Method for inhibiting corrosion of metal pad

A metal pad, dry etching technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve problems such as metal pad corrosion, achieve corrosion inhibition, solve chip packaging yield decline, Solve the effect of increasing the failure rate of the wire bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

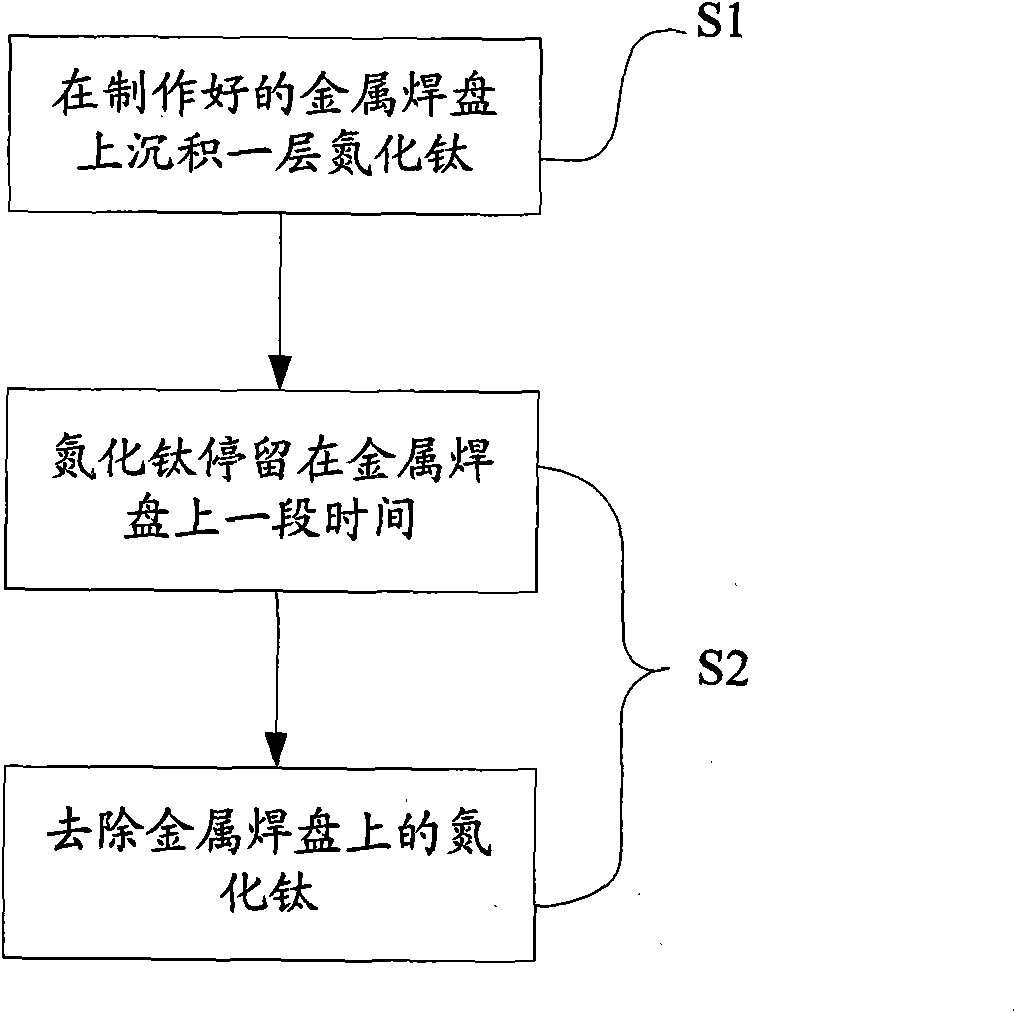

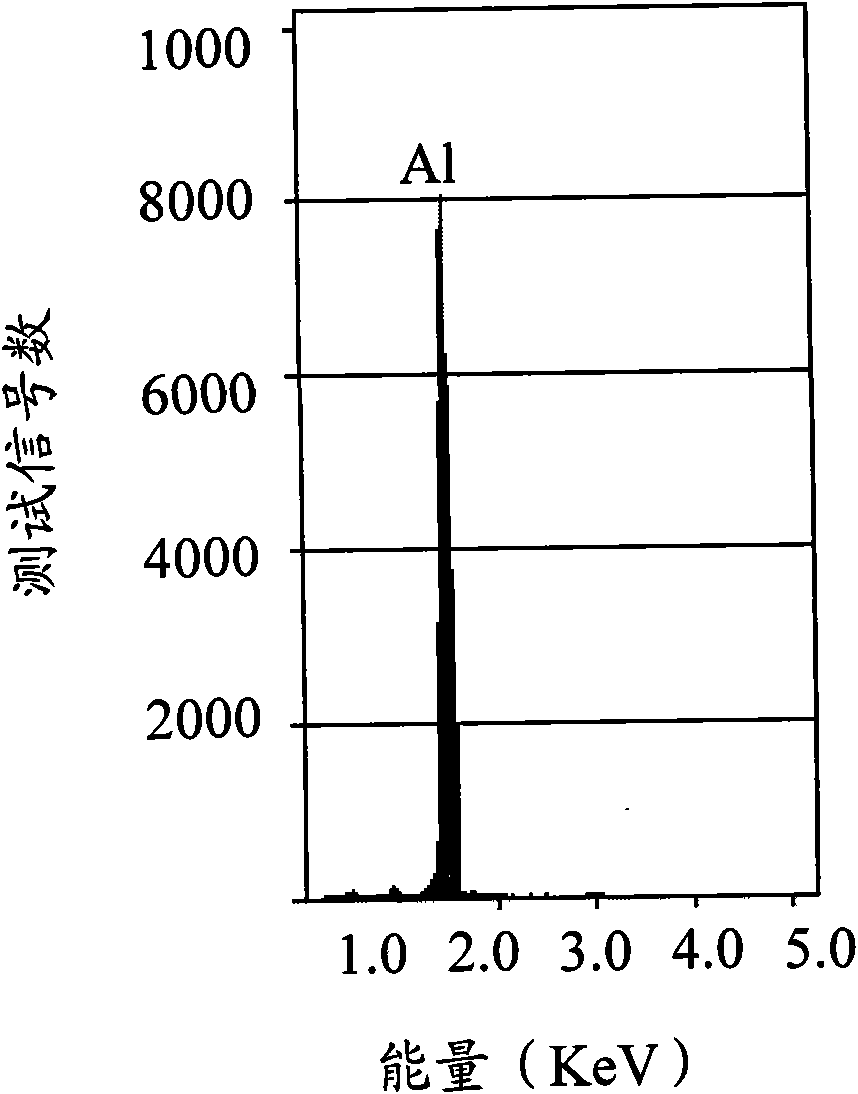

[0016] For the method of suppressing metal pad corrosion of the present embodiment, please refer to figure 1 , which includes the following steps: S1: forming a titanium nitride layer on the prepared metal pad; S2: removing the metal pad after the titanium nitride layer formed in step 1 remains on the metal pad for a preset time TiN layer on top.

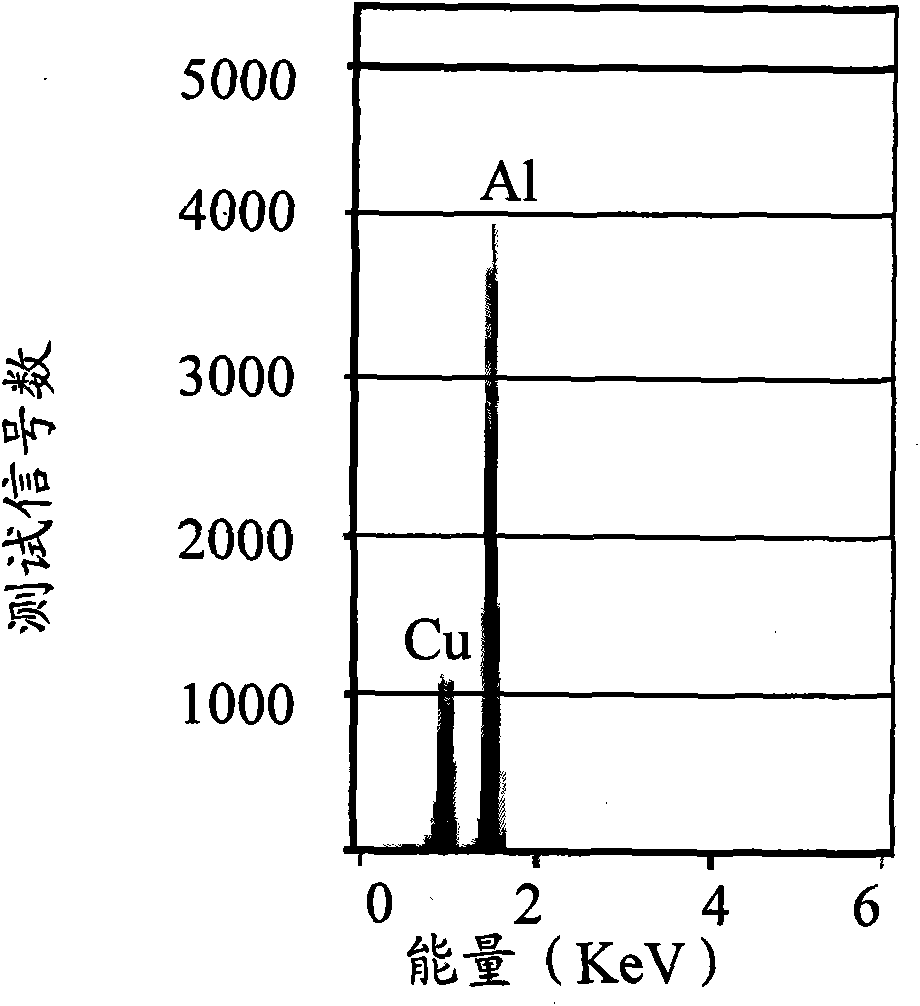

[0017] Wherein, the material of the metal pad is an alloy of copper and aluminum. Alloys of copper and aluminum are currently commonly used materials for making metal pads. In this way, the problem of process compatibility existing in the adoption of new materials can be avoided, and the cost can be reduced.

[0018] The thickness of the titanium nitride layer formed in step S1 is 700˜1000 angstroms. In order to minimize the process time and cost occupied by the present invention, the thickness of the titanium nitride formed in step 1 should not be too thick.

[0019] The carbon nitride layer formed in step S1 is formed by chemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com