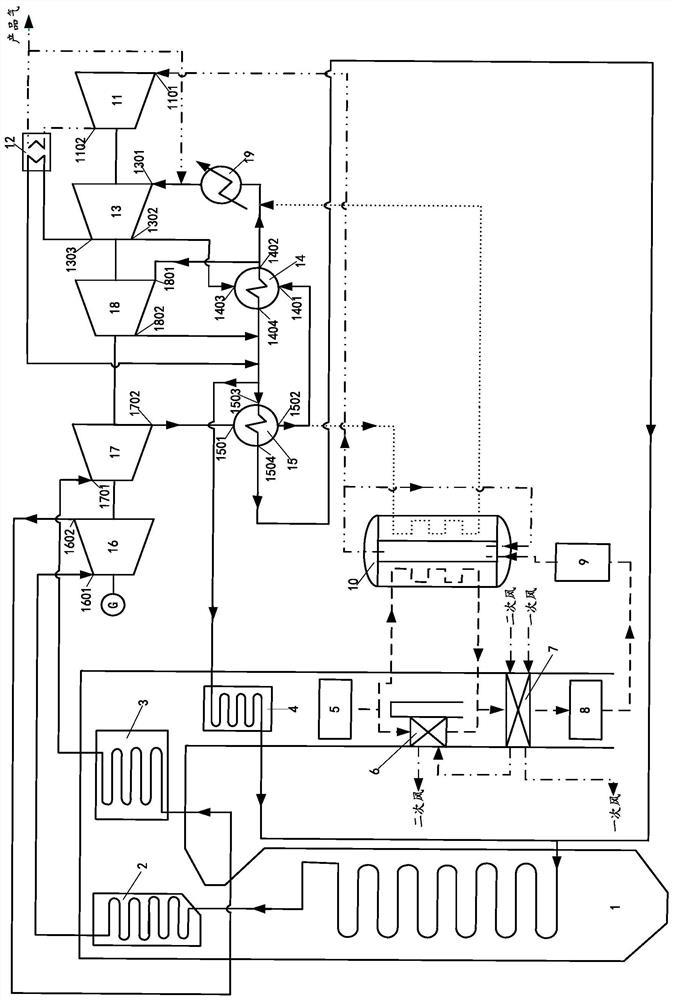

Power station system and method for coupling temperature swing adsorption carbon capture

A technology of temperature-swing adsorption and carbon capture, which is applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of consumption of net efficiency of power generation, high cost of absorbents, and easy to be corroded, so as to achieve high practicability, energy The effect of maximizing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, only a part of the embodiments of the present invention, not all the embodiments, and are not intended to limit the present invention.

[0061] The inventors found that the current power station systems that use supercritical carbon dioxide cycle power generation basically adopt the chemical absorption method for carbon capture, that is, the alcohol amine decarbonization process based on MEA. In the current technical scheme, it is necessary to extract about Working medium carbon dioxide with a temperature of 80bar at about 210°C is used as a heat source for the boiling solvent in the chemical absorption method, but thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com