Prism film, and preparation method and apparatus thereof

A prism film and prism technology, applied in prisms, printing devices, lenses, etc., can solve the problems of prism film quality and reliability decline, long cycle, complex processing technology, etc., and achieve convenient and adjustable prism direction and cycle, low cost, Solve the effect of film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

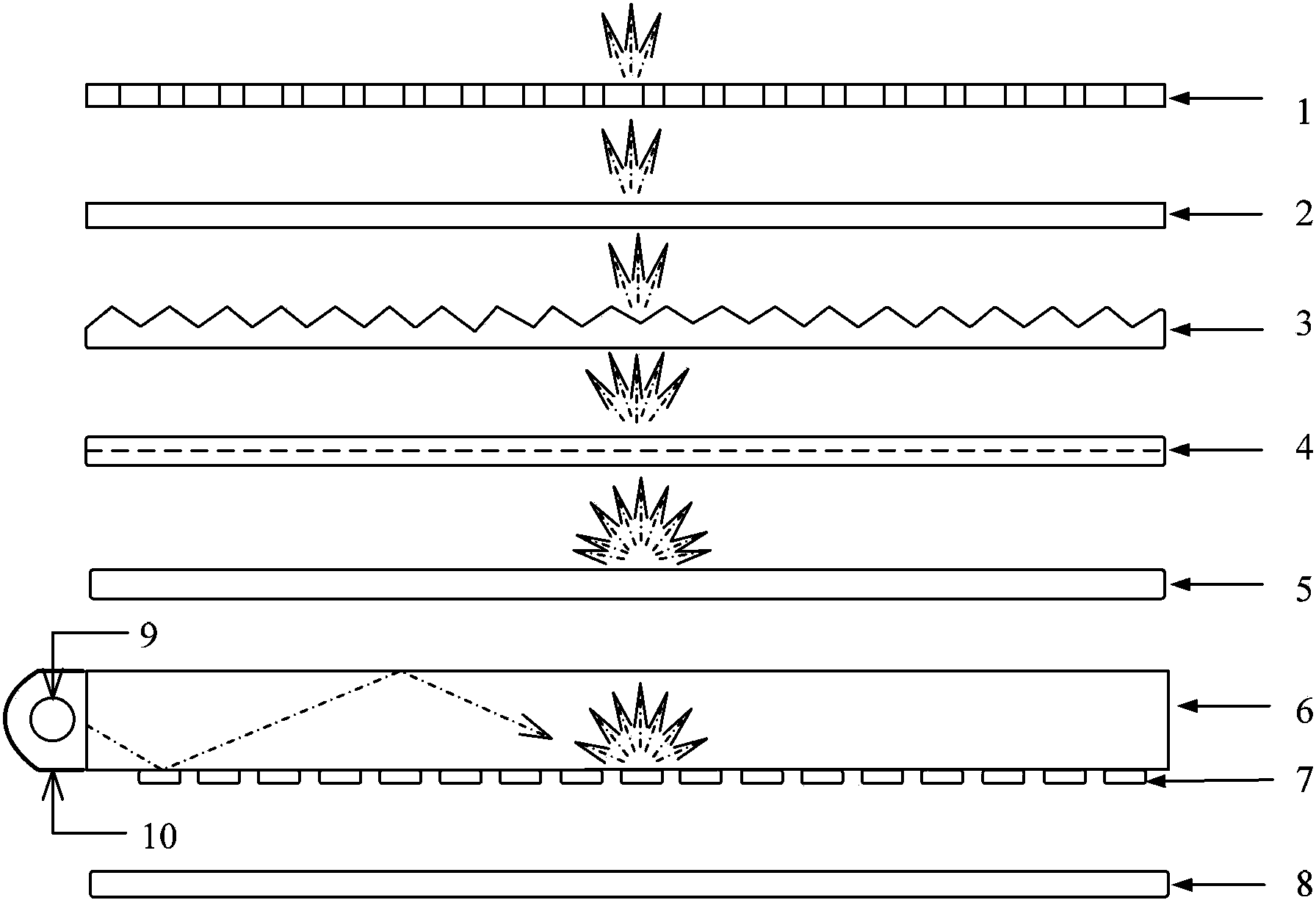

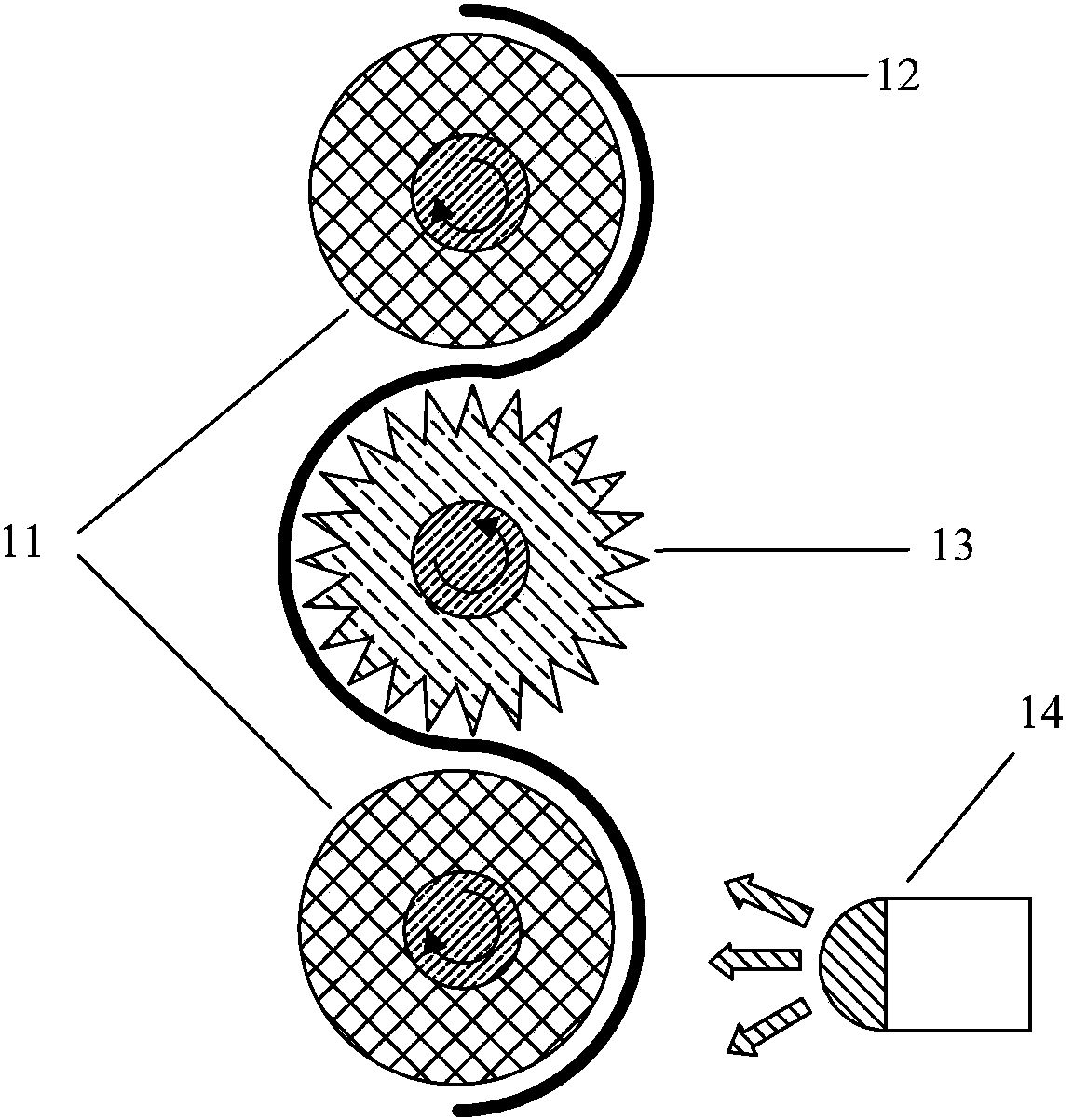

[0053] The basic idea of the present invention is: a method for preparing a prism film, comprising: coating a photoresist on the surface of a substrate to obtain a sample coated with photoresist; performing laser interference lithography on the sample; The sample after laser interference lithography is developed and fixed, and prism protrusions with different modulation depths are formed on the surface of the sample to obtain a fixed prism film; the fixed prism film is air-dried to obtain the final formed prism film, and The prism film whose modulation depth changes randomly can prevent the occurrence of defects such as film material adhesion.

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail by citing the following embodiments and referring to the accompanying drawings.

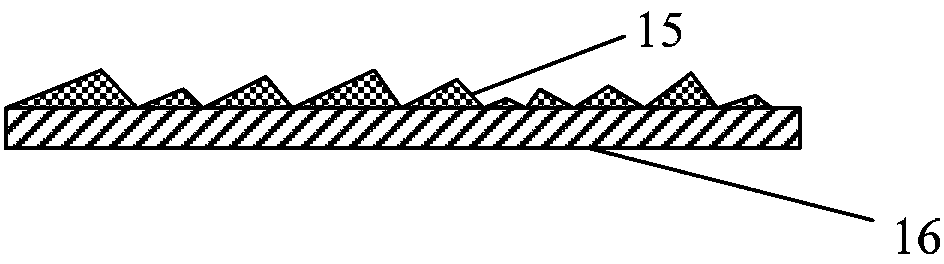

[0055] like image 3 As shown, the prism film includes a substrate 16 and a plurality of pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com