Method and system for realizing phase shift in laser interference lithography

A technology of laser interference and positioning system, which is applied in the direction of microlithography exposure equipment, optics, optical components, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

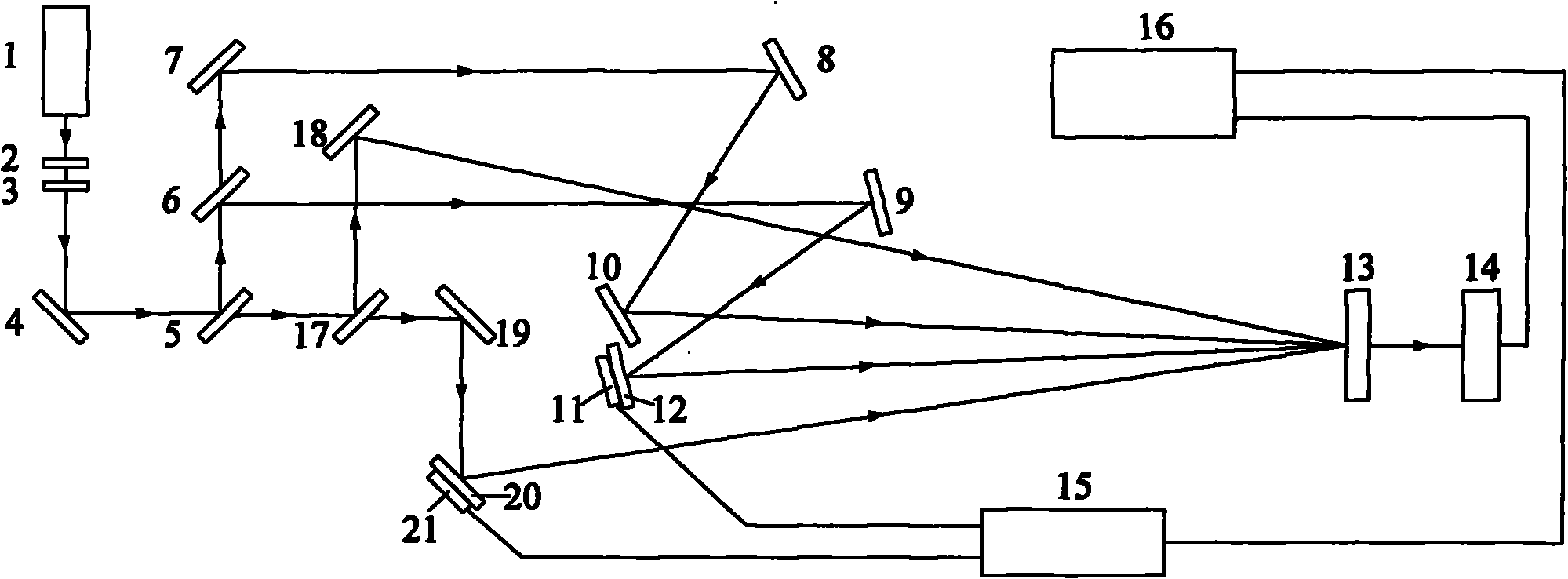

[0028] Such as figure 1 As shown, the four-beam laser interference lithography system adopted in the present invention includes a laser 1 (wavelength 632.8nm), a half-wave plate 2, a polarizer 3, mirrors 4, 7, 8, 9, 10, 12, 18, 19 , 20, beam splitting devices 5, 6, 17, PZT 11, 21 (3 microns / 200 volts), beam expander 13, photocoupler CCD 14, voltage source 15 and computer 16. Among them, PZT 11 is fixed on mirror 12, and PZT 21 is fixed on mirror 20. When voltage source 15 applies different voltages to PZT 11 and PZT 21, PZT 11 and PZT 21 are deformed and move along their axial direction , so that the reflector also moves along the axial direction of PZT 11 and PZT 21, thus changing the optical path and realizing the phase shift and positioning of the interference pattern. The system can detect phase shift through CCD 14 and feedback control phase shift and positioning through computer 16 .

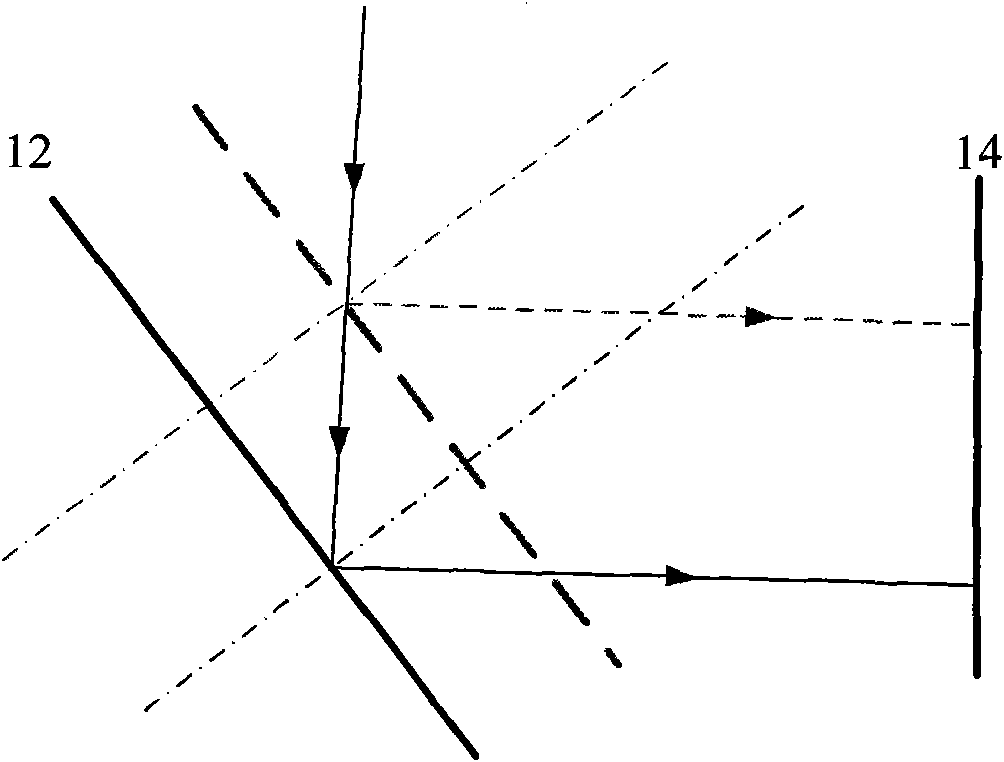

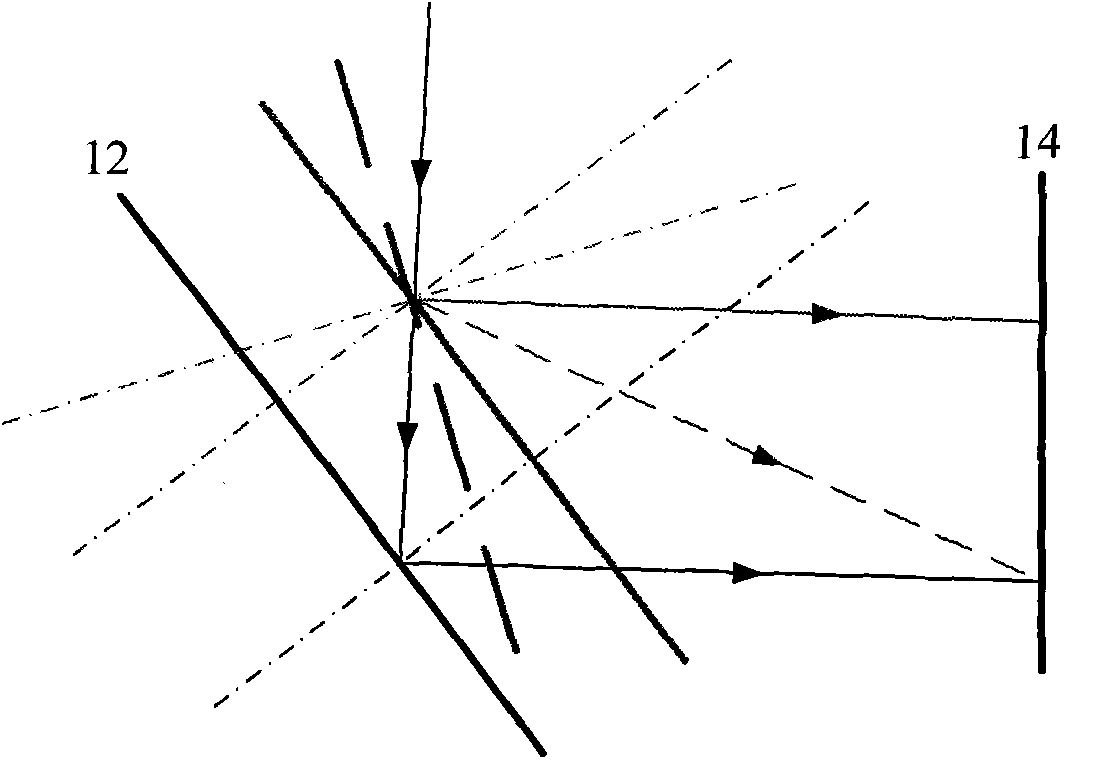

[0029] Such as figure 2 As shown, the optical path can be changed by adjusting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com