Laser interferometric lithography system with application of blazed grating

A technology of laser interference lithography and blazed grating, which is applied in the field of laser interference lithography system, can solve problems such as unguaranteed monochromaticity, difficulty in finding a laser light source, and limited selection range, so as to reduce the loss of light energy and expand the selection range, the effect of reducing the spectral line width requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

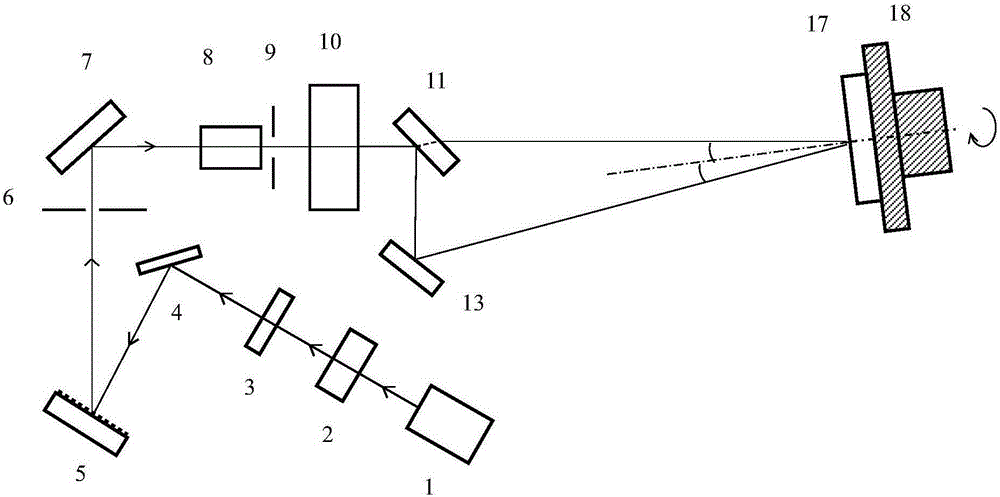

[0023] An embodiment of the present invention provides a laser interference lithography system using a blazed grating, such as figure 1 As shown, the laser interference lithography system includes a light source assembly, a beam expander and collimator assembly, a multi-beam splitting and beam combining assembly, and a substrate stage 18. The light source assembly includes a coherent light source 1, a first lens 2, and a second lens 3 , the blazed grating 5, the light beam emitted by the coherent light source 1 passes through the first lens 2 and the second lens 3 in turn, and then irradiates on the blazed grating 5 after being refracted by the reflector 4. After being diffracted by the blazed grating 5, the wavelength is equal to The beam of the first-order blazing wavelength exits through the small hole diaphragm 6, and then the filtered laser beam is expanded and collimated into parallel light by the beam expander and collimator component, and the beam is divided into multip...

Embodiment 2

[0035] An embodiment of the present invention provides a laser interference lithography system using a blazed grating, such as figure 2 As shown, the laser interference lithography system includes a light source assembly, a beam expander and collimator assembly, a multi-beam splitting and beam combining assembly, and a substrate stage 18. The light source assembly includes a coherent light source 1, a first lens 2, and a second lens 3 , the blazed grating 5, the laser beam emitted by the coherent light source 1 successively passes through the lens group composed of the first lens 2 and the second lens 3 to reduce the divergence angle, and then irradiates the blazed grating 5 after refracting the optical path by the reflector 4 Above, after being diffracted by the blazed grating 5, the light beam with a wavelength equal to the first-order blazed wavelength exits through the small hole diaphragm 6, and then the filtered laser beam is expanded and collimated into parallel light b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grating constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com