Method for preparing biomimetic colour super-hydrophobic coating by multi-beam interference photoetching technology

A multi-beam interference, super-hydrophobic coating technology, applied in the field of bionic micro-manufacturing, can solve problems such as restricting applications, and achieve the effect of promoting development, good decorative effect, and promoting simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

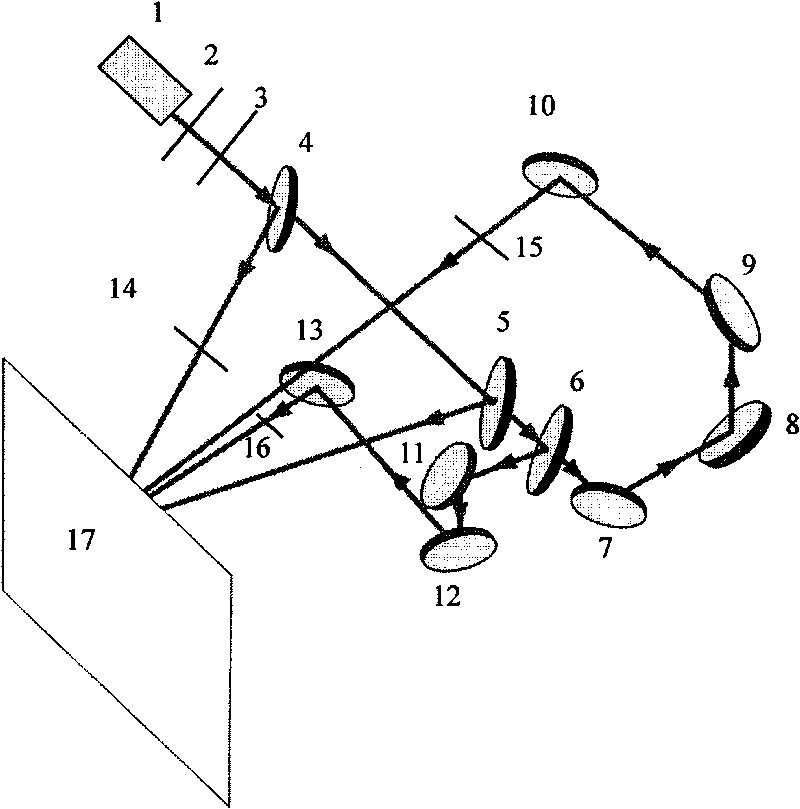

[0051] (1) Build a four-beam laser interference system.

[0052] figure 1 It is a schematic diagram of the optical path of four-beam laser interference. The laser used was a triple frequency, mode-locked, neodymium-doped yttrium aluminum garnet single-mode laser (Lab-Series) provided by American Spectroscopy. The production process of four coherent lasers is as follows:

[0053] After the 355nm laser beam emitted by the laser 1 is enclosed and expanded by the lenses 1 and 2, the light reflected by the beam splitter 3 is the first coherent light. The light transmitted from the beam splitter 4 is the incident light of the beam splitter 5, and the light reflected from the beam splitter 5 is the second beam of coherent light. The first beam of coherent light and the second beam of coherent light are coplanar. The light transmitted from the beam splitter 5 passes through the beam splitter 6, and the reflected light from the beam splitter 6 passes through the two mirrors 11 and 12 to ...

Embodiment 2

[0070] (1) Build an interference lithography system. Same as Example 1.

[0071] (2) Preparation of interference materials with different thicknesses.

[0072] Adjust the speed of the homogenizer to obtain different film thicknesses to control the height of the final structure. When the speed of the homogenizer is 1000 rpm, 3000 rpm, and 6000 rpm, the resulting film thicknesses are 1.5 μm, 1 μm, and 300 nm, respectively.

[0073] (3) Interference lithography and development process.

[0074] When the height of the structure changes, the roughness of the material also changes, and the hydrophobic properties are also different. Such as Figure 4 As shown, (b), (e), (h) are oblique SEM pictures with the same diameter and structure heights of 300 nm, 1 μm, and 1.5 μm, respectively, and the measured contact angles are 132°, 151°, and 156°, respectively. It can be seen that as the height of the micropillars increases, the contact angle gradually increases. In addition, as the exposure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com