Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

227 results about "Hexanedioic Acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

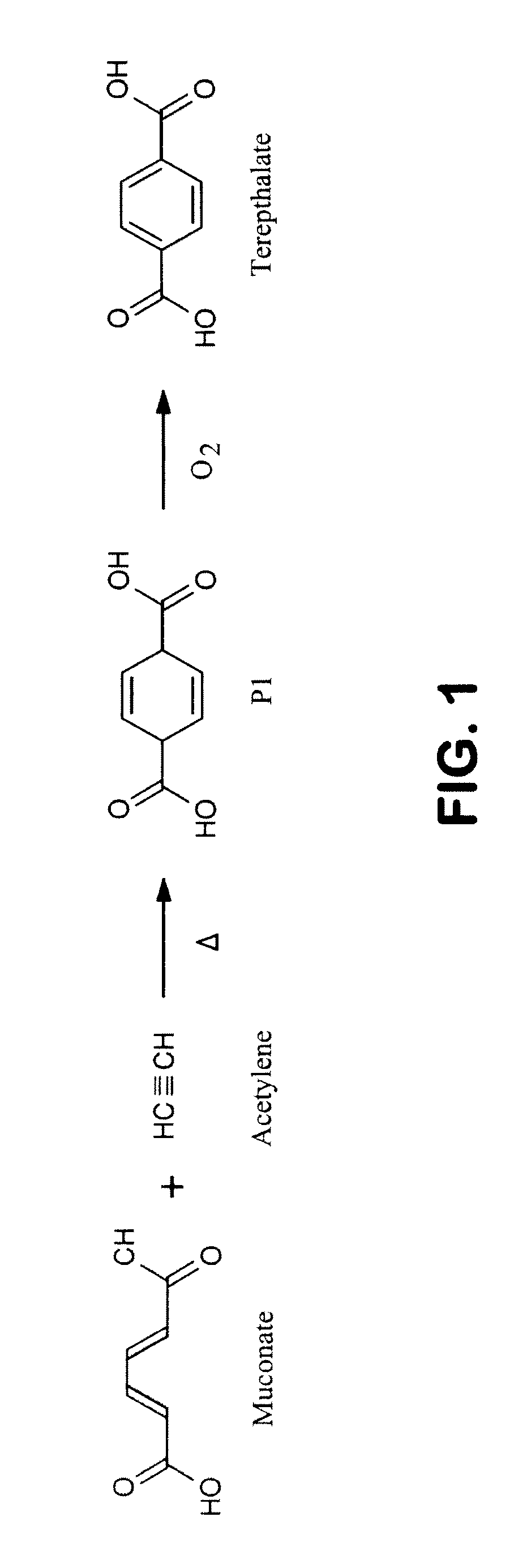

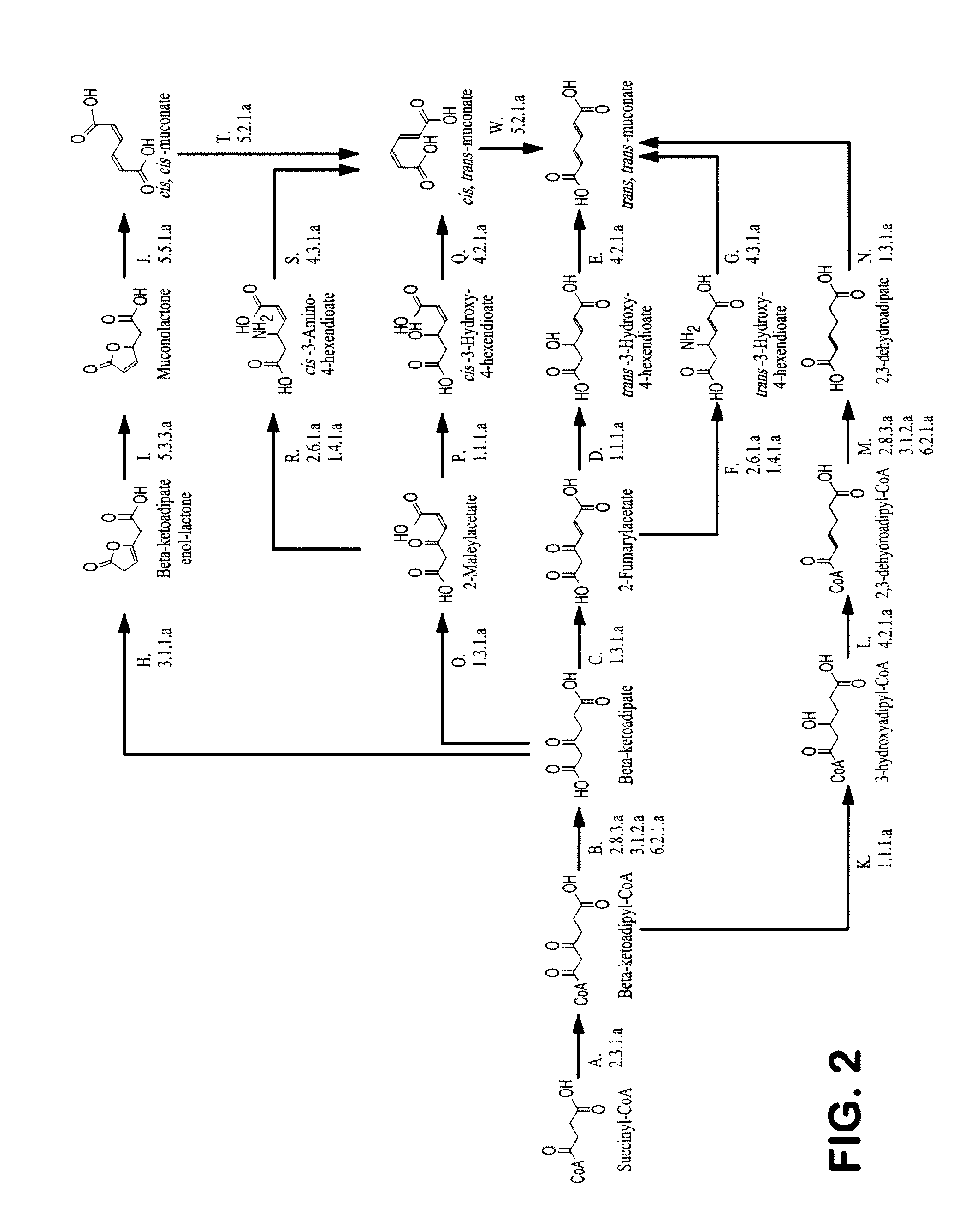

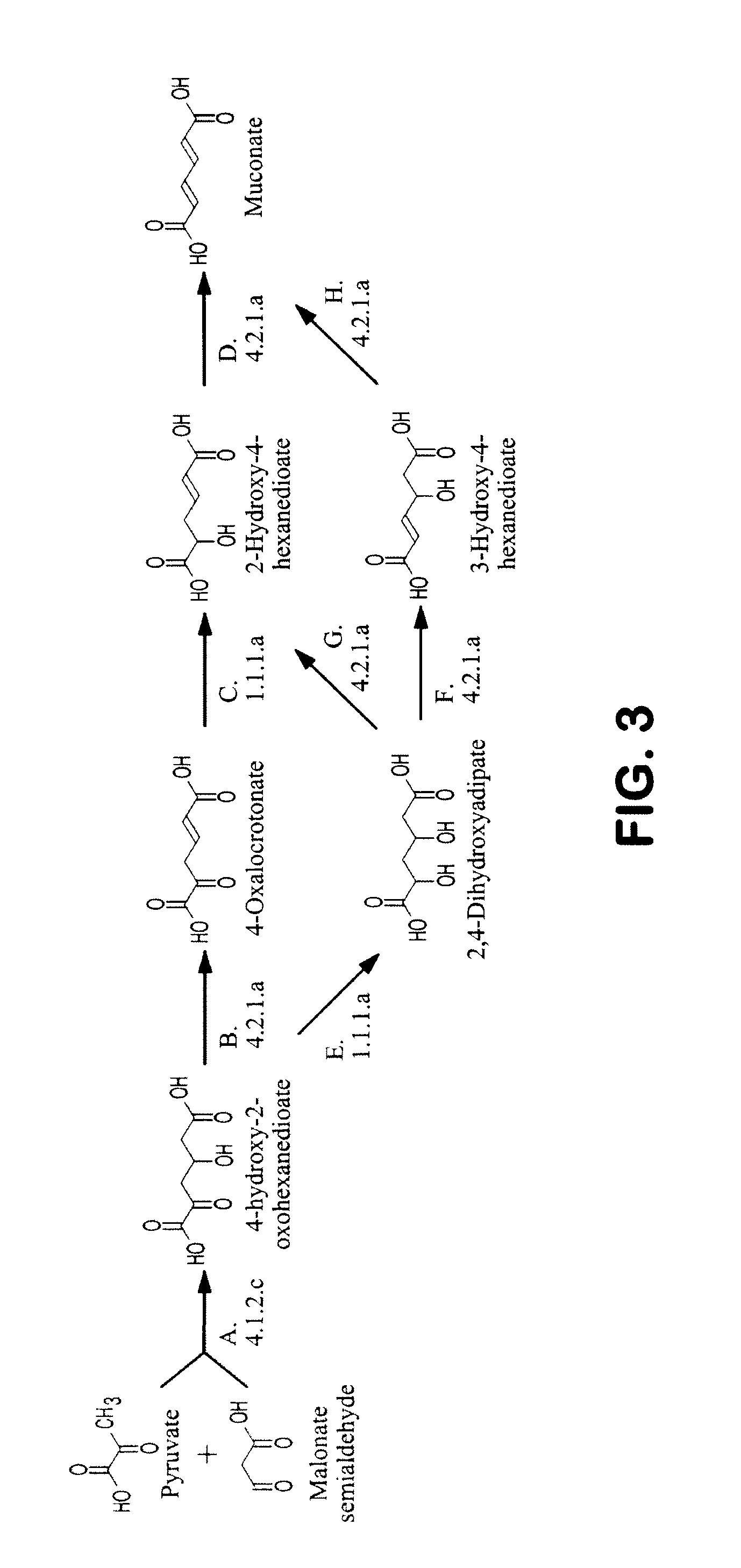

Semi-synthetic terephthalic acid via microorganisms that produce muconic acid

The invention provides a non-naturally occurring microbial organism having a muconate pathway having at least one exogenous nucleic acid encoding a muconate pathway enzyme expressed in a sufficient amount to produce muconate. The muconate pathway including an enzyme selected from the group consisting of a beta-ketothiolase, a beta-ketoadipyl-CoA hydrolase, a beta-ketoadipyl-CoA transferase, a beta-ketoadipyl-CoA ligase, a 2-fumarylacetate reductase, a 2-fumarylacetate dehydrogenase, a trans-3-hydroxy-4-hexendioate dehydratase, a 2-fumarylacetate aminotransferase, a 2-fumarylacetate aminating oxidoreductase, a trans-3-amino-4-hexenoate deaminase, a beta-ketoadipate enol-lactone hydrolase, a muconolactone isomerase, a muconate cycloisomerase, a beta-ketoadipyl-CoA dehydrogenase, a 3-hydroxyadipyl-CoA dehydratase, a 2,3-dehydroadipyl-CoA transferase, a 2,3-dehydroadipyl-CoA hydrolase, a 2,3-dehydroadipyl-CoA ligase, a muconate reductase, a 2-maleylacetate reductase, a 2-maleylacetate dehydrogenase, a cis-3-hydroxy-4-hexendioate dehydratase, a 2-maleylacetate aminoatransferase, a 2-maleylacetate aminating oxidoreductase, a cis-3-amino-4-hexendioate deaminase, and a muconate cis / trans isomerase. Other muconate pathway enzymes also are provided. Additionally provided are methods of producing muconate.

Owner:GENOMATICA INC

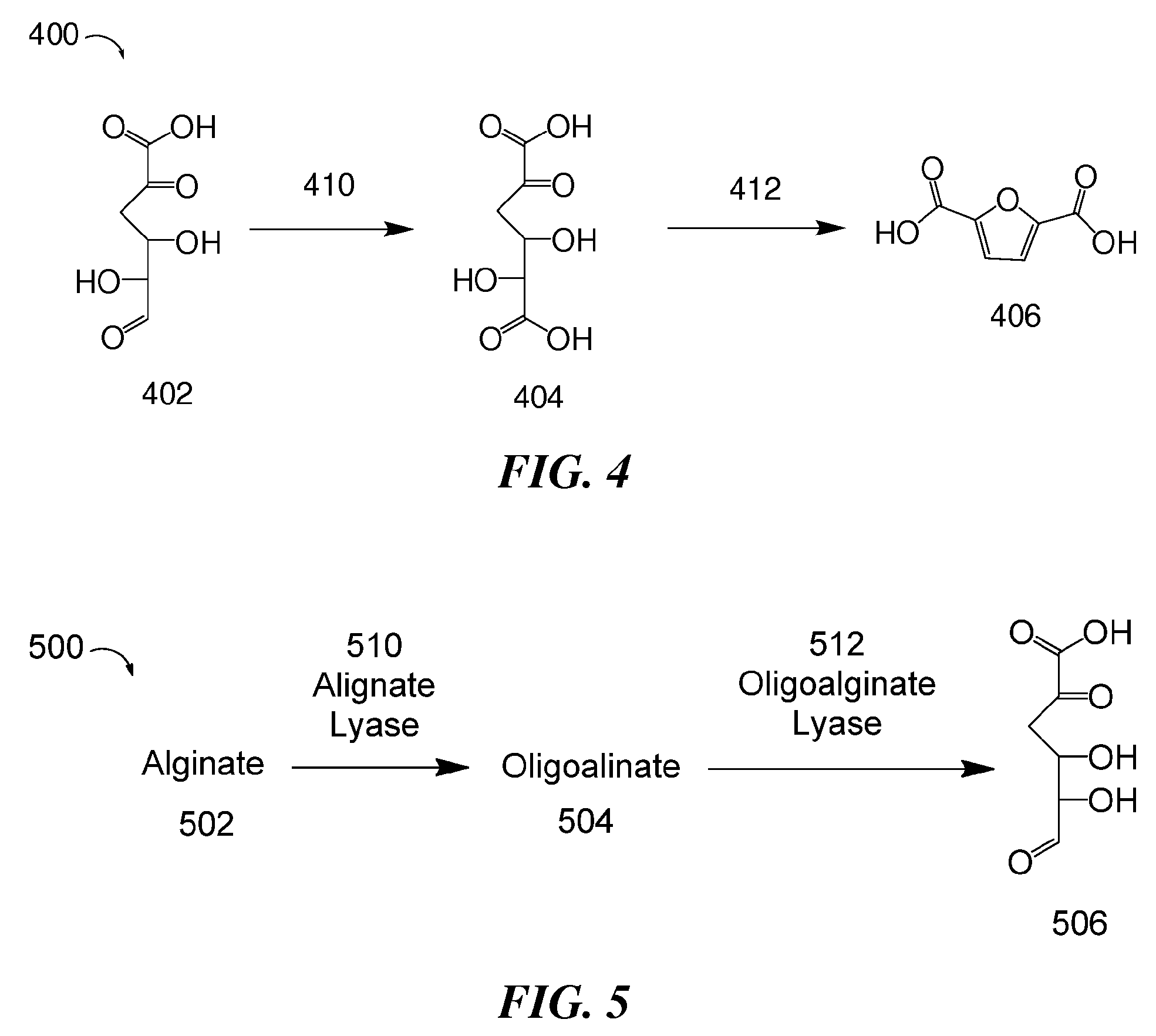

Universal refrigerant resistant solvent-free impregnating resin for high and low voltage motor and preparation method thereof

ActiveCN102604384ASolve defects such as inability to be used universallyLow VOC contentLow voltageSolvent free

The invention relates to a universal refrigerant resistant solvent-free impregnating resin for a high and low voltage motor and a preparation method thereof. The impregnating resin is composed of 45-65 parts of unsaturated polyesterimide resin solution with 65-75% of solid content, 15-35 parts of oxazolidone resin solution with 75-85% of solid content, 10-25 parts of environment-friendly dilutingagent, 3-8 parts of curing agent, 1-3 parts of initiating agent and 0.01-0.06 part of polymerization inhibitor; the raw material formula of an unsaturated polyesterimide resin comprises a first monomer, a second monomer and a third monomer, wherein the first monomer is selected from one or multiple of neopentyl glycol, propoxylation bisphenol A and trihydroxyethyl isocyanurate; the second monomeris selected from one or multiple of isophthalic acid, hexanedioic acid, trimellitie anhydride and maleic anhydride; and the third monomer is a compound containing imide groups. The resin provided by the invention has low content of VOC (Volatile Organic Compounds), resists novel refrigerating fluids such as R134a and is universal for the high and low voltage motor.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Rear cross-linking heatproof emulsion pressure-sensitive adhesive and method for producing same

InactiveCN102911630AImprove heat resistanceImprove moisture resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkFunctional monomer

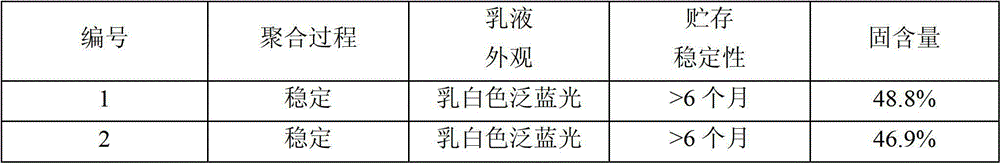

The invention discloses a rear cross-linking heatproof emulsion pressure-sensitive adhesive and a method for producing the same. The rear cross-linking heatproof emulsion pressure-sensitive adhesive contains the following components in parts by weight: 100 parts of hard and soft monomer, 0-4 parts of functional monomer, 0.01-2 parts of rear cross-linking monomer, 0.5-3 parts of emulsifying agent, 0.1-2 parts of initiating agent, 0.025 part of buffering agent and 0.01-2 parts of hexanedioic acid, wherein the hard and soft monomer is prepared from a soft monomer and a hard monomer according to the mass ratio of (65-100):(0-35). According to the method, diacetone acrylamide is firstly adopted as the rear cross-linking monomer to pre-emulsify the whole monomers, then, a batch-fed method is adopted to prepare copolymer emulsion, and finally, the hexanedioic acid is added into the copolymer emulsion so as to obtain rear cross-linking emulsion. The pressure-sensitive adhesive which is prepared by coating the rear cross-linking emulsion can simultaneously have good initial adhesion, permanent adhesion and 180-degree peeling strength as well as good temperature resistance; and moreover, the method for producing is simple, convenient to operate and easy to control.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

High molecular weight aliphatic-aromatic copolyester and preparation method thereof

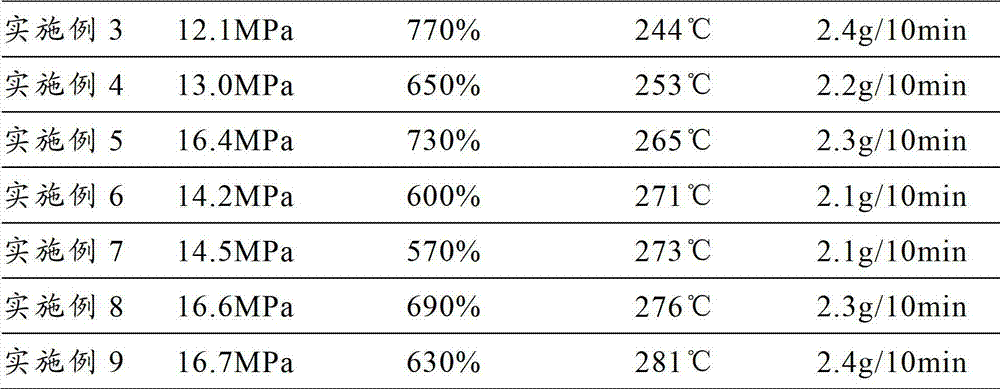

The invention relates to the technical field of polymer materials, and especially relates to high molecular weight aliphatic-aromatic copolyester and a preparation method thereof. The preparation method of high molecular weight aliphatic-aromatic copolyester comprises following steps: (1) adding aromatic monomers, 1,4-butanediol, hexanedioic acid, and a catalyst into an intermittent reactor, carrying out esterification reactions under the protection of inert gas, and carrying out condensation polymerization reactions after the esterification reactions are over so as to obtain a PBAT prepolymer; (2) subjecting the obtained PBAT prepolymer to a chain propagation treatment with a double screw extruder when adopting a chain extender so as to obtain a PBAT copolyester with a number-average molecular weight Mn of 10000 to 100000. Compared to the prior art, the preparation method of PBAT copolyester is capable of simplifying the production technology, and has the advantages of controllable operation, realization of continuous production, and reduction on production cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

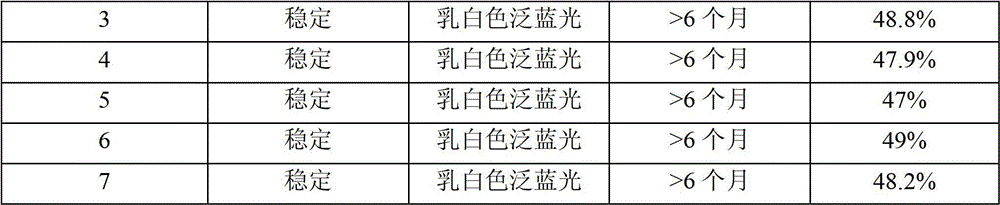

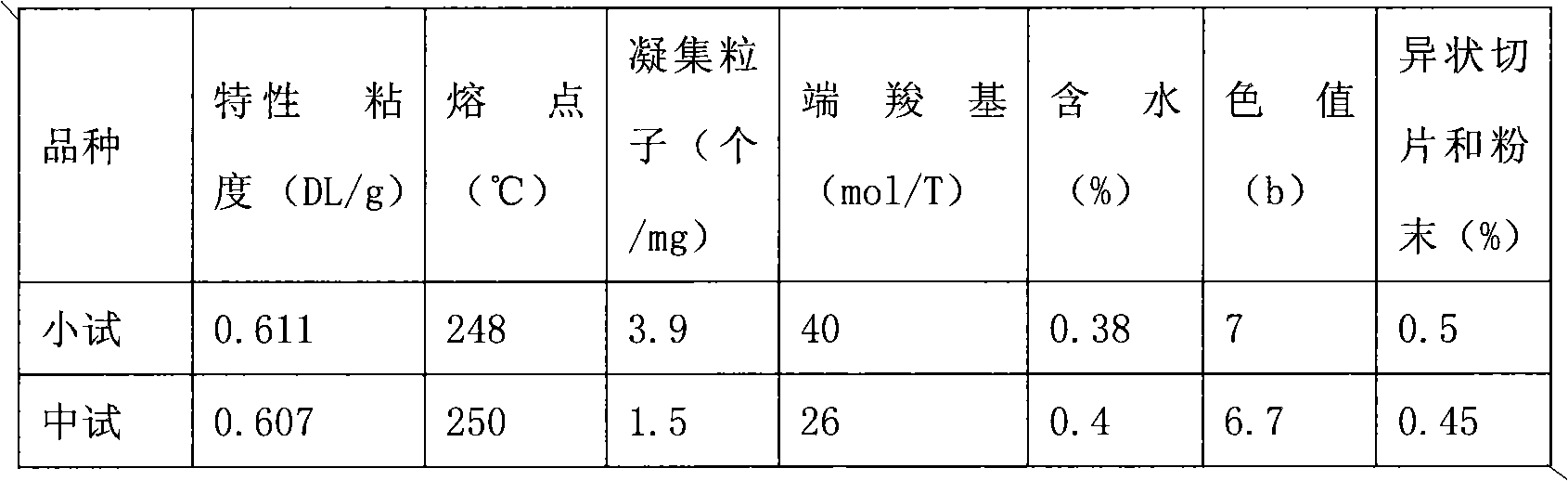

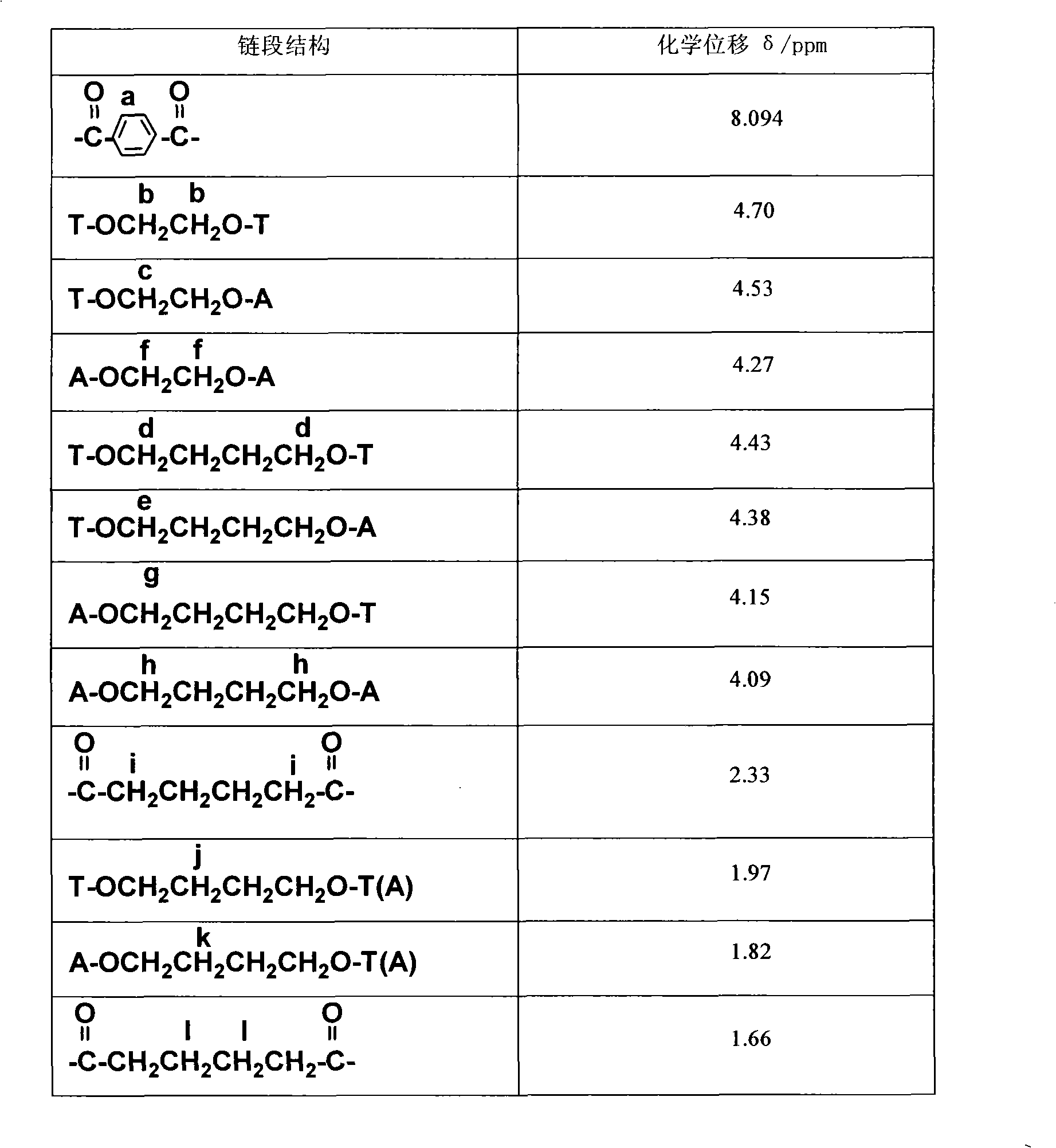

High-shrinkage cation normal-pressure easy-to-dye polyester chip and preparation method thereof

The invention discloses a high-shrinkage cation normal-pressure easy-to-dye polyester chip and a preparation method thereof. The high-shrinkage cation normal-pressure easy-to-dye polyester chip comprises the following components: 66-68 percent of purified terephthalic acid, 23-21 percent of glycol, 3.2-5.5 percent of isophthalic acid digylcol ester-5-sodium sulfonate, 2.1-3.3 percent of polyethylene glycol, 0.5-0.7 percent of isophthalic acid, 3.1-4 percent of hexanedioic acid, 0.012-0.036 percent of antimony acetate and 0.005-0.055 percent of antioxidant. The high-shrinkage cation normal-pressure easy-to-dye polyester chip is subjected to an esterification reaction at the pressure of 0.25-0.3MPa and the temperature of 250-260DEG C and a polycondensation reaction at the temperature of 230-270DEG C and at the vacuum degree of 0.08-0.098MPa and temperature preservation after the temperature reaches 272-278DEG C. The high-shrinkage cation normal-pressure easy-to-dye polyester chip has the advantages of high dyeing rate and dye suction rate at normal temperature and normal pressure, bright color, favorable performances of high shrinkage and resisting pilling, spinnability, drafting property and favorable physical property and post treatment performance of fibers.

Owner:PETROCHINA CO LTD

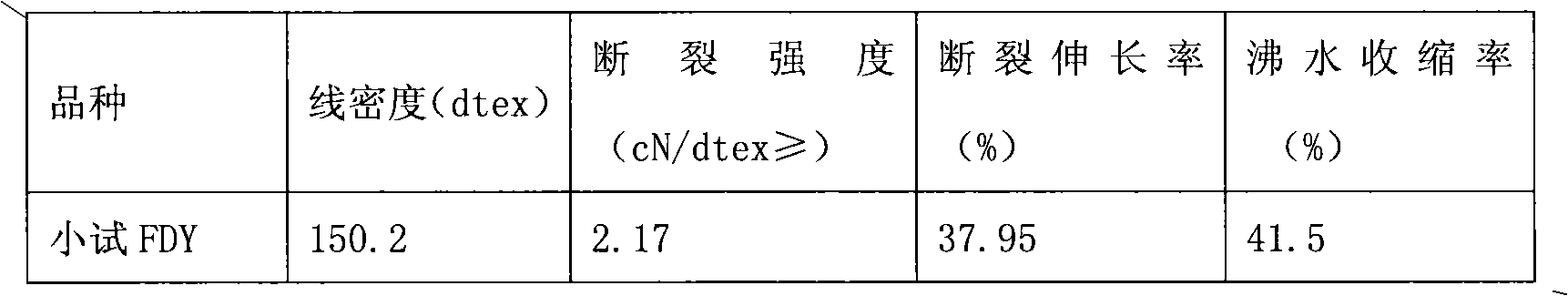

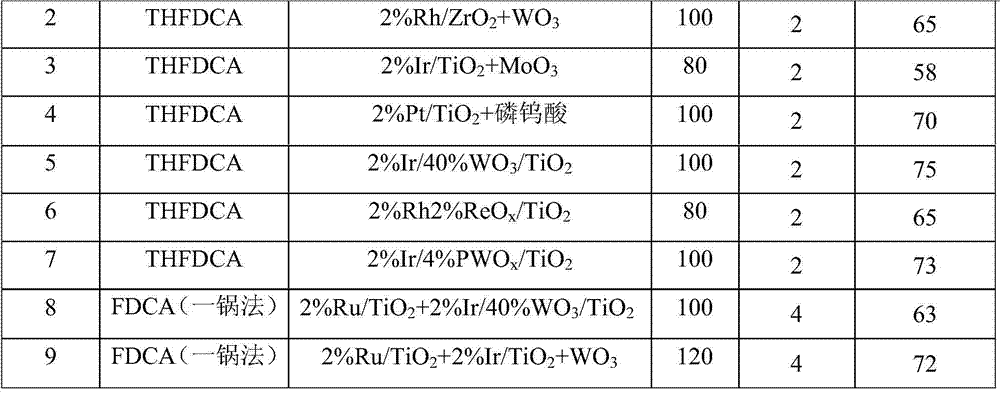

Method for preparing hexanedioic acid from furan-2,5-dicarboxylic acid

ActiveCN107011154AReduce manufacturing costOrganic compound preparationCarboxylic compound preparationFuranHydrogen

The invention discloses a method for preparing hexanedioic acid. The method comprises a step of converting furan-2,5-dicarboxylic acid or tetrahydrofuran-2,5-dicarboxylic acid into hexanedioic acid in water through a chemical catalysis method, wherein the step is specifically selected from any one of the following steps (1)-(3): (1) enabling tetrahydrofuran-2,5-dicarboxylic acid to react with hydrogen under catalysis of a hydrodeoxygenation catalyst to obtain hexanedioic acid; (2) enabling furan-2,5-dicarboxylic acid to react with hydrogen under catalysis of a hydrogenation catalyst and a hydrodeoxygenation catalyst to obtain hexanedioic acid; and (3) carrying out the substeps of (1) enabling furan-2,5-dicarboxylic acid to react with hydrogen under catalysis of a hydrogenation catalyst to obtain tetrahydrofuran-2,5-dicarboxylic acid and (2) enabling tetrahydrofuran-2,5-dicarboxylic acid to react with hydrogen under catalysis of the hydrodeoxygenation catalyst to obtain hexanedioic acid. According to the method, water is used as a solvent; other impurity elements are not introduced except for the used heterogeneous catalyst, so that the production cost is further reduced; meanwhile, the method is more environmentally friendly.

Owner:PEKING UNIV

Biodegradable material poly(hexanedioic acid-para-phthalic acid-butanediol ester) foaming particles preparation method

The invention discloses a biodegradable material poly(hexanedioic acid -para-phthalic acid-butanediol ester) (PBAT) foaming particles preparation method which is characterized in that the preparation method comprises the following steps: placing PBAT particles in an airtight container of which the temperature is 120-142 DEG C and the volume is 25 times or more than 25 times of the total volume of the particles, injecting 8-20MPa of pressure gas in the container, keeping the temperature and the pressure for 5-30min, and then relieving the pressure in a speed of 5-20MPa / s to the normal pressure to obtain the PBAT foaming particles. The cell diameter of the PBAT foaming particles is 10-260mu m and the density is 0.13-0.35g / cm<3>. The invention has simple process, easy operation, short production cycle and low cost, thus being applicable to the industrialized production.

Owner:浙江博发新材料股份有限公司

700V high-voltage aluminum electrolytic capacitor electrolyte

InactiveCN106252079AHigh molecular weightLow mobilityLiquid electrolytic capacitorsSalicylic acidGluconic acid

Disclosed is a 700V high-voltage aluminum electrolytic capacitor electrolyte. The electrolyte comprises 50-80% of main solvent, 20-50% of auxiliary solvent, 5-20% of main solute, 2-10% of auxiliary solute, 0.1-1% of auxiliary additive and 5-15% of spark additive, wherein the main solute comprises one or more of azelaic acid, ammonium hydrogen azelate, ammonium sebacate, decane dicarboxylic acid, 7, 9-dimethyl-7, 9-dimethoxy carbonyl-1, 11-dodecane dicarboxylic acid, and 7, 8-dimethyl-7, 8-dimethoxy carbonyl-1, 14 tetradecane dicarboxylic acid; and the auxiliary solvent comprises one or more of ammonium salicylate, salicylic acid, oxalic acid, malonic acid, succinic acid, ammonium benzoate, ammonium maleate, ammonium hydrogen maleate, ammonium adipate and hexanedioic acid. The spark voltage of the electrolyte is greater than 700V; and in addition, the electrolyte is simple to prepare, stable in performance and excellent in related parameters.

Owner:HUNAN AIHUA GRP

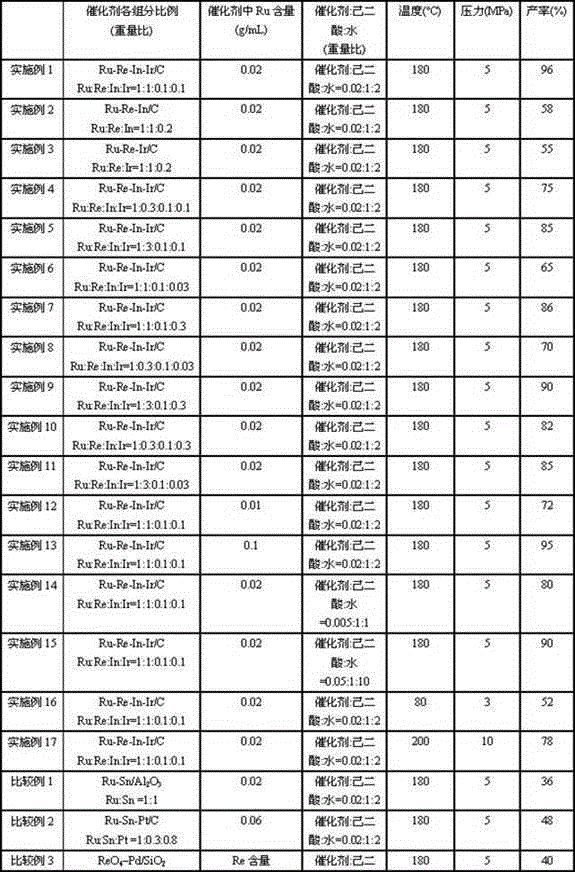

Catalyst for preparing 1,6-hexanediol through direct reduction of adipic acid

ActiveCN104549254AOrganic compound preparationHydroxy compound preparationActivated carbonPtru catalyst

The invention relates to a catalyst for preparing 1,6-hexanediol through direct reduction of adipic acid. According to the catalyst, the problem of low reaction yield in the process of preparing 1,6-hexanediol through the direct reduction of the adipic acid in the prior art is mainly solved. The catalyst comprises active components and a carrier, wherein the active components comprise at least one of Ru, Re, In and Ir; the carrier is activated carbon. According to the technical scheme, the problem is well solved. The catalyst can be applied to the industrial production for preparing 1,6-hexanediol through the direct reduction of adipic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

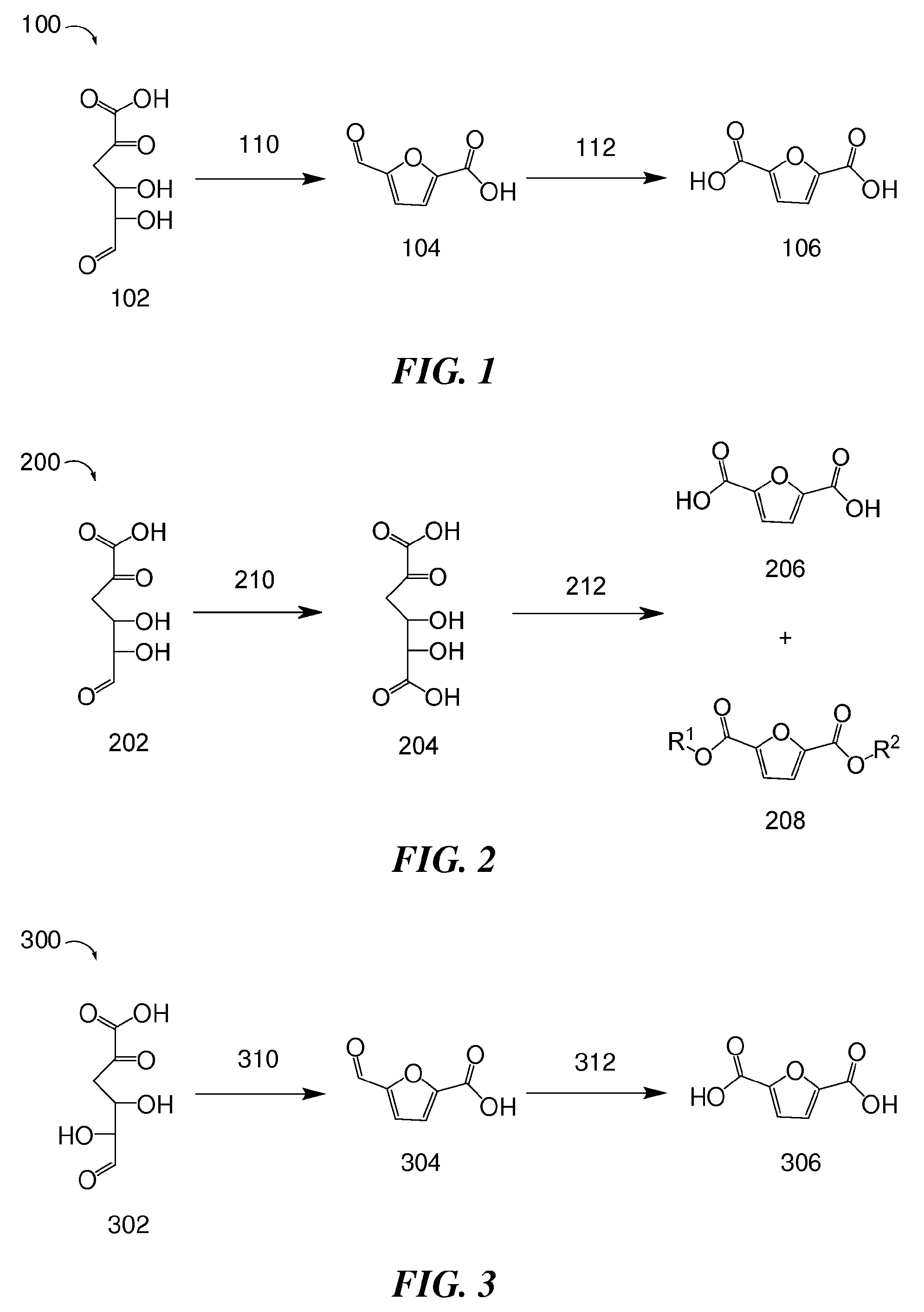

Methods for preparing 2,5-furandicarboxylic acid

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

High-performance modified fluororubber cable sheath material

InactiveCN104312059AImprove performanceHigh hardnessRubber insulatorsInsulated cablesPolyesterEnvironmental resistance

The invention discloses a high-performance modified fluororubber cable sheath material which comprises the following raw material components in parts by weight: 55-75 parts of fluororubber, 10-20 parts of silicone rubber, 5-10 parts of fluorinated silicone rubber, 5-10 parts of epoxidized natural rubber, 5-18 parts of pre-expanded organic clay, 10-25 parts of white carbon black, 6-15 parts of boron carbide, 2-4 parts of stearic acid, 5-10 parts of active magnesium oxide, 3-9 parts of nano calcium carbonate, 6-15 parts of calcium hydroxide, 1-2.8 parts of novel plant-based environment-friendly rubber oil, 2-4.5 parts of hexanedioic acid propylene glycol polyether, 1-1.6 parts of triethyl O-acetylcitrate, 3-6 parts of epoxy tetrahydrodioctyl phthalate, 0-1.8 parts of iron sesquioxide, 3-8 parts of a coupling agent, 2-5 parts of a vulcanizing agent, 1.5-3.5 parts of an accelerant and 2-6 parts of an anti-aging agent. The high-performance modified fluororubber cable sheath material disclosed by the invention has high hardness, compressive strength, tensile strength and elasticity, is used for manufacturing cable sheaths and is good in comprehensive performance and long in service life.

Owner:安徽华峰电缆集团有限公司

Antifreeze Concentrate and Coolant Compositions and Preparation Thereof

InactiveUS20090001313A1Improve thermal stabilityOther chemical processesHeat-exchange elementsBenzoic acidOctanoic Acids

A toxicological friendly antifreeze composition having improved thermal stability is provided. In one embodiment, the antifreeze composition comprises from 5 to 80 wt. % of an aqueous freezing point depressant selected from alkali metal salts of acetates, formates, proprionates, adipiates, and succinates, and mixtures thereof; 0.1 to 10 wt. % of at least one of a 2-ethylhexanoic acid, isononanoic acid and 3,5,5-trimethylhexanoic acid; and 0.1 to 10 wt. % of at least one of octanoic acid, nonanoic acid, decanoic acid, undecanoic acid, dodecanoic acid, neodecanoic acid, benzoic acid, 2-hydroxybenzoic acid, p-terbutylbenzoic acid, and mixtures thereof. In one embodiment, the composition is employed as a concentrate in admixture with 10 to 90 wt. % water.

Owner:CHEVROU USA INC

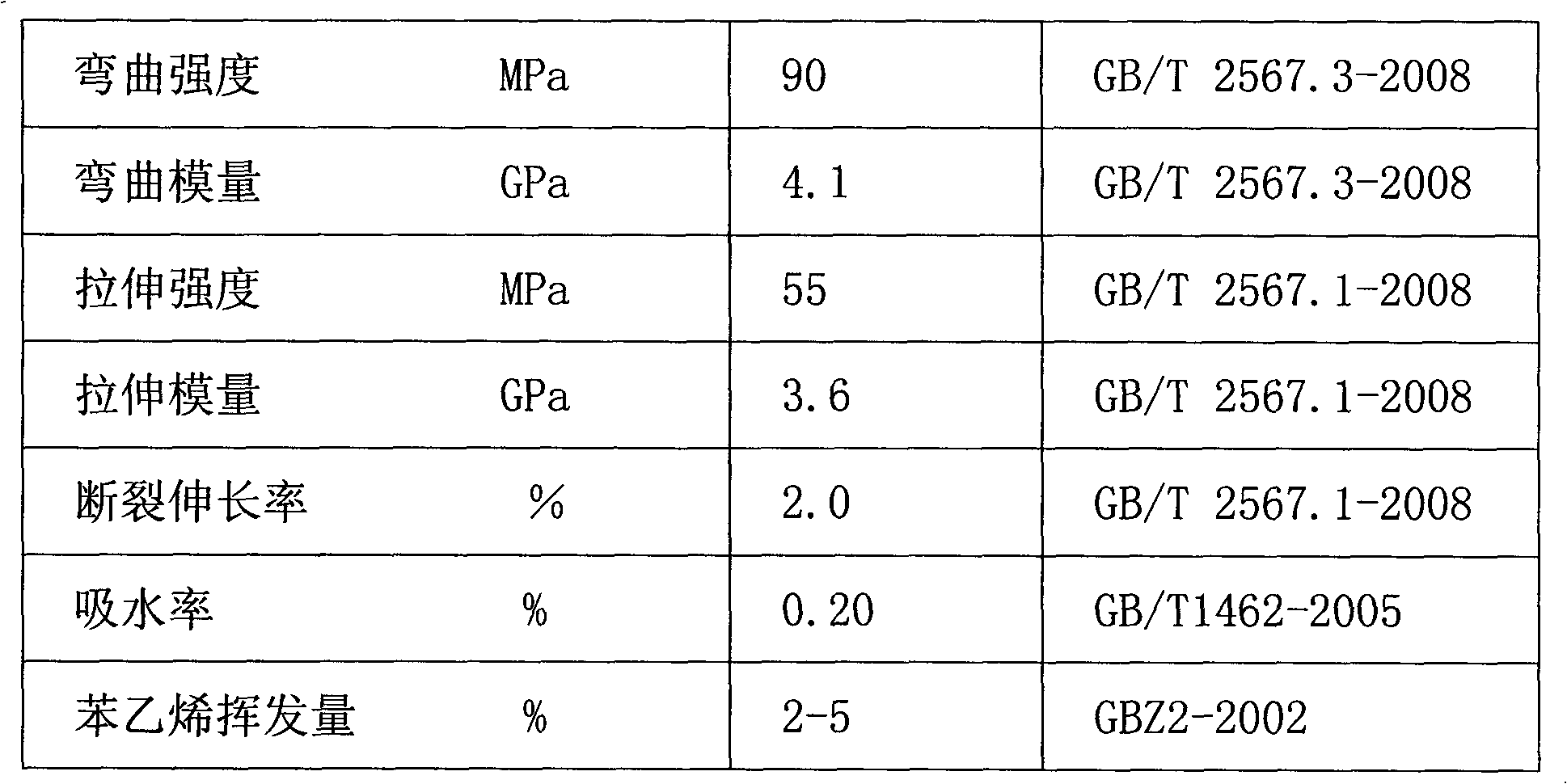

Low-volatization unsaturated polyester resin suitable for large glass steel structural layer and manufacturing method thereof

The invention relates to a high molecular compound, in particular to a low-volatization unsaturated polyester resin for manufacturing a large glass steel structural layer. The unsaturated polyester resin is prepared by dissolving a reaction product of a condensation reaction of propylene glycol, ethylene glycol, hexanedioic acid, phthalic anhydride and cis-butenedioic anhydride into styrene after the condensation reaction is completed. N20 type aerosol, M30 exothermic peak inhibitor and 0.02 portion of B20 surface active agent are added to the unsaturated polyester resin, and thixotropic index and viscidity required by provision can be achieved by high-speed and uniform dispersing through a stirring mill. The invention has the advantages of being suitable for hand pasting and injection molding process, having the characteristics of sagging resistance, high water resisting property, low exothermic peak and low volatilization of the styrene, being suitable for large thickness workpiece glass steel products of fan cover, glass steel boat, and the like, and having high intensity of the products, good weather resisting property and good water resisting property.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

Demoulding agent

The invention discloses a demoulding agent. The demoulding agent is prepared from, by weight, 12%-18% of organic dibasic acid, 7%-16% of sodium hydroxide, 2%-6% of sodium polymethacrylate, 0.2%-0.8% of isodecanol polyoxyethylene ether, 0.1%-0.5% of polyacrylamide, 0.5%-4% of polyisobutylene succinic anhydride, 1%-7% of organic silicon resin, 0.1%-0.2% of defoamer and the balance water, wherein the organic dibasic acid adopts phthalandione or isophthalic acid or hexanedioic acid. The demoulding agent does not contain graphite and has excellent high-temperature adhesion property, lubricating property and cooling property, the demoulding effect is good, the compatibility with water is excellent, removing through water washing is facilitated, an extremely strong protective effect is exerted on a mold, and it can be guaranteed that residues of the mold are less, the surface is bright and smooth, and the service life of the mold is greatly prolonged.

Owner:JIANGSU HANDEFU IND GOODS SCI & TECH

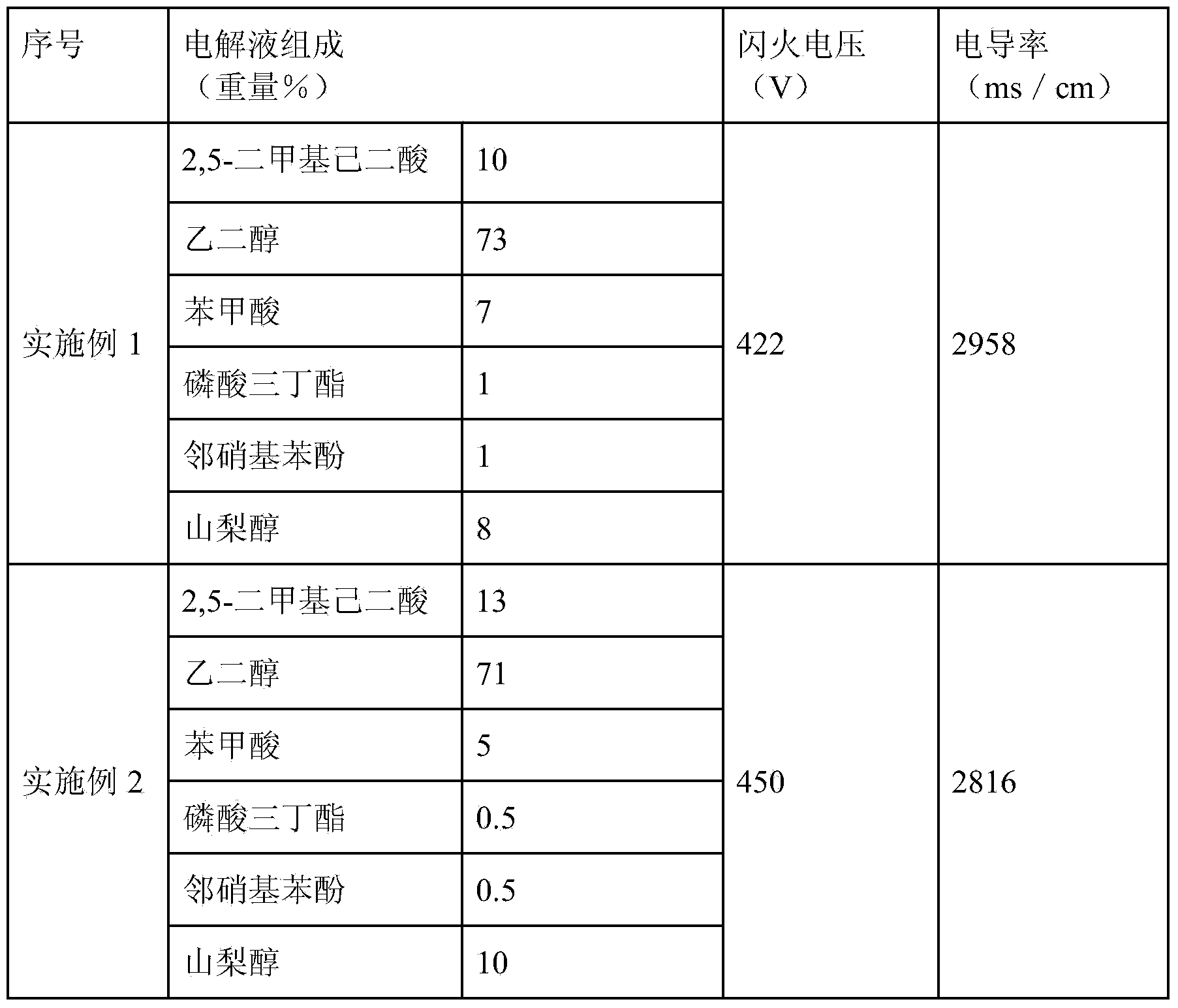

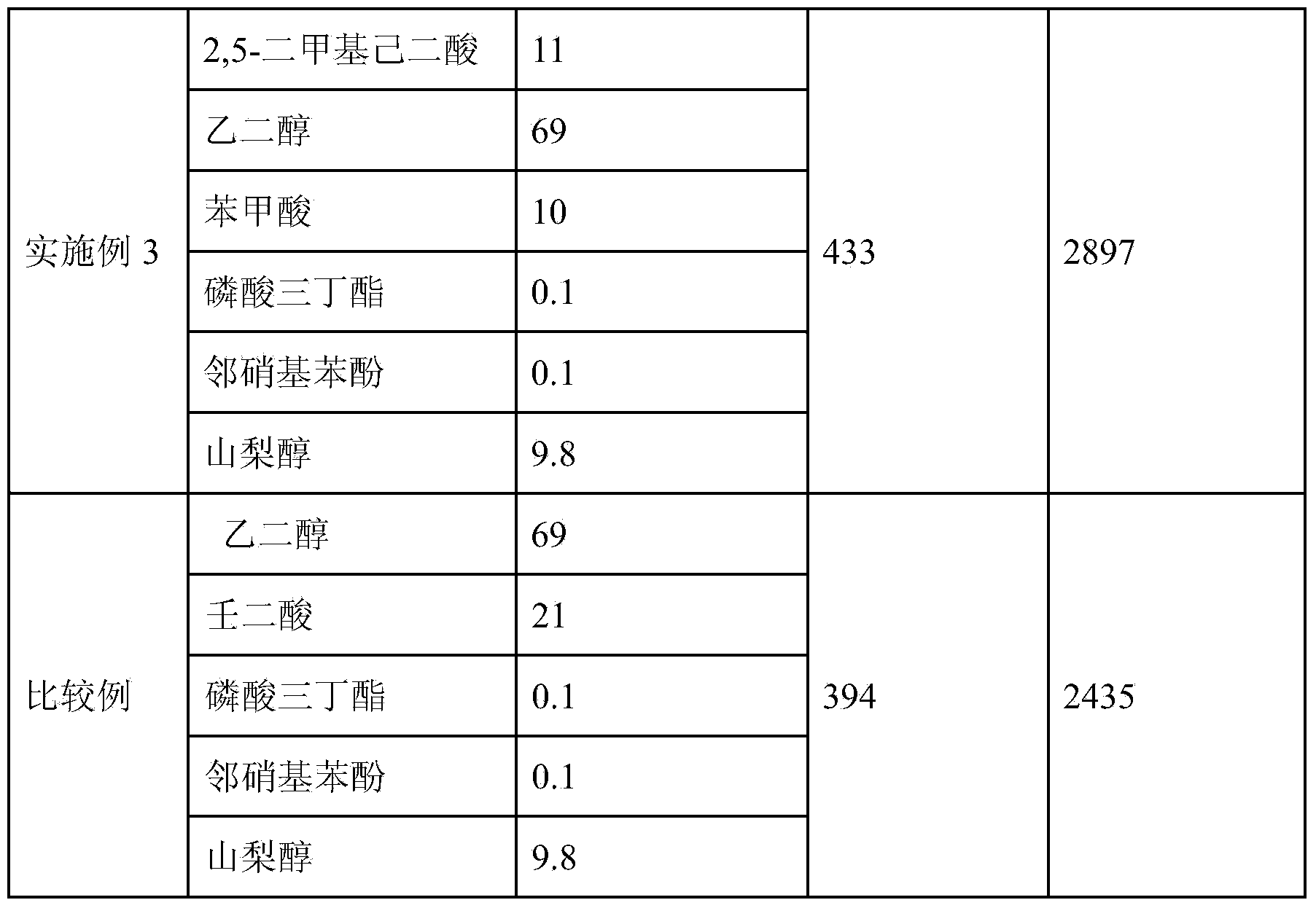

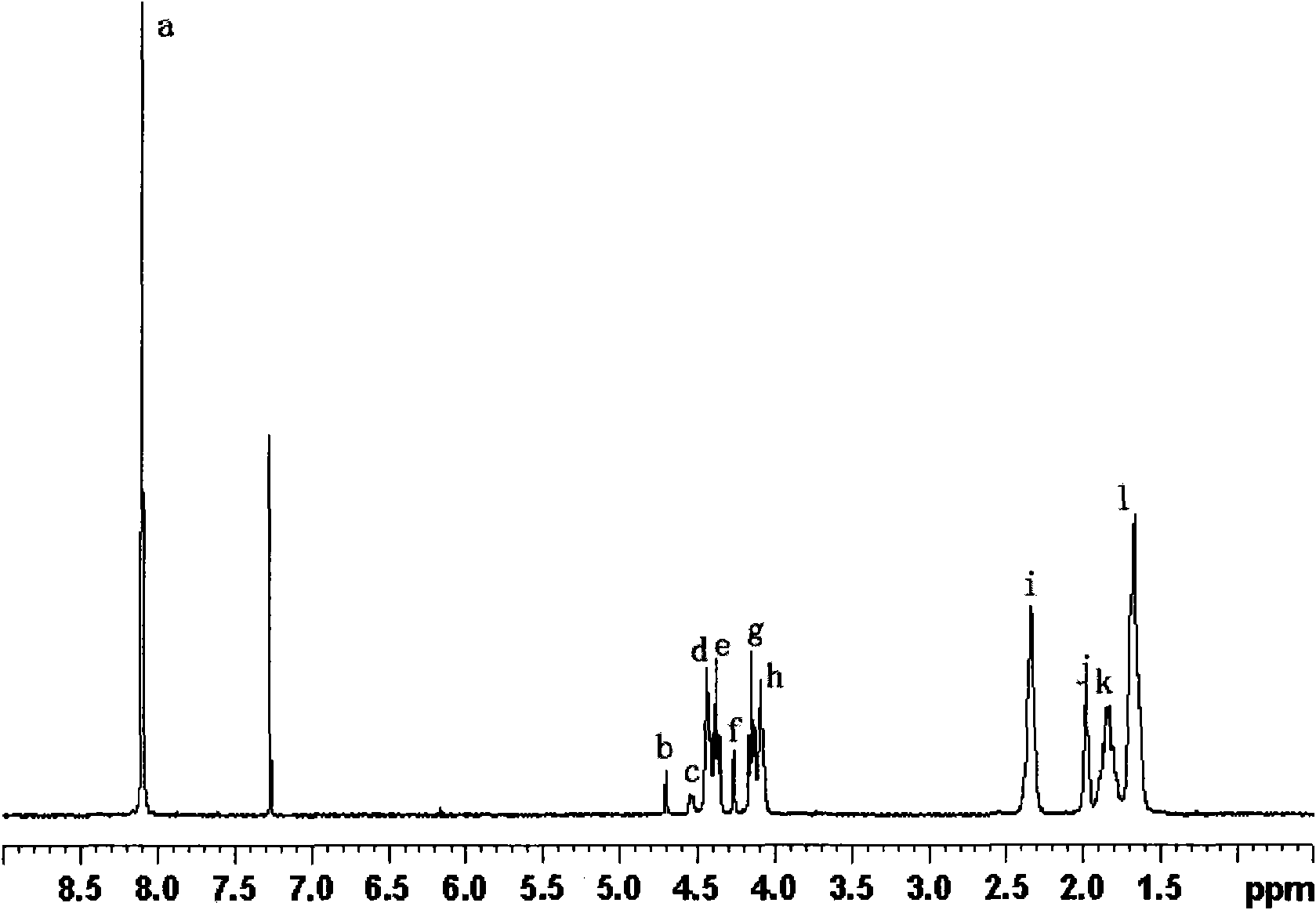

Electrolyte for aluminum electrolytic capacitor

InactiveCN103928234AImprove low temperature performanceSolution to short lifeElectrolytic capacitorsSolubilityBenzoic acid

The invention relates to an electrolyte for an aluminum electrolytic capacitor. The electrolyte for the aluminum electrolytic capacitor is prepared from 10%-15% of a main electrolyte, 5%-10% of an auxiliary electrolyte, 65%-73% of a solvent, 10%-20% of a sparking voltage increasing agent, 0.1%-1% of a waterproof mixture and 0.1%-1% of a hydrogen eliminating agent, wherein 2,5-dimethyl hexanedioic acid serves as the main electrolyte, benzoic acid serves as the auxiliary electrolyte, and ethylene glycol serves as the solvent. The electrolyte for the aluminum electrolytic capacitor has the advantages that due to the fact that the 2,5-dimethyl hexanedioic acid serves as the main electrolyte, the solubility and the thermostability of the 2,5-dimethyl hexanedioic acid are better in the ethylene glycol, and medium-pressure or high-pressure aluminum electrolytic capacitors containing the electrolyte has the advantages of being long in service life and good in low-temperature performance.

Owner:NANTONG RUITAI ELECTRONICS

Biodegradable copolyester and preparation method thereof

ActiveCN102140165AHigh intrinsic viscosityOvercome the disadvantage that it cannot be carried out under normal pressureCopolyesterEsterification reaction

The invention relates to biodegradable copolyester and a preparation method thereof. The preparation method comprises the following steps of: undergoing an esterification reaction on pure terephthalic acid, hexanedioic acid, 1,4-butylene glycol and ethylene glycol under normal pressure at the temperature of between 150 DEG C and 220 DEG C, wherein the molar ratio of the pure terephthalic acid to the hexanedioic acid is (3:7)-(8:2), the molar ratio of the ethylene glycol to the 1,4-butylene glycol is (1:9)-(9:1), and the ratio of the total mole number of the pure terephthalic acid and the hexanedioic acid to the total mole number of the ethylene glycol and the 1,4-butylene glycol is 1:(1.0-1.8); and undergoing condensation polymerization under the pressure of between 10 Pa and 150 Pa to obtain the copolyester, wherein the dosage of a titanium compound is 200-1,200 ppm relative to the total weight of terephthalic acid and the hexanedioic acid, the dosage of an antimony compound is 100-600 ppm relative to the total weight of the terephthalic acid and the hexanedioic acid, and the dosage of a phosphorous compound is 50-400 ppm relative to the total weight of the terephthalic acid and the hexanedioic acid. The biodegradable copolyester has the advantages of low raw material price, reaction at low temperature and under low pressure and high inherent viscosity.

Owner:PETROCHINA CO LTD

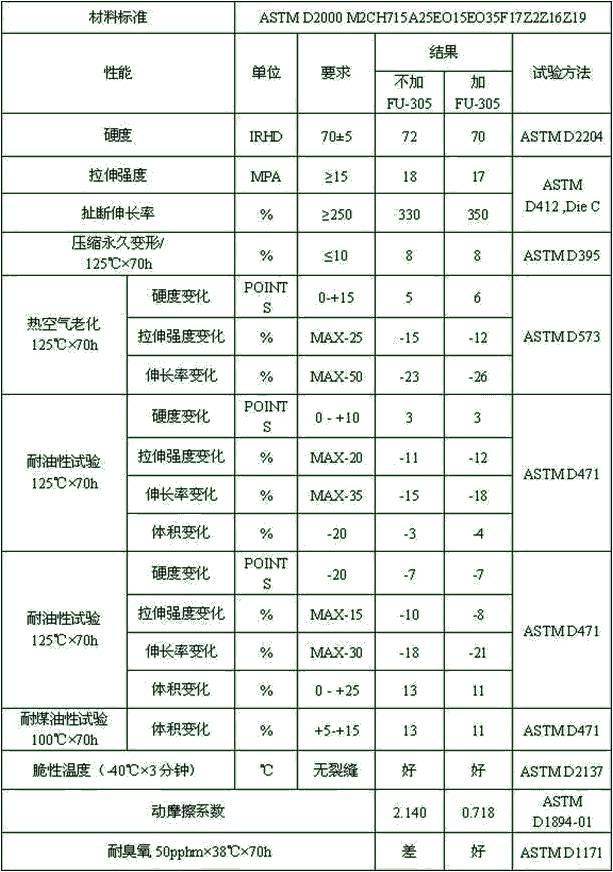

Self-lubricating material for filter sealing piece and preparation method thereof

InactiveCN102504370AReduce coefficient of frictionAvoid stickingOther chemical processesRubber materialPolymer science

The invention discloses a self-lubricating material for a filter sealing piece and a preparation method thereof, belonging to the fields of sealing rubber materials and preparation methods thereof. The self-lubricating material consists of the following components in percentage by weight: 40-45 percent of nitrile rubber, 20-25 percent of high-wear-resistance carbon black, 10-15 percent of semi-reinforced carbon black, 3.0-5.0 percent of zinc oxide, 0.5-1.0 percent of stearic acid, 1.0-1.5 percent of 4,4'-di(phenyl isopropyl)diphenylamine, 0.5-1.0 percent of 1,3-dihydro-4(or 5)-methyl-2H-benzimidazole-2-thione zinc salt, 0.1-0.3 percent of sulfur, 1.0-2.0 percent of accelerant DTDM (Dithiodimorpholine), 0.5-1.0 percent of accelerant CZ, 3.0-6.0 percent of hexanedioic acid di[2-(2-butoxy oxethyl)ethyl ester] and 1.0-1.5 percent of fluorine wax FU-305. The method comprises the following preparation steps of: compounding a master batch; performing two-stage vulcanization on the master batch; and vulcanizing. A layer of uniform, transparent and bright film with high adhesion is formed when the fluorine wax FU-305 is transferred onto the surface of a rubber product, so that the frictioncoefficient of the surface of the rubber sealing piece is reduced, bonding between the rubber piece and a metal body is prevented effectively, and the ozone aging resistance is enhanced effectively.

Owner:南京金三力高分子科技有限公司

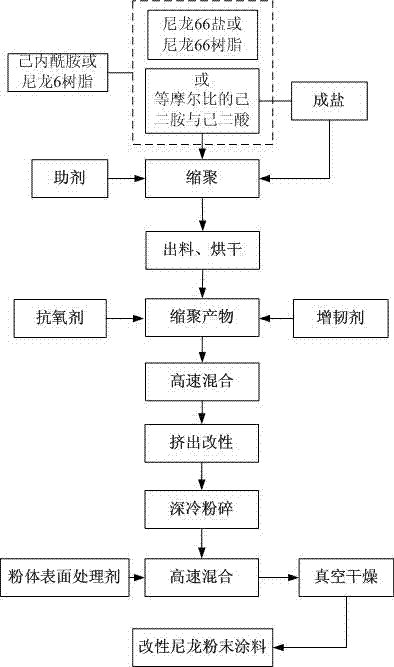

Modified nylon powder coating and preparation method thereof

InactiveCN102898941AFull play to the melting pointReduce regulationPowdery paintsPolyamide coatingsPolymer scienceNylon 12

The invention discloses a modified nylon powder coating and a preparation method thereof. The preparation method comprises the following steps of: firstly preparing a polymerization product by performing polymerization reaction on the following main synthetic materials in parts by mass: 50 to 80 parts of caprolactam or nylon 6 resin, 20 to 50 parts of nylon 66 salt, nylon 66 resin or equal mole ratio of hexamethylene diamine and hexanedioic acid, and 0.02 to 1.7 parts of an auxiliary agent; and then preparing the modified nylon powder coating through the processes of extrusion modification, deep cooling crushing and treatment with a powder surface treatment agent. The auxiliary agent comprises an antioxidant, a nucleating agent and a molecular weight adjusting agent. The modified nylon powder coating prepared by the method is lower in melting point, simple in process control and stable in product quality, can partially substitute nylon 11 and nylon 12 powder products, can effectively reduce the using cost of nylon powder, is favorable for application popularization of the nylon powder, and has a great market potential.

Owner:NANJING INST OF TECH

PVC external lubricant

InactiveCN101327625AImprove the lubrication effectImprove free movementBase-materialsChemical industryPentaerythritol

The present invention discloses a PVC outer lubricant, which includes the following ingredients with the following mass percentages: 40 percent to 70 percent of stearic acid; 10 percent to 30 percent of pentaerythritol ester; 5 percent to 40 percent of fumaric acid. The PVC outer lubricant adopts the fumaric acid to replace the original hexanedioic acid, and the fumaric acid is the regurgitated acid obtained by recovering and processing waste liquid produced by other chemical industries. The recycling of the waste liquid not only can pretect environment but also can reduce cost. With the advantages of nontoxic fumaric acid, good lubricating property, good free flowing property, good inadhesion and little precipitation, the PVC outer lubricant greatly decreases the frequency of halting a machine to insert rollers in the process of production, thus reducing the labor intensity of operators, increasing production efficiency and ensuring good demoulding effect, and therefore the economic benefit of products is increased. The PVC outer lubricant can improve the strength and the cold-resisting property of PVC products to a certain degree. The PVC outer lubricant is widely applicable to PVC sheets, transparent sheets, color sheets, ground sheets, films, pelleting and sectional material processing, etc.

Owner:夏森林

Antibacterial high-filled degradable plastic

The invention discloses antibacterial high-filled degradable plastic. The antibacterial high-filled degradable plastic is prepared from, by weight, 25-80 parts of biodegradable materials, 30-75 parts of filling powder, 2-10 parts of auxiliaries and 3-5 parts of nano antibacterial agents, wherein the nano antibacterial agents adopt ZnO-Ag nanocomposite antibacterial agents. The plant degradable materials comprise any one of poly(butylene succinate), polybutylene hexanedioic acid terephthalate and polylactic acid; the filling powder comprises any one of wood powder, modified starch, modified calcium carbonate, modified talcum power, modified pulverized fuel ash, montmorillonoid and kaolin. The antibacterial high-filled degradable plastic is easy to degrade, good in plasticity, capable of resisting bacteria and preventing corrosion and suitable for being applied to production and manufacture of various plastic products.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Method for synthesizing cyclohexanone-oxime from cyclohexane in one step

InactiveCN102001966AIncrease profitNo pollution in the processOxygen compounds preparation by hydrocarbon oxidationOximes preparationChemical synthesisReaction temperature

The invention discloses a method for synthesizing cyclohexanone-oxime from cyclohexane in one step, relating to the field of chemical synthesis. The method comprises the following steps of: adding a titanium-silicate molecular sieve TS-1 used as a catalyst into a synthesis reactor at normal pressure with cyclohexane, H2O2 and ammonia water as raw materials, wherein 0.2g of the catalyst titanium-silicate molecular sieve TS-1is added in 1 mmol of cyclohexane; and controlling the reaction temperature at 25-80 DEG C and the reaction time for 1-30h to synthesize cyclohexanone-oxime in one step, wherein the molar ratio of cyclohexane to H2O2 to ammonia water is 1:1.5-3.5:1.5-2. The method has simple process conditions and mild reaction conditions. Byproducts generated in the reaction process are KA oil and hexanedioic acid which have higher application value, and can greatly improve the utilization rate of resources. The whole process is basically free of environmental pollution and truly realizes zero emission.

Owner:XIANGTAN UNIV

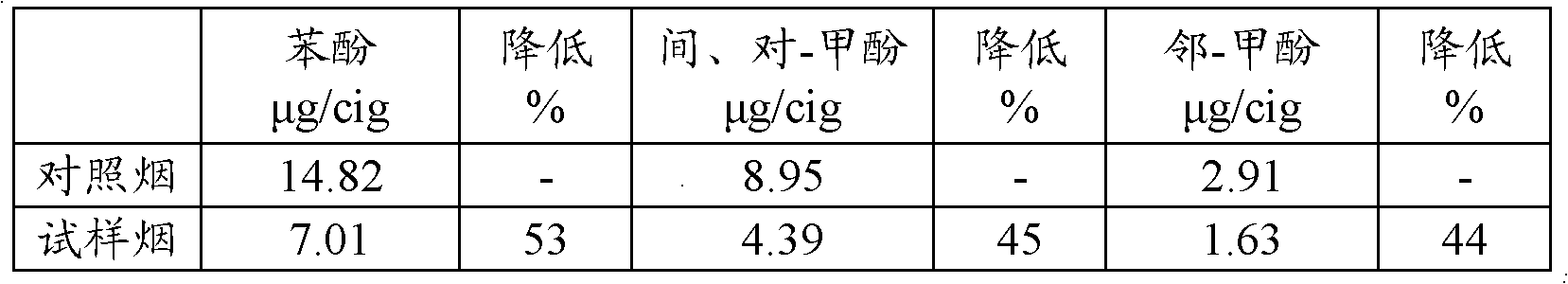

Poly glucosamine hexanedioic acid vinyl ester material for reducing content of phenol type substances

ActiveCN101919591AReduce the harmful components of phenolsReduce contentTobacco smoke filtersBinary compoundOrganic compound

The invention discloses a poly glucosamine hexanedioic acid vinyl ester material for reducing the content of phenol type substances. The composite material is the material which takes a porous material as a carrier and alternately loads polyanions and hydrophilic polycations on the porous material in the way of carrying out self-assembly layer upon layer, and the hydrophilic polycations are loaded on the outmost layer of the porous material, wherein the hydrophilic polycations are poly glucosamine hexanedioic acid vinyl ester hydrochloride. The composite material can be used for preparing cigarette filters and can be prepared into the binary compound cigarette filters or the three-section compound cigarette filters. The poly glucosamine hexanedioic acid vinyl ester material can reduce the phenol type harmful substances in cigarette smoke by utilizing the water selectivity in the composite material; simultaneously, as a large number of flavor organic compounds can not be dissolved in water, the poly glucosamine hexanedioic acid vinyl ester material can avoid the loss of flavor components and keep the inherent quality of cigarettes.

Owner:CHINA TOBACCO ZHEJIANG IND +1

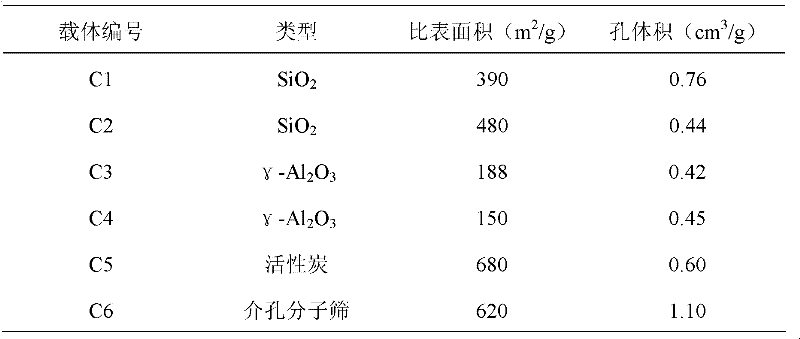

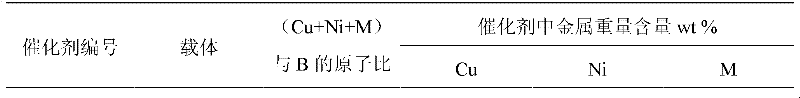

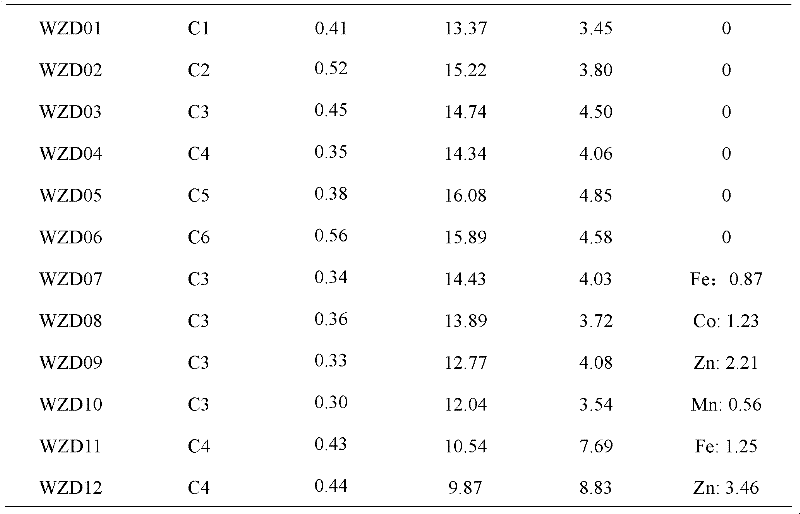

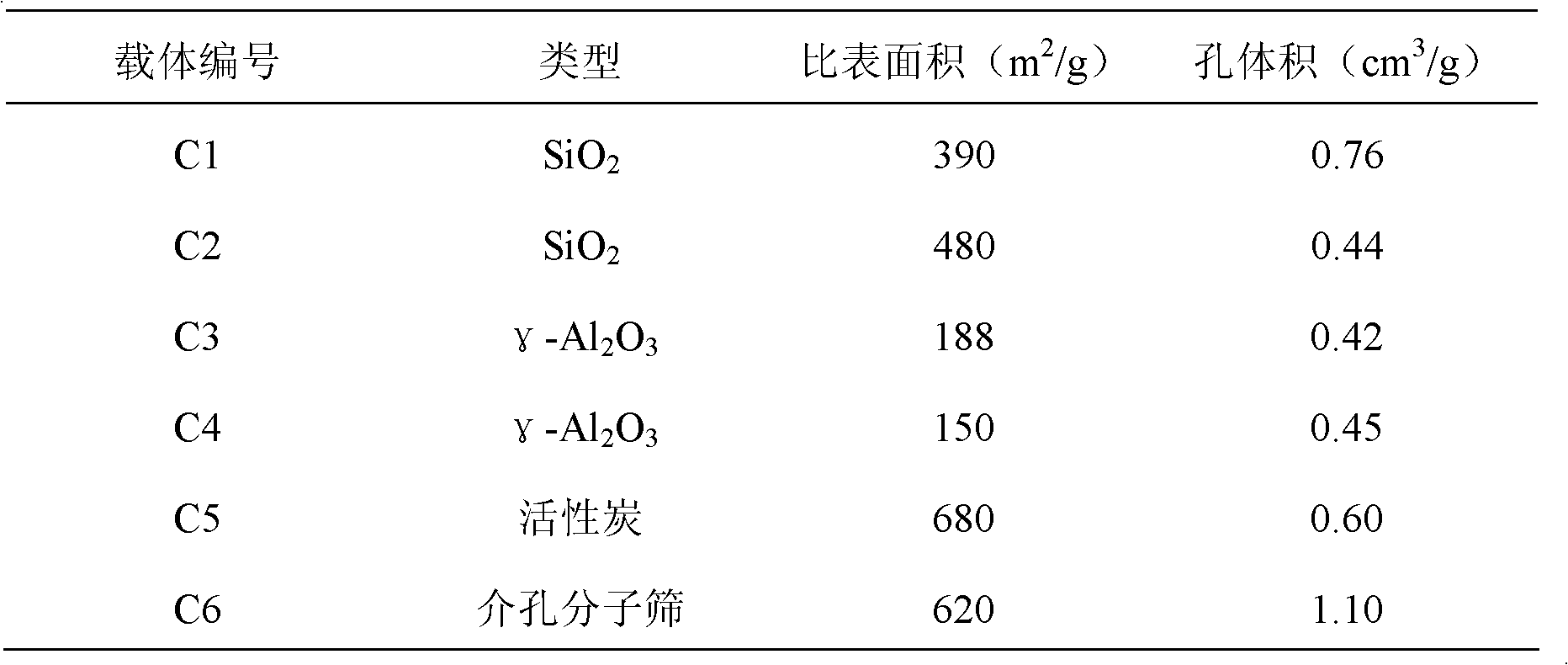

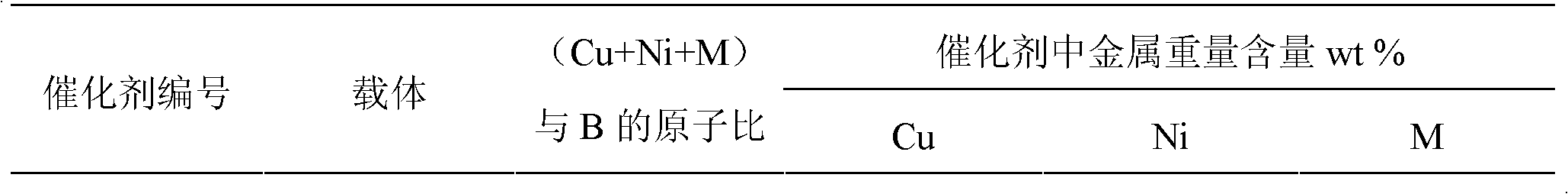

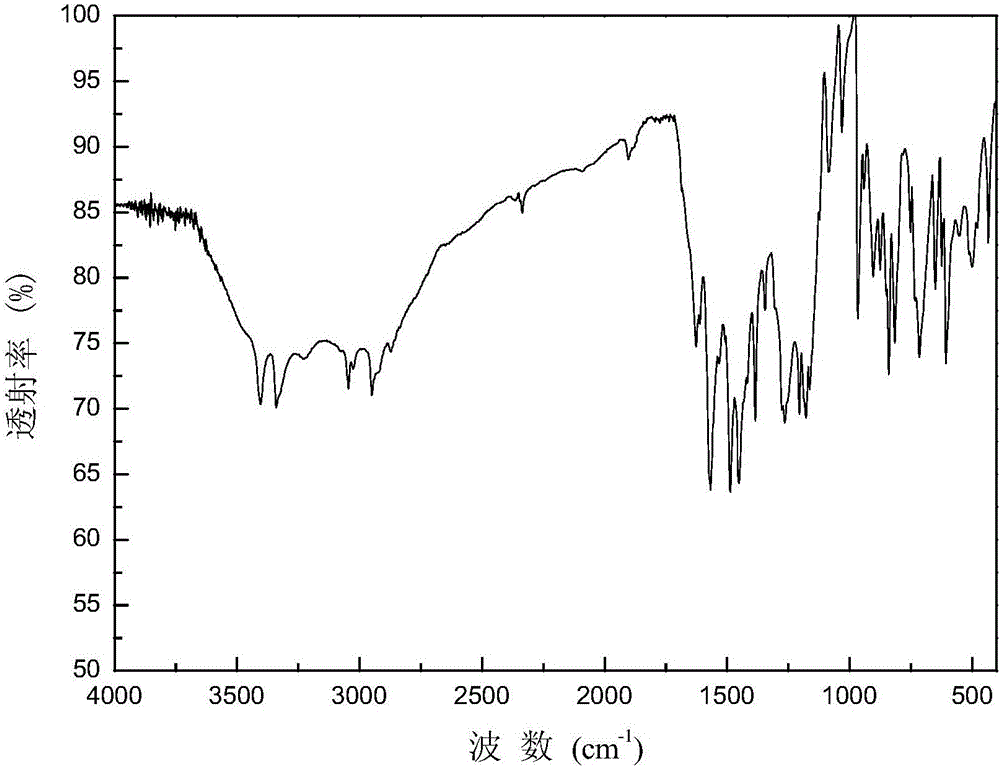

Catalyst for preparation of 1,6-hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester and preparation method and application thereof

ActiveCN102380389ASimple preparation processRelieve pressureMolecular sieve catalystsOrganic compound preparationMetalloleSpace velocity

The invention provides a catalyst for preparation of 1,6-hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester and a preparation method and application thereof. The catalyst comprises, by weight, 5%-30% of Cu, 2-10% of Ni, 5%-20% of B, 0%-5% of metallic addition and the balance being a porous carrier. Since the catalyst is applied to reaction for preparation of hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester, pressure during reaction can be reduced effectively, the liquid hourly space velocity is increased and H2-to-ester ratio is lowered.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Catalyst for preparation of 1,6-hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester and preparation method and application thereof

ActiveCN102380389BSimple preparation processRelieve pressureMolecular sieve catalystsOrganic compound preparationMetalloleSpace velocity

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Instant crease resistant peptide eye cream and preparation method thereof

InactiveCN108670896AImprove wrinklesPromote swellingCosmetic preparationsToilet preparationsWrinkle skinBetaine

The invention discloses instant crease resistant peptide eye cream, which is mainly prepared from rice bran oil, niacinamide, macadimia nut oil, euglena gracilis polysaccharide, cetostearyl alcohol, cetearyl glucoside, purslane flower / leaf / stem extracts, glycyrrhiza glabra leaf extracts, glycine betaine, polydimethylsiloxane, hexanedioic acid / neopentyl glycol / trimellitic anhydride copolymers, VP / VA copolymers, amodimethicone, palmitoyl pentapeptide-4, tripeptide-1, hydrolyzed collagen and the like. The VP / VA copolymers and theeuglena gracilis polysaccharide in the eye cream can form a breathable thin film at the periphery of the eye skin; the eye crease region is filled; the black eye is faded; the eye dropsy condition is relieved; palmitoyl pentapeptide-4 and tripeptide-1 can stimulate regeneration of the collagen and the albumen; the crease generation is retarded; the eye thin veins are relieved; the glycine betaine can promote palmitoyl pentapeptide-4 and tripeptide-1 to directly reach the corium layer for stimulating the regeneration of collagen and elastin; the normal metabolic process of cells is not influenced; the instant crease removal effect is high; safety and no stimulation are realized.

Owner:SHAANXI HUIKANG BIO TECH CO LTD

Polyvinyl chloride synthetic leather for sports shoes and manufacturing method of polyvinyl chloride synthetic leather

InactiveCN102995454AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsTextiles and paperPolyesterPolyvinyl chloride

The invention discloses a polyvinyl chloride (PVC) synthetic leather for sports shoes. The polyvinyl chloride synthetic leather comprises a surface layer, a foaming layer, an adhering layer, and a brushing fabric, and is characterized in that the surface layer is prepared from the following raw materials in parts by weight: 40-50 parts of SG-1 type PVC resin, 70-80 parts of SG-6 type PVC resin, 30-35 parts of hexanedioic acid propylene glycol polyester, 25-30 parts of n-butyl methacrylate, 15-20 parts of sebacic acid propylene glycol polyester, 5-6 parts of PVC color paste, 1-2 parts of bis(isooctyl thioglycolate) dioctyldllauryltin, 1-2 parts of calcium stearate, 1-2 parts of dimethyl bis(isooctyl thioglycolate) and 5-10 parts of modified attapulgite. The PVC synthetic leather is increased in flexibility through the improvement of a formula and a process, has a natural comfortable hand feel similar to a natural leather, is not easily broken or torn and damaged after 3-5 years, and is suitable for being used as a fabric of the sports shoes.

Owner:HEFEI ANSHAN COATING FABRICS

Method for preparing hexanedioic acid from cyclohexane oxidation byproducts

InactiveCN102464579AHigh recovery rateImprove economyOrganic compound preparationCarboxylic preparation by oxidationAqueous solutionOxidizing agent

The invention relates to a method for preparing hexanedioic acid from cyclohexane oxidation byproducts. The method comprises the following steps: 1, hydrolyzing raw materials light oil byproducts of a cyclohexane oxidation reaction by adding water to them to make epoxycyclohexane in the light oil byproducts hydrolyze to form 1,2-cyclohexanediol; 2, carrying out primary separation to obtain crude 1,2-cyclohexanediol; 3, adding water to form an aqueous 1,2-cyclohexanediol solution; and 4, adding a catalyst and an oxidant to carry out an oxidation reaction to oxidize 1,2-cyclohexanediol in the aqueous solution into hexanedioic acid. The method which uses the cyclohexane oxidation byproducts as the raw materials can obtain hexanedioic acid in a high recovery rate within a short reaction time.

Owner:CHINA PETROCHEM DEVMENT

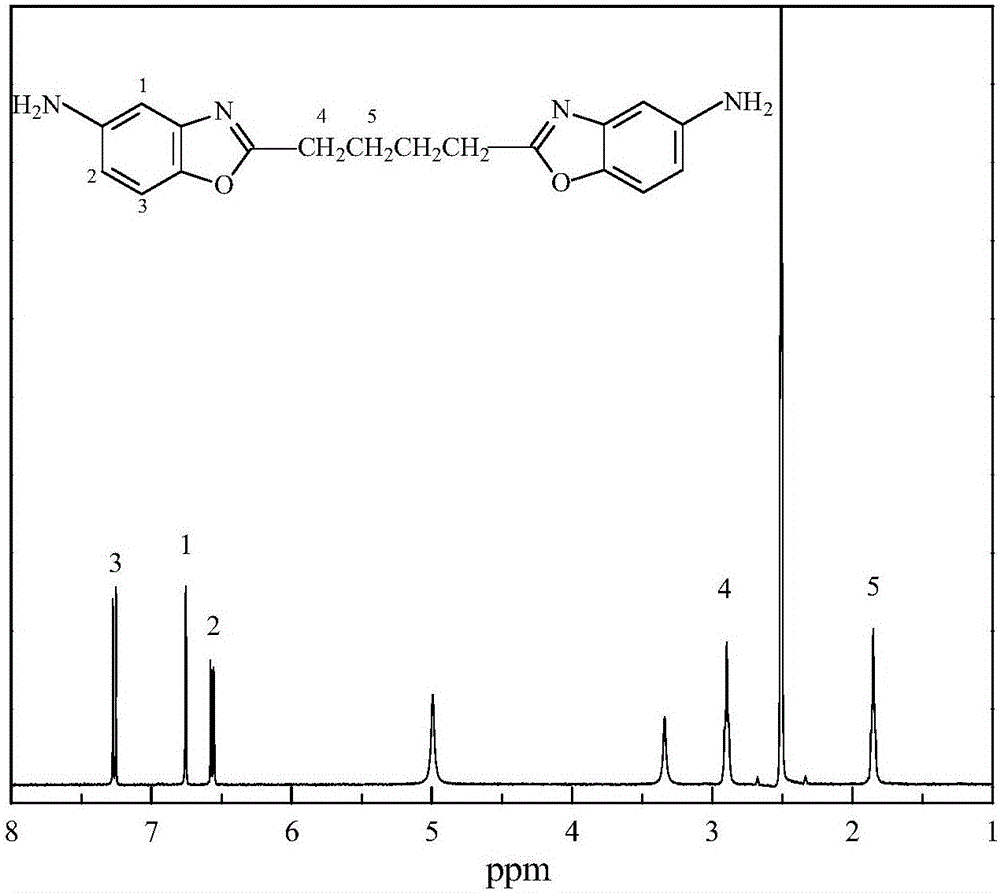

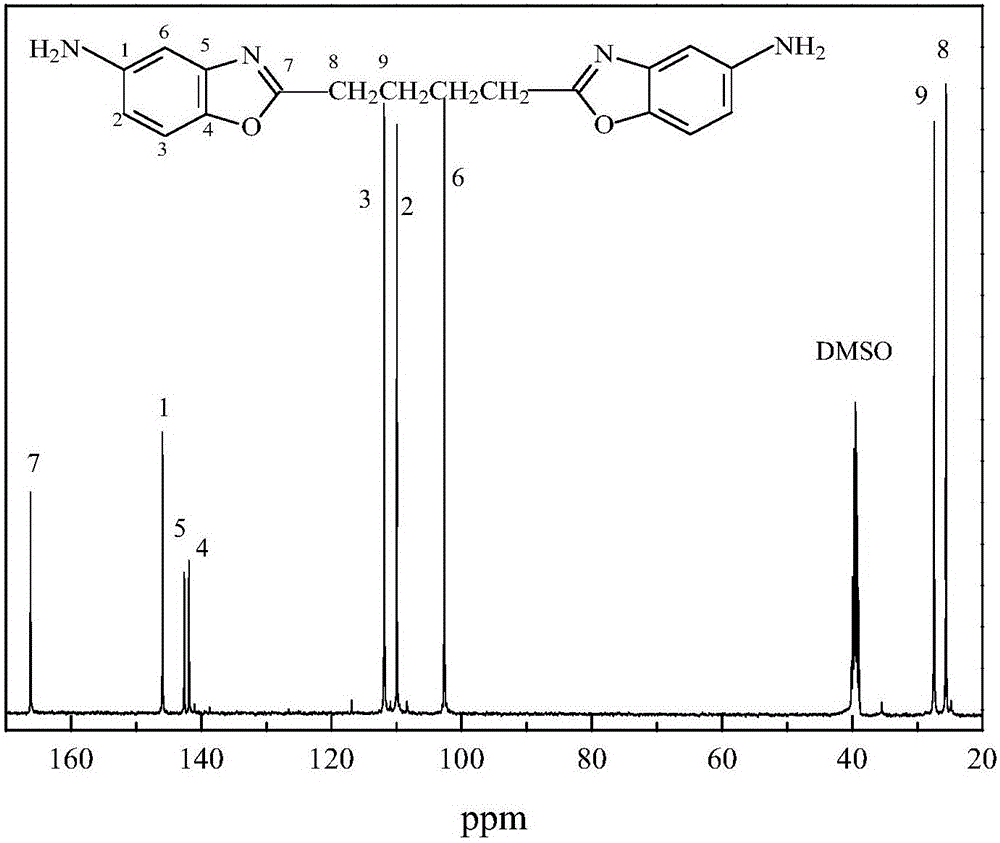

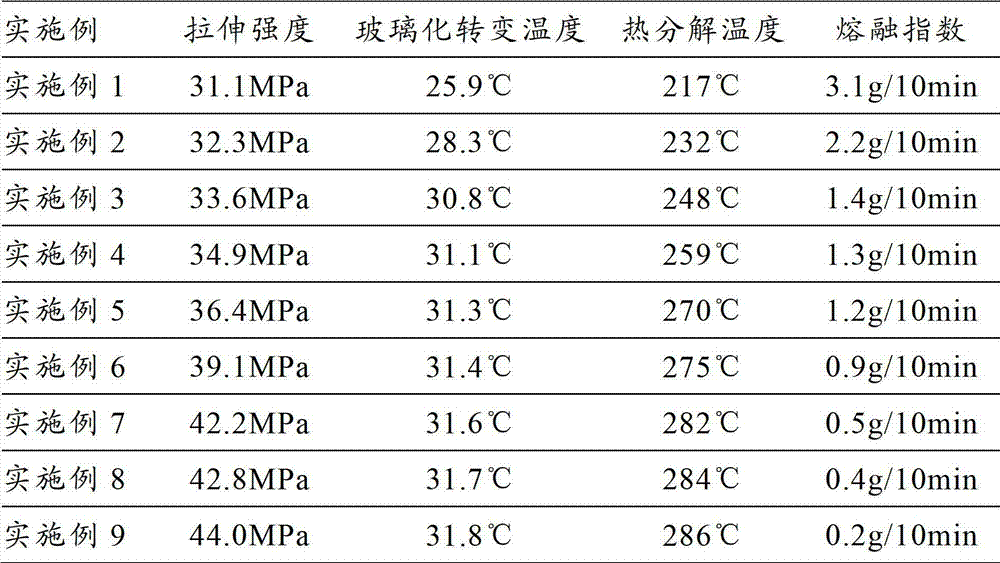

Preparation methods and applications for diaminebenzoxazole and copolyamide electrolyte of diaminebenzoxazole

ActiveCN105017171AImprove thermal stabilityIncrease intermolecular forcesOrganic chemistrySecondary cellsPolyethylene glycolPolymer thin films

The invention provides preparation methods and applications for diaminebenzoxazole and a copolyamide electrolyte of the diaminebenzoxazole. The invention relates to synthetic methods for a novel diaminebenzoxazole compound and copolyamide of the novel diaminebenzoxazole compound. The invention is to solve the problem of low mechanical property and electrical conductivity of a conventional PEO polymer electrolyte. According to the invention, 2,2'-butylidenedi[5-amidobenzoxazole] is prepared with 2,4-diaminophenol hydrochloride and hexanedioic acid as raw materials and polyphosphoric acid as a solvent; the 2,2'-butylidenedi[5-amidobenzoxazole] respectively reacts with polyethyleneglycol dicarboxylic acid, and sulfonic lithium (sodium)-contained dicarboxylic acid or sulfonic lithium (sodium)-contained diamine so as to prepare a copolyamide I and a copolyamide II; meanwhile, the copolyamide is applied as an electrolyte of a solid lithium-ion battery. According to the invention, by introducing 2,2'-butylidenedi[5-amidobenzoxazole] into a polyamide structure, electrical conductivity and mechanical property of a polymer thin film are improved.

Owner:HARBIN INST OF TECH

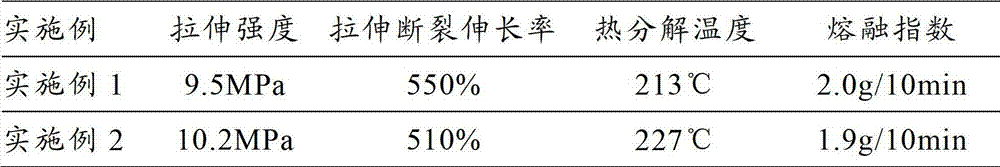

Modified poly (propylene carbonate) and preparation method thereof

The invention provides modified poly (propylene carbonate), which comprises a cross-linked poly (propylene carbonate) with polyphenyl polymethylene polyisocyanates as a cross-linking agent, as well as a polymer of hexanedioic acid and 1,2-propylene glycol ester, wherein the mass ratio of poly (propylene carbonate) to the polyphenyl polymethylene polyisocyanates is 100:(0.1-2), and the mass ratio of the cross-linked poly (propylene carbonate) to the polymer of hexanedioic acid and 1,2-propylene glycol ester is 100:(5-20). A preparation method of the modified poly (propylene carbonate) comprises the following steps: blending and extruding the poly (propylene carbonate) and the polyphenyl polymethylene polyisocyanates to obtain the cross-linked poly (propylene carbonate); and blending and extruding the cross-linked poly (propylene carbonate) and the polymer of hexanedioic acid and 1,2-propylene glycol ester to obtain the modified poly (propylene carbonate). The modified poly (propylene carbonate) provided by the invention is good in thermal stability, high in tensile elongation at break, good in transparency and capable of being biodegraded completely.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Light alkyd resin for interior decoration and furniture coating and preparation method thereof

The invention discloses light alkyd resin for interior decoration and furniture coating, which is formed by the following raw materials: glycerol, palmitoleic acid, benzoic acid, hexanedioic acid, neopentyl glycol, phthalic anhydride, tetramethylolmethane and dimethylbenzene; the preparation method comprises the following steps: a. the palmitoleic acid, the benzoic acid, the hexanedioic acid, the glycerin, the neopentyl glycol, the phthalic anhydride, the tetramethylolmethane and the dimethylbenzene are thrown in a reactor one time, are heated and are stirred; b. carbon dioxide gas flows in the reactor to protect temperature rise, when the temperature is raised to 130-180 DEG C and kept for 1-3 hours, at the moment, the dimethylbenzene flows back, and then the temperature is raised to 200 plus / minus 5 DEG C at the temperature raising speed with 8-12 DEG C per hour, and then the temperature is kept for 4-8 hours; c. a sample is taken out in the step b for measuring viscosity, when the viscosity reaches desired value, the temperature is cooled to 130-180 DEG C, so as to obtain the modified alkyd resin; d. the alkyd resin in the step c is transferred to another reactor, and then 2.5-8.5 percent of dimethylbenzene is added, the mixture is mixed uniformly to obtain the water-white alkyd resin liquid.

Owner:四川巴德士新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com