Organic chemical silvering liquid medicine

An electroless silver plating, organic technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., to achieve the effects of not easy to change color, solve environmental problems, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

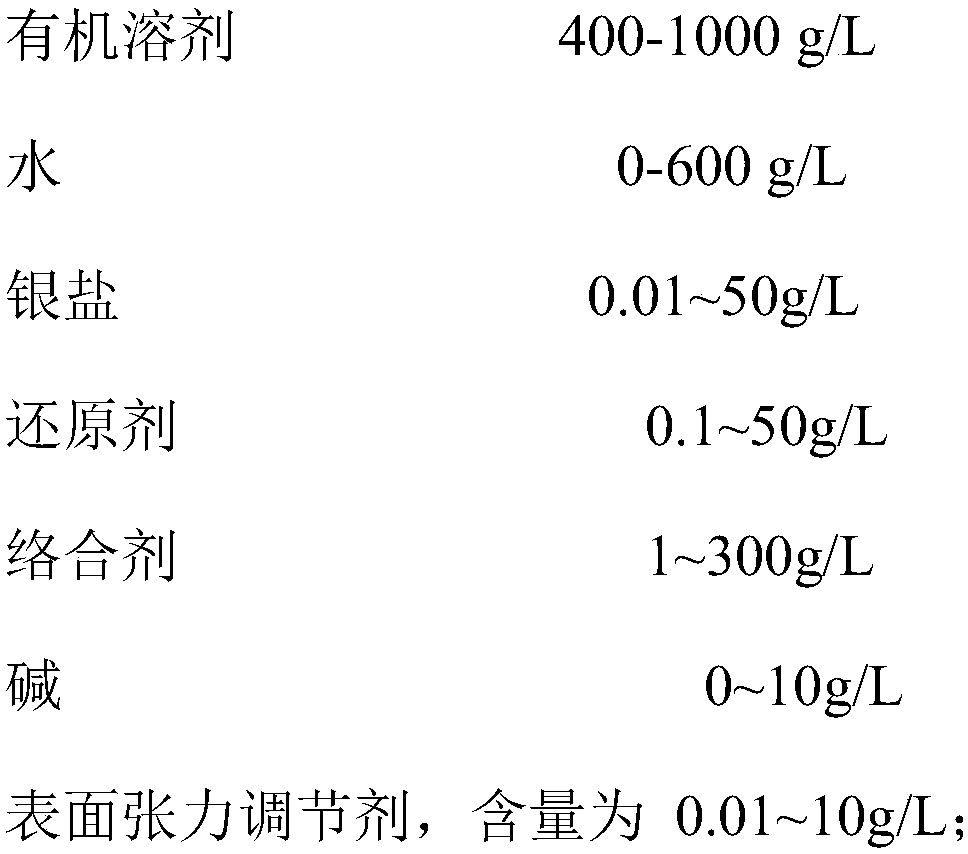

[0034] Organic chemical silver plating solution A, its components and dosage are:

[0035]

[0036]

[0037] The application method is as follows:

[0038] Add 1 gram of copper powder into dilute sulfuric acid solution and ultrasonically stir for 3 minutes, settle and separate, wash with deionized water for 3 times, then soak in presoaking solution, settle and separate, then add 1L of silver plating solution A drop by drop while ultrasonically stirring and heating to 45°C for reaction 1 hour. After the product is separated by sedimentation, it is washed with post-wash liquid medicine, washed with water, separated and dried.

[0039] It can be observed with the eyes that the color of the copper powder has turned gray after silver plating. The state of the coating on the surface of the copper powder is further observed with an electron microscope (SEM), and analyzed by energy spectroscopy (EDS). The results show that the copper powder has been well coated. Cover the surf...

Embodiment 2

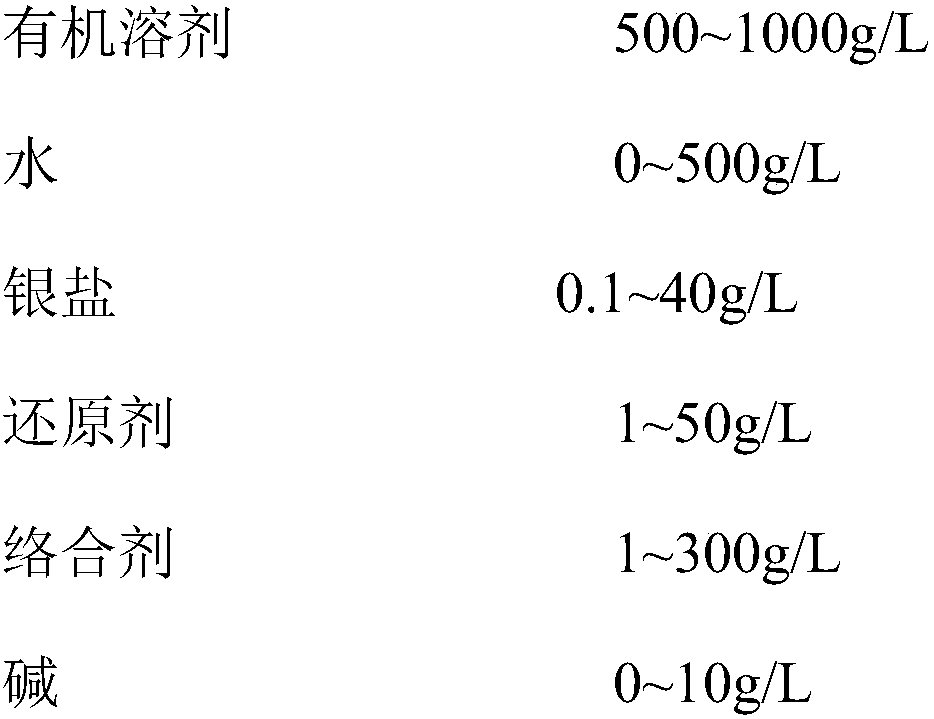

[0041] Organic chemical silver plating solution B, its components and dosage are:

[0042]

[0043]

[0044] Use the usual horizontal electroless plating production line for printed circuit boards, use silver plating potion B, and carry out silver plating according to the following process:

[0045] Degreasing, microetching, water washing, pre-dipping (the pre-dipping solution is the corresponding silver plating solution without silver salt), immersion silver, post-washing, water washing and drying.

[0046] The silver-plated PCB board is tested by section and metallographic microscope, and the sag rate is ≤1%, which shows that there is basically no "Giavani effect".

Embodiment 3

[0048] Organic chemical silver plating solution C, its components and dosage are:

[0049]

[0050]

[0051] The preparation method and application method are the same as in Example 2. The PCB board has been tested by section and metallographic microscope, and the sag rate is ≤1%, which shows that there is basically no "Giavani effect".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com