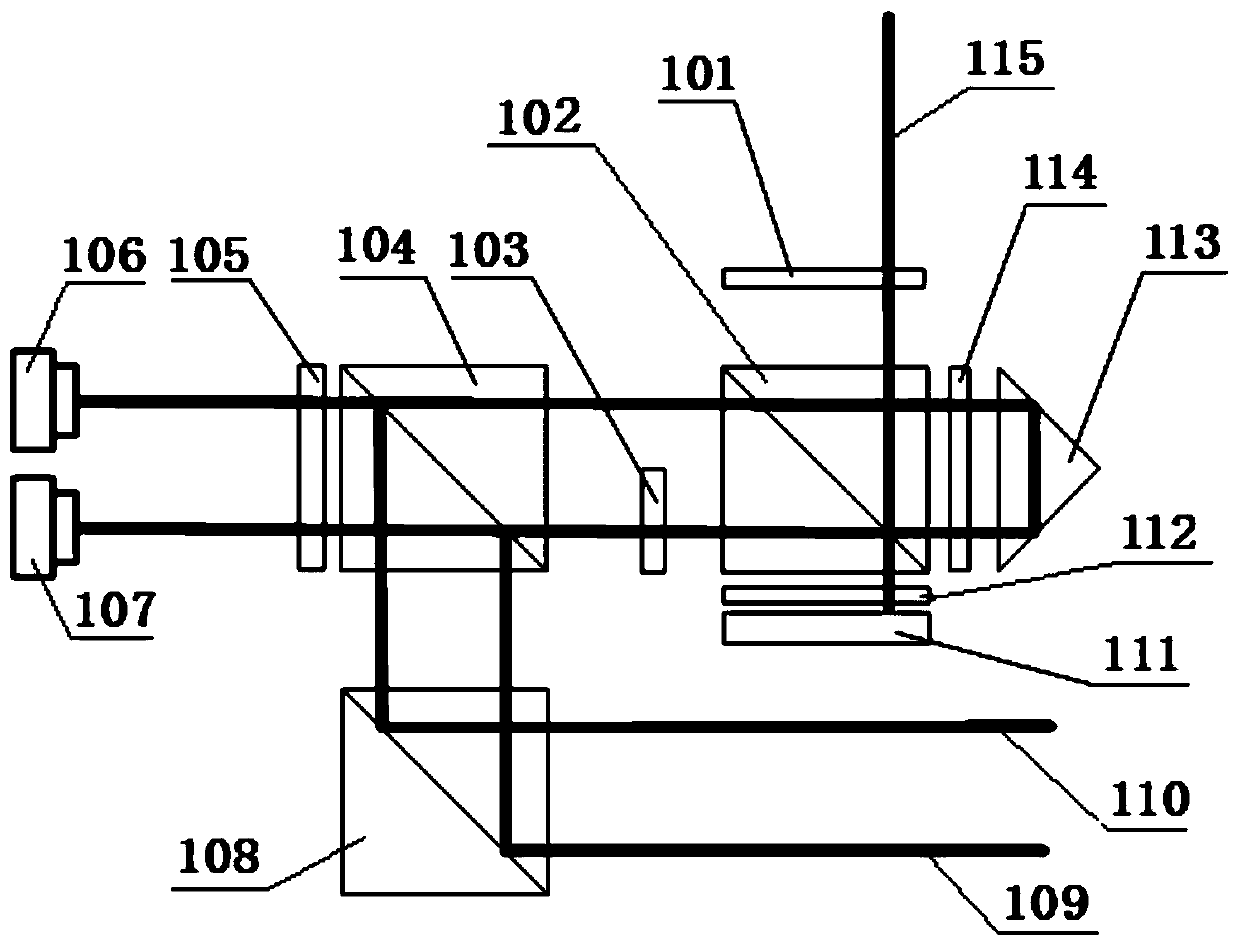

Laser Interference Lithography Apparatus Using Fiber as Spatial Filter and Beam Expander

InactiveUS20140118715A1Photomechanical exposure apparatusMicrolithography exposure apparatusFiberBeam expander

In a laser interference lithography apparatus, a laser source provides a first laser beam, and an optics assembly is optically coupled to the laser source and receives and processes the first laser beam into one or multiple second laser beams. An exposure stage carries a to-be-exposed object. The fiber assembly receives and processes the second laser beam(s) into one or multiple single mode and stable coherent third laser beams without spatial noise. An interference pattern is generated on the to-be-exposed object using the third laser beam(s). The apparatus is configured without a pin hole spatial filter and a beam expander being disposed on an optical path from an output end of the laser source to the exposure stage.

Owner:NATIONAL TSING HUA UNIVERSITY

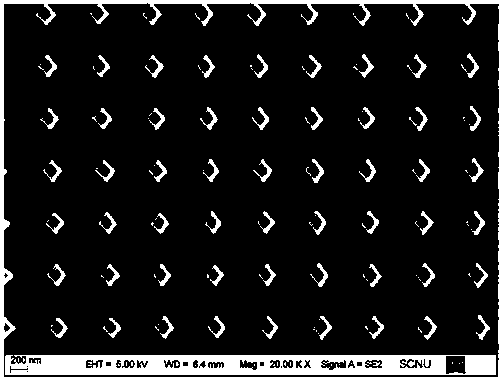

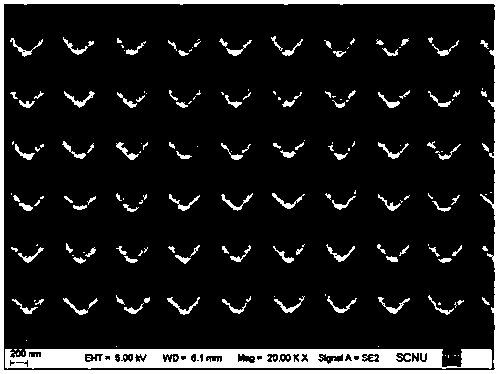

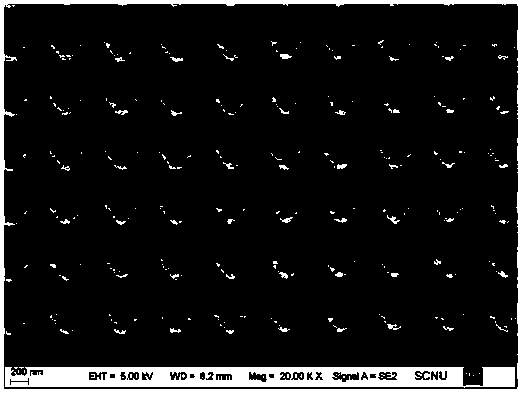

Surface-enhanced Raman spectroscopy substrate and preparation method and application thereof

InactiveCN108827933AImprove performancePrecise thickness controlRaman scatteringSquare arraySurface-enhanced Raman spectroscopy

The invention provides a surface-enhanced Raman spectroscopy substrate and a preparation method and application thereof. The method comprises the following steps: performing cleaning and hydrophobic treatment to silicon substrate in sequence; forming a polymer layer on the silicon substrate; carving on the polymer layer with ultraviolet laser interference light to form a nanometer square array structure; using inducing coupling plasma to etch the nanometer square array structure of the polymer layer to transfer and form a silicon nanometer square structure; plating a metal active layer on thesilicon nanometer square structure to obtain the SERS ( surface-enhanced Raman spectroscopy) substrate. The method provided by the invention has the advantages of simple and convenient process and lowcost; the SERS substrate can be prepared quickly in a large-area manner; besides, the endpoint of a periodic gold nanometer square structure on the SERS substrate is sharp, and the clearance betweenthe tips of the structure is controllable, so that Raman signals can be enhanced advantageously; and the method is very suitable for mass production and application.

Owner:SOUTH CHINA NORMAL UNIVERSITY

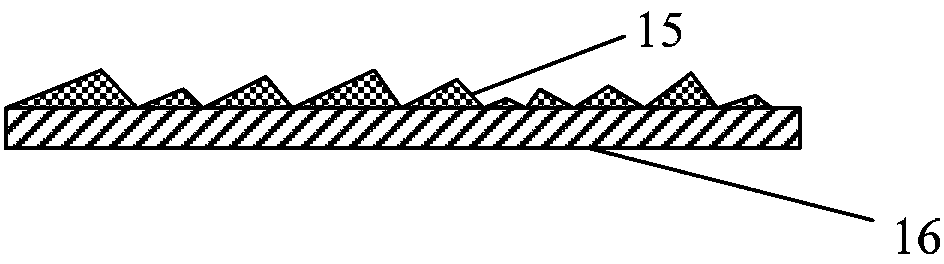

Prism film, and preparation method and apparatus thereof

ActiveCN103630953ALow costRandom distribution of modulation depthPrismsPhotomechanical apparatusResistPrism

The invention provides a prism film, and a preparation method and apparatus thereof. The prism film comprises a base material. The base material is provided with prism protrusions formed by a photosensitive resist. The at least two prism protrusions have different heights. According to the invention, the prism film is prepared by using laser interference lithography so that the advantages include simplicity, rapidness and low cost; and the modulation depth of the surface of the prepared prism film is randomly distributed, the prism direction and period can be conveniently adjusted, and the problems of image display such as film material adhesion, Moire patterns and the like between the prism film and other film materials or a liquid crystal panel can be effectively solved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

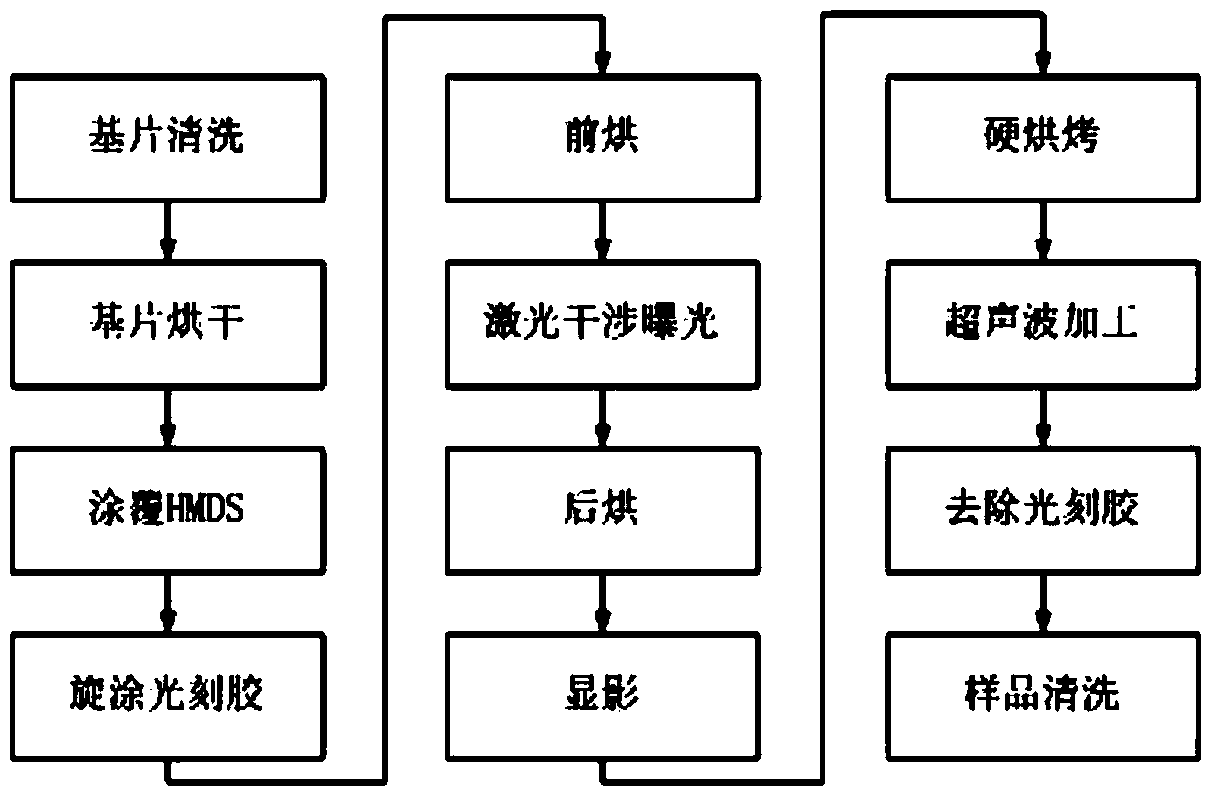

Method for preparing micro-nano textures through ultrasonic vibration

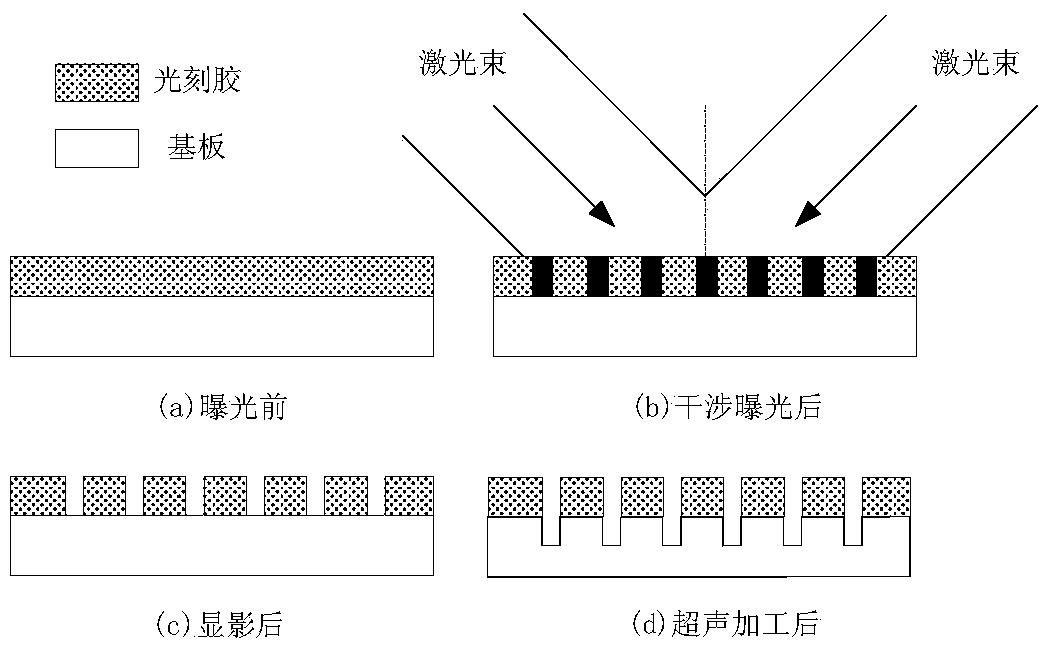

InactiveCN103991839AWon't breakGood graphics transferDecorative surface effectsChemical vapor deposition coatingMicro nanoUltrasonic machining

The invention discloses a method for preparing micro-nano textures through ultrasonic vibration and belongs to a preparation method of silicon surface micro-nano textures. The method comprises the following steps: firstly, uniformly coating a layer of photo-etching glue on the surface of a substrate by using a glue homogenizer; then carrying out interferential exposure on the substrate with the photo-etching glue in a laser interferometer system to realize texturing treatment on the photo-etching glue; and finally machining the substrate in an ultrasonic machining system, removing the substrate material in an area which is not covered by the photo-etching glue, gradually increasing the removal depth along with the increase of the ultrasonic machining time, controlling exposure parameters of laser interference photo-etching and ultrasonic vibration machining parameters to prepare periodic micro-nano textures which are controllable in size and large in area. The method for preparing the micro-nano textures through ultrasonic vibration has the advantages that the method is pollution-free due to the adoption of ultrasonic vibration machining, simple to operate, free of damage to the photo-etching glue layer on the surface of the substrate and good in pattern transfer effect; by changing the size of a vibration tool, different areas can be machined; by means of the ultrasonic vibration, the machining accuracy is high and the surface quality is good; the substrate is relatively small in stress in the machining process.

Owner:CHINA UNIV OF MINING & TECH

Quick controllable manufacturing method of large-area micron/nanometer texture on metal material surface

InactiveCN105081488AEasy to achieve large area exposureAvoid makingElectrical-based auxillary apparatusElectrolysisImage resolution

The invention provides a quick controllable manufacturing method of a large-area micron / nanometer texture on a metal material surface; and the method realizes the preparation of simple-complex, large-area and controllable-size micron / nanometer structures on metal surfaces with low cost and high efficiency through combining with the characteristic that the laser interference photoetching and the micro electrolytic machining both can reach submicron-level and nanometer-level resolutions and by using the characteristics that the laser interference photoetching is easy to realize large-area exposure and the micro electrolytic machining can machine all electric conducting materials. The method can reduce the machining cost and largely shorten the machining period, and has significant meaning on the research of tribological properties of textured surfaces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Laser interferometric lithography system with application of blazed grating

ActiveCN105242499ANarrowing the line widthReduced Linewidth RequirementsPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingLight energy

The invention discloses a laser interferometric lithography system with the application of blazed grating. The laser interferometric lithography system comprises a light source module, a beam spread collimation module, a multiple beam split and beam combination module and a substrate holder. The light source module comprises a coherent light source, a first lens, a second lens and blazed grating. A laser beam emitted from the coherent light source successively passes through the first lens and the second lens and then passes through a reflector to make a light path bend over, and light is illuminated on the blazed grating. A light beam with wave length being equal to first-order blaze wavelength after blazed grating diffraction passes through a small aperture to be emitted out, and then passes through the beam spread collimation module and the multiple beam split and beam combination module to be split into multiple coherent light beams. The multiple coherent light beams are simultaneously converged and illuminated onto the substrate surface on the substrate holder. The system provided by the invention has advantages of high efficiency of light energy utilization and long coherence length. Flexibility and tolerance for light path adjustment are enhanced, linewidth requirement of a laser light source is also reduced, and selection range of the laser light source is broadened.

Owner:XIAN TECHNOLOGICAL UNIV

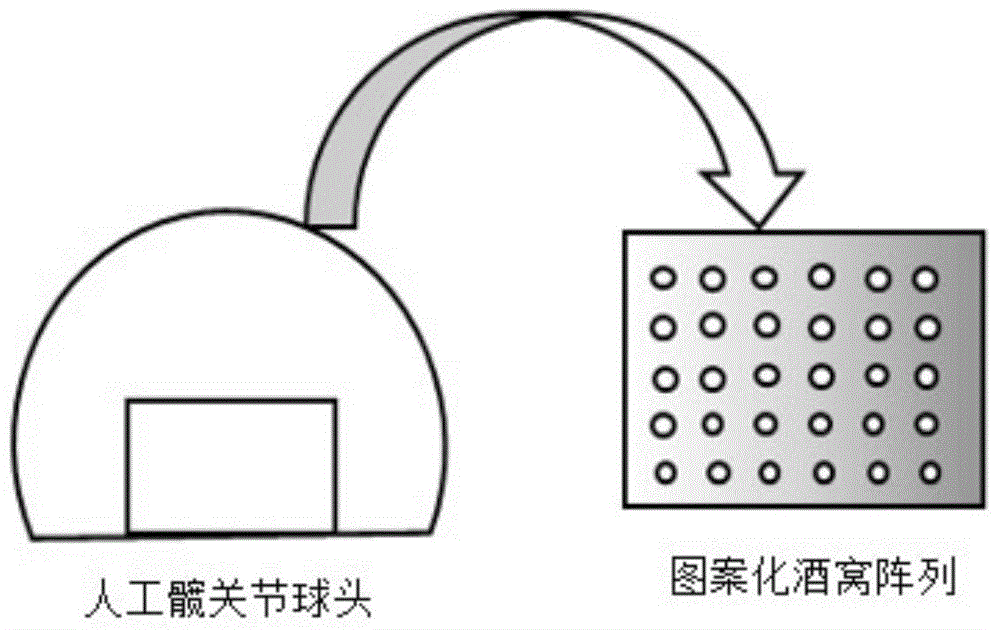

Method for preparing low-friction and high-hardness artificial hip joint ball through surface patterning

ActiveCN105055050AImprove tribological performanceHigh hardnessJoint implantsHip jointsFriction effectTissue fluid

The invention relates to a method for preparing a low-friction and high-hardness artificial hip joint ball through surface patterning. The low-friction and high-hardness artificial hip joint ball is made from a CO-Cr-Mo alloy material, and the method is characterized in that patterned dimple arrays are formed on the surface of the artificial hip joint ball, namely the patterned dimple arrays are made on the friction surface of the artificial hip joint ball through laser interferometric lithography to form a small temporary synovial fluid or tissue fluid storage device, and meanwhile the actual contact area between friction pairs is decreased and abrasive grains produced in the friction process are accommodated to achieve the friction-reducing purpose. The instantaneous high temperature of laser enables the grains to be refined, the material hardness is enhanced, and the artificial hip joint with low friction and high hardness is obtained. The low-friction and high-hardness artificial hip joint ball has good lubricating property and can reduce the friction effect between interfaces of the friction pairs of the artificial hip joint and reduce friction. In addition, the hardness is improved, the abrasion is reduced, and the friction and abrasion resisting performance of an existing artificial hip joint ball is optimized.

Owner:CHANGCHUN UNIV OF SCI & TECH

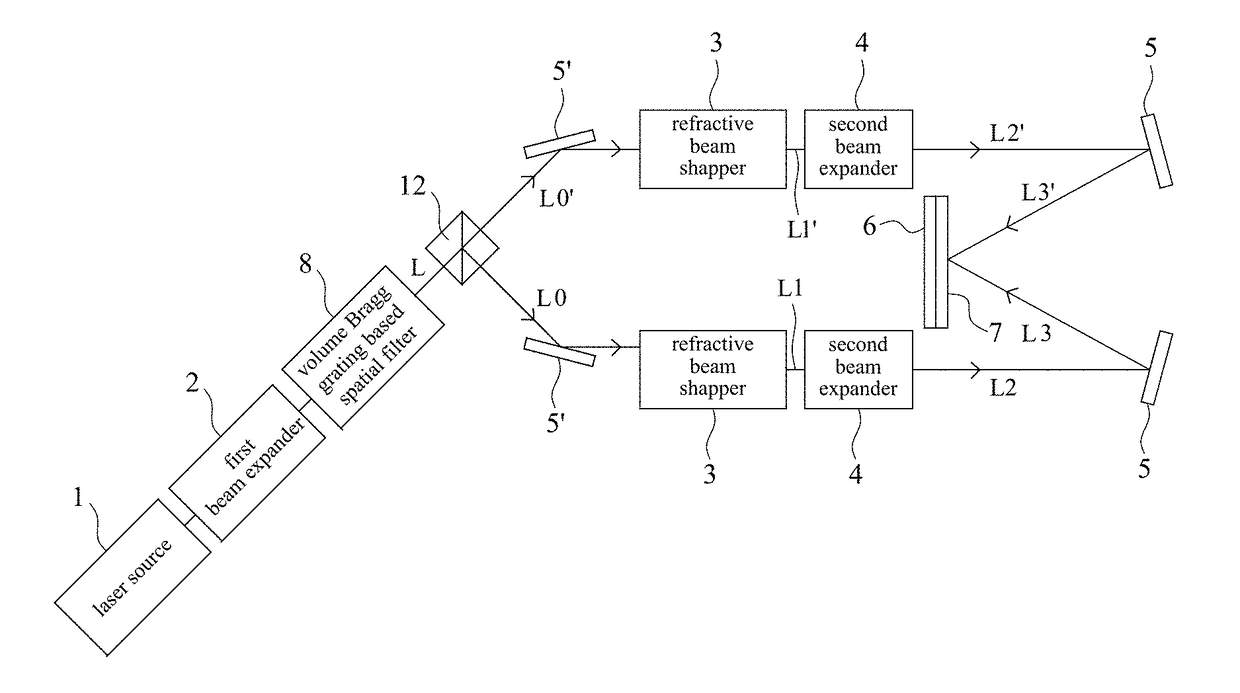

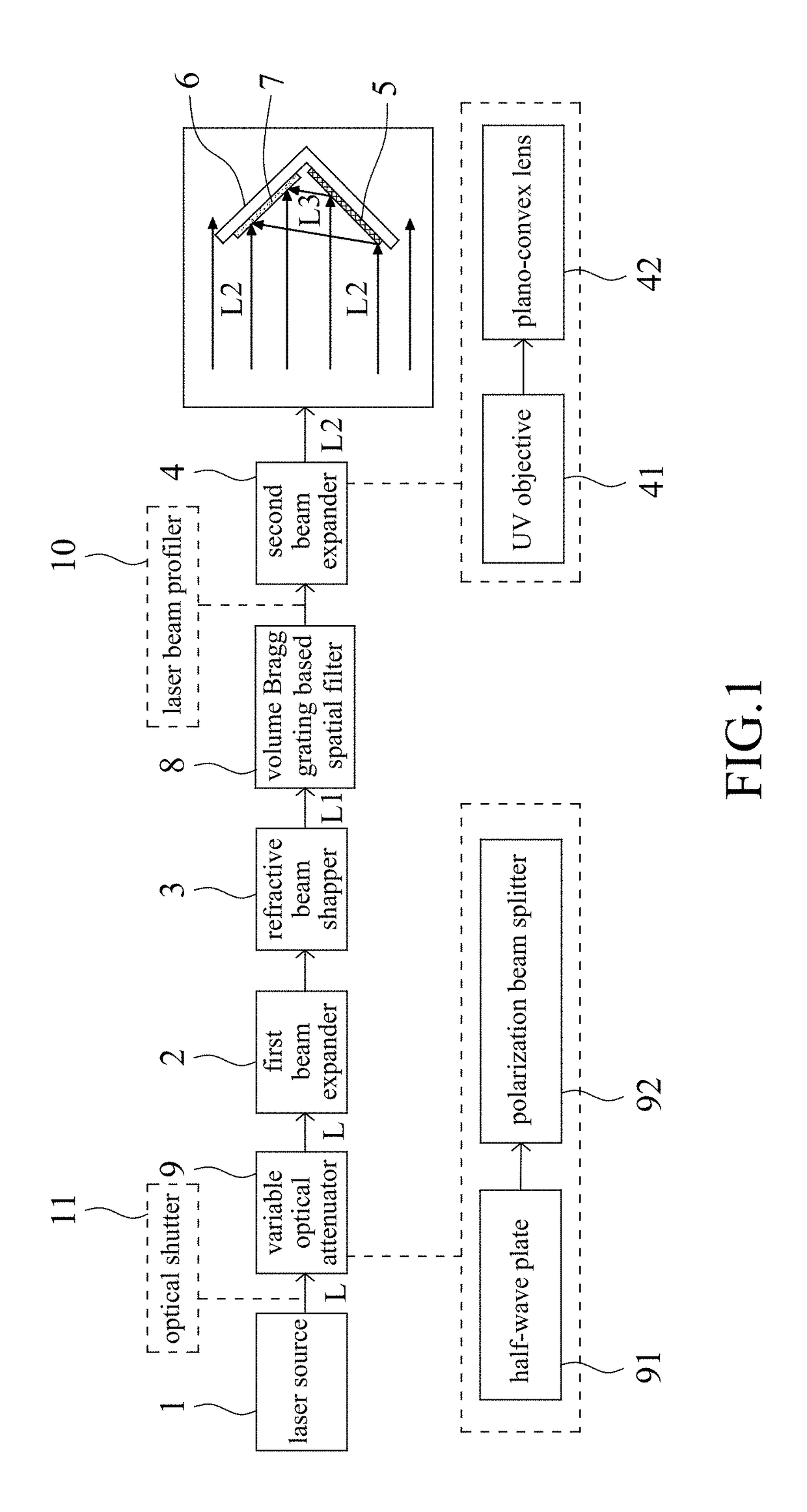

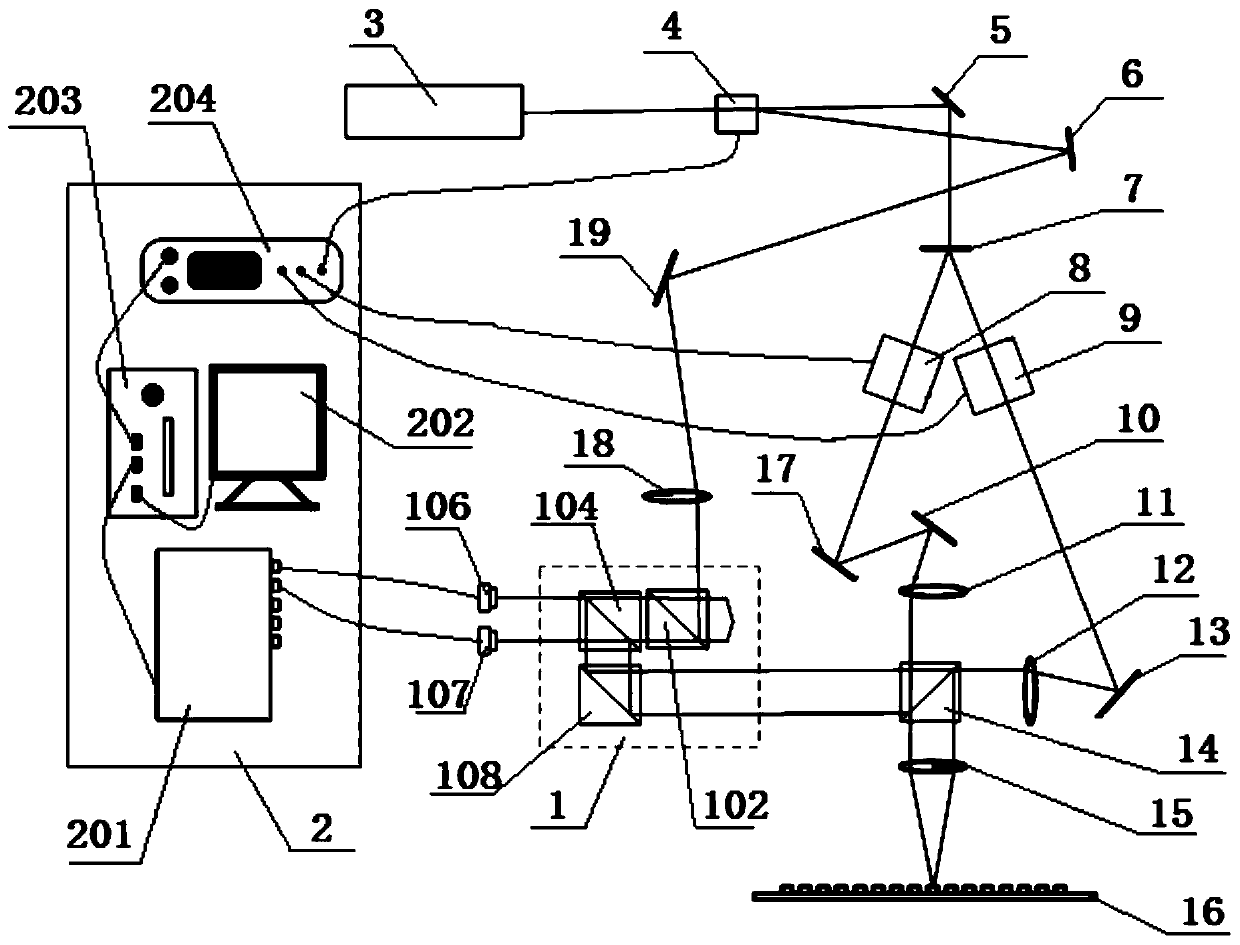

Laser interference lithography system with flat-top intensity profile

ActiveUS20170329146A1Uniform light fieldUniform exposure dosePhotomechanical apparatusOptical elementsBeam expanderLight beam

A laser interference lithography system with flat-top intensity profile comprises a laser source for emitting a coherent laser beam, a first beam expander for adjusting the coherent laser beam size, a refractive beam shaper for converting a Gaussian intensity profile inherent to the coherent laser beam into a flat-top one and outputting a first collimated laser beam, a second beam expander for receiving the first collimated laser beam and outputting a second collimated laser beam, a sample holder for holding a substrate, and at least one reflector for reflecting the second collimated laser beam to generate a third collimated laser beam. The second and third collimated laser beams are transmitted to the substrate at a predetermined angle to create an interference pattern exposed onto the substrate.

Owner:NAT SUN YAT SEN UNIV

Laser interference photoetching system

ActiveCN110806680ASmall sizePhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splitterGrating

The invention belongs to the technical field of optical instruments and meters, and discloses a laser interference photoetching system, which comprises a laser, a first reflector, a grating beam splitter, a second reflector, a first universal reflector, a first lens, a second universal reflector, a second lens, a beam splitter prism, a control module, an angle measurement module, a third lens anda substrate, wherein the control module comprises a signal processing end, a controller and a driver; the signal processing end is connected with the angle measuring module; the controller is connected with the signal processing end and the driver; and the driver is connected with the first universal reflector and the second universal reflector. A light source emitted by the laser is divided intotwo beams of light through the system and focused on the substrate for exposure; and by adjusting the exposure angle, the manufacturing of the large-area grating with the gradient period is realized.The size of the grating manufactured in a scanning interference photoetching mode is not limited by the size of an exposure light spot, and a large-size gradient period grating can be manufactured.

Owner:TSINGHUA UNIV +1

Preparation technology for increasing effective photosensitive area of photoelectric material

InactiveCN102169921AImprove effectivenessIncrease the areaFinal product manufacturePhotomechanical exposure apparatusMicro nanoLight beam

The invention discloses a preparation technology for increasing the effective photosensitive area of a photoelectric material or a photoelectric element. The principle of the preparation technology comprises the following steps of: controlling the quantity of exposed light beams, light beam polarization and an incident angle to obtain a micro-nano structure with different periods and characteristic sizes by laser interference photoetching; and increasing the real effective area of a P-N junction within unit area on the structure by semiconductor doping. Because the photoelectric material or the photoelectric element is manufactured by using the technology and a method, the effective photosensitive area can be increased on a large scale within the unit area, and then light absorption rate is improved; the application prospect of the technology is wider due to the properties of self cleaning and anti-reflection of the micro-nano structure; the technology is particularly applied to the field of solar batteries; and conversion efficiency is improved on a large scale.

Owner:CHANGCHUN UNIV OF SCI & TECH

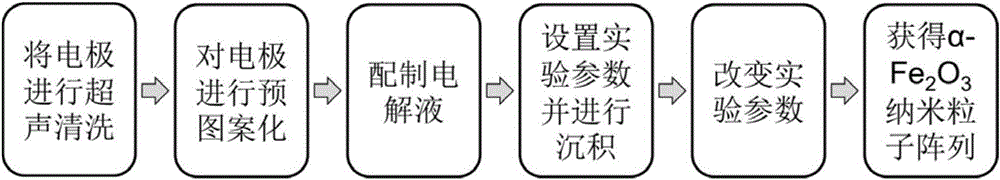

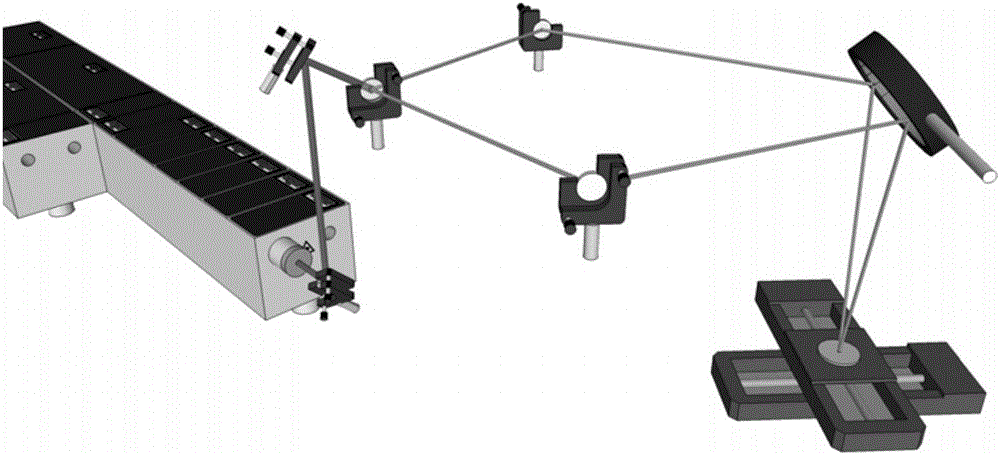

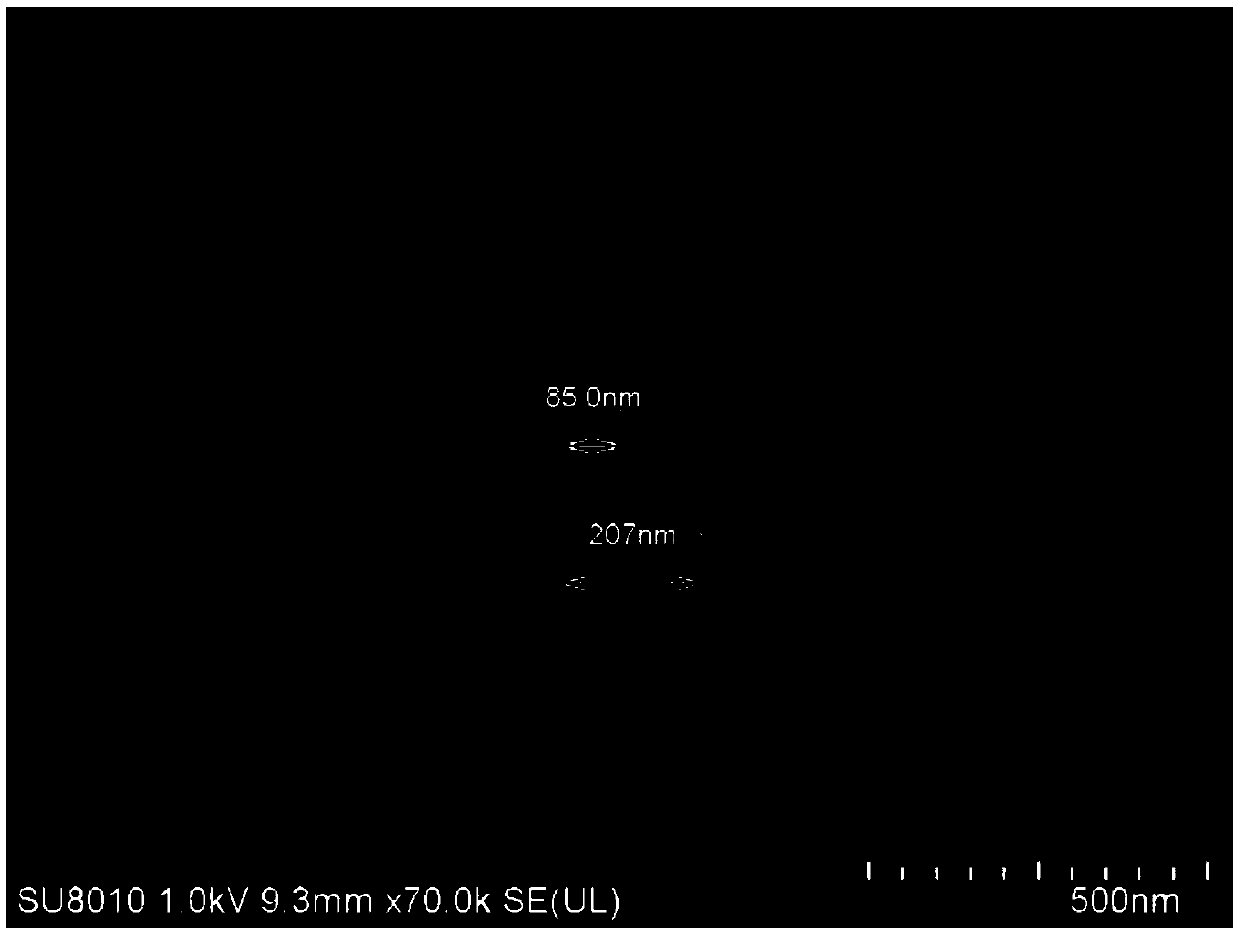

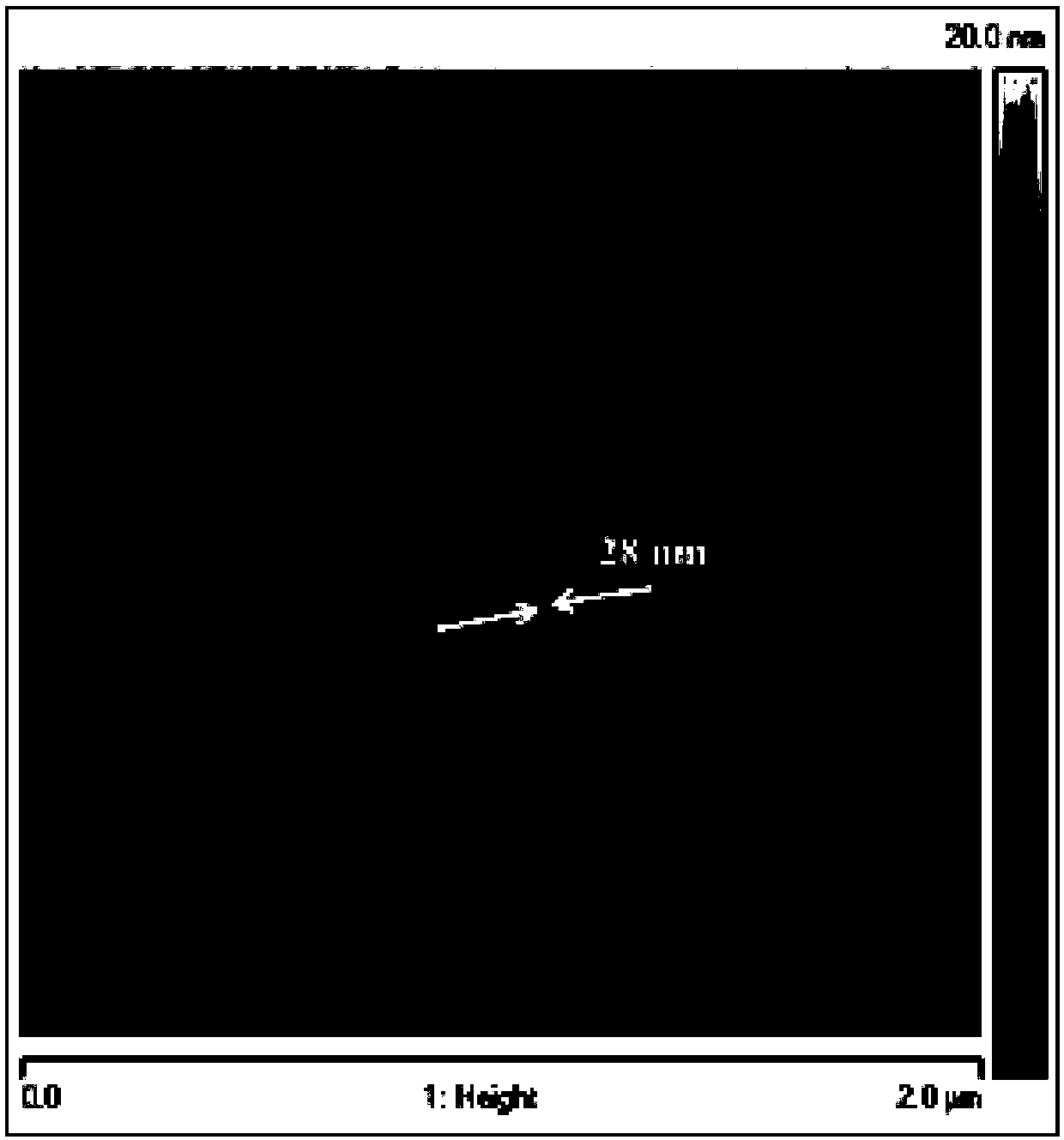

Method of adopting electrochemical deposition to prepare patterned orderly alpha-Fe2O3 nanoparticle array

ActiveCN106350846AReduce manufacturing costRaw materials are easy to getElectrolytic inorganic material coatingNanotechnologyDispersityWorkstation

A method of adopting electrochemical deposition to prepare a patterned orderly alpha-Fe2O3 nanoparticle array includes: adopting an electrochemical workstation, using ITO conductive substrate after laser interference photoetching as a working electrode, a saturated calomel electrode as a reference electrode, a high-purity iron sheet as a pair electrode and a mixed solution of FeCl2 and FeCl3 as an electrolyte, adopting a triphase electrode system to soak the working electrode, the pair electrode and the reference electrode in the electrolyte at the same time, and setting needed temperature for electrochemical deposition; adopting a timing current method to electrochemically deposit on the working electrode to obtain the patterned orderly alpha-Fe2O3 nanoparticle array having high dispersity. Double-beam single-exposure is utilized to pre-pattern the electrodes, and the nanoparticle array of a large-scale patterned orderly structure is prepared. A cathode electrodeposition method is used in the process of electrochemical deposition, equipment is simple, preparation cost is low, and high-temperature heating or annealing treatment is not needed; used chemicals are nontoxic and harmless, and the prepared patterned orderly alpha-Fe2O3 nanoparticle array is high in repeatability and stability.

Owner:CHANGCHUN UNIV OF SCI & TECH

Chemical amplification photoresist composition and application thereof in ultraviolet lithography

ActiveCN110032040AHigh sensitivityIncrease roughnessPhotomechanical exposure apparatusMicrolithography exposure apparatusFuranUltraviolet lights

The invention relates to a chemical amplification photoresist compositions which are each prepared by taking a series of molecular glass compounds, which take tetraphenyl furan, tetraphenyl pyrrole, tetraphenyl thiophene, pentaphenylpyridine, tetraphenyl bisphenol A and calixarene bisphenol A, as cores as main body materials and taking a photoacid generator, a solvent and the like as auxiliary materials through combination. The photoresist composition is spin-coated on a substrate to prepare a photoresist film with uniform thickness, and the photoresist film is applied to ultraviolet light source exposure of 200-450nm, and is particularly suitable for far-field and near-field photoetching technologies, such as 365nm I line photoetching, 248nm deep ultraviolet photoetching, 436nm G line photoetching and the like, such as an ultraviolet exposure machine, 365nm laser direct writing near-field photoetching, 365nm laser interference photoetching and other ultraviolet photoetching technologies.

Owner:INST OF CHEM CHINESE ACAD OF SCI

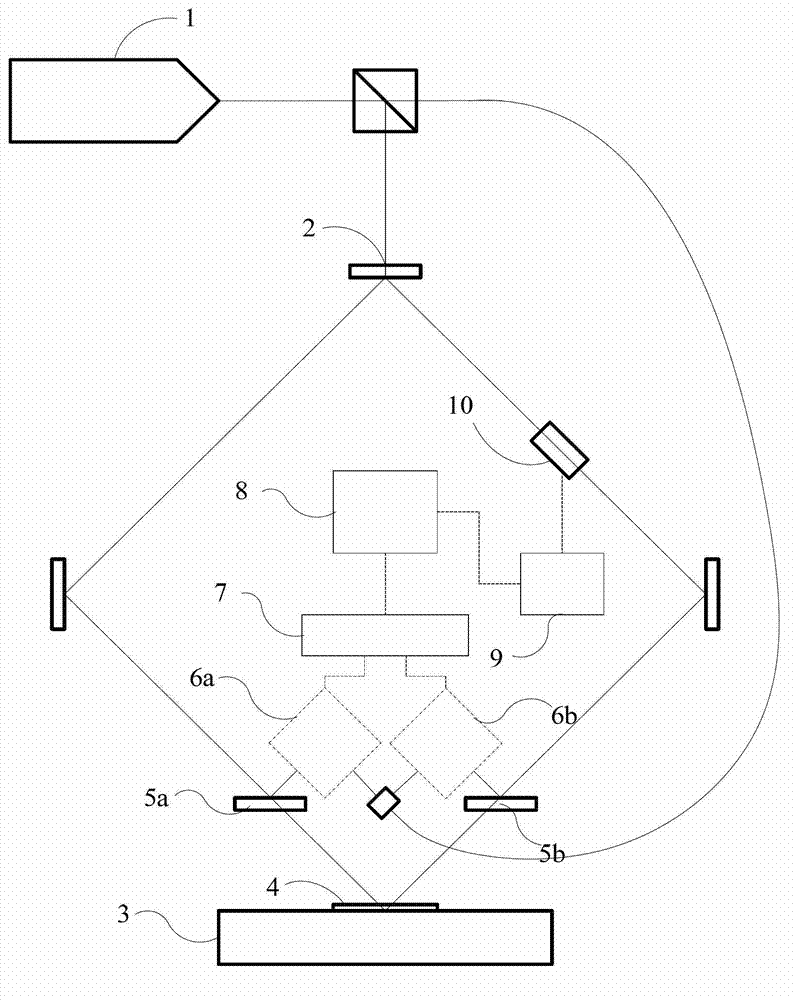

Exposure beam phase measurement method in laser interference lithography and lithography system

ActiveCN110716397AReal-time measurementRealize real-time controlDiffraction gratingsPhotomechanical exposure apparatusGratingInterference lithography

The invention belongs to the technical field of optical instruments and meters, and discloses an exposure beam phase measurement method in laser interference lithography. The method comprises the steps: separating measuring light from an exposure light beam of laser interference lithography and inputting the measuring light into a laser phase measuring interferometer to carry out phase measurementon the exposure light beam of laser interference lithography; and introducing a reference light beam homologous with the laser interference lithography exposure light beam, inputting the reference light beam into the laser phase measuring interferometer, processing the reference light beam by the laser phase measuring interferometer to form an interference measurement light signal, and performingresolving to obtain the phase of the laser interference lithography exposure light beam. The invention discloses a laser interference lithography system. The system comprises the laser phase measurement interferometer, a controller and a phase modulator; the system adopts the exposure light beam phase measurement method in laser interference lithography, and the laser phase measurement interferometer is used for measuring whether the phase of the exposure light beam drifts or not; the controller controls the phase modulator to carry out phase modulation, the locking of exposure fringe phase drift is completed, and the manufacturing of a high-precision variable-period grating is achieved.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com