Chemical silver plating solution

A technology of chemical silver plating and silver ions, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problem of high level of Giavanni effect, yellowing of silver surface, many holes in copper layer under silver, etc. problems, to achieve the effect of uniform and dense appearance, improve penetration ability, and ensure quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Chemical silver plating solution formula:

[0042]

[0043]

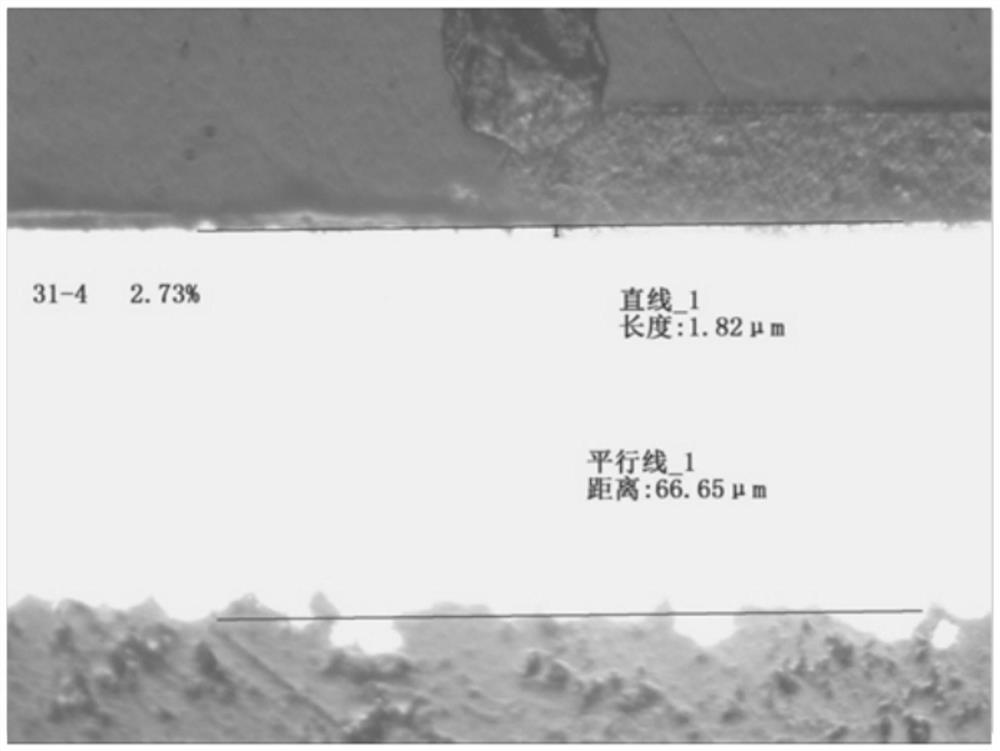

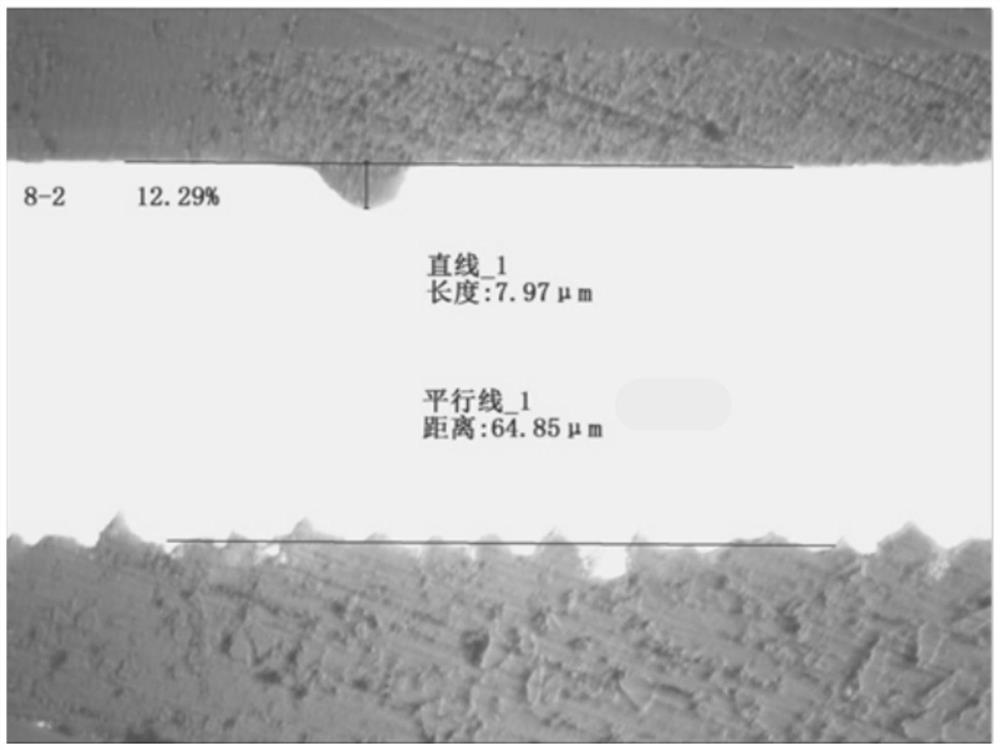

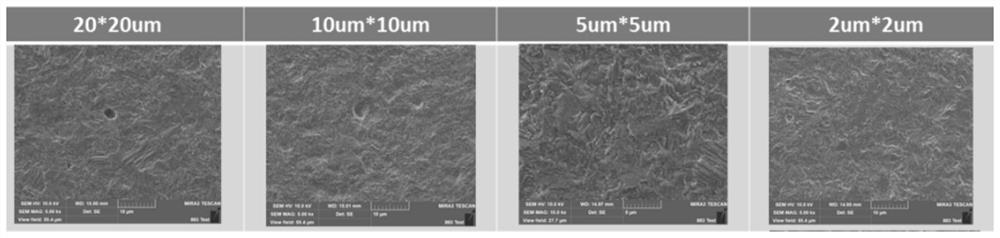

[0044] The silver layer is deposited on the copper layer by using the above electroless silver plating solution to obtain a silver layer with bright surface, bluish white appearance, dense and uniform structure, and no loose holes.

Embodiment 2

[0046] Chemical silver plating solution formula:

[0047]

[0048] The silver layer is deposited on the copper layer by using the above electroless silver plating solution to obtain a silver layer with bright surface, bluish white appearance, dense and uniform structure, and no loose holes.

Embodiment 3

[0050] Chemical silver plating solution formula:

[0051]

[0052]

[0053] The silver layer is deposited on the copper layer by using the above electroless silver plating solution to obtain a silver layer with bright surface, bluish white appearance, dense and uniform structure, and no loose holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com