Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Galvanic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The galvanic effect of mixed metals in the mouth can cause voltages tens to hundreds of times greater than what the brain produces, and may cause currents and electromagnetism that interfere with the brain's electrical impulses--impulses which control the voluntary and involuntary actions of the body as well as the mind.

Catalyst loading CoCr(Mn/Al)FeNi high-entropy alloy nano particles and preparation method and application of catalyst

ActiveCN109999830AIncrease mixing entropyGood fade effectMaterial nanotechnologyWater contaminantsActivated carbonHigh entropy alloys

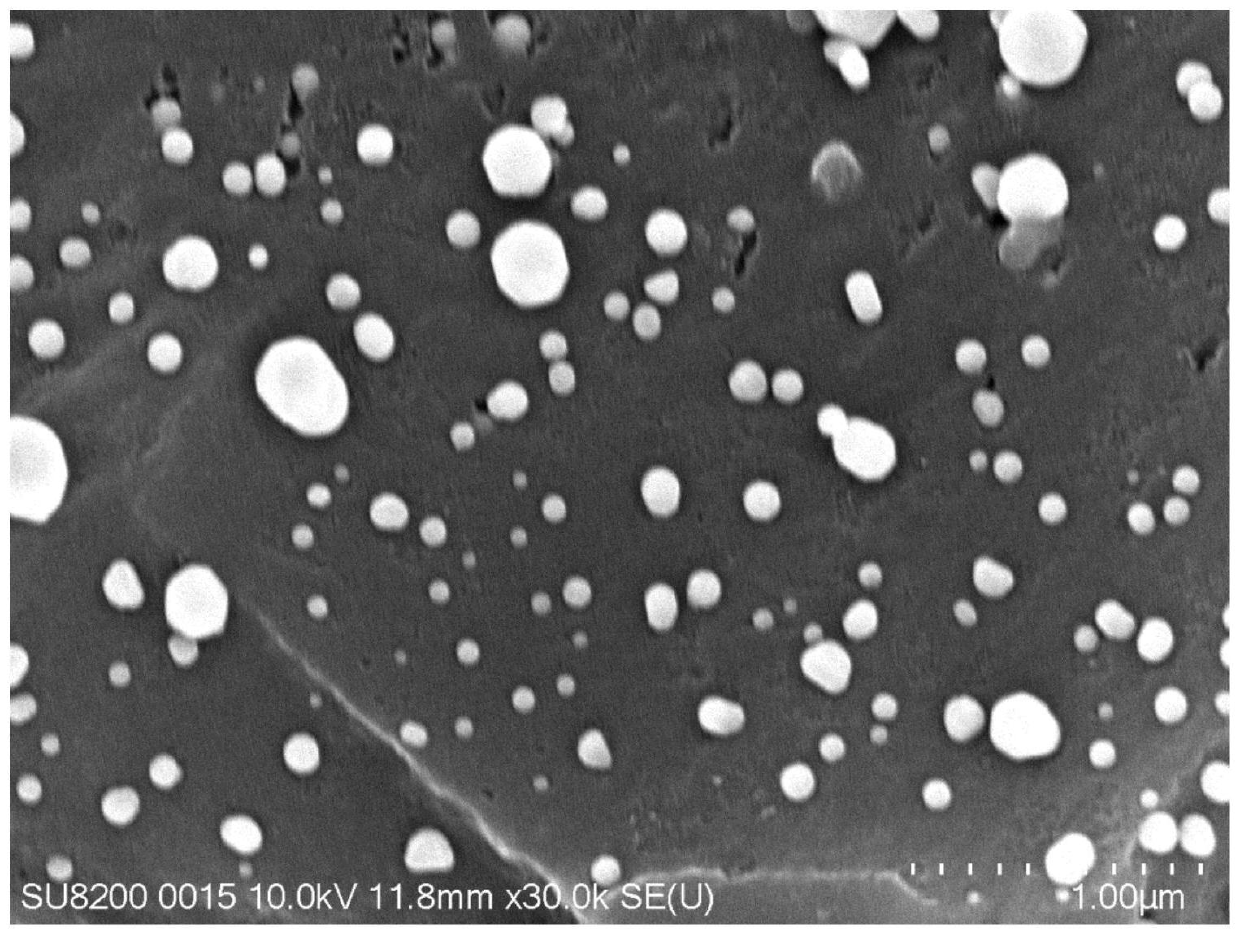

The invention discloses a catalyst loading CoCr(Mn / Al)FeNi high-entropy alloy nano particles and a preparation method and application of the catalyst. Activated carbon or a mineral material is adoptedas the matrix of the catalyst, the CoCr(Mn / Al)FeNi high-entropy alloy nano particles are loaded on the surface of the matrix, wherein the mass content of the matrix is 90-97% by weight. The CoCr(Mn / Al)FeNi high-entropy alloy nano particles loaded on the carrier are uniformly distributed, the loading capacity is controllable, the catalytic performance is excellent, and a galvanic effect can be achieved by the high-entropy alloy particles and the matrix at a nanometer scale, so that the catalytic degradation performance on azo dye is improved greatly.

Owner:CHINA UNIV OF MINING & TECH

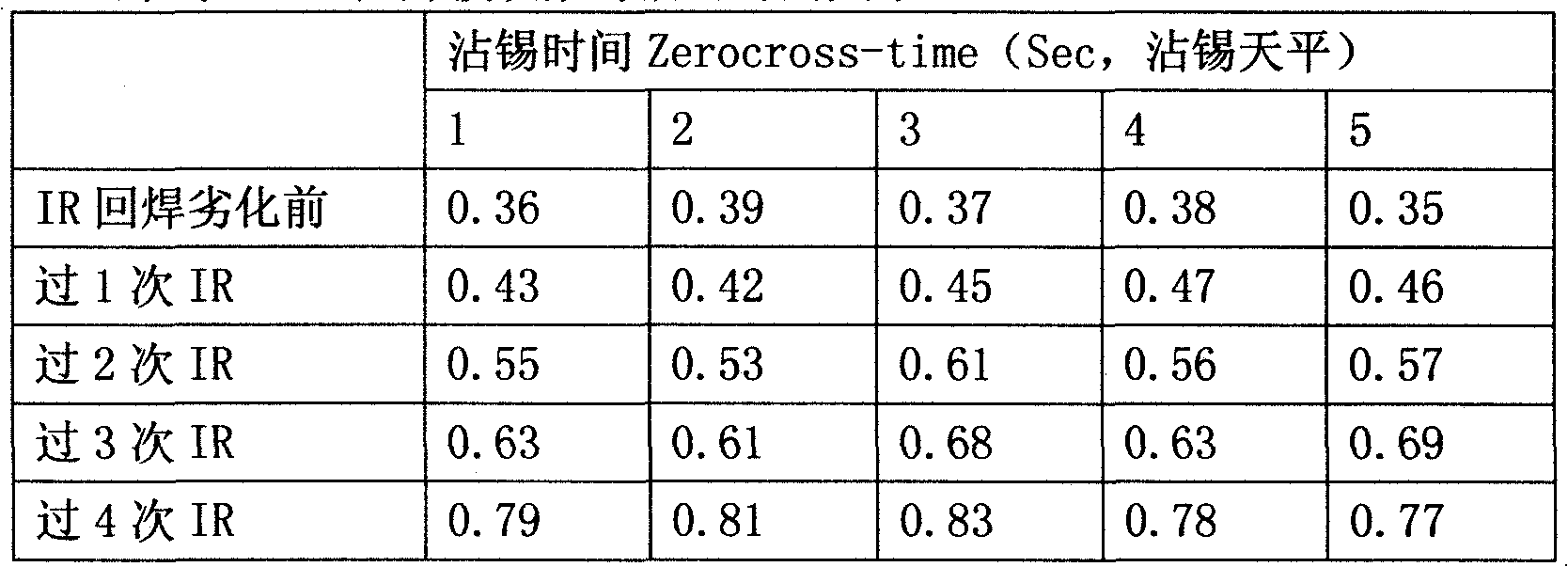

Organic solderability preservative pre-soaking treating agent and organic solderability preservation film forming method

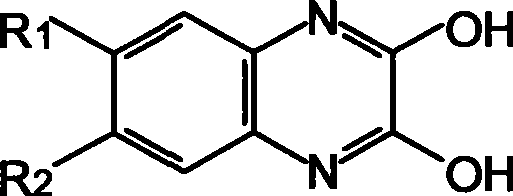

InactiveCN101508051AFast film formationShort duration of actionArc welding apparatusMetallic material coating processesQuinoxalineBuffering agent

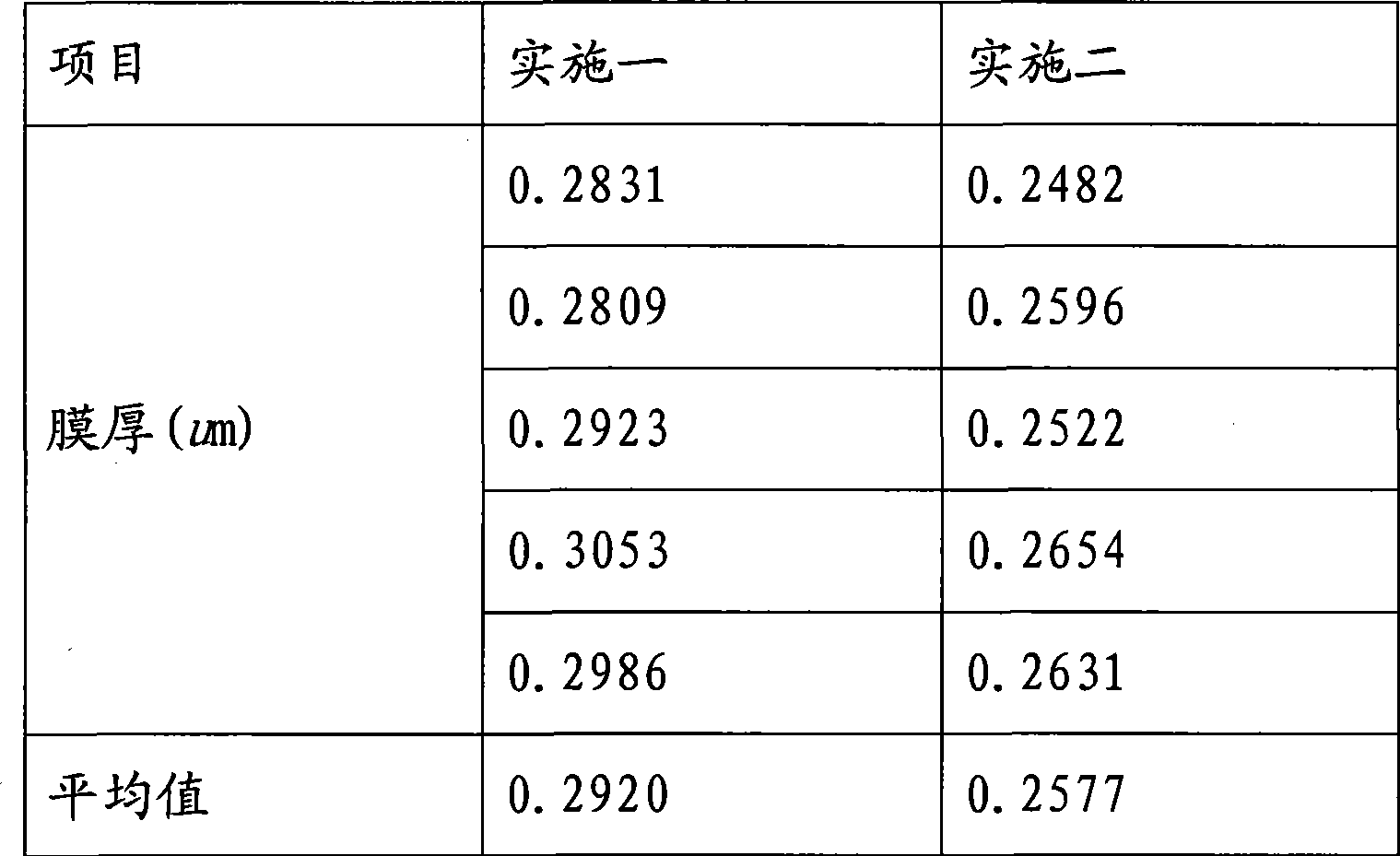

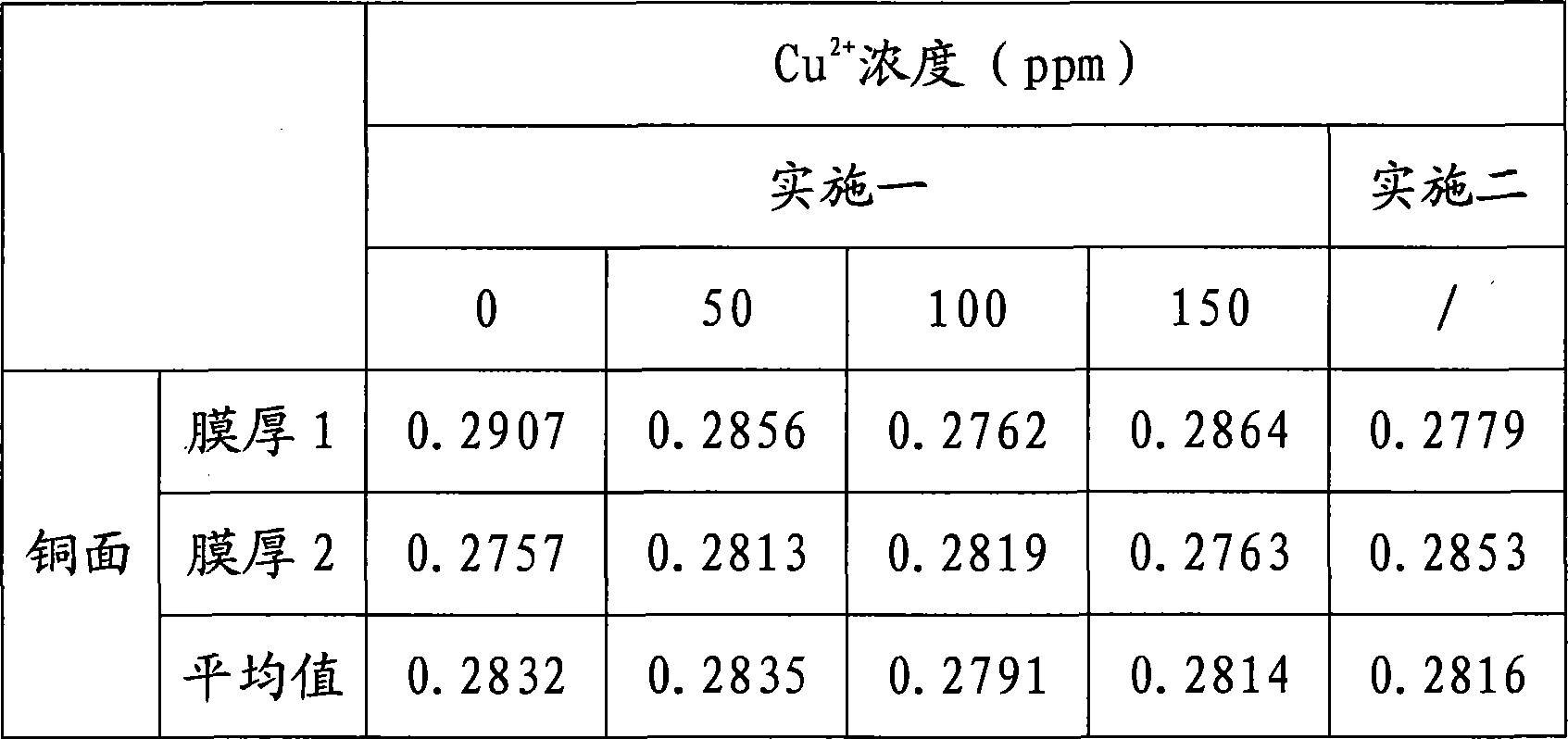

The invention relates to the technical field of printed circuit board solderability preservation, in particular to an organic solderability preservative preimpregnation finishing agent and an organic solderability preservative forming method. The adopted organic solderability preservative preimpregnation finishing agent comprises the following components in percentage by weight: 0.05 to 6.0 percent of nanometer accelerating agent, 0.01 to 2.0 percent of quinoxaline compound, 0.05 to 2.0 percent of inorganic base, 0.001 to 15.0 percent of ammonia or amine buffering agent, 0.001 to 0.5 percent of metallic salts, and 0.01 to 5.0 percent of halide. The invention firstly forms a nano material active layer on the copper face, and can increase the thickness of the organic solderability preservative by more than 20 percent in the same reaction time, reduce metal pollution speed of tank liquor, double the service life of the tank liquor, prevent galvanic effect, ensure good appearance of a printed circuit board, reduce the thickness of intermetallic compounds (IMC) after soldering, and guarantee the shear strength of welding joints and reliability of welding spots.

Owner:林原标 +1

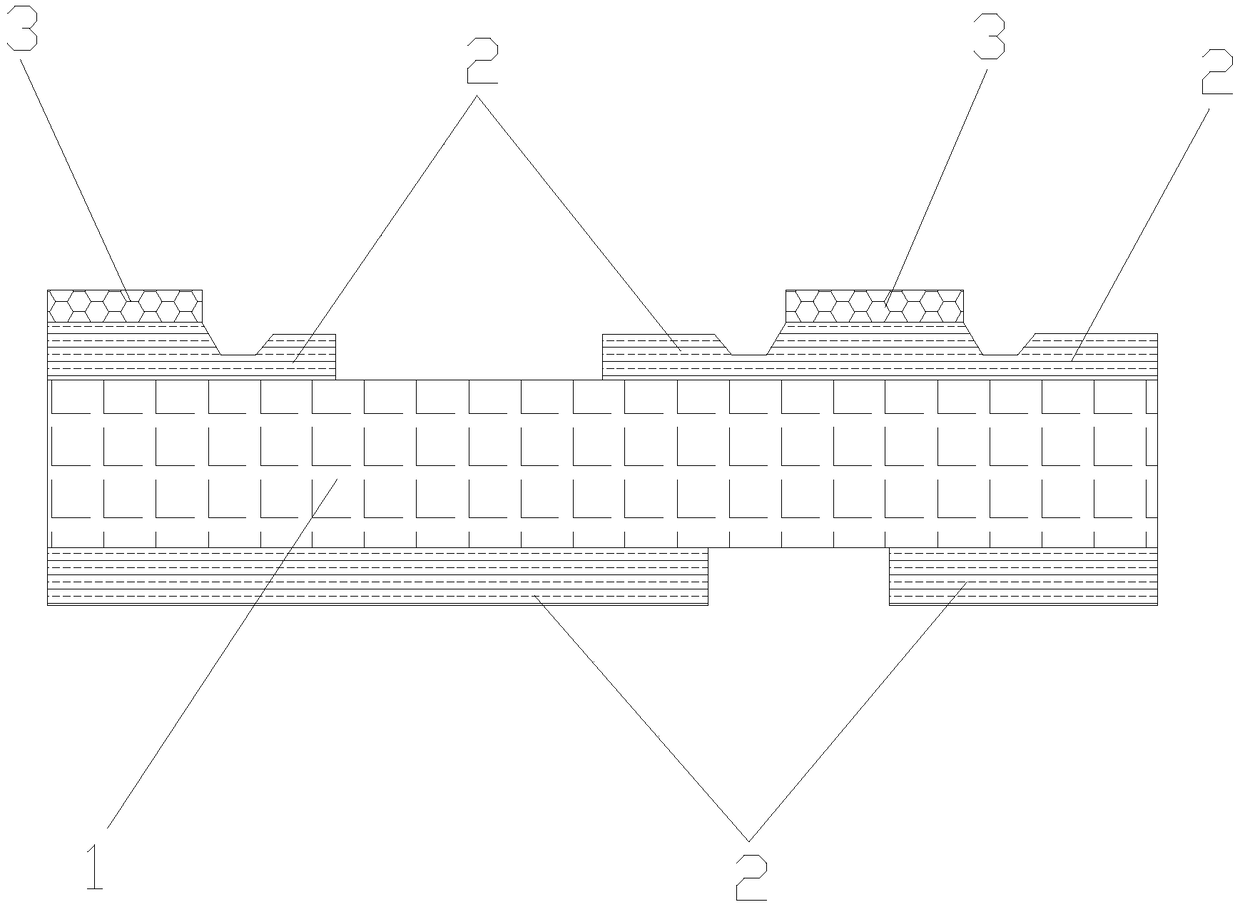

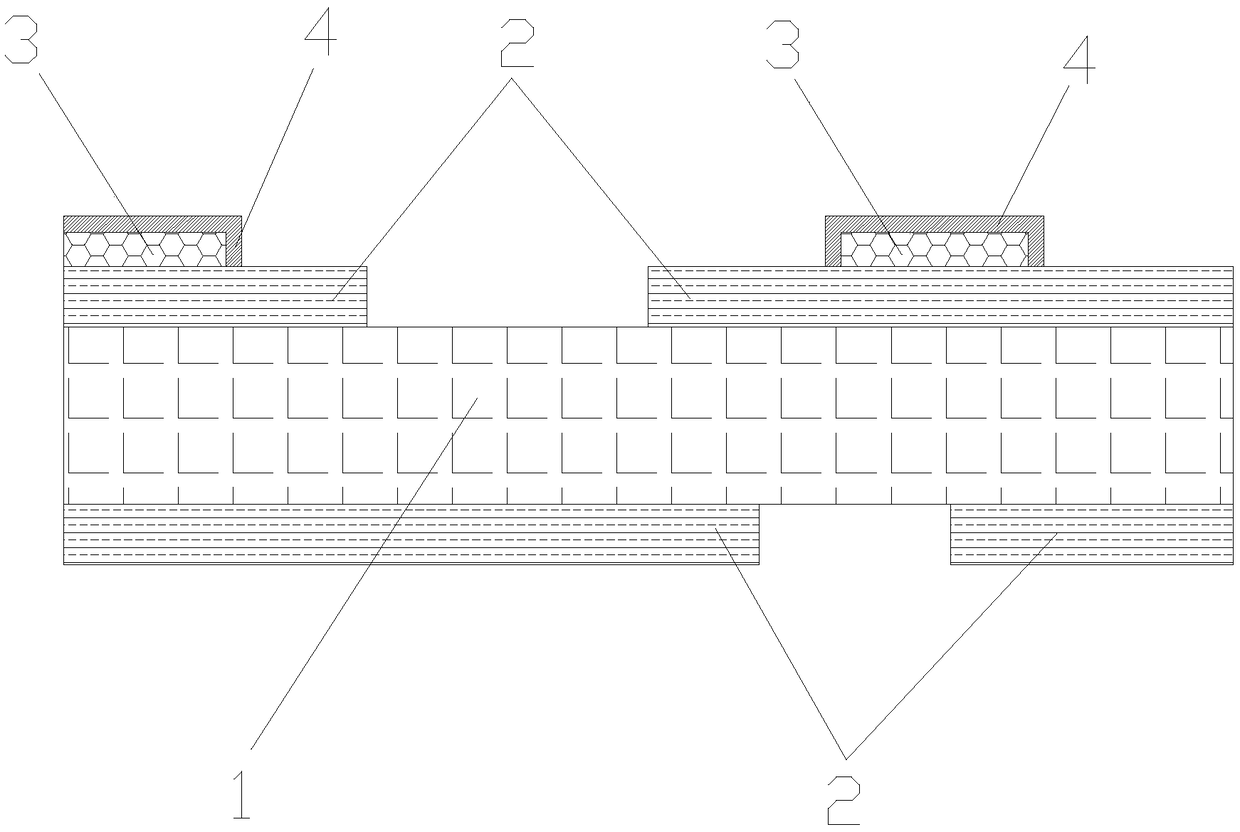

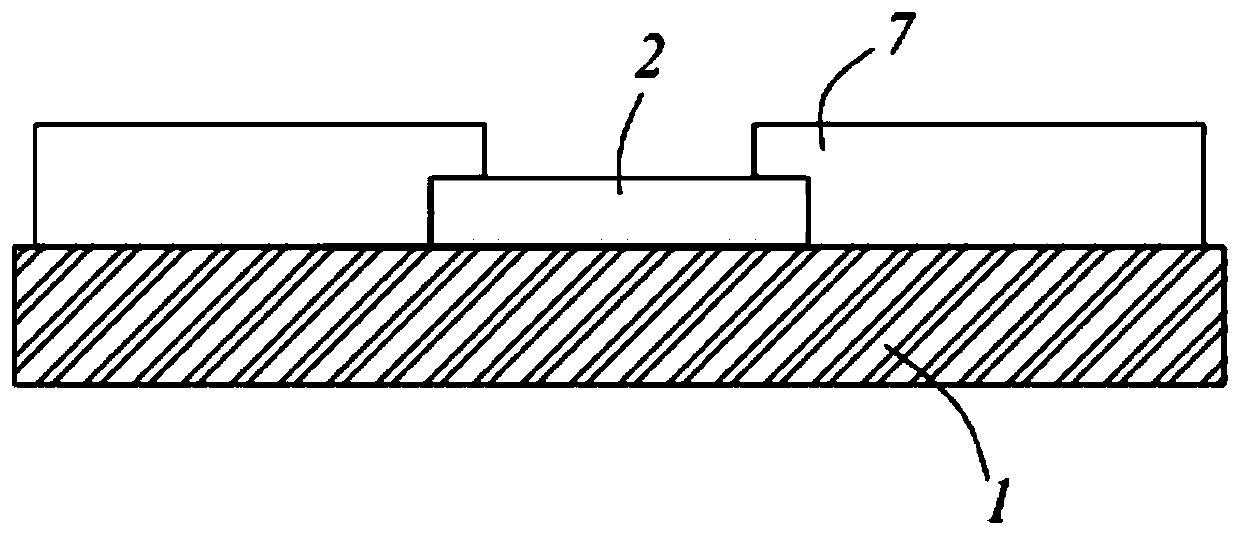

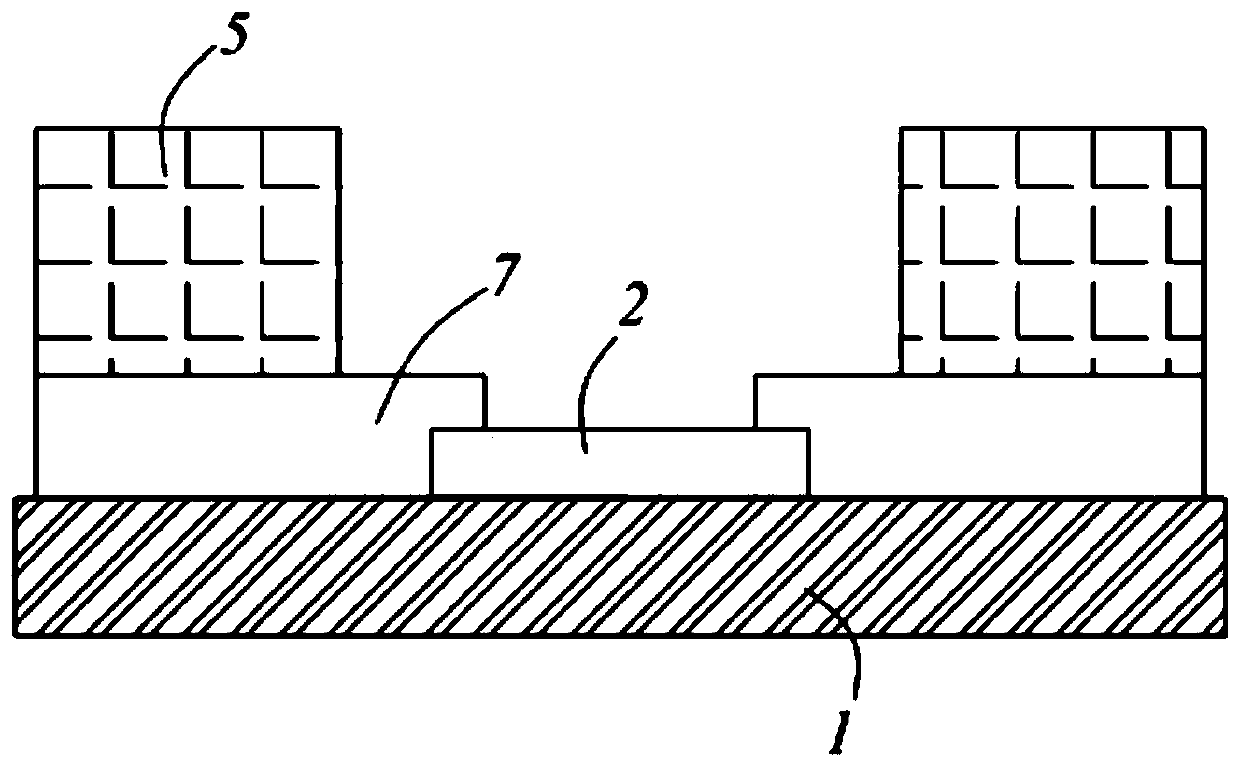

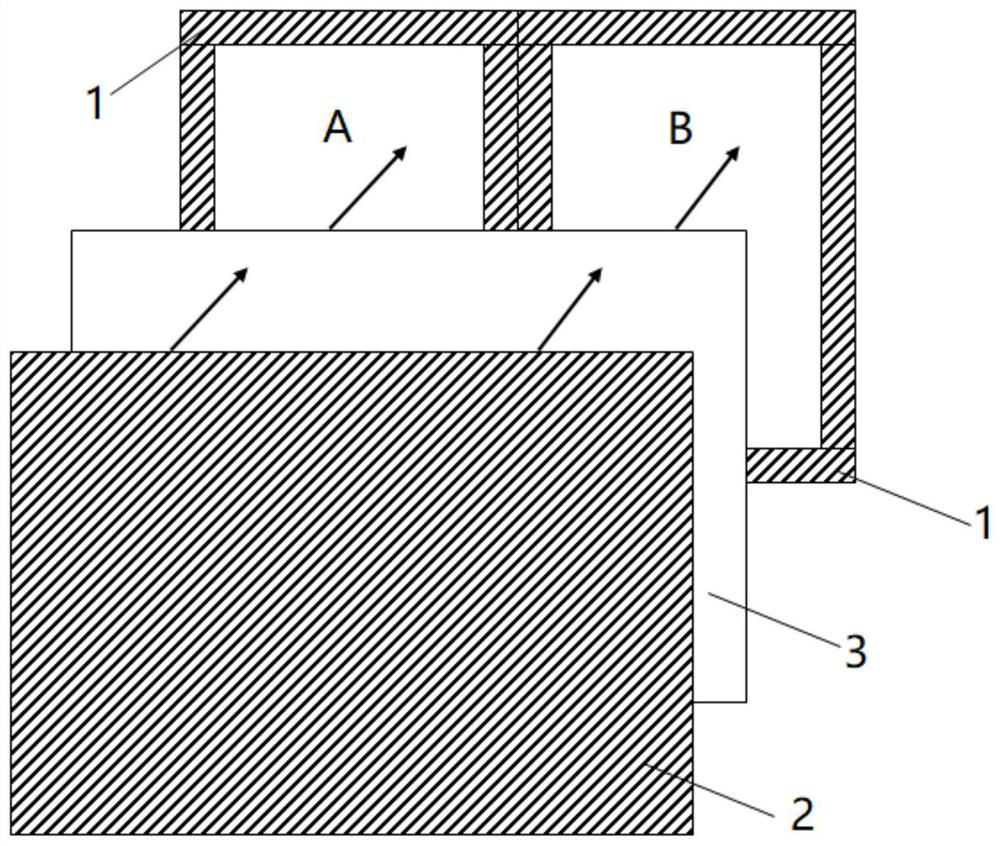

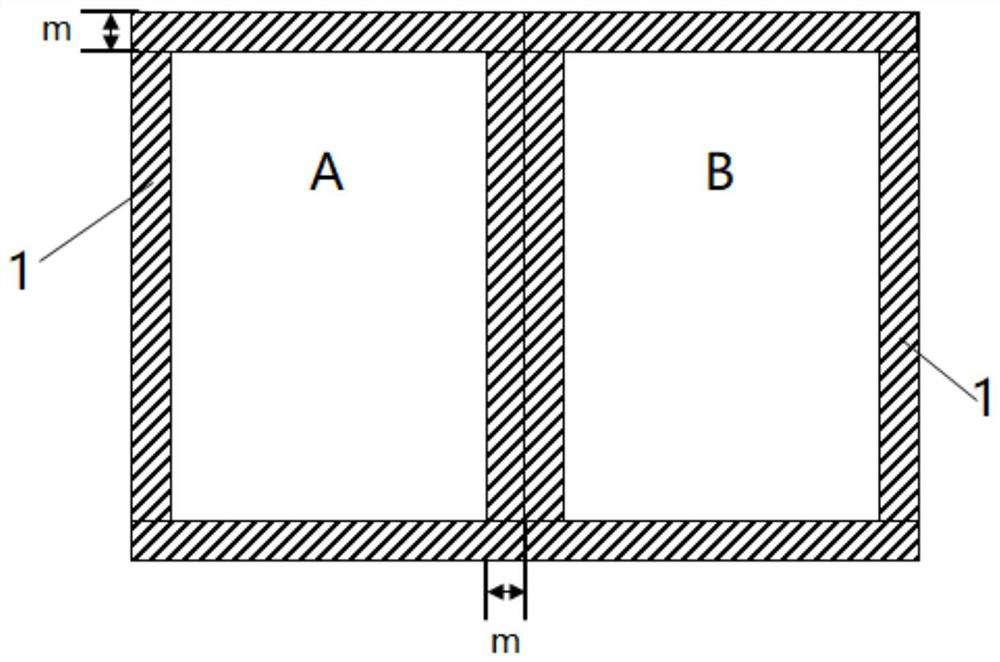

Ground structure and mobile terminal

ActiveCN107205064ARealize electrostatic protectionAvoid layeringDigital data processing detailsPrinted circuitsElectricityElectrical battery

The invention provides a ground structure and a mobile terminal. The ground structure comprises a touch screen ground wire, a voltage clamper and a metal middle frame, wherein a first end of the voltage clamper is electrically connected with the touch screen ground wire, a second end of the voltage clamper is electrically connected with the metal middle frame, the touch screen ground wire is arranged on a frame of a touch screen of the mobile terminal and used for releasing static electricity entering from the side of the touch screen. Thus, when the static electricity enters the mobile terminal from the side of the touch screen, the ground structure can release the static electricity to realize static electricity protection of the mobile terminal, and meanwhile, when no static electricity enters the mobile terminal from the side of the touch screen, the problem of layering of the touch screen ground wire and the touch screen due to the galvanic effect because the touch screen ground wire and the metal middle frame contact with electrolyte simultaneously can be solved effectively.

Owner:VIVO MOBILE COMM CO LTD

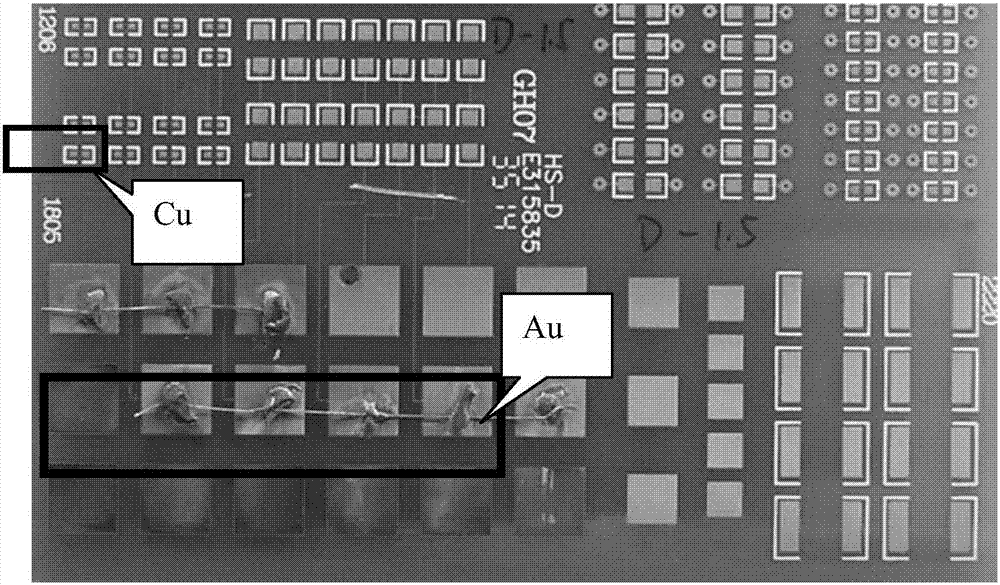

Application of triamine base substituted phenol or triamine base substituted thiophenol and micro-etching treating fluid

ActiveCN107022762APrevent the phenomenon of "hair color"Shorten speedElectrochemical responseEtching

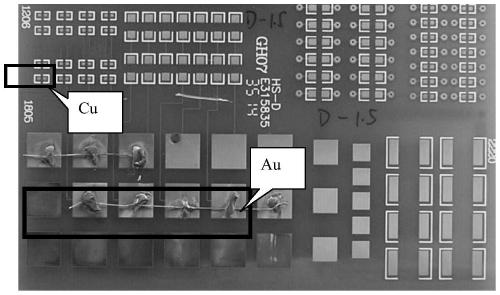

The invention relates to micro-etching treating fluid. The micro-etching treating fluid comprises 30.0-60.0 g / L of sulfuric acid, 10.0-20.0 g / L of hydrogen peroxide, 0.1-1.0 g / L of hydrogen peroxide stabilizer, 2.0-5.0 g / L of inhibitor and 1 L of added water. The inhibitor is selected from the triamine base substituted phenol or the triamine base substituted thiophenol. The above micro-etching treating fluid is used for printed circuit board OSP pretreatment, a clean and rough copper surface can be formed, a protection film can be formed in combination with a copper face in the micro-etching process, the copper face electron supplying speed during the copper-gold electrochemical reaction is reduced, accordingly the potential difference between the copper and the gold is reduced, the biting corrosion rate of a copper welding pad is reduced, generation of the galvanic effect is restrained to the maximum degree, the phenomena of the color difference, area reduction or line excessive corrosion or even biting off cannot happen to the copper face connected with the gold face and obtained after micro-etching treatment, and meanwhile the phenomenon of coloring after OSP treatment can be effectively prevented from happening to the copper surface.

Owner:GUANGDONG GUANGHUA SCI TECH +1

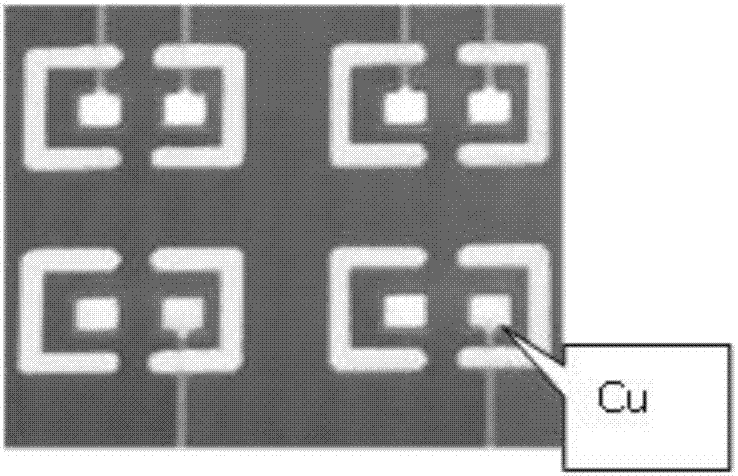

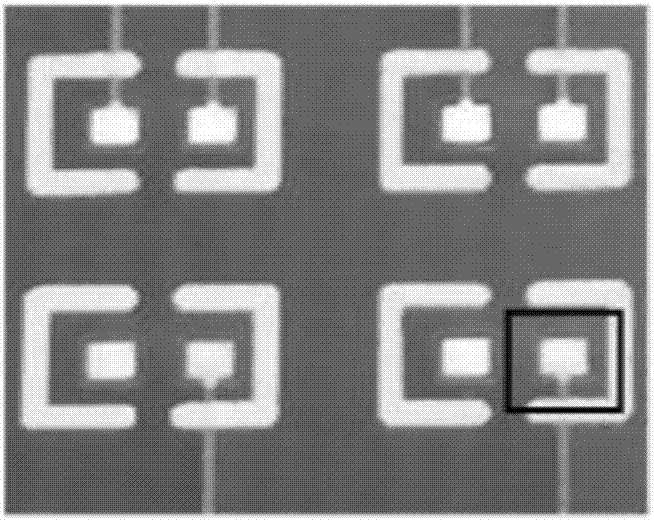

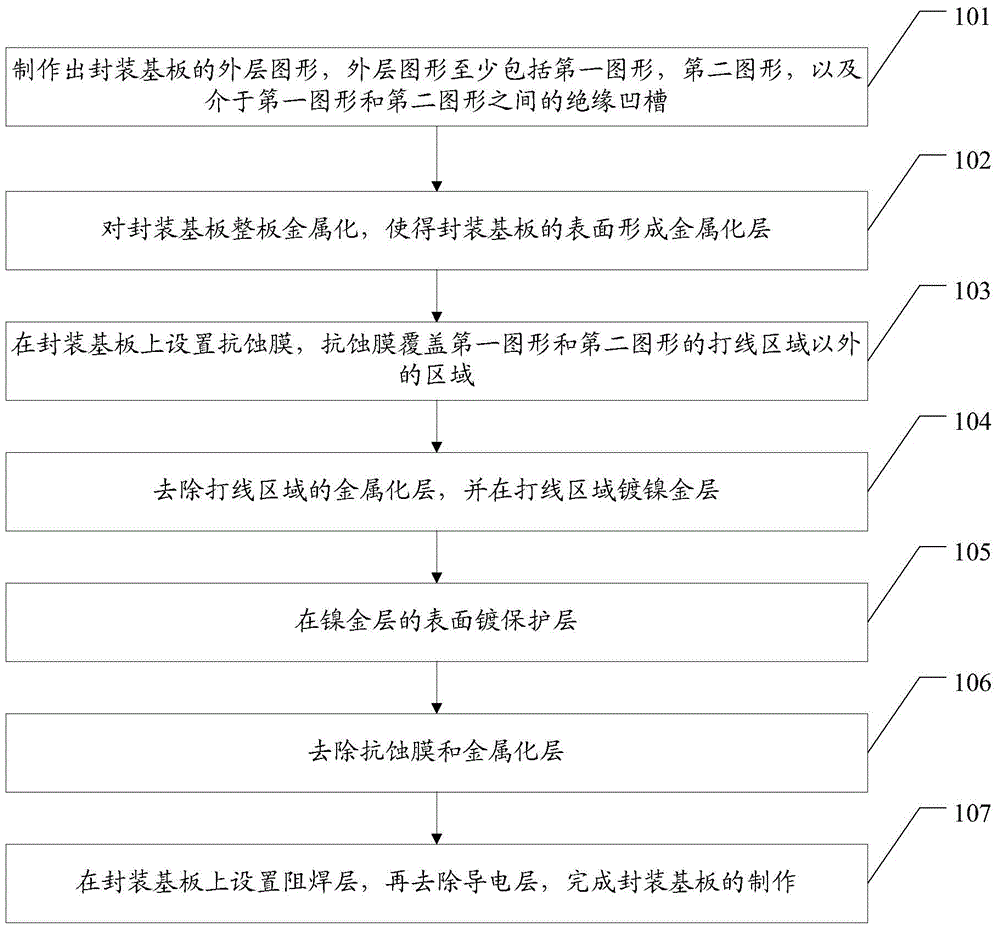

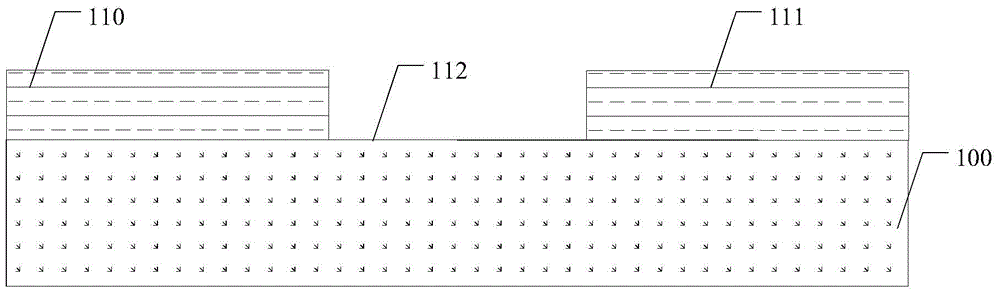

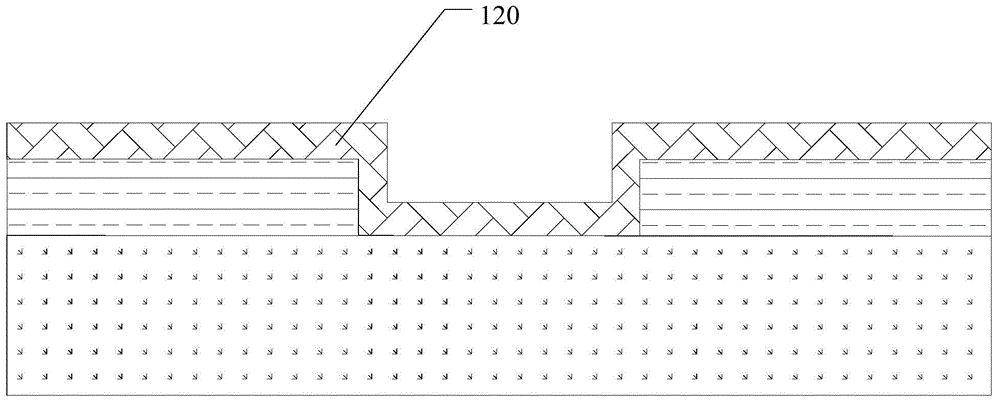

Method for producing package substrate

ActiveCN105489504AWill not cause corrosionNo chemical reactionSemiconductor/solid-state device manufacturingState of artResist

The invention discloses a method for producing a package substrate. The method includes the following steps of: producing an outer graph, wherein the outer graph at least includes a first graph, a second graph, and an insulation groove arranged between the first graph and the second graph; performing metallization on the whole package substrate to allow a surface of the package substrate to form a metallization layer; arranging a corrosion-resistant film which covers areas of the first graph and the second graph except line areas; removing the metallization layer on the line areas, and plating a nickel gold layer onto the line areas; plating a protective layer onto a surface of the nickel gold layer; removing the corrosion-resistant film and the metallization layer; arranging a solder resist layer on the package substrate, and removing the protective layer to complete production of the package substrate. The method can be used to solve the problem in the prior art of galvanic effect.

Owner:SHENNAN CIRCUITS

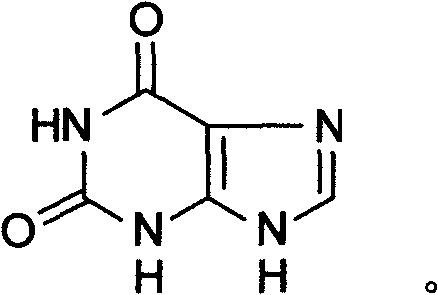

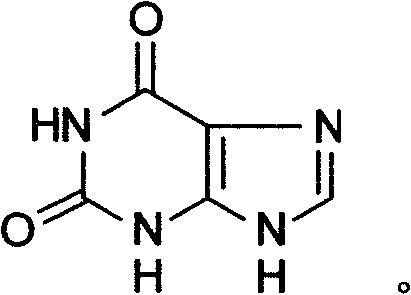

Etching liquid capable of effectively retarding galvanic effect

The invention relates to an etching liquid capable of effectively retarding a galvanic effect. The etching liquid is mainly prepared by dissolving an etchant and a nitrogen-containing pentabasic heterocyclic compound with a specific ratio into water. Therefore, when a substrate containing at least one first metal (for example, gold) and at least one second metal (for example, copper) is subjected to wet etching by a user with the etching liquid, the nitrogen-containing pentabasic heterocyclic compound can form an organic protective film on the first metal with relatively reduction potential, so as to effectively avoid the phenomenon of excessive etching caused by the effects on the second metal caused by the galvanic effect. A chemical structure of the nitrogen-containing pentabasic heterocyclic compound is shown in a chemical formula 1; and the chemical formula 1 is as shown in the specification.

Owner:E CHEM ENTERPRISE CORP

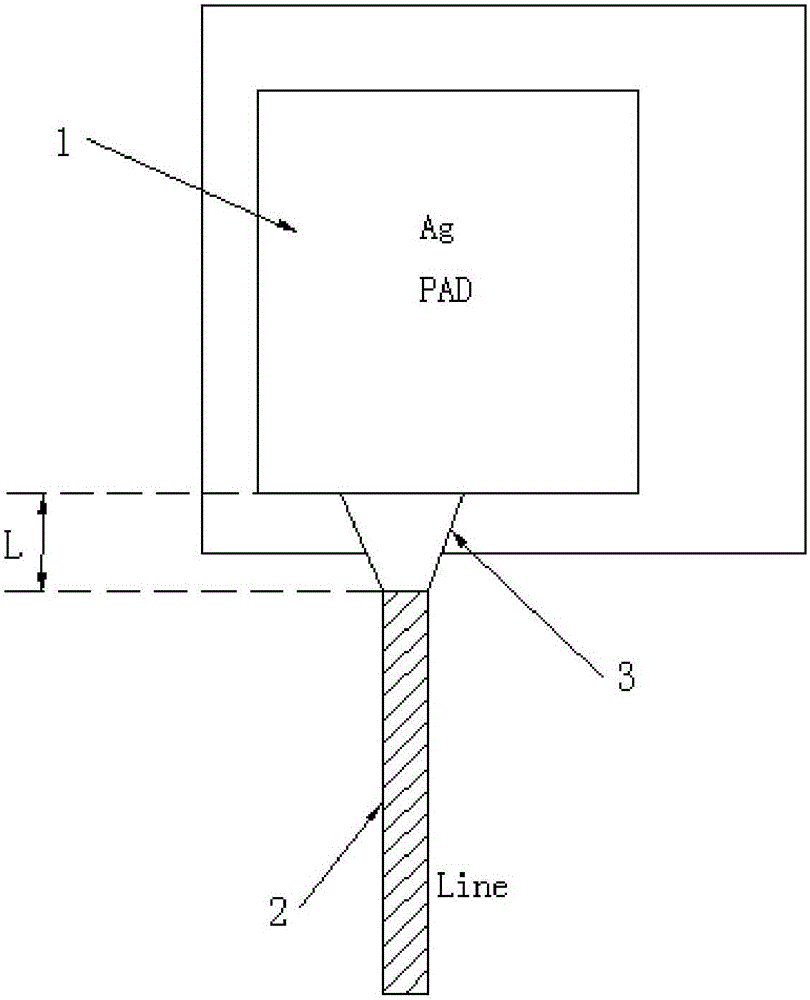

PCB bonding pad/line connection structure

InactiveCN104994685AGuarantee the quality of finished productsImprove electrical performancePrinted circuit aspectsElectrical connection printed elementsResistSolder mask

The invention discloses a PCB bonding pad / line connection structure. A PCB comprises a substrate. The substrate is provided with a bonding pad and a line which are connected. The connection place of the bonding pad and the line is provided with a teardrop structure, and the length of the teardrop structure meets the following formula: L>=o+e+a, wherein the L is the length of the teardrop structure, the o is the dimension of a single edge of a solder mask window, the e is solder resist offset and the a is ink lateral erosion amount. By comprehensively considering the solder mask window information, the solder resist offset and the ink lateral erosion information, a teardrop in a suitable size is obtained, and the length of the teardrop added to the connection place between the bonding pad and the line is allowed to be larger than the risk value generated due to the galvanic effect, thereby preventing the phenomenon that the connection place between the bonding pad and the line is etched broken, ensuring quality of finished products of a PCB effectively and ensuring stability of electrical performance of the PCB.

Owner:竞陆电子(昆山)有限公司

OSP (organic solderability preservative) preimpregnation agent

InactiveCN105081614AShort duration of actionFast film formationWelding/cutting media/materialsSoldering mediaMetal contaminationOrganic solderability preservative

The invention relates to the technical field of printed circuit board shielded welding, in particular to an OSP (organic solderability preservative) preimpregnation agent. The OSP preimpregnation agent comprises 30 g / L-50 g / L of cyclic ketone compound, 1 g / L-5 g / L of amine compound and the balance water. According to the OSP preimpregnation agent, an active layer can be firstly formed on a copper surface, the forming speed of an organic solderability preservative film is increased, and the thickness of the organic solderability preservative film can be increased by more than 20% within the same reaction time. The OSP preimpregnation agent is alkaline preimpregnation treating agent liquid medicine with a higher pH value, corrosion to the copper surface can be reduced, the metal contamination speed of tank liquor is lowered, and the service life of the copper surface can be prolonged by one time. The galvanic effect can be avoided, and the good appearance of a printed circuit board can be ensured. The thickness of intermetallic compounds obtained after tin soldering can be lowered, and the shear strength of a welding connector and the reliability of welding points are guaranteed.

Owner:东莞市富默克化工有限公司

Organic metal shielded welding film and preparation method thereof

ActiveCN106413275AImprove the convenience of appearance visual inspectionGood tinning effectDouble resist layersNon-metallic protective coating applicationTinningVisual inspection

The invention provides an organic metal shielded welding film and a preparation method thereof. A novel surface treatment mode is an innovative process technology between an organic shielded welding film and metalized surface treatment; namely, a physical isolation protective layer is created; the protective layer is composed of a main clad layer and an organic protective layer; the main clad layer comprises silver metal and organic metal; the main clad layer is positioned on the surface of a circuit board; and the organic protective layer is positioned on the surface of the main clad layer. The organic metal shielded welding film has all performances of an OSP film, and simultaneously, has type chemical silver surface treatment performances; the preparation process is simple; the appearance visual inspection convenience is greatly improved; the tinning effect can be effectively improved; and the galvanic effect in the production process can be inhibited.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

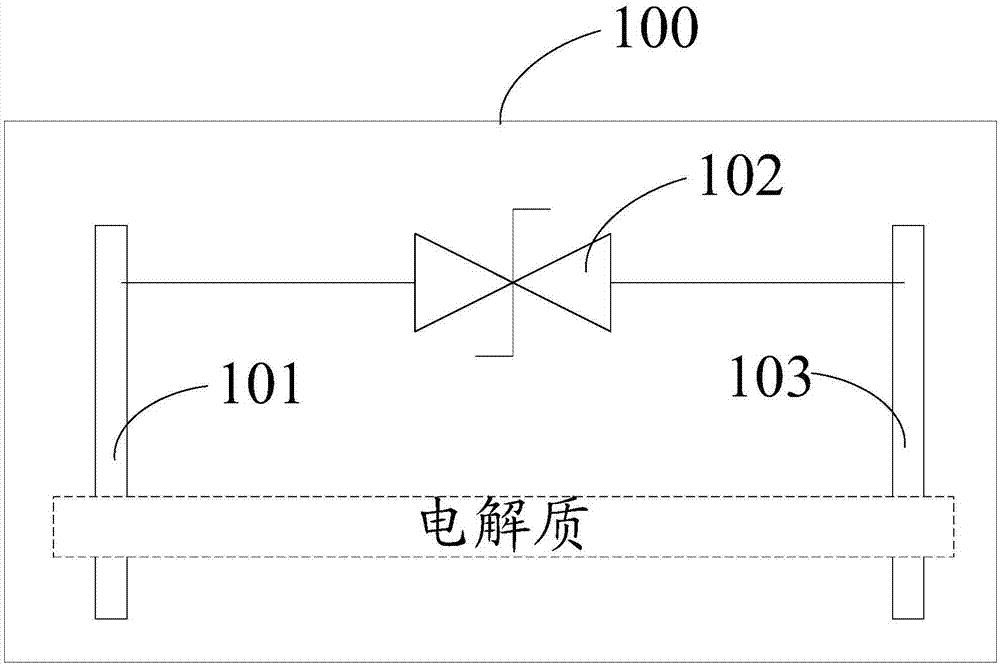

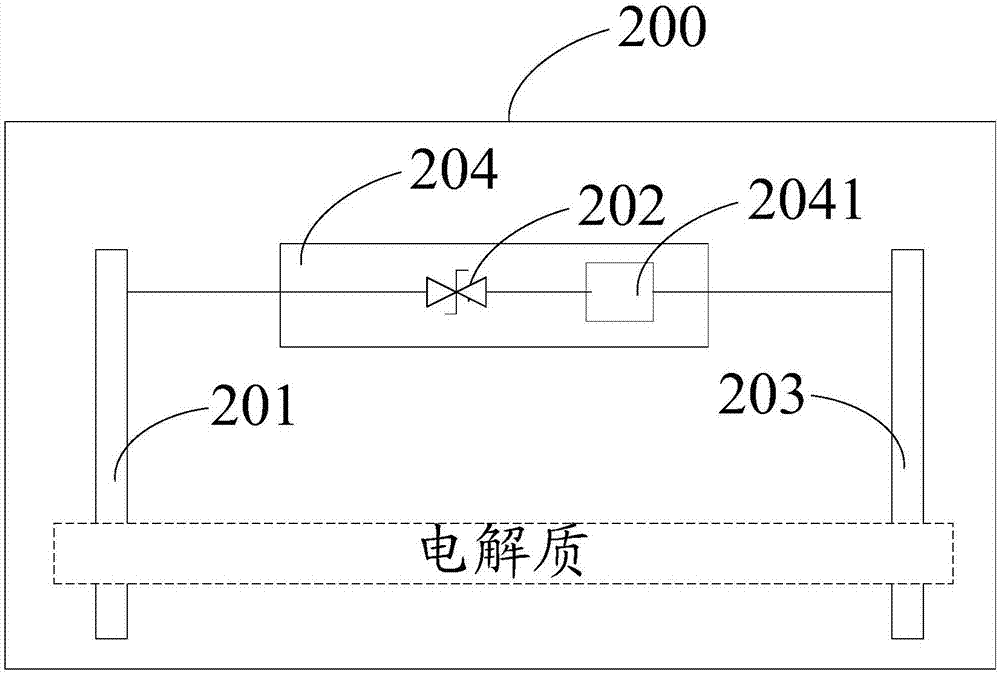

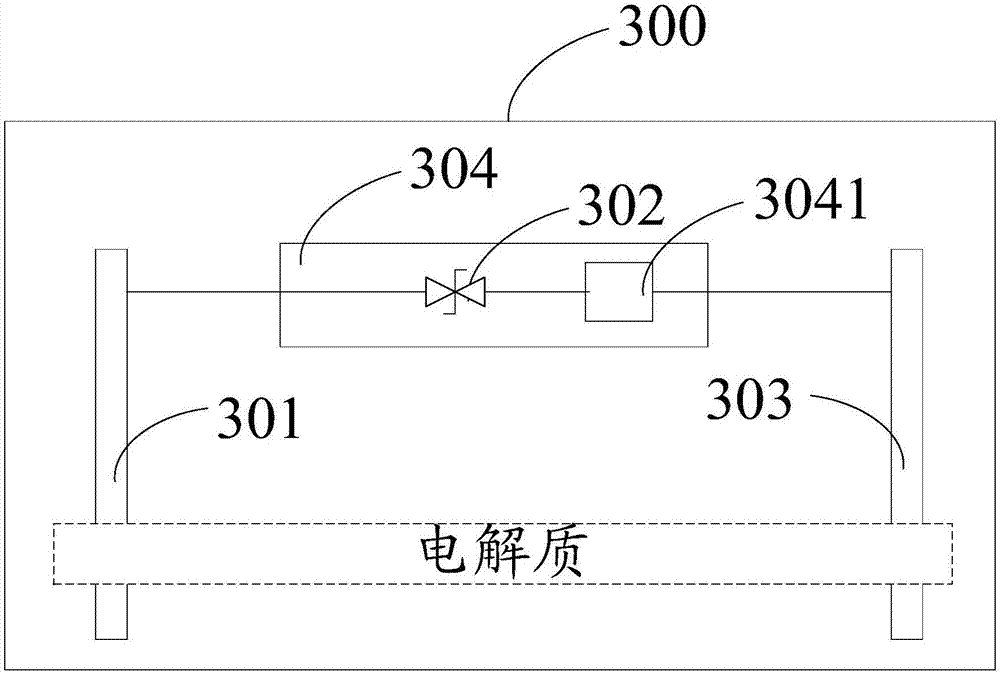

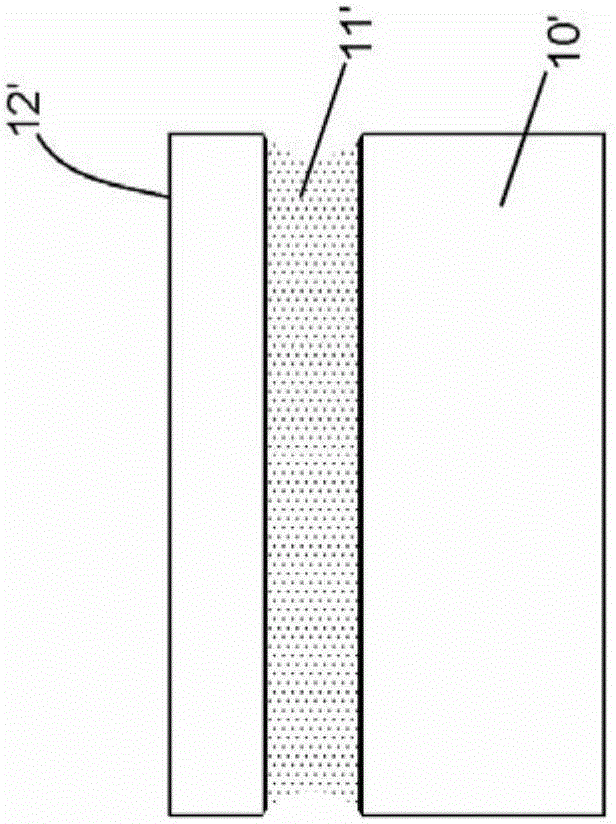

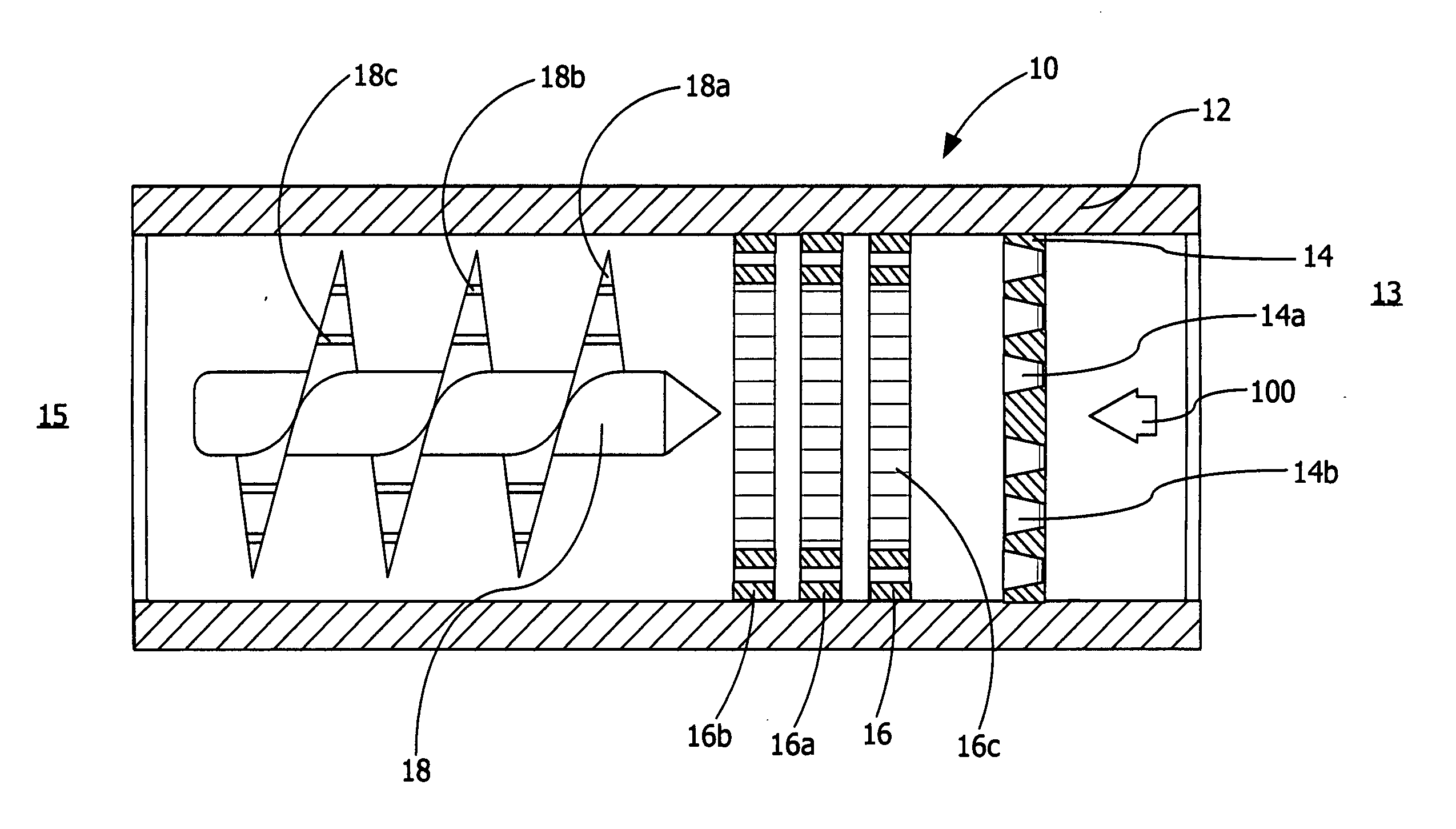

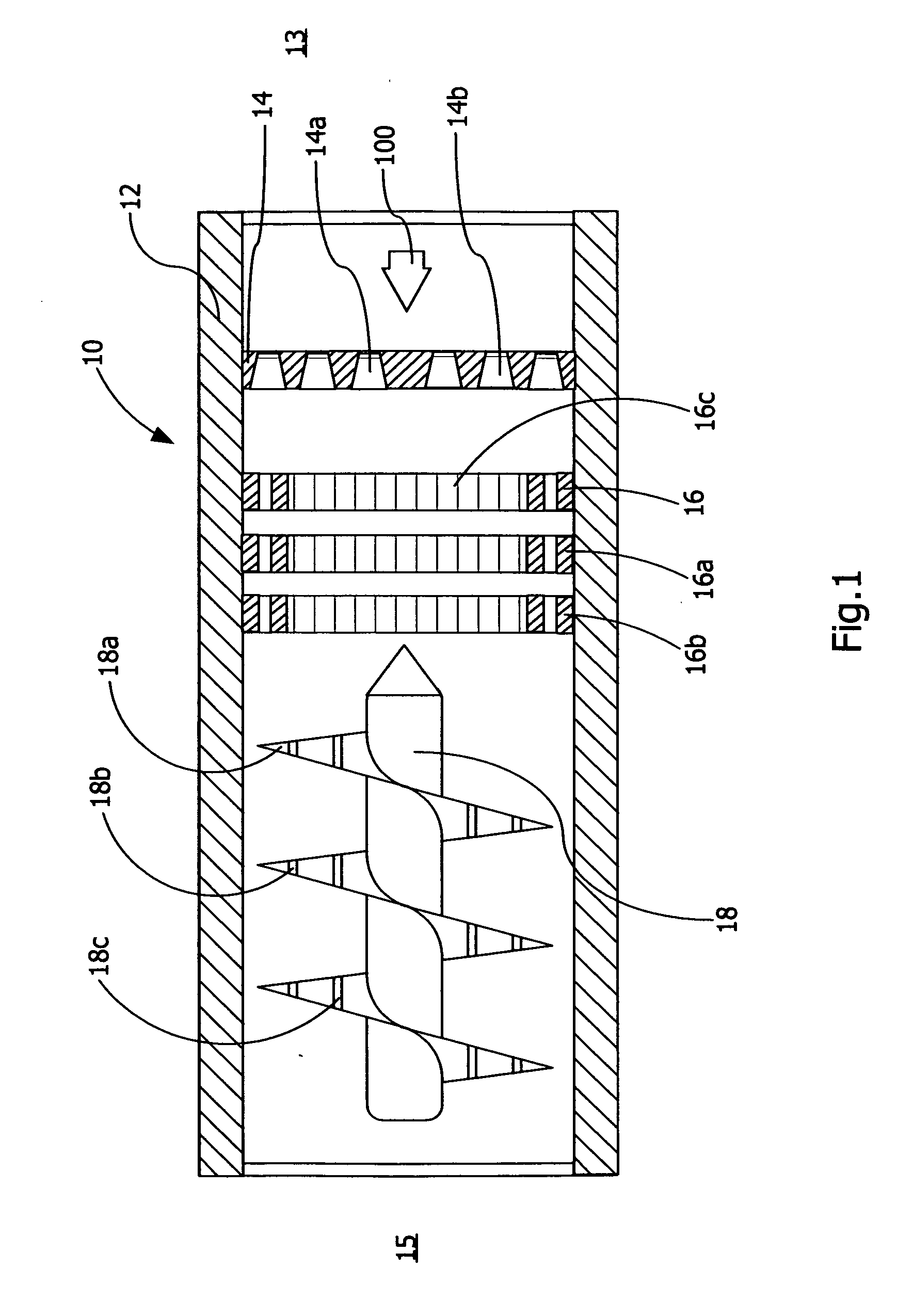

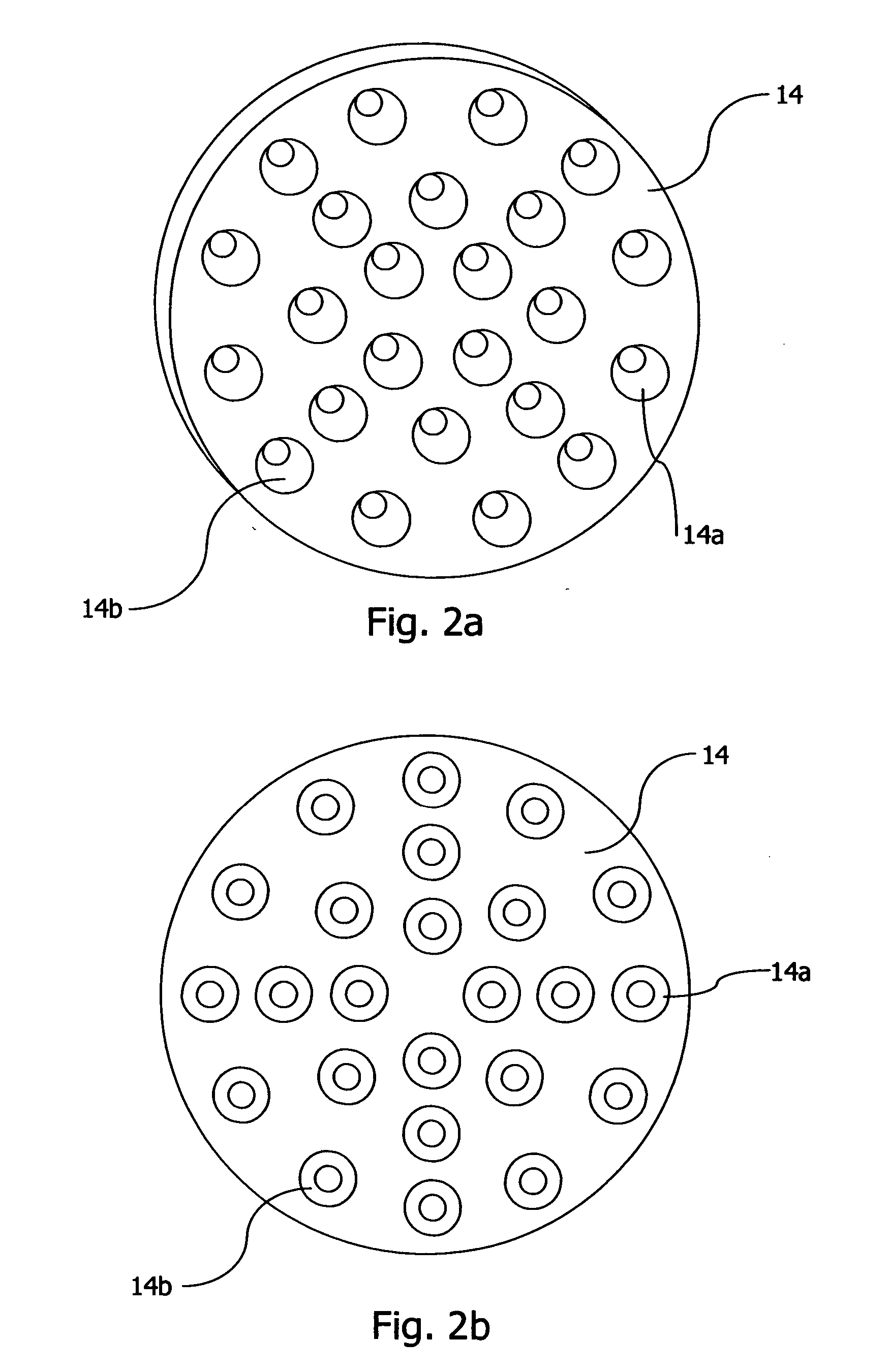

Method and apparatus for separating contaminants in fluids and gas

InactiveUS20060070963A1Easy to separatePromoting bubble formationWaste water treatment from quariesWater/sewage treatment by centrifugal separationGalvanic effectDissimilar metal

The present invention relates generally to promote separating and filtering contaminants from a mixture of water with oil and / or gas. More particularly, the present invention relates to a method and apparatus for separating contaminants within fluids and gases utilizing a galvanic effect from dissimilar metals within the apparatus.

Owner:CODY LINERS

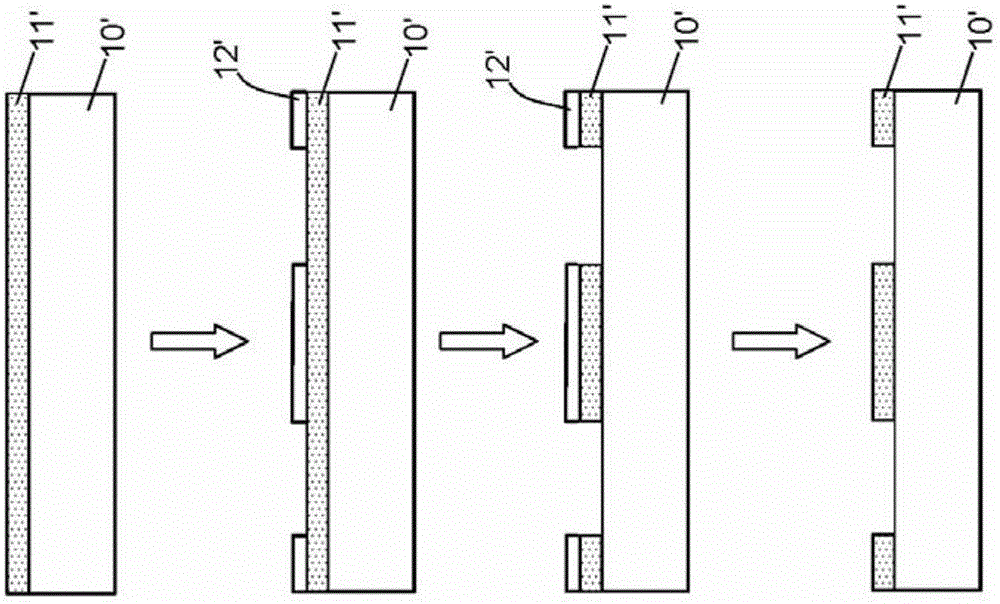

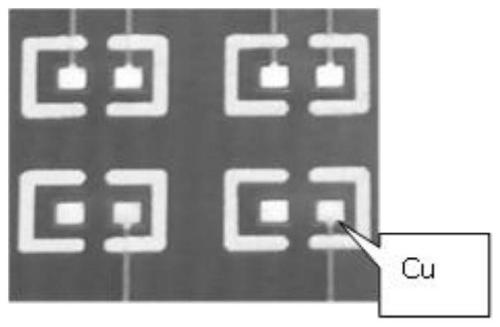

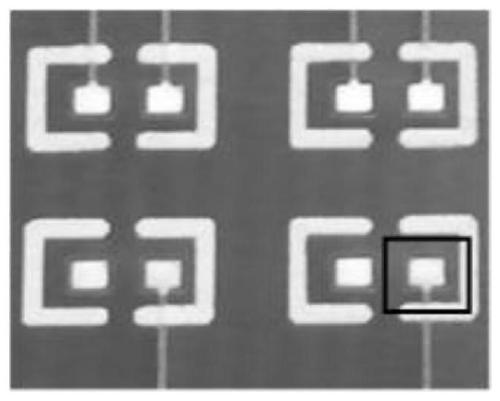

Printed-circuit board preparation method capable of avoiding galvanic effect

InactiveCN108925054AAvoid the Giavani EffectHigh precisionConductive material chemical/electrolytical removalConductive pattern reinforcementCopperPrinted circuit board

The invention discloses a printed-circuit board preparation method capable of avoiding a galvanic effect. The printed-circuit board preparation method comprises the following steps that a base plate is prepared, and specifically, the base plate is provided with a copper layer and a metal layer electrically connected with the copper layer; a film is pasted, and specifically, protective film is covered on the metal layer; exposure is carried out, and specifically, the base plate pasted with the protective film is exposed; development is carried out, specifically, development treatment is carriedout on the base plate after the completion of exposure, the protective film of unexposed areas is cleaned and removed, the copper layer is exposed, and the remaining protective film fully covers themetal layer; micro erosion or roughening treatment is carried out, and specifically, the micro erosion or roughening treatment is carried out on the base plate; and the film is removed, specifically,after the micro erosion or roughening treatment is finished, and the protective film on the metal layer is removed through the film stripping process to obtain a printed-circuit board. According to the printed-circuit board preparation method, the metal layer on the copper layer is sealed and covered through increasing dry film or wet film, and the effect of the galvanic effect in the preparationprocess is avoided.

Owner:AKM ELECTRONICS INDAL PANYU

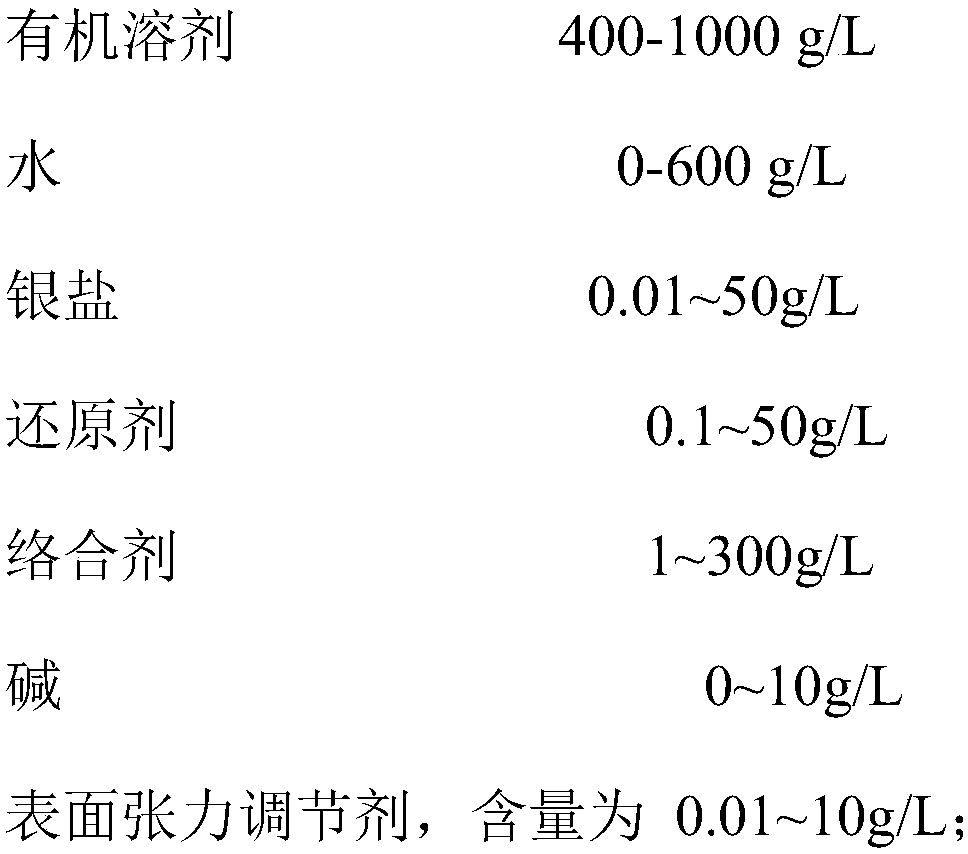

Organic chemical silvering liquid medicine

InactiveCN108251826AAvoid the "Giavanni" EffectPotions with low toxicityLiquid/solution decomposition chemical coatingOrganic solventCopper

The invention discloses organic chemical silvering liquid medicine. The organic chemical silvering liquid medicine comprises following components including 400 g / L-1,000 g / L of an organic solvent, 0 g / L-600 g / L of water, 0.01 g / L-50 g / L of silver salt, 0.1 g / L-50 g / L of a reducing agent, 1 g / L-300 g / L of a complexing agent, 0 g / L-10 g / L of alkali and 0.01 g / L-10 g / L of a surface tension adjustingagent. According to the organic chemical silvering liquid medicine, silvering does not depend on the replacement reaction mechanism, the organic chemical silvering liquid medicine can be widely applied to copper powder silvering and printed circuit board silvering, and the galvanic effect in the printed circuit board industry is avoided; the liquid medicine is low in toxicity, a plating solution can be used for a long term, replacement is not needed, and the severe environment protection problem is solved; and a clad layer is dense, corrosion resistance is good, and color changing is not likely to happen.

Owner:厦门银方新材料科技有限公司

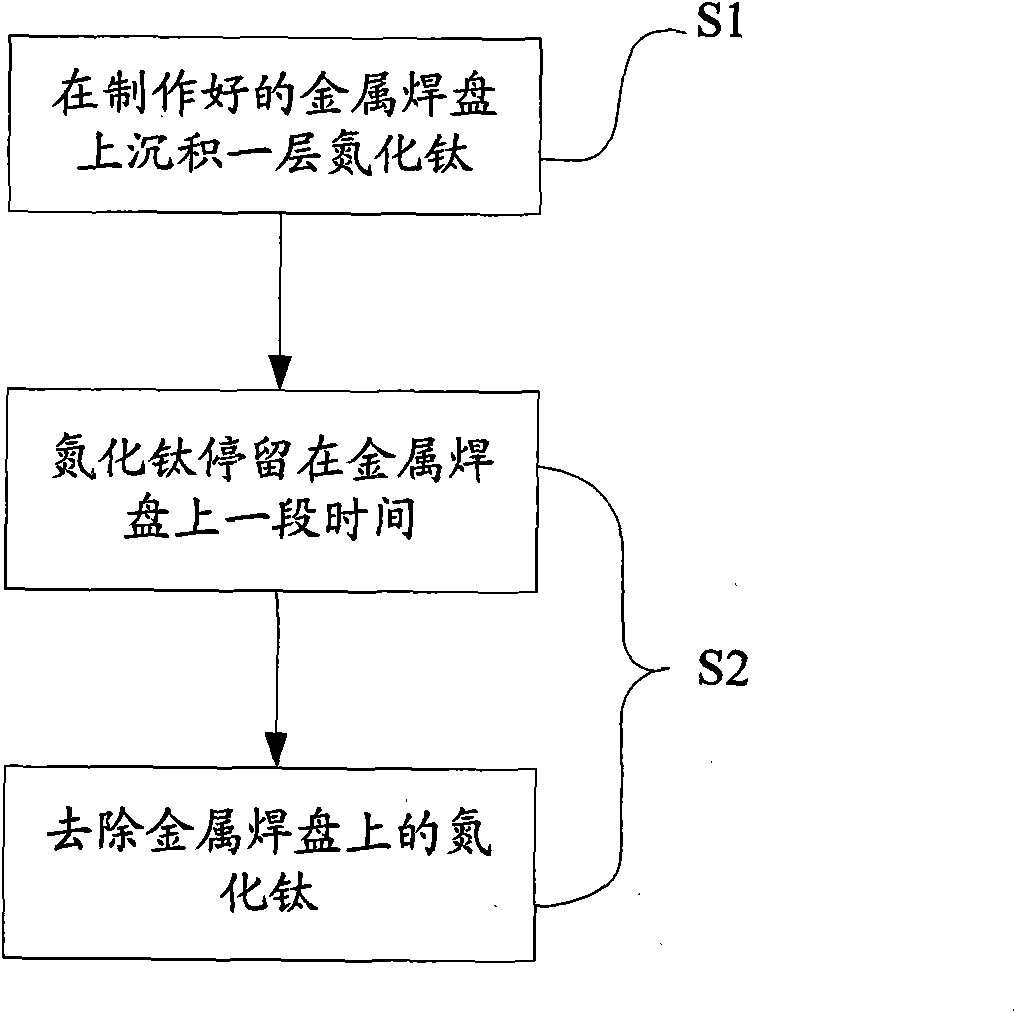

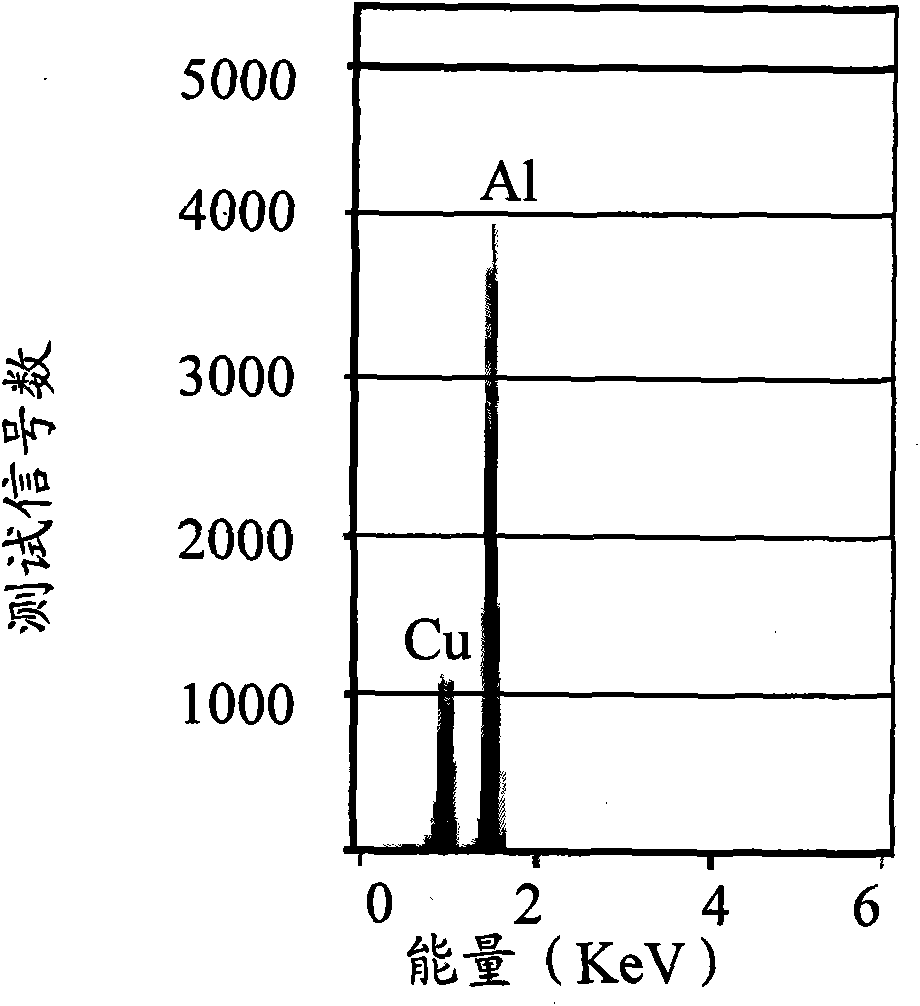

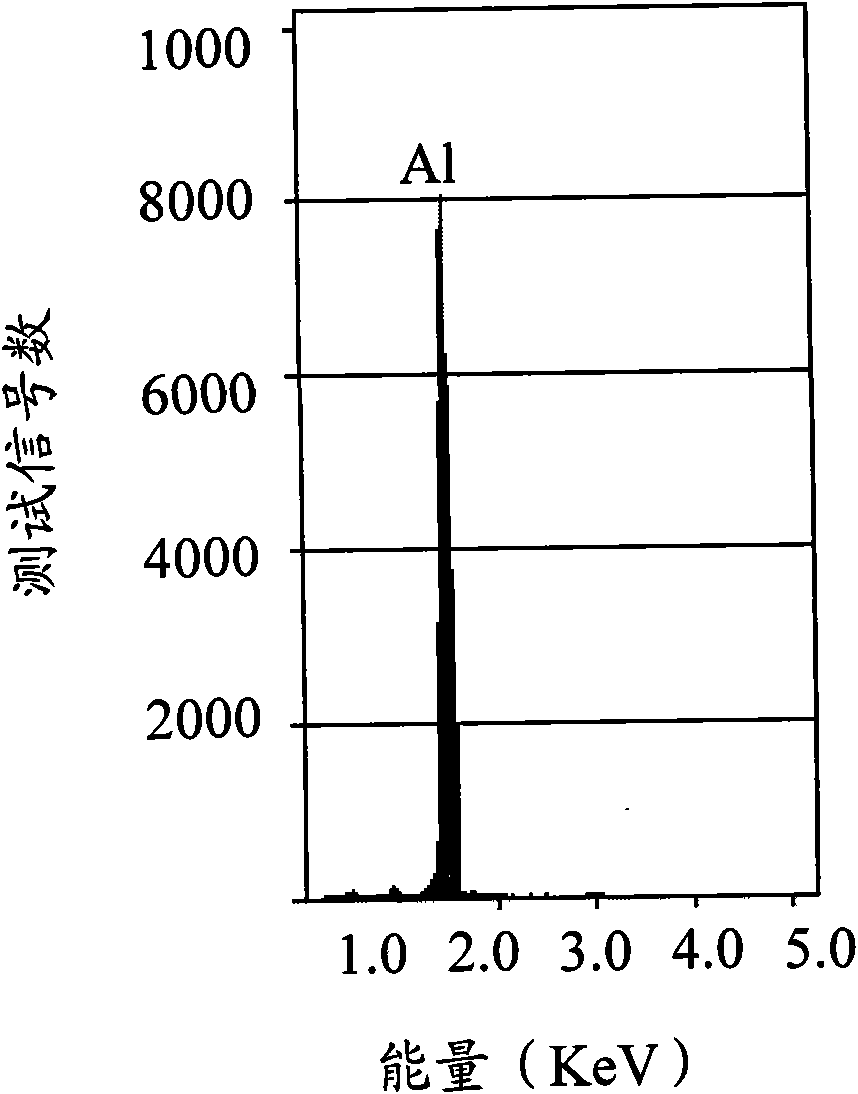

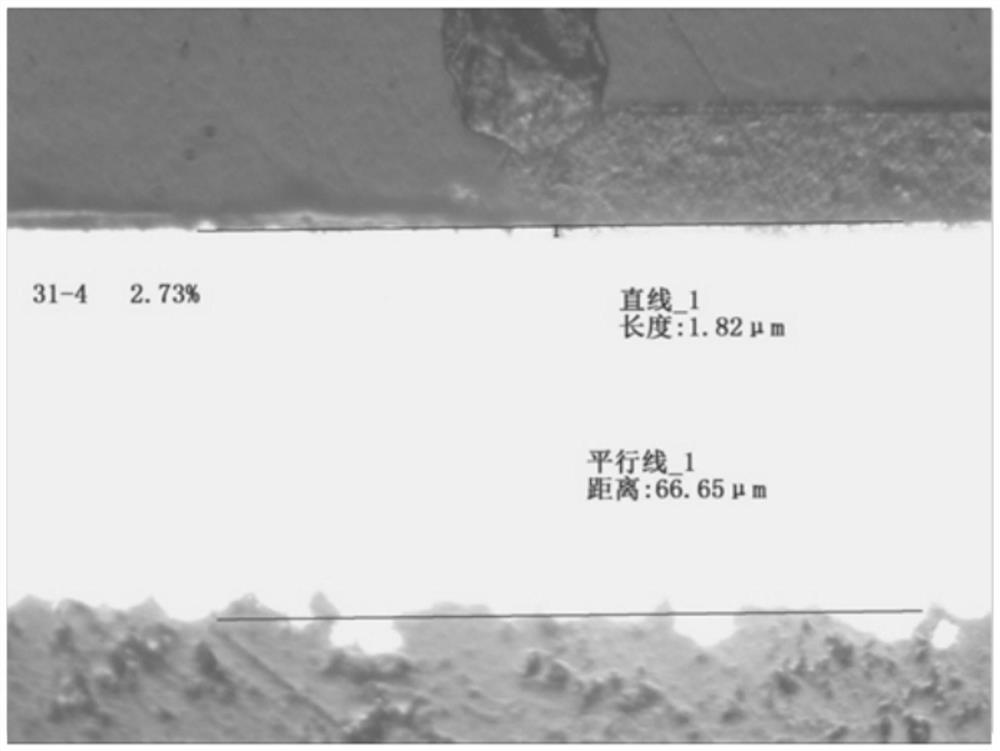

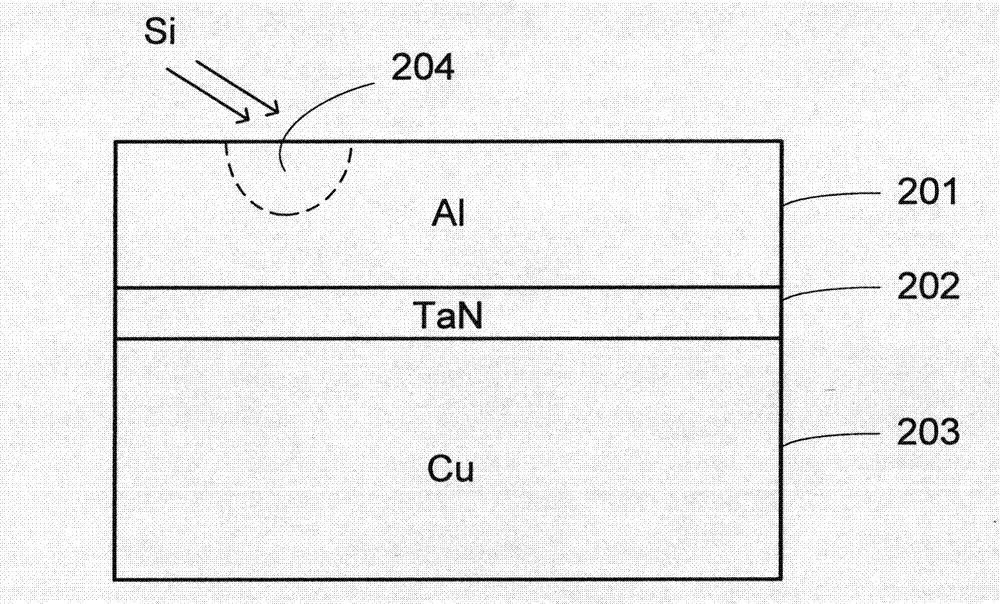

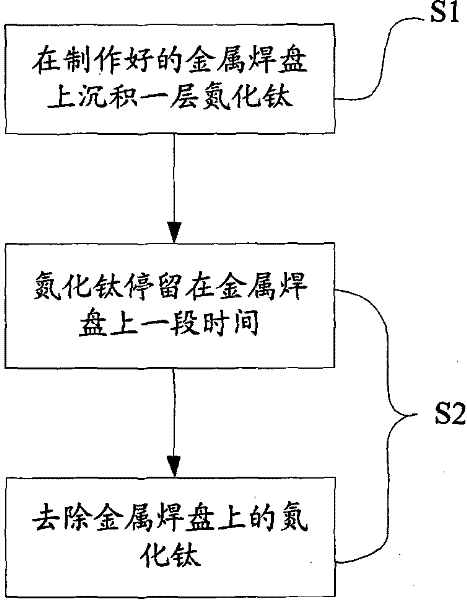

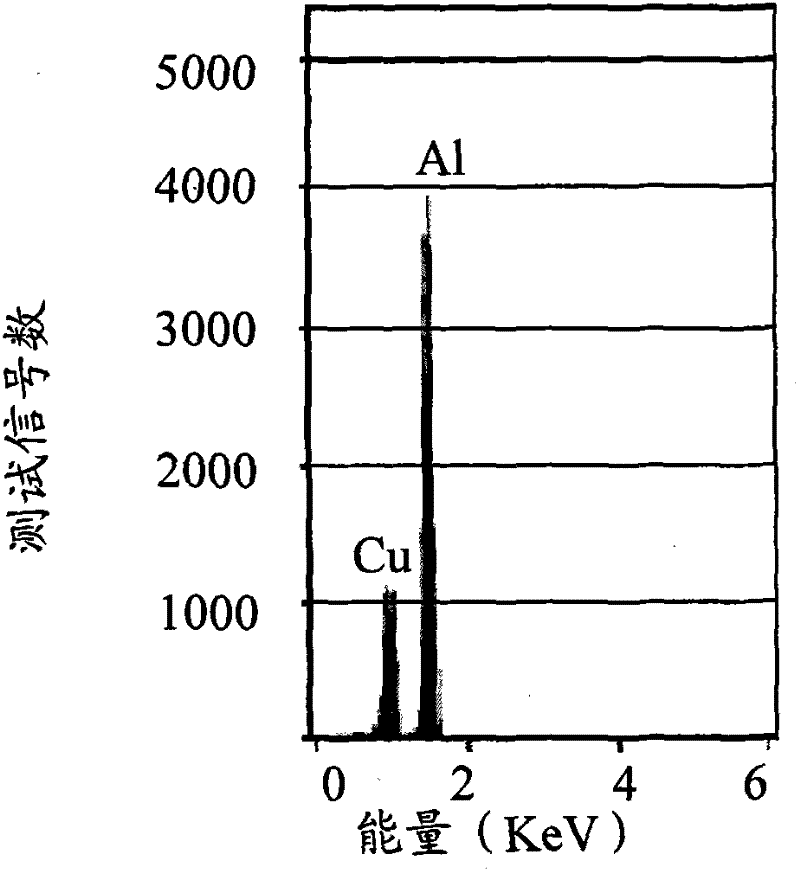

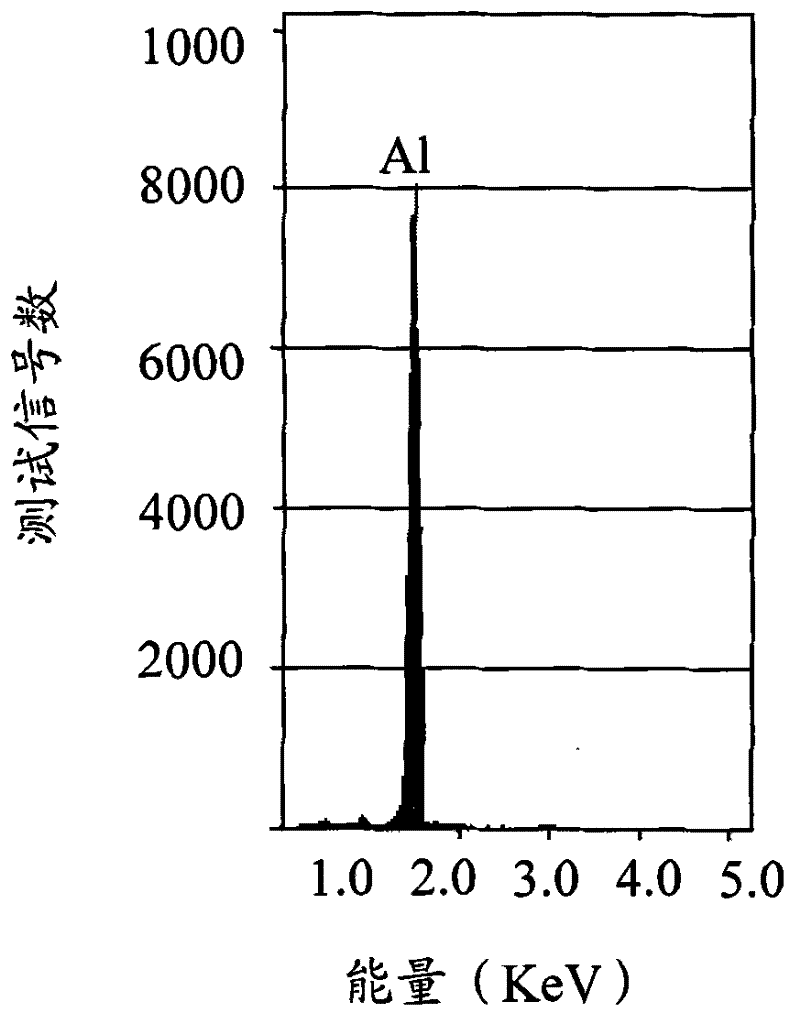

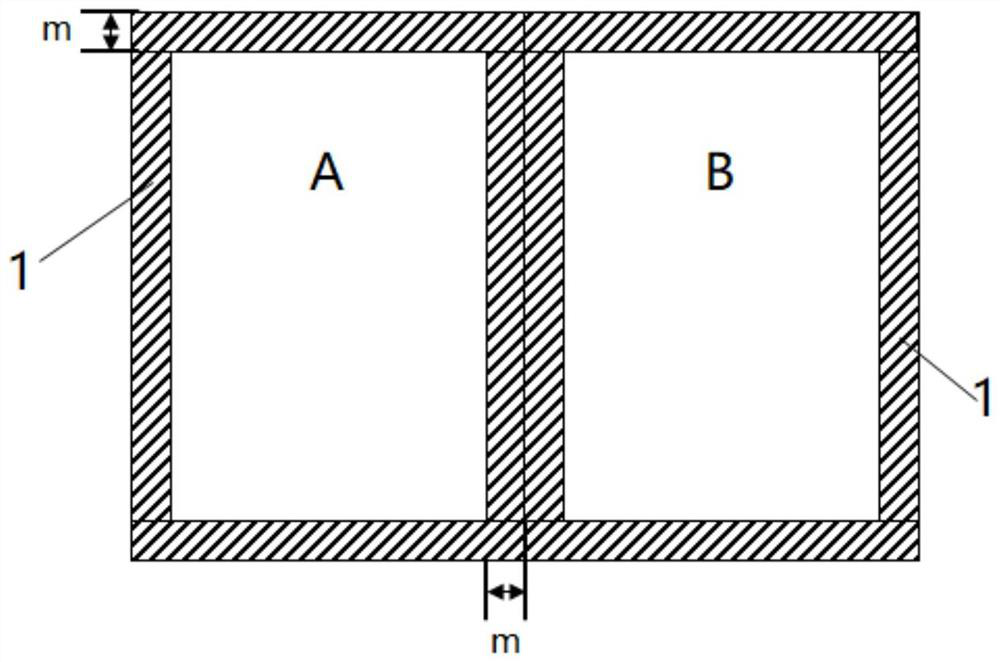

Method for inhibiting corrosion of metal pad

ActiveCN101654774AAvoid corrosionInhibition of galvanic effectChemical vapor deposition coatingFailure rateTitanium nitride

The invention provides a method for inhibiting corrosion of a metal pad. The metal pad is made from an alloy of aluminum and copper. The method is used for inhibiting the corrosion of the metal pad manufactured on a chip caused by galvanic effect in a cleaning environment. The method comprises the following steps: 1, forming a titanium nitride layer on the metal pad; and 2, after the titanium nitride layer is reserved on the metal pad for a preset time, removing the titanium nitride layer on the metal pad. A small amount of titanium nitride is spread to the metal pad by forming the titanium nitride layer and removing the titanium nitride layer to inhibit the copper in the metal pad from precipitating from a crystal boundary of the aluminum so as to inhibit the corrosion of the metal pad caused by the galvanic effect. The method for inhibiting the corrosion of the metal pad can effectively solve the problems of wire bonding failure rate increase and packaging yield reduction caused by the corrosion of the metal pad on the chip.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Purification treatment method of industrial wastewater

InactiveCN106145544AReduce pollutionAvoiding the Risks of More Hazardous ChemicalsTreatment using aerobic processesTreatment by combined electrochemical biological processesDecompositionNitration

The invention discloses a purification treatment method of industrial wastewater. Wastewater is treated sequentially through a water collecting well, a coarse bar screen, a primary sedimentation tank, a pH adjusting tank, a microbial oxidation battery-COD decomposition and power-generation device, a nitrification reaction tank, a biological nitrogen removal tank, a secondary sedimentation tank and a water purification tank. The purification treatment method creatively utilizes a characteristic that Shewanella oneidensis can oxidize and decompose organic matters to generate bio-electric energy; a microbial electrode attached with Shewanella oneidensis strain is used as a cathode, and a ruthenium dioxide electrode is used as an anode, so when sufficient oxygen exists, the Shewanella oneidensis can oxidize and decompose the organic matters in a solution through biochemical reaction and produce free electrons, carbon dioxide and water, so as to achieve the purposes of decomposing and removing the organic matters in wastewater; meanwhile, the microbial electrode and the ruthenium dioxide electrode form a galvanic effect in the solution, so that the free electrons can perform directional movement to generate available current.

Owner:涂瑞强

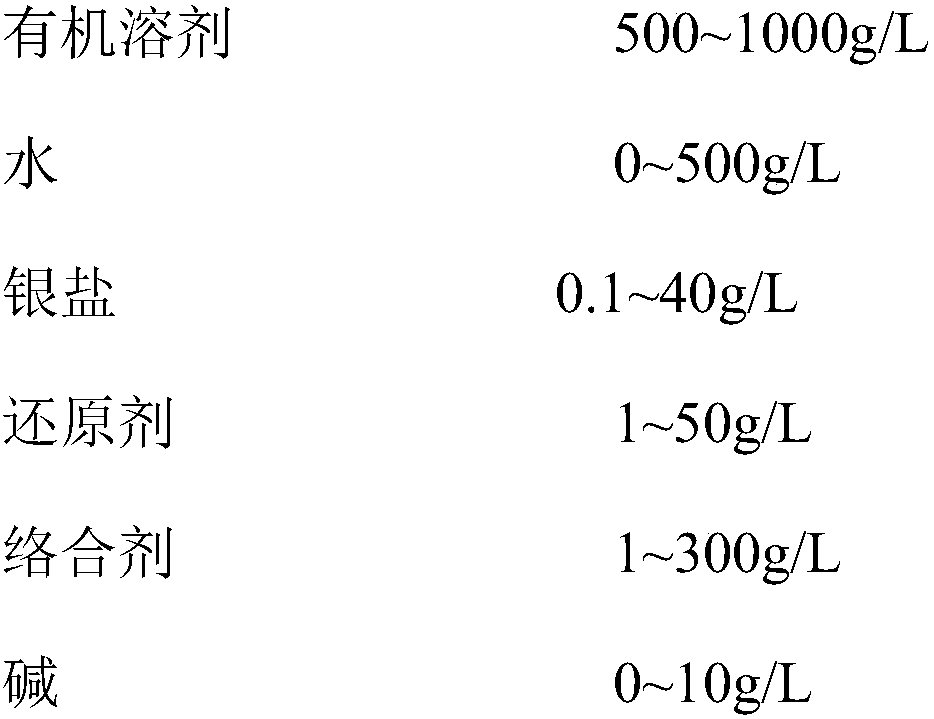

Chemical silver plating solution

PendingCN113897601AEnsure quality stabilityGuaranteed permeabilityLiquid/solution decomposition chemical coatingChemical platingSilver plate

Owner:深圳市虹喜科技发展有限公司

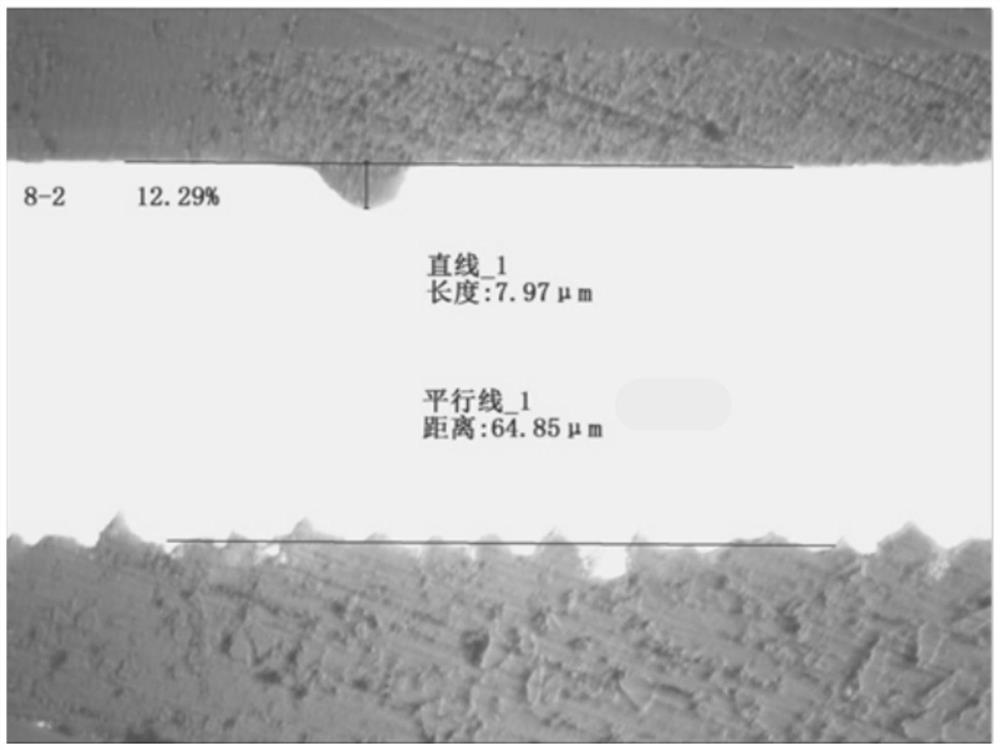

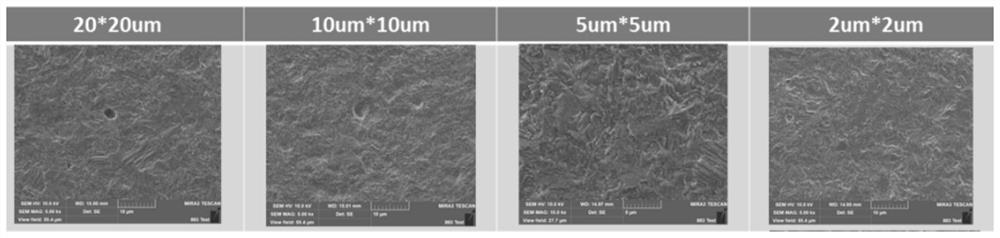

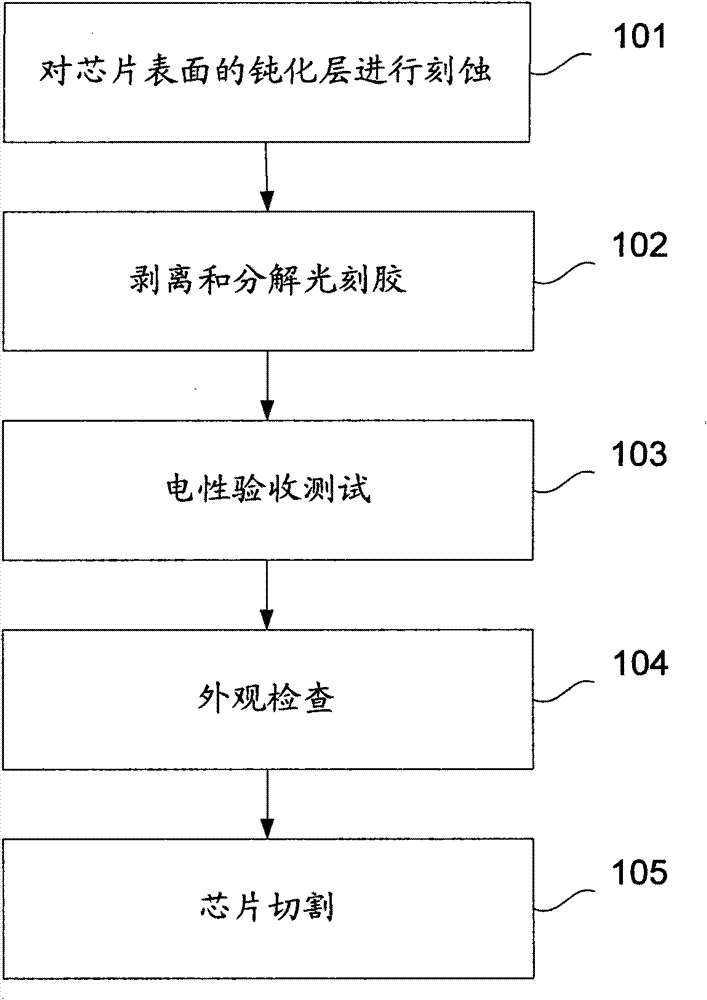

Method for improving chip cutting

ActiveCN102024752BReduce pollutionQuality improvementSolid-state devicesPhotomechanical apparatusPhotoresistSilicon

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Application of triamine-substituted phenol or triamine-substituted thiophenol and microetching treatment solution

ActiveCN107022762BPrevent the phenomenon of "hair color"Shorten speedElectrochemical responseEtching

The invention relates to micro-etching treating fluid. The micro-etching treating fluid comprises 30.0-60.0 g / L of sulfuric acid, 10.0-20.0 g / L of hydrogen peroxide, 0.1-1.0 g / L of hydrogen peroxide stabilizer, 2.0-5.0 g / L of inhibitor and 1 L of added water. The inhibitor is selected from the triamine base substituted phenol or the triamine base substituted thiophenol. The above micro-etching treating fluid is used for printed circuit board OSP pretreatment, a clean and rough copper surface can be formed, a protection film can be formed in combination with a copper face in the micro-etching process, the copper face electron supplying speed during the copper-gold electrochemical reaction is reduced, accordingly the potential difference between the copper and the gold is reduced, the biting corrosion rate of a copper welding pad is reduced, generation of the galvanic effect is restrained to the maximum degree, the phenomena of the color difference, area reduction or line excessive corrosion or even biting off cannot happen to the copper face connected with the gold face and obtained after micro-etching treatment, and meanwhile the phenomenon of coloring after OSP treatment can be effectively prevented from happening to the copper surface.

Owner:GUANGDONG GUANGHUA SCI TECH +1

A kind of organometallic solder protection film and preparation method thereof

ActiveCN106413275BImprove the convenience of appearance visual inspectionGood tinning effectDouble resist layersNon-metallic protective coating applicationTinningVisual inspection

The invention provides an organic metal solder protection film and its preparation method. The new surface treatment method is an innovative process technology between organic solder protection film and metallized surface treatment, that is, to create a layer of physical isolation protection layer , the protective layer is composed of a main plating layer and an organic protective layer, the main plating layer includes silver metal and organic metal, the main plating layer is located on the surface of the circuit board, and the organic protective layer is located on the surface of the main plating layer. This organometallic solder protection film not only has all the properties of OSP film, but also has the surface treatment performance of type chemical silver. Giovanni effect.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

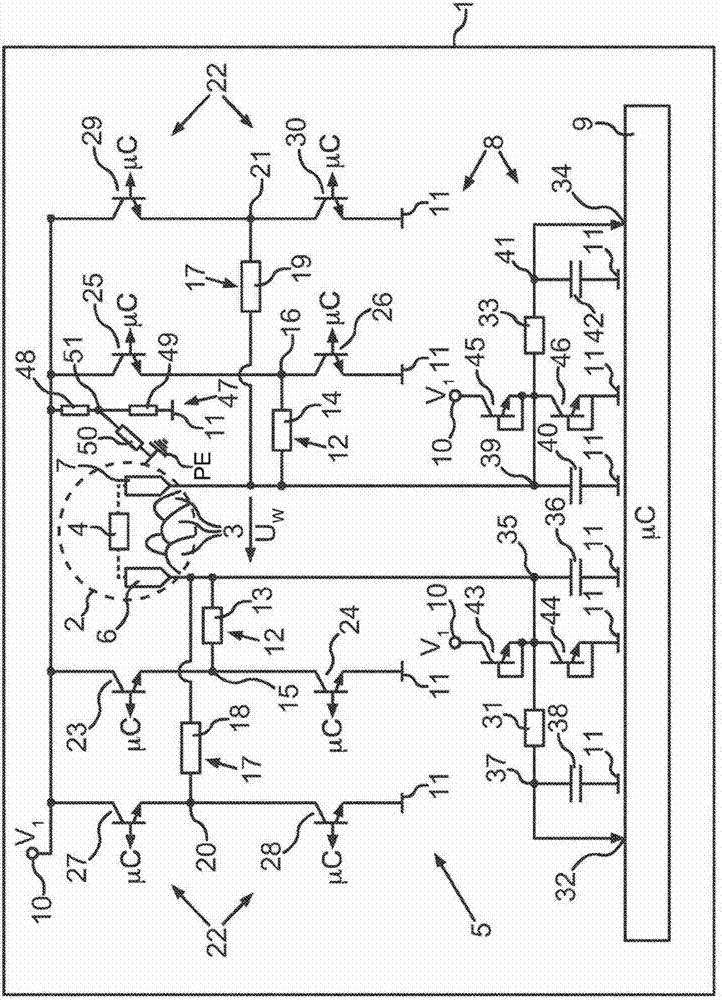

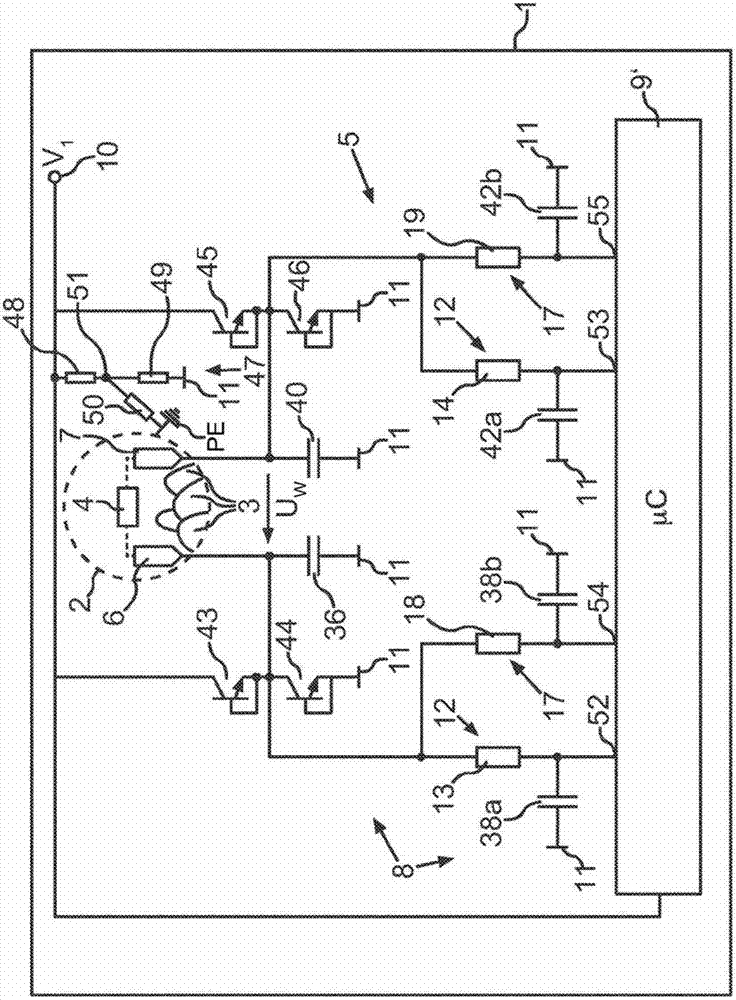

Household appliance for drying laundry items and method for determining a measurement variable correlated to a level of dryness

Owner:BOSCH SIEMENS HAUSGERATE GMBH

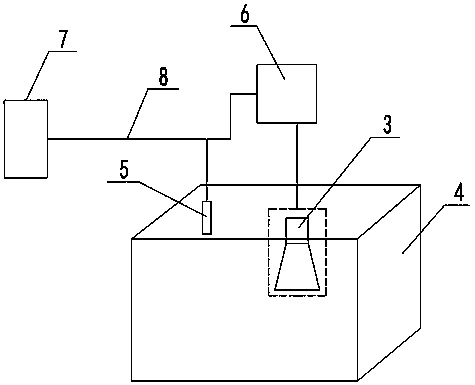

PCB ultrasonic wave silver melting tank and silver melting method thereof

PendingCN110324977AQuality improvementEffective penetrationPrinted circuit manufactureMelting tankChemical reaction

The invention discloses a PCB ultrasonic wave silver melting tank. The PCB ultrasonic wave silver melting tank comprises a silver melting tank body, wherein a row of rollers are arranged in the silvermelting tank body, and a plurality of water knives are arranged on the silver melting tank body at the positions of two sides of the rollers; the silver melting tank body is internally provided witha plurality of ultrasonic generators, the ultrasonic generators are positioned on two sides of the rollers, the ultrasonic generators are connected with an ultrasonic host through signal wires, and the ultrasonic host is connected with the main control panel through a lead. By utilizing the cooperation of the ultrasonic waves and the water knives, liquid medicine can effectually penetrate slight gaps and apertures on the PCB to perform effective chemical reaction and perform heavy silver operation so as to effectively reduce and improve the Galvanic effect and improve the quality of PCB.

Owner:BRAIN POWER (QING YUAN) CO LTD

A kind of integrated circuit board metal surface protective agent

ActiveCN103993301BAchieve one-time protectionDoes not affect appearanceMetallic material coating processesO-Phosphoric AcidSilanes

The present invention relates to an integrated circuit board metal surface protection agent. More specifically the present invention discloses a composition for protecting the double metal surface or the alloy surface, wherein the composition contains 1 part by weight of a first component, 0-50 parts by weight of a second component, and 0.01-40 parts by weight of a synergist, the first component is selected from a compound having a mercapto functional group, each molecule of the compound has more than 6 carbon atoms, the second component is selected from alkyl phosphoric acid, alkyl phosphate, a derivative of alkyl phosphate, an oleic acid imidazoline compound, a derivative of an oleic acid imidazoline compound, organic silane, fatty acid and a derivative thereof, and the synergist is selected from alpha-cyclodextrin and a derivative thereof, beta-cyclodextrin and a derivative thereof, and gamma-cyclodextrin and a derivative thereof. The composition has the excellent metal surface protection function, and particularly can be used for preventing deposition of one metal onto the other metal due to the Galvanic effect during the integrated circuit board electroplating process.

Owner:SHANGHAI TECHN INST OF ELECTRONICS & INFORMATION

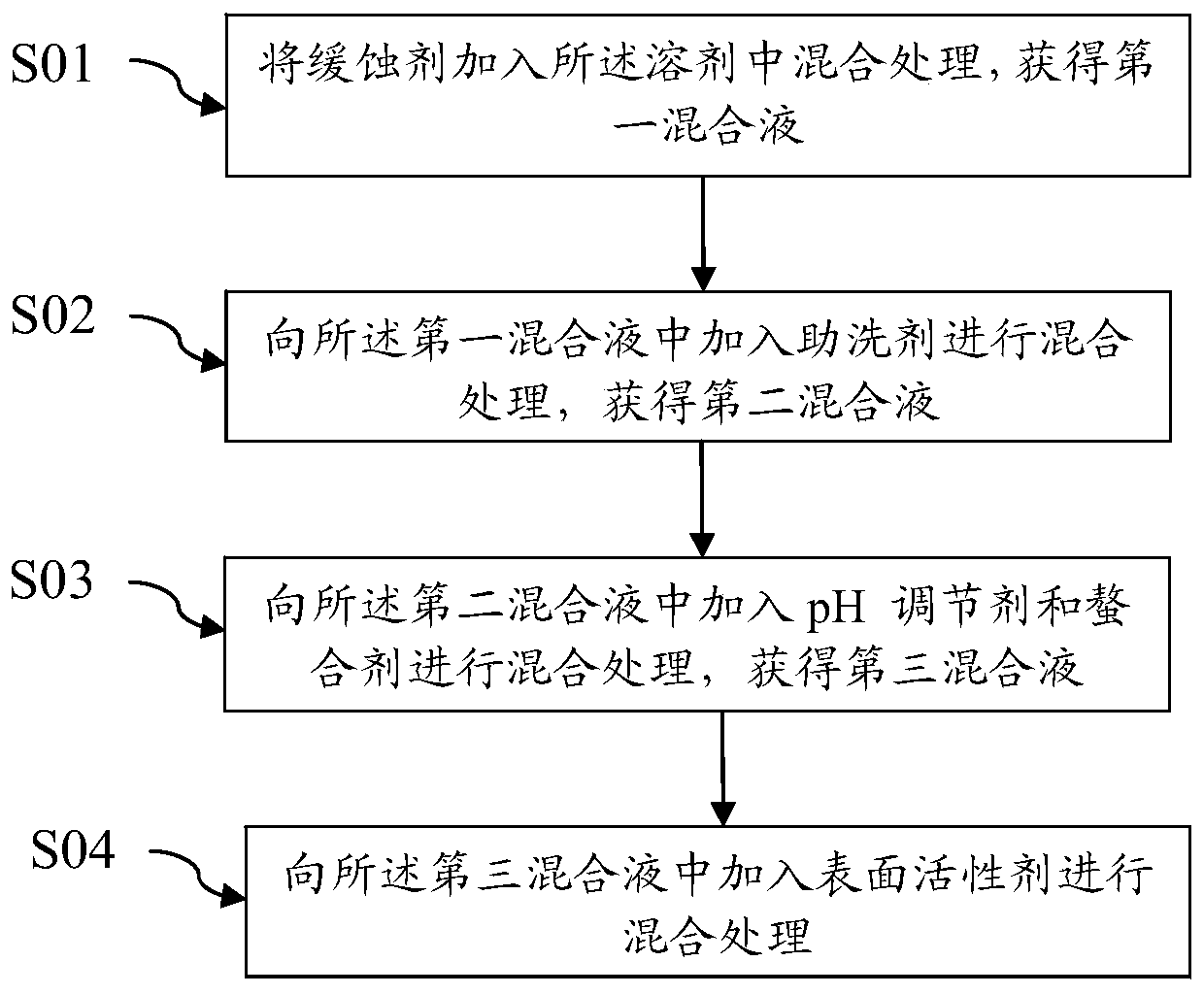

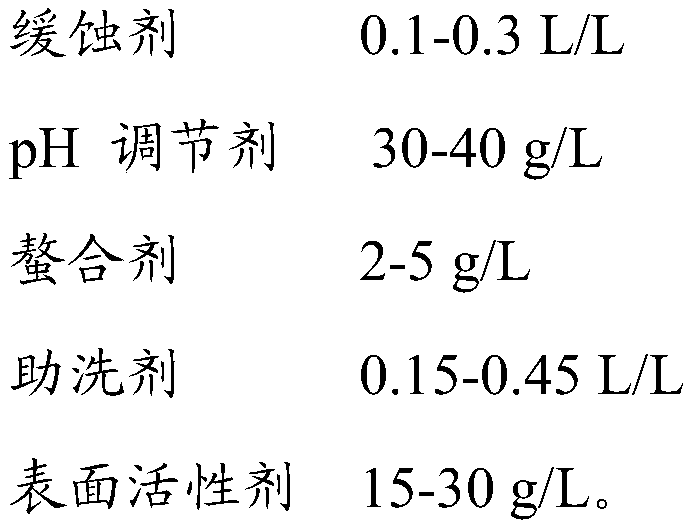

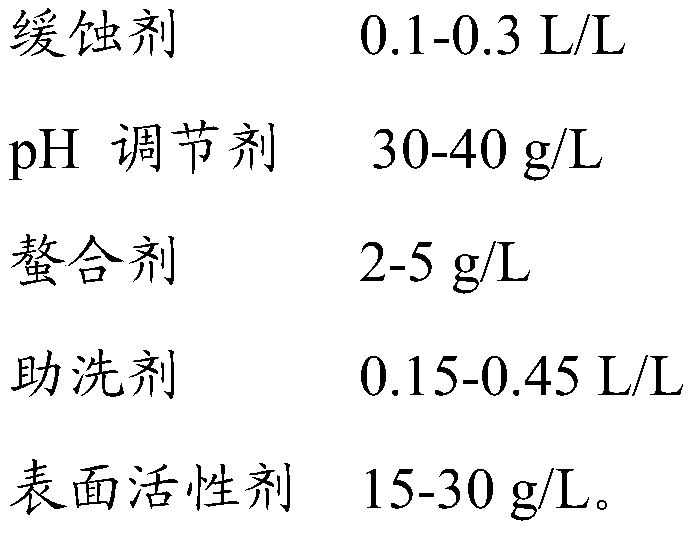

Sealing agent and its preparation method and application

InactiveCN110167281BEffective osmotic exchange cleaningEfficient removalLiquid/solution decomposition chemical coatingNon-metallic protective coating applicationActive agentSolvent

The invention discloses a hole sealing agent and a preparation method and application thereof. The hole sealing agent disclosed by the invention comprises a solvent and further comprises the followingcomponents in concentration: 0.1-0.3L / L of a corrosion inhibitor, 30-40g / L of a pH regulator, 2-5g / L of a chelating agent, 0.15-0.5g / L of a builder, and 5-30g / L of a surfactant. The hole sealing agent disclosed by the invention can be used for effectively carrying out permeation exchange cleaning on a plating layer to realize an effective cleaning effect on the plating layer; and the hole sealingagent can form a film with the surface of the plating layer and reinforce the formed film layer, so that the corrosion resistance and the corrosion resistance of the plating layer are improved, and the galvanic effect of the plating layer is effectively reduced or avoided. The preparation method of the hole sealing agent is easy in control of process conditions and high in efficiency. The hole sealing agent can be applied to the fields of PCBs (Printed Circuit Boards) such as gold plating plates, so that the corrosion resistance and the corrosion resistance of the plating layers of the PCBs such as the gold plating plates are improved, the galvanic effect of the plating layers is reduced or avoided, and the zero-scrap production of the PCB such as the gold plating plates is realized.

Owner:ZHUHAI CHINA EAGLE ELECTRONIC CIRCTCUIS CO LTD +1

Wafer bump and manufacturing method of wafer bump

InactiveCN111384016AImprove antioxidant capacityPrevent oxidationSemiconductor/solid-state device detailsSolid-state devicesWaferPotential difference

The invention provides a wafer bump and a manufacturing method of the wafer bump. The wafer bump comprises a semiconductor substrate located at the bottom, a circuit layer located on the semiconductorsubstrate, a first metal layer and a second metal layer; wherein the first metal layer and the second metal layer are located above the circuit layer; the first metal layer is located between the second metal layer and the circuit layer, the wafer bump further comprises a first photoresist arranged around the side surface of the first metal layer and an isolation layer located between the first metal layer and the circuit layer, and the height of the first photoresist is not lower than that of the first metal layer. The wafer bump can prevent the first metal layer from being oxidized. The manufacturing method of the wafer bump is simple in process, the manufactured wafer bump is high in oxidation resistance, and the galvanic effect caused by the potential difference between the two kindsof metal can be resisted.

Owner:CHIPMORE TECH CORP LTD

Method for inhibiting corrosion of metal pad

ActiveCN101654774BAvoid corrosionInhibition of galvanic effectChemical vapor deposition coatingFailure rateTitanium nitride

Owner:SEMICON MFG INT (SHANGHAI) CORP

Valve body manufacturing method

A method for manufacturing a valve body, comprising the following steps: 1) Melting copper in a closed environment, adding carbon and mixing them thoroughly; 2) injecting the material in step 1 into a mold cavity under pressure to form a "convex" shape Valve body; 3) Slowly cool down the workpiece in step 2 and take it out; 4) Electroplate the workpiece in step 3; 5) Grind the inner wall of the workpiece in step 4; 6) Turn both ends of the workpiece in step 5 out thread. The invention adopts the method of adding carbon to improve the wear resistance of the inner surface of the valve body, slow down the corrosion of the copper valve body, and avoid the generation of the original battery effect.

Owner:慈溪市华盛低压电器厂

A Method for Evaluation of Galvanic Corrosion Under Thin Liquid Film

ActiveCN113533187BTruly reflect the galvanic effectSimple methodWeather/light/corrosion resistanceSaline mistSalt spray test

The invention discloses a method for evaluating galvanic corrosion under a thin liquid film, which comprises the following steps: (1) preparing a lap joint sample; (2) preparing a control sample; (3) salt spray test; (4) evaluating corrosion , the test sample A, the test sample B, and the control sample A were determined. 0 , control sample B 0 The respective average corrosion depths, respectively Z tst‑A ,Z tst‑B ,Z ref‑A ,Z ref‑B , according to the statistical t test to judge Z tst‑A Is it significantly different from Z ref‑A ,Z tst‑B Is it significantly different from Z ref‑B , if Z tst‑A Significantly different from Z ref‑A And Z tst‑B Significantly different from Z ref‑B , then calculate the respective galvanic effect values of material A and material B. The invention uses the corrosion depth data to quantify the description of the corrosion degree, can more accurately evaluate the galvanic effect between different metals, and is convenient for objective comparison.

Owner:DONGFENG MOTOR GRP

an osp presoaker

InactiveCN105081614BShort duration of actionFast film formationWelding/cutting media/materialsSoldering mediaMetal contaminationOrganic solderability preservative

The invention relates to the technical field of printed circuit board shielded welding, in particular to an OSP (organic solderability preservative) preimpregnation agent. The OSP preimpregnation agent comprises 30 g / L-50 g / L of cyclic ketone compound, 1 g / L-5 g / L of amine compound and the balance water. According to the OSP preimpregnation agent, an active layer can be firstly formed on a copper surface, the forming speed of an organic solderability preservative film is increased, and the thickness of the organic solderability preservative film can be increased by more than 20% within the same reaction time. The OSP preimpregnation agent is alkaline preimpregnation treating agent liquid medicine with a higher pH value, corrosion to the copper surface can be reduced, the metal contamination speed of tank liquor is lowered, and the service life of the copper surface can be prolonged by one time. The galvanic effect can be avoided, and the good appearance of a printed circuit board can be ensured. The thickness of intermetallic compounds obtained after tin soldering can be lowered, and the shear strength of a welding connector and the reliability of welding points are guaranteed.

Owner:东莞市富默克化工有限公司

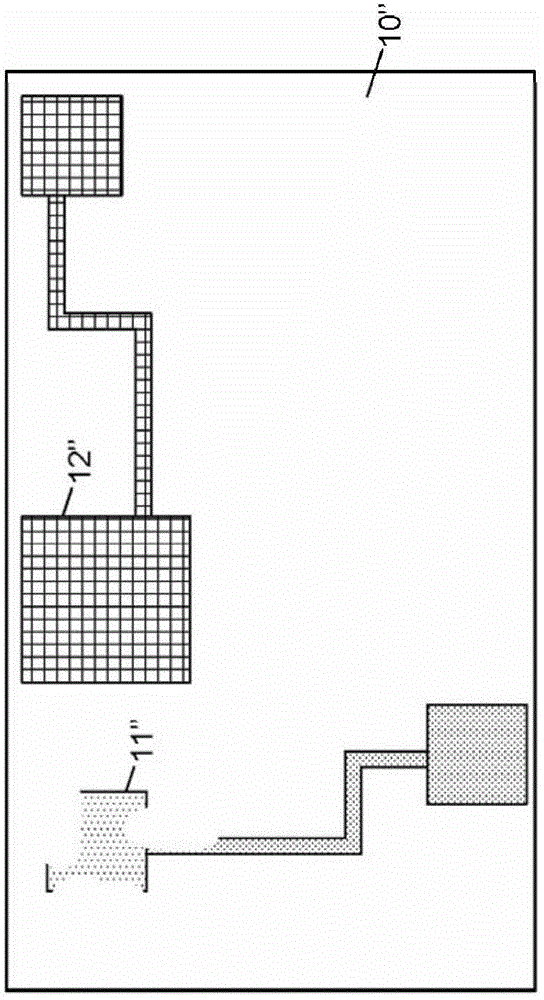

Circuit board processing method capable of reducing galvanic effect

PendingCN111935907ASmall side erosionPrevent side erosionLithography/patterningSolder maskProcess engineering

The invention provides a circuit board processing method capable of reducing galvanic effect. The circuit board processing method comprises the following steps of solder resist ink bottoming, exposure, primary development, solder mask, secondary development, primary curing, quick pressing, secondary curing and surface treatment. The time of the primary curing is 5 to 15min; and the time of the secondary curing is 45 to 85 minutes. According to the invention, the galvanic effect can be effectively avoided, the production quality is improved, the rejection rate is obviously reduced, and the yield is improved.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH

Method for evaluating galvanic corrosion under thin liquid film

ActiveCN113533187ATruly reflect the galvanic effectSimple methodWeather/light/corrosion resistanceSaline mistSalt spray test

The invention discloses a method for evaluating galvanic corrosion under a thin liquid film. The method comprises the following steps: (1) preparing a lap joint sample; (2) preparing a control sample; (3) carrying out a salt spray test; (4) carrying out corrosion evaluation, namely measuring the average corrosion depths of the to-be-tested sample A, the to-be-tested sample B, the control sample A0 and the control sample B0, namely Ztst-A, Ztst-B, Zref-A and Zref-B, detecting and judging whether the Ztst-A is obviously different from the Zref-A and the Ztst-B is obviously different from the Zref-B according to statistics t, and if the Ztst-A is obviously different from the Zref-A and the Ztst-B is obviously different from the Zref-B, calculating respective galvanic effect values of the material A and the material B. According to the method, the description of the corrosion degree is quantified by using the corrosion depth data, the galvanic couple effect between different metals can be evaluated more accurately, and objective comparison is facilitated.

Owner:DONGFENG MOTOR GRP

Copper and copper alloy surface conditioning agent

ActiveCN101575704BHigh temperature packageGood lookingMetallic material coating processesOrganic filmHalogen

The invention belongs to the technical field of surface treatment of metallic materials, and in particular relates to a copper and copper alloy surface conditioning agent. The aqueous solution of the copper and copper alloy surface conditioning agent comprises 0.02 to 5.0 weight percent of Purine compounds, 0.1 to 10.0 weight percent of inorganic base and 0.01 to 1.0 weight percent of halogen compounds. The copper and copper alloy surface conditioning agent uses the Purine compounds with high melting point to replace benzimidazoles compounds with low melting point used in the prior art; a printed circuit board treated by the copper and copper alloy surface conditioning agent can endure high-temperature encapsulation more and adapt to the surface mounting technology (SMT) for times, Galvanic effect is not easy to cause, and good appearance of the printed circuit board can be guaranteed; and the forming rate of an organic film on the surface of copper or copper alloy can be accelerated,and deposit is difficult to be generated and pollutes liquid medicines, so that the service life of the liquid medicines is prolonged.

Owner:林原标

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com