Surface-enhanced Raman spectroscopy substrate and preparation method and application thereof

A surface-enhanced Raman and substrate technology, applied in the field of Raman spectroscopy, can solve the problems of uneven distribution, poor control of large-area order, low efficiency, etc., to achieve enhanced Raman scattering, rapid large-area production, Craft a simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

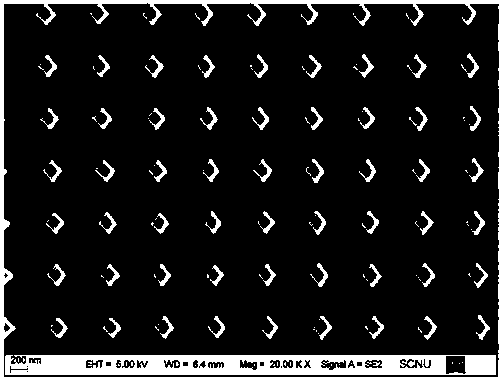

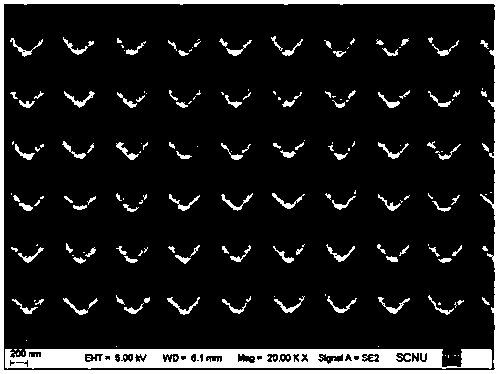

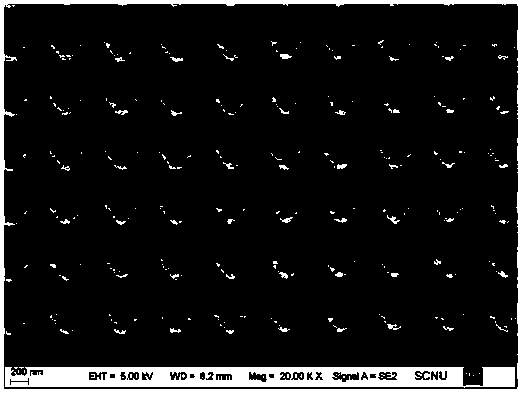

Image

Examples

Embodiment 1

[0037] (1) The silicon substrate is cleaned and hydrophobically treated in sequence: first, the silicon substrate dissociated into a certain size is ultrasonically cleaned in acetone, isopropanol, and deionized water, and then rinsed with deionization and blown dry with nitrogen. Then, a layer of hexamethyldisilazane (HMDS) with a thickness of 5 nanometers is covered on the surface of the silicon substrate by means of steam, so that the surface of the silicon substrate can obtain better hydrophobicity.

[0038] (2) Get the silicon substrate that has been cleaned and treated with hydrophobicity, place it in a homogenizer with a rotating speed of 4000rpm, and add an appropriate amount of AR-P3740 positive photoresist (produced by Allresist, Germany) dropwise on the silicon substrate. After the bottom surface was spin-coated for 45 seconds, it was taken out and baked at 90° C. for 2 minutes, and the average thickness of the obtained photoresist was 300 nm.

[0039] (3) First, usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com