Method for producing package substrate

A technology for encapsulating substrates and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the Giavani effect and achieve the effect of protecting the metallization layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

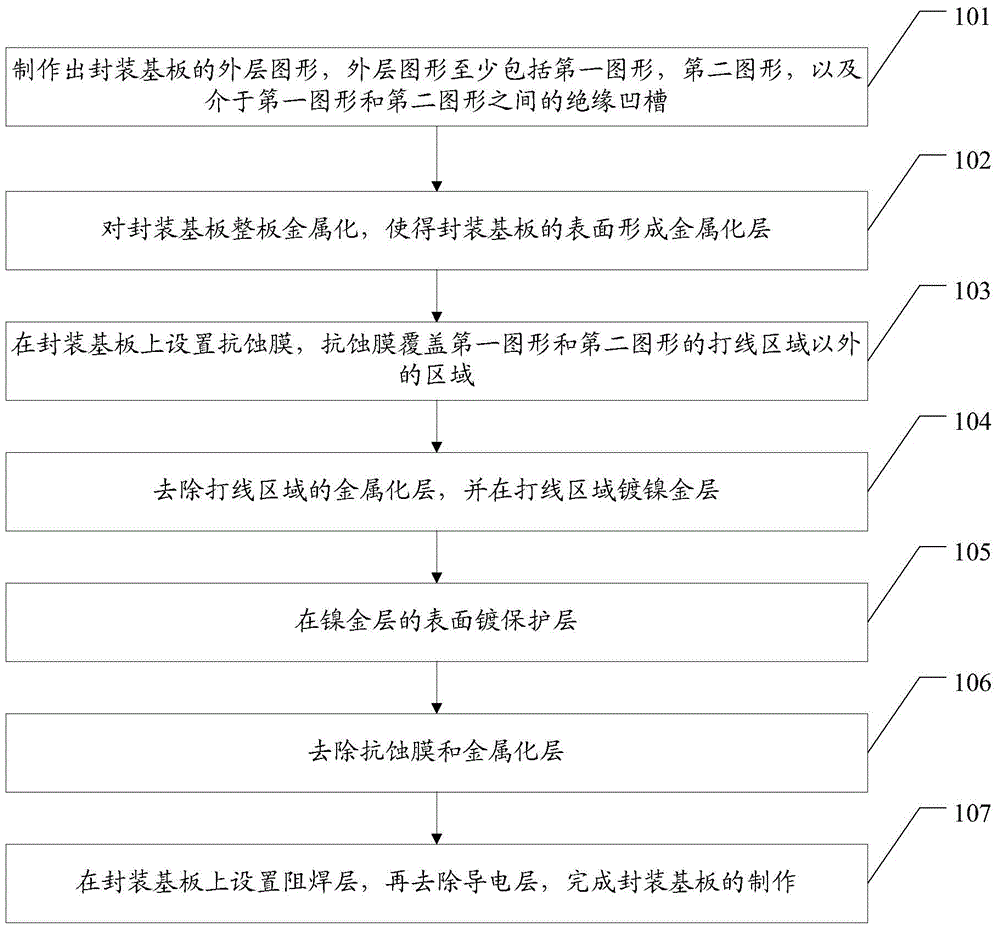

[0024] Please refer to figure 1 , an embodiment of the present invention provides a method for manufacturing a packaging substrate, which may include:

[0025] 101. Fabricate the outer pattern of the packaging substrate, the outer pattern at least includes a first pattern, a second pattern, and an insulating groove between the first pattern and the second pattern;

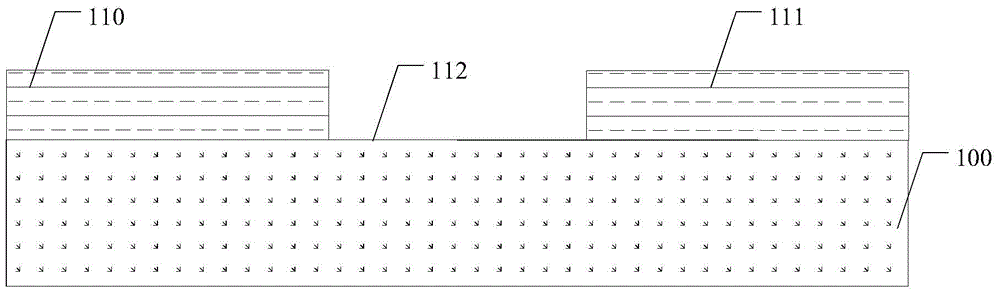

[0026] Please refer to figure 2 , making the outer pattern of the packaging substrate, the outer pattern is attached to the substrate 100, the outer pattern at least includes a first pattern 110, a second pattern 111, and a pattern between the first pattern 110 and the second pattern 111 The insulating groove 112 between them.

[0027] It should be noted that the substrate may be a substrate composed of resin glass fibers, which is not specifically limited here.

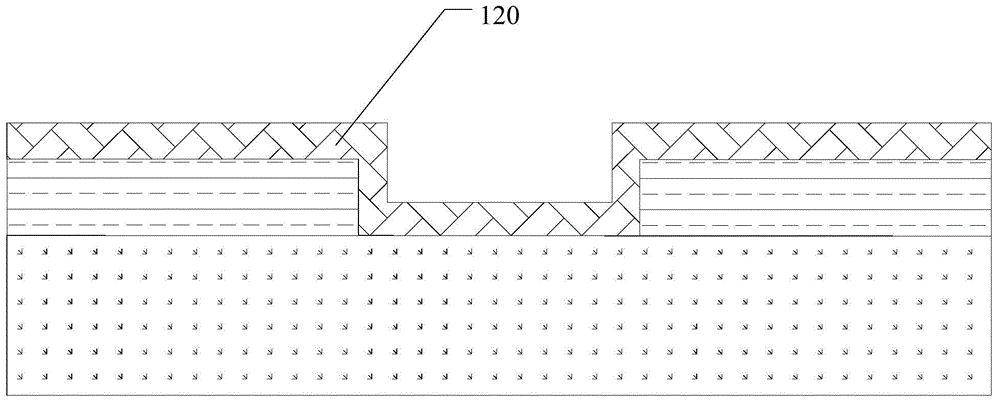

[0028] 102. Metallize the entire package substrate, so that a metallized layer is formed on the surface of the package substrate;

[0029] Please re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com