Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Organic solderability preservative" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

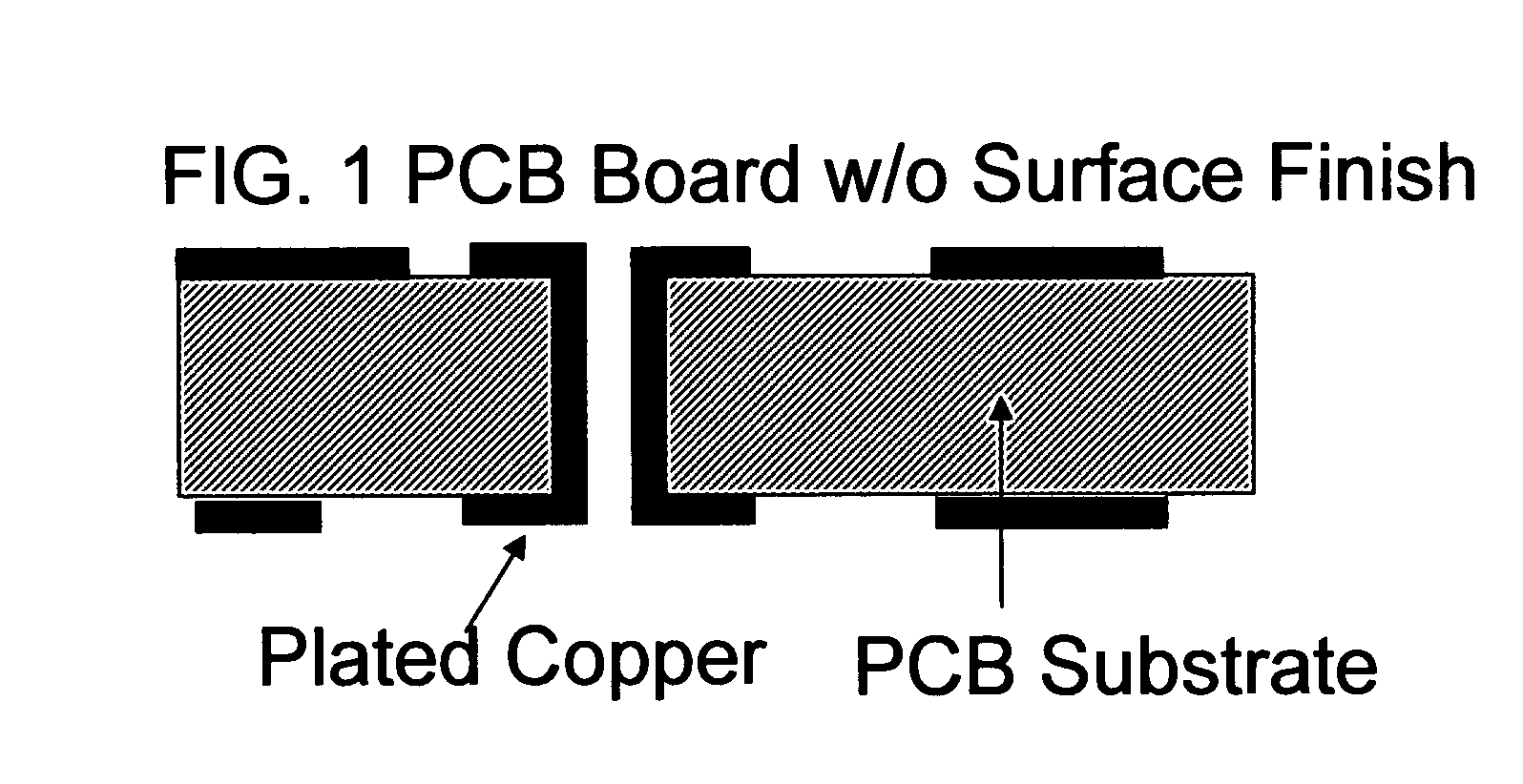

Organic solderability preservative (OSP) is a method for coating of printed circuit boards. It uses a water-based organic compound that selectively bonds to copper and protects the copper until soldering.

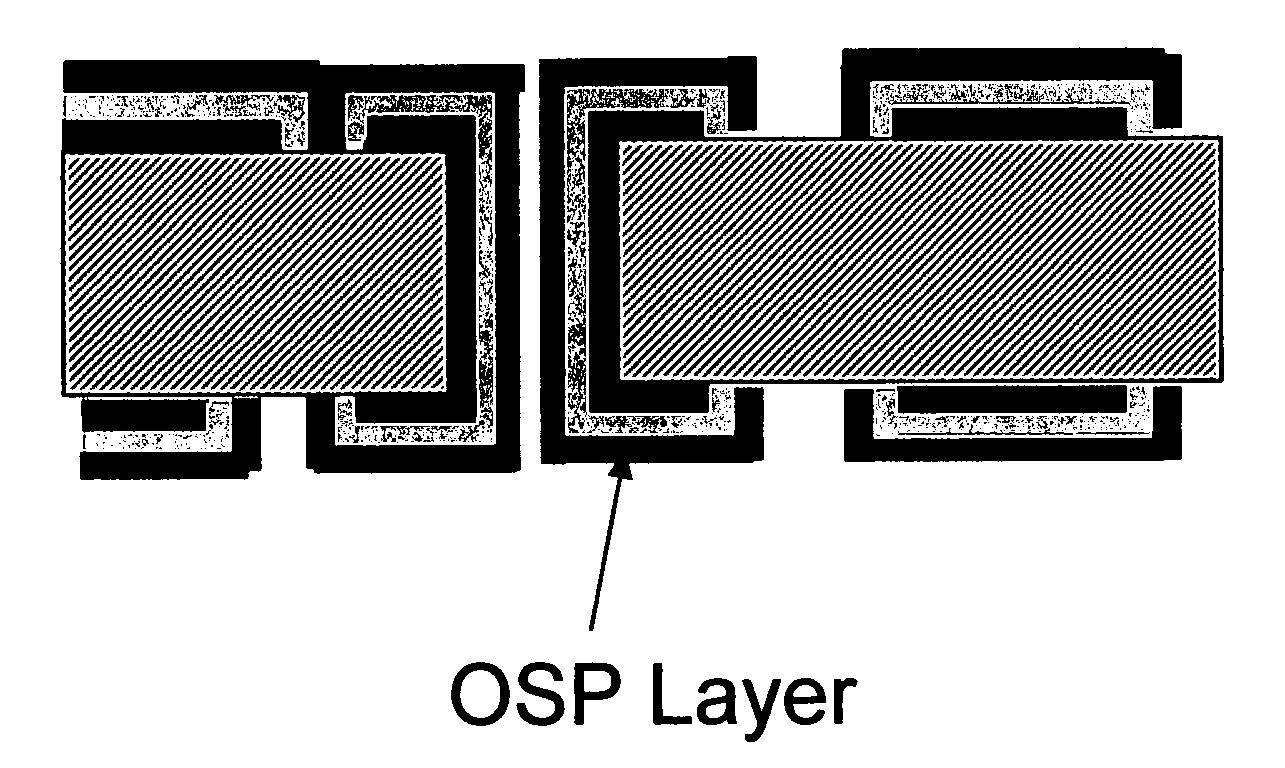

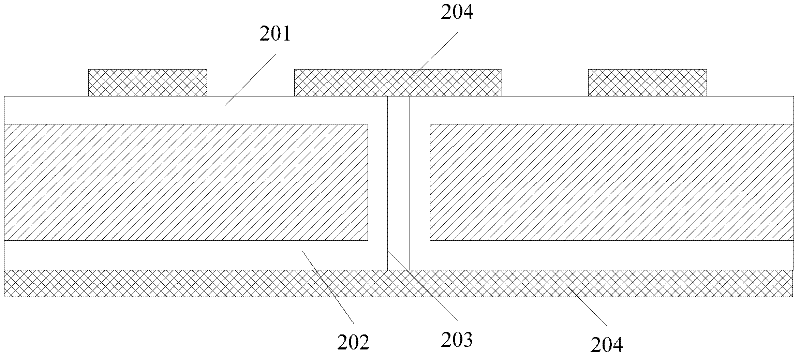

Copper on organic solderability preservative (OSP) interconnect

InactiveUS20090008796A1Semiconductor/solid-state device detailsSolid-state devicesCopper wireSemiconductor chip

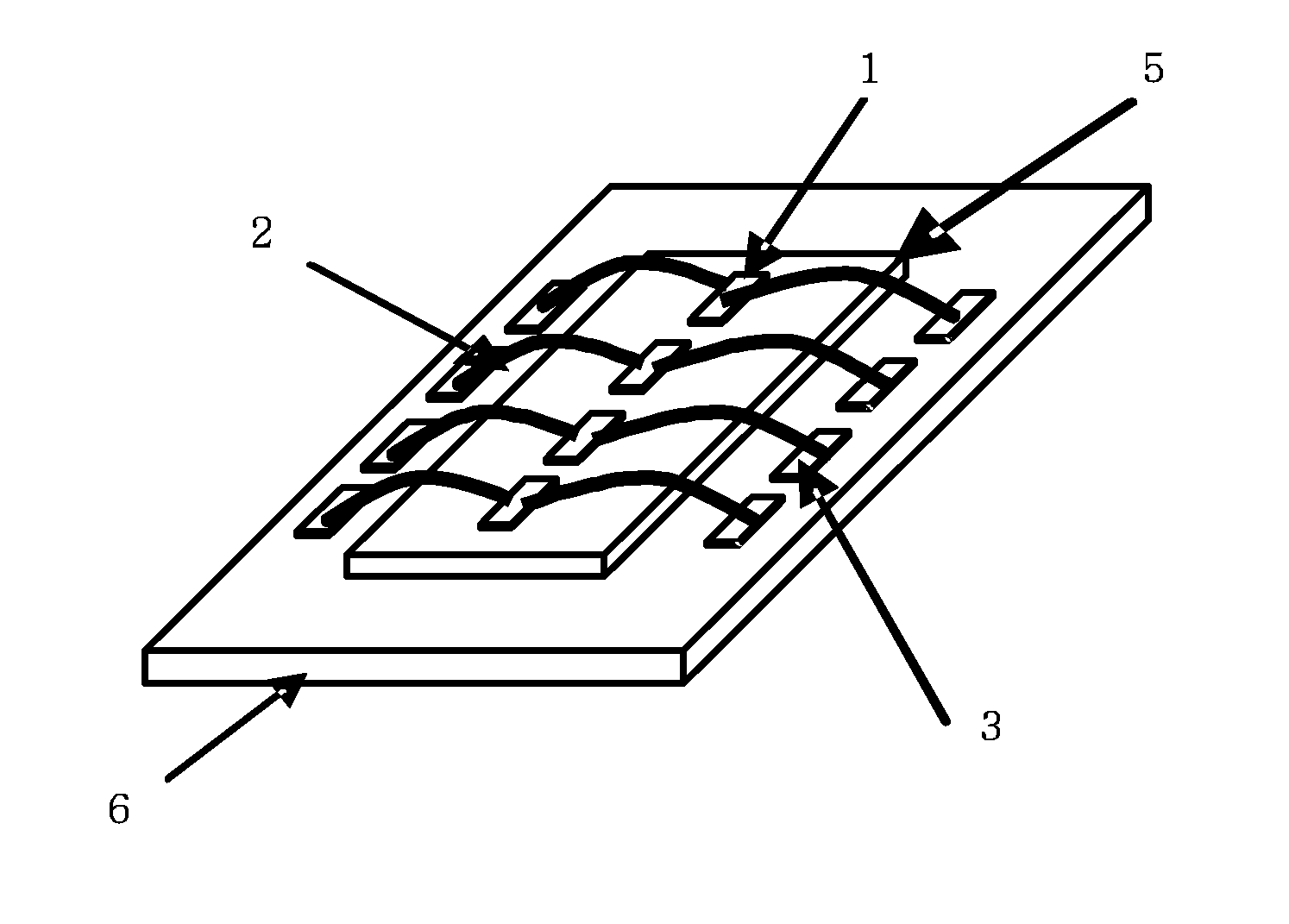

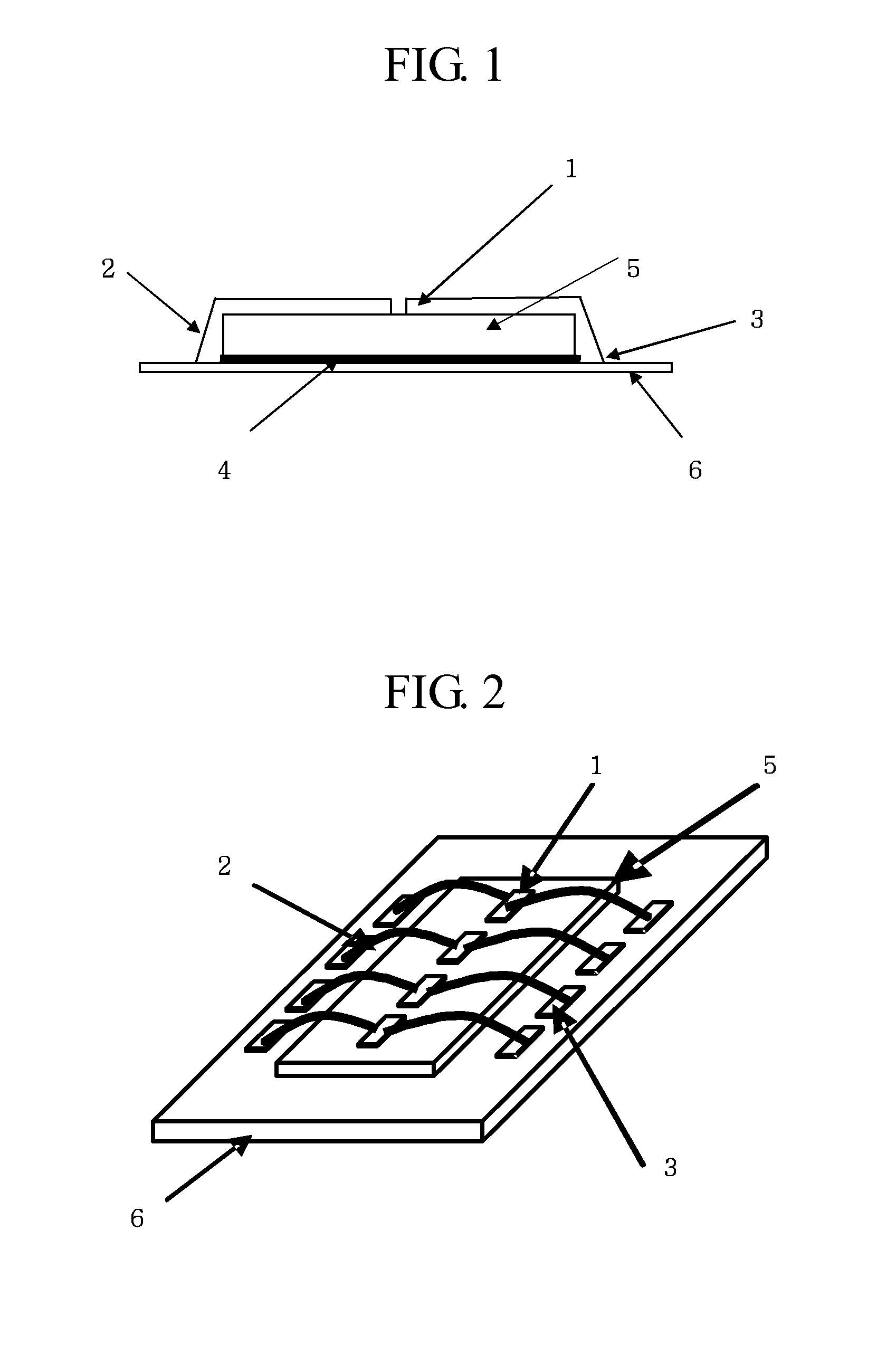

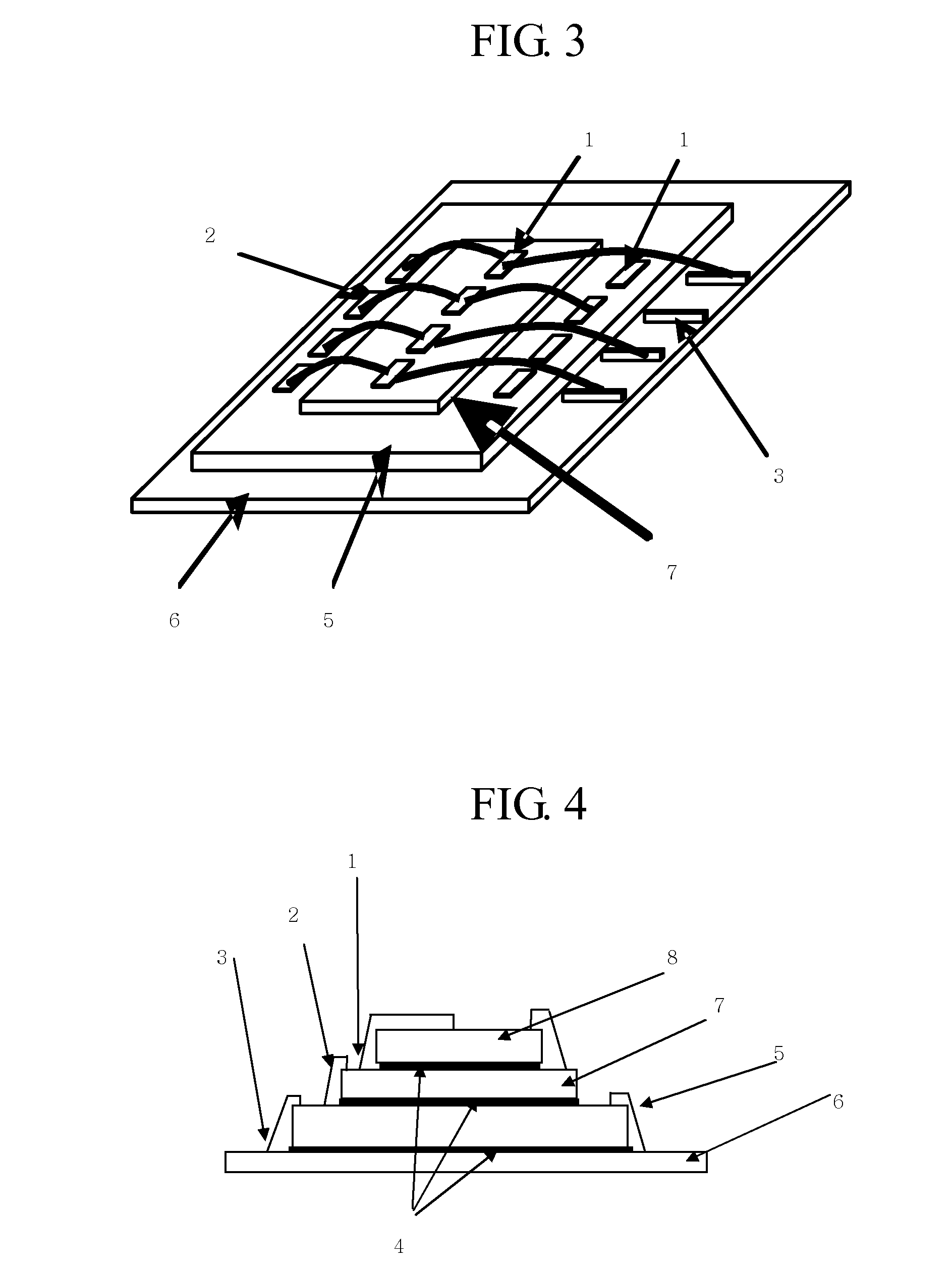

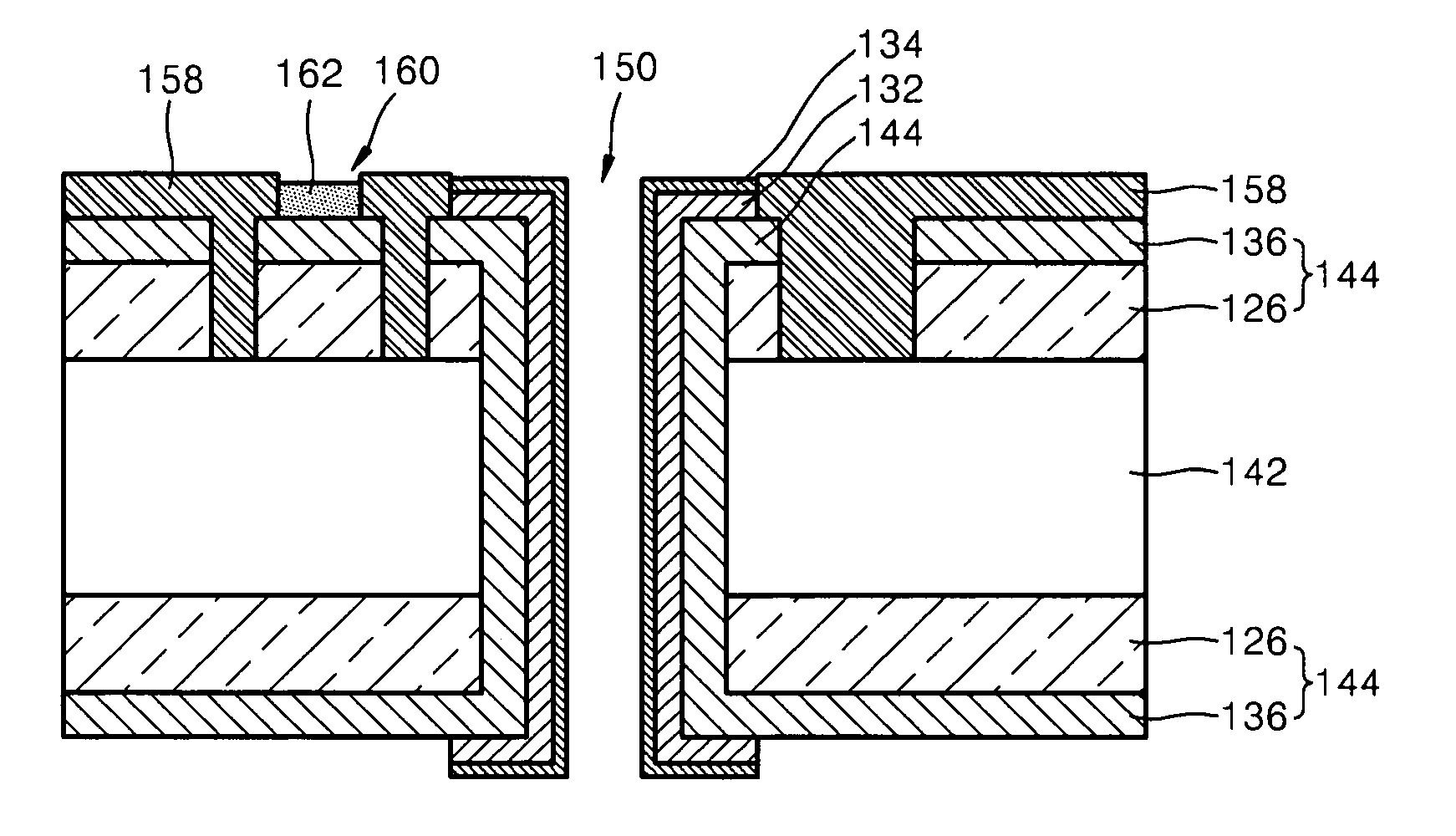

Provided is a semiconductor package, and a method for constructing the same, including a first substrate, a first semiconductor chip attached to the first substrate, and a first copper wire. At least one of the first substrate and the first semiconductor chip has an Organic Solderability Preservative (OSP) material coated on at least a portion of one surface, and the first copper wire is wire bonded through the OSP material to the first substrate and the first semiconductor chip.

Owner:UNITED TEST & ASSEMBLY CENT LTD

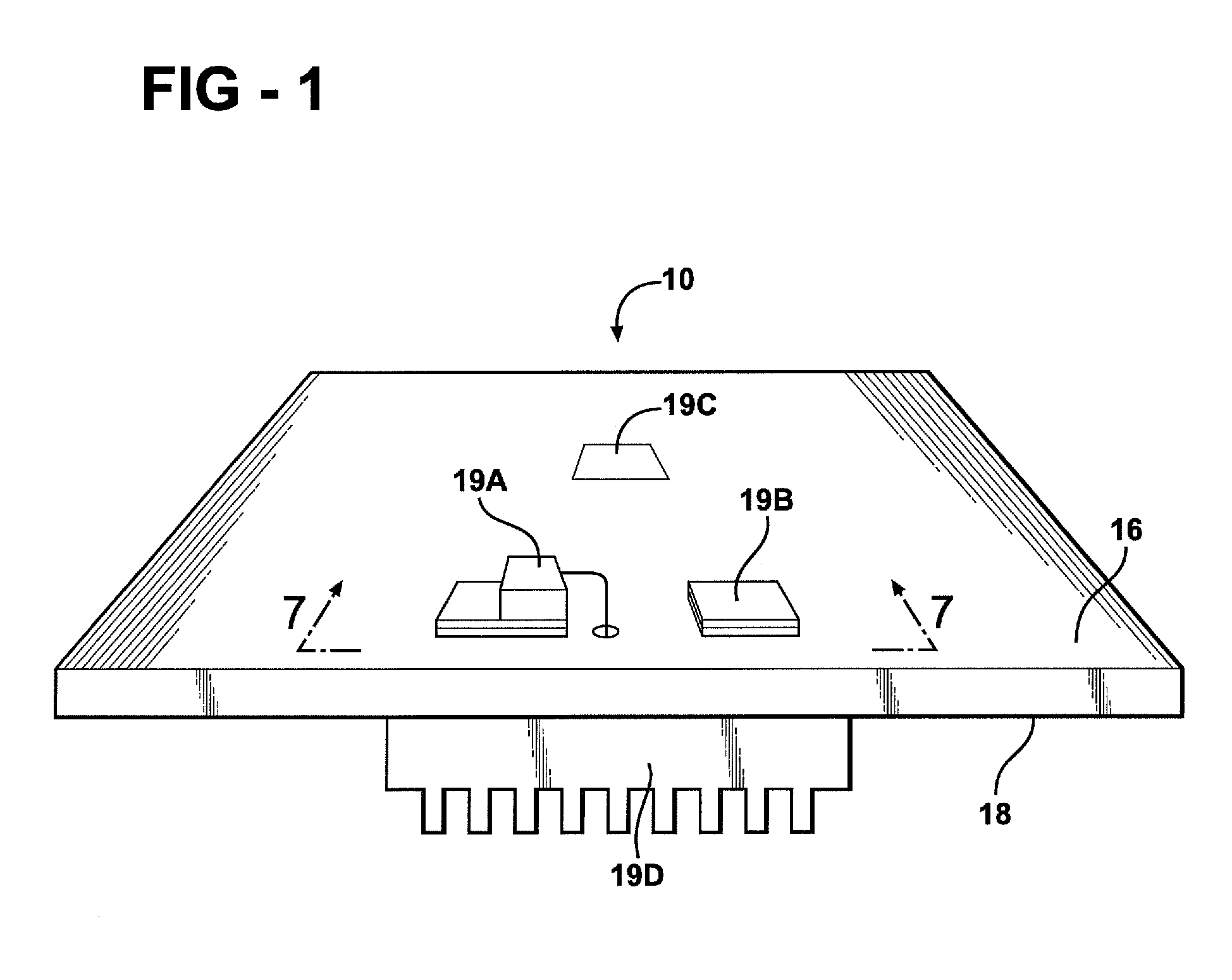

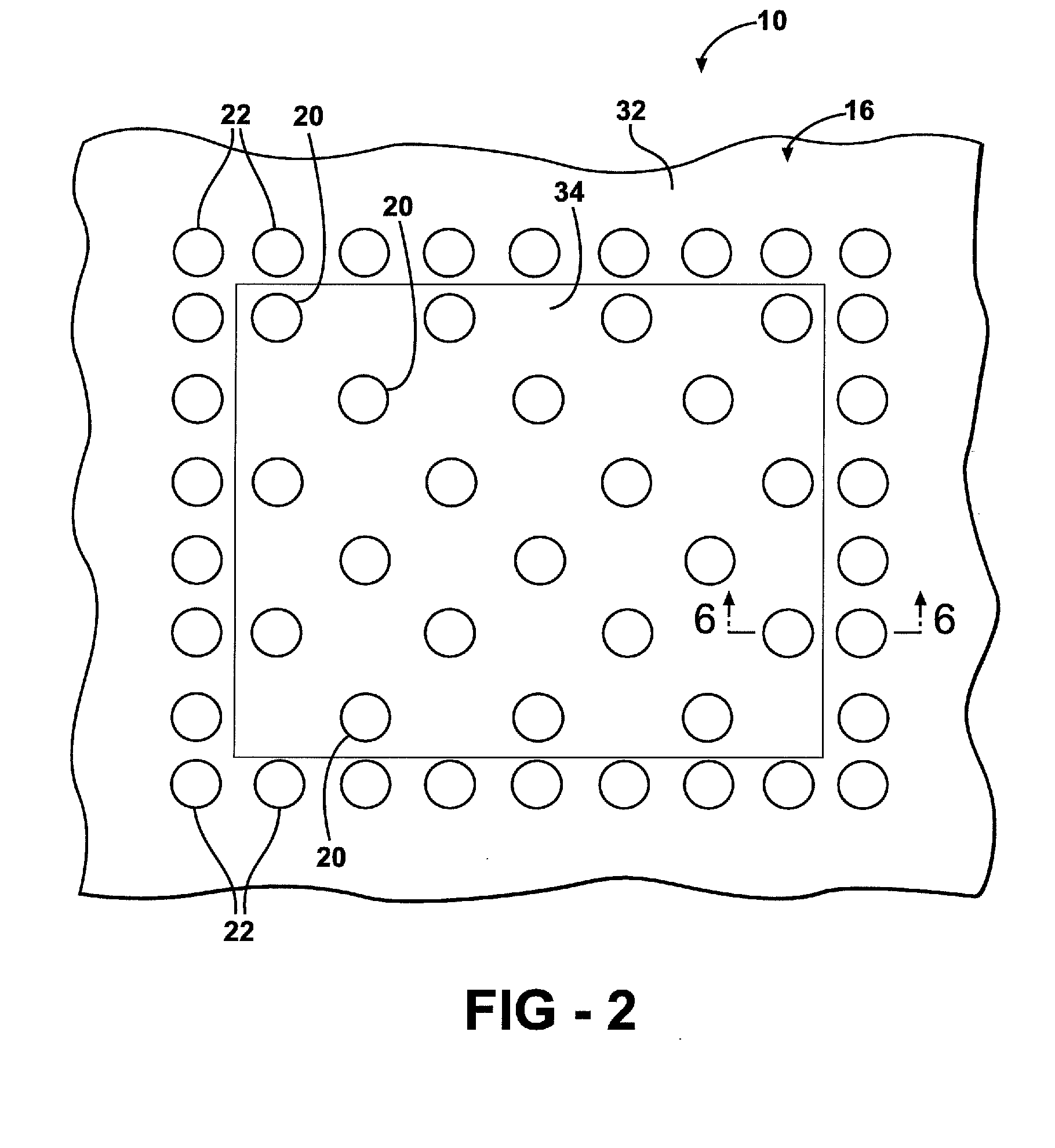

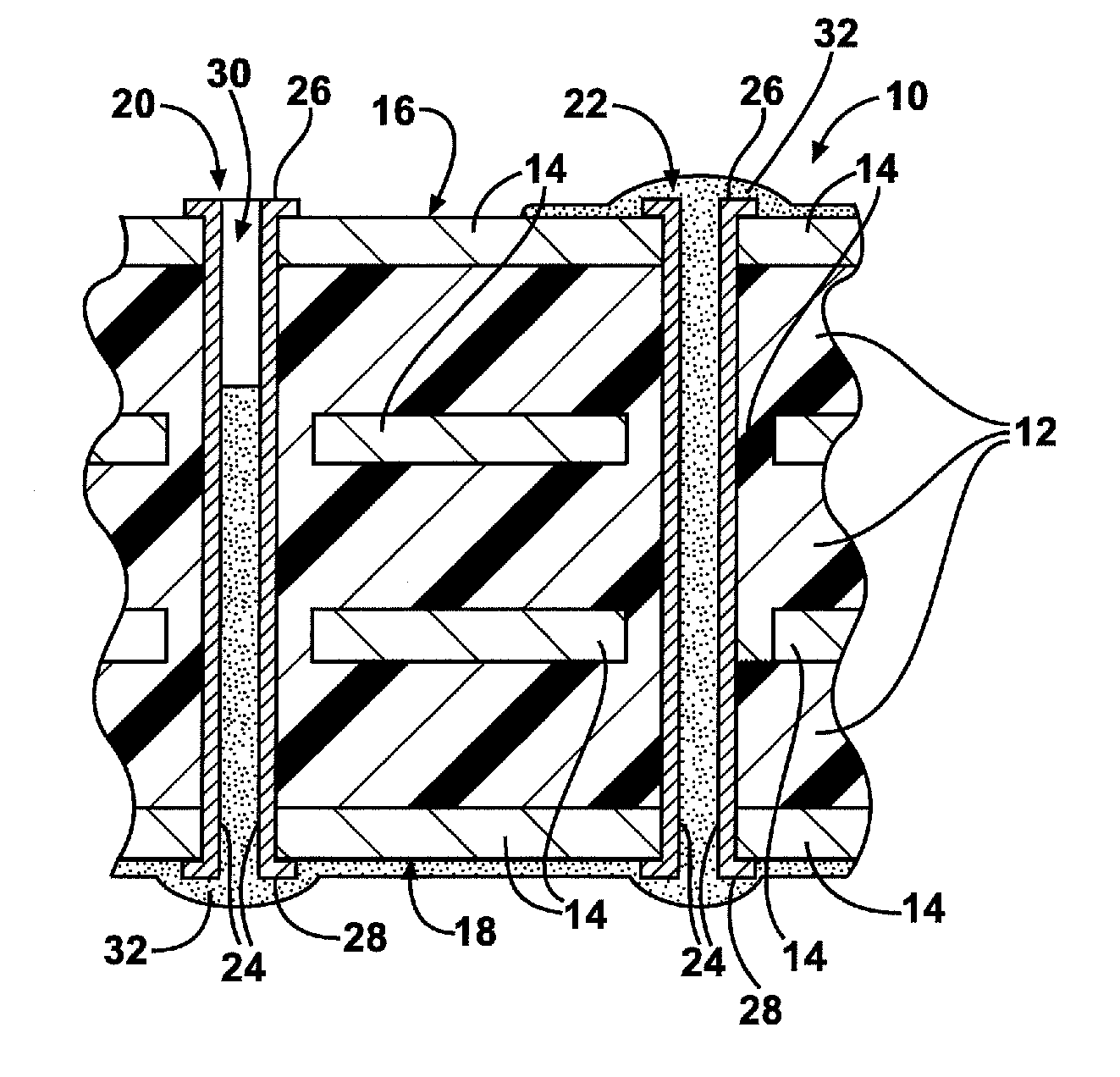

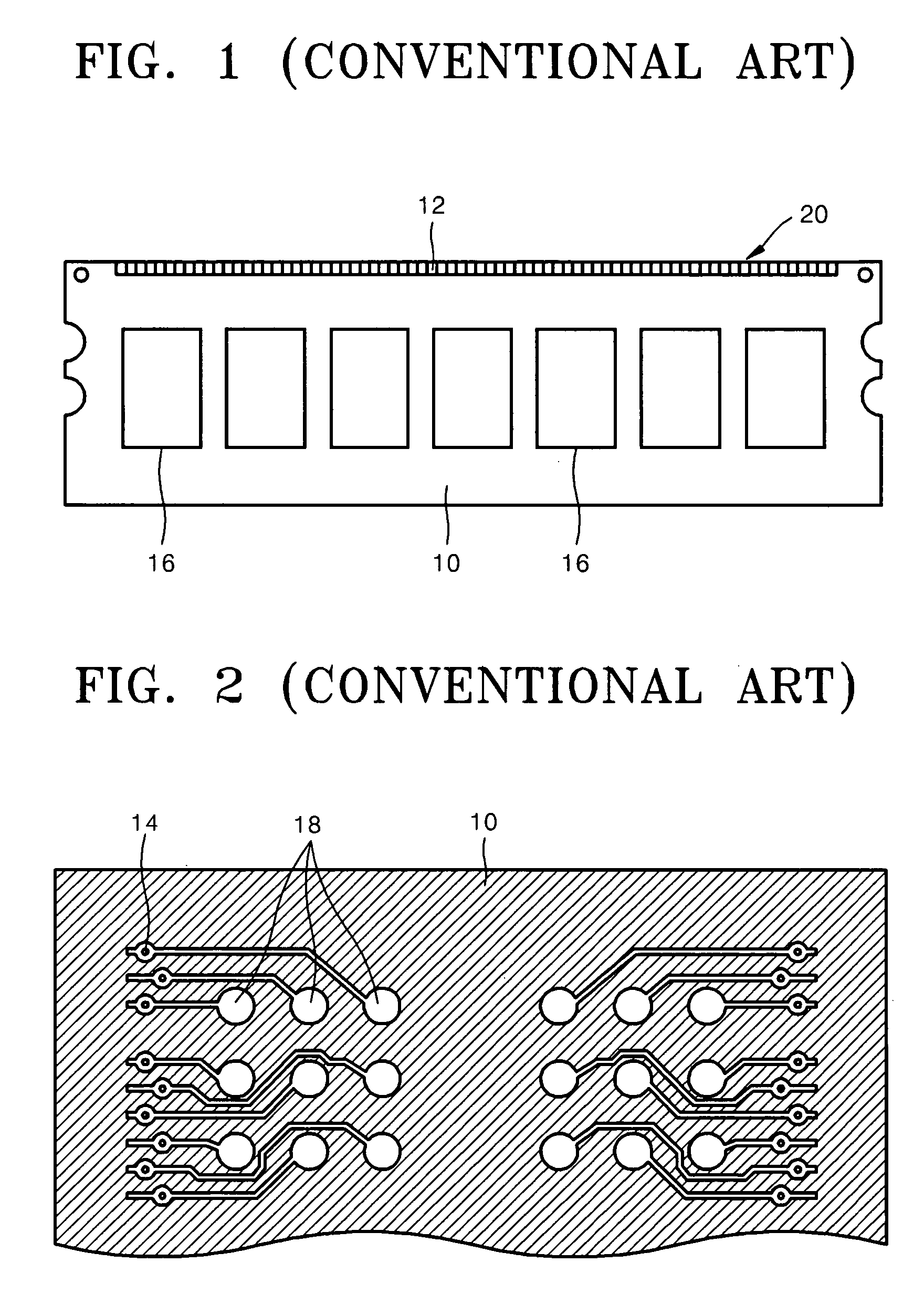

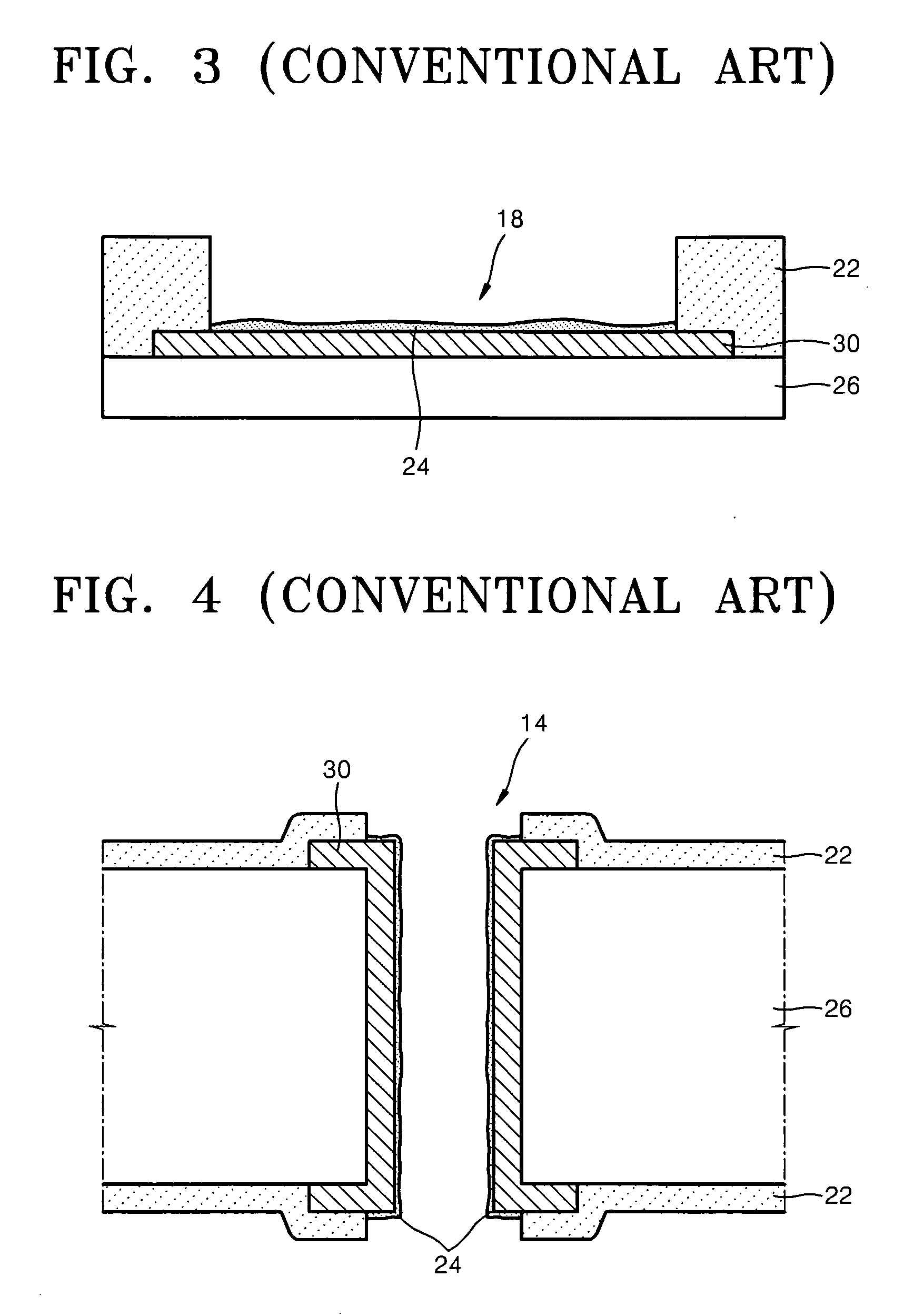

Method of manufacturing a printed circuit board

ActiveUS20090294165A1Easy to manufactureNot require time-consuming reworkPrinted circuit assemblingPrinted circuit aspectsSolder maskOrganic solderability preservative

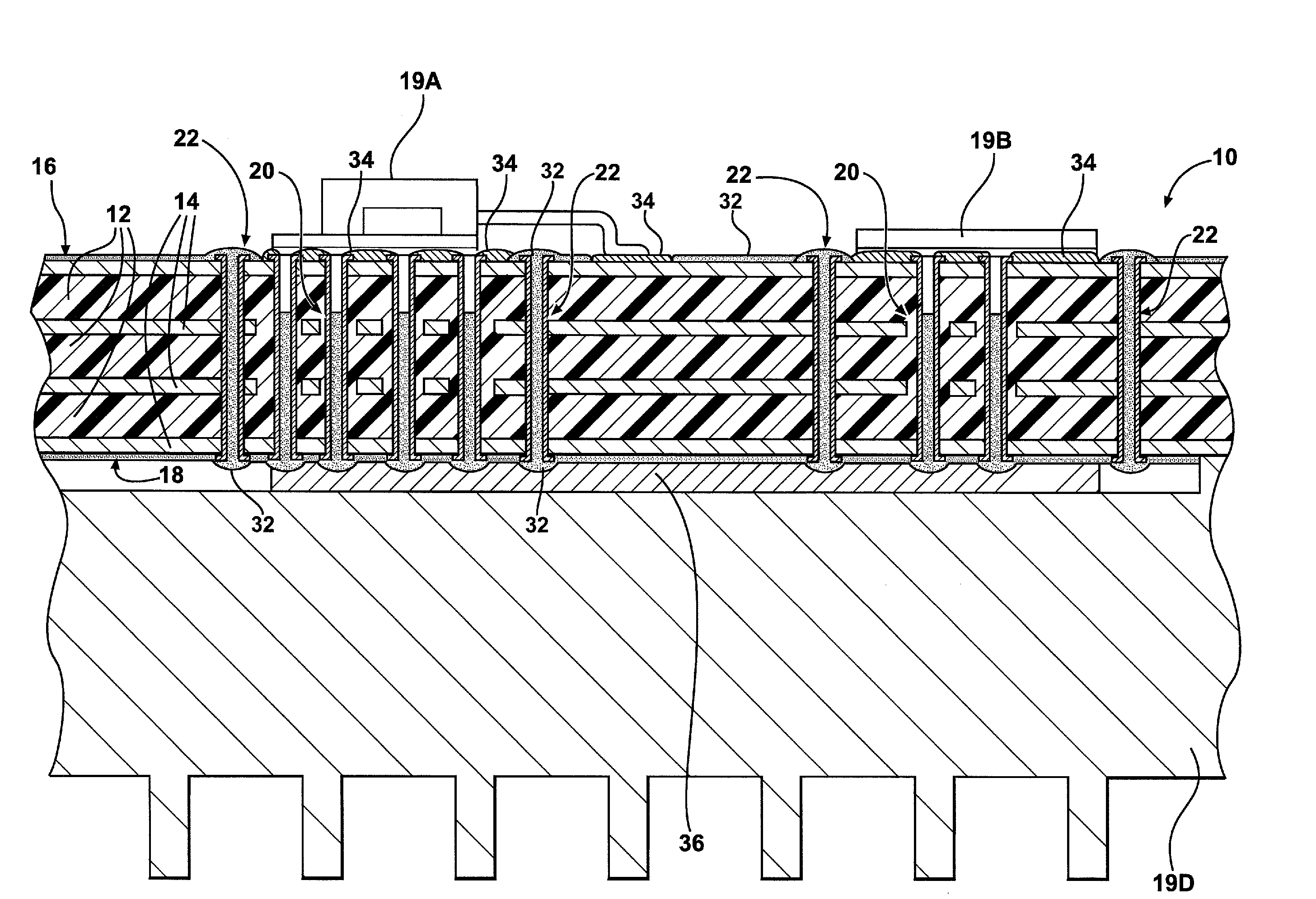

A method of manufacturing a printed circuit board (PCB) includes of disposing thermal transfer vias and electrical vias through the PCB. The method further includes filling holes of the vias with a solder mask. The thermal transfer vias are filled to about 70% of capacity while the electrical vias are completely filled. Once filled, surfaces of the PCB are coated with an organic solderability preservative.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Method of manufacturing a printed circuit board

ActiveUS8166650B2Easy to manufactureNot require time-consuming reworkPrinted circuit assemblingPrinted circuit aspectsSolder maskOrganic solderability preservative

A method of manufacturing a printed circuit board (PCB) includes of disposing thermal transfer vias and electrical vias through the PCB. The method further includes filling holes of the vias with a solder mask. The thermal transfer vias are filled to about 70% of capacity while the electrical vias are completely filled. Once filled, surfaces of the PCB are coated with an organic solderability preservative.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

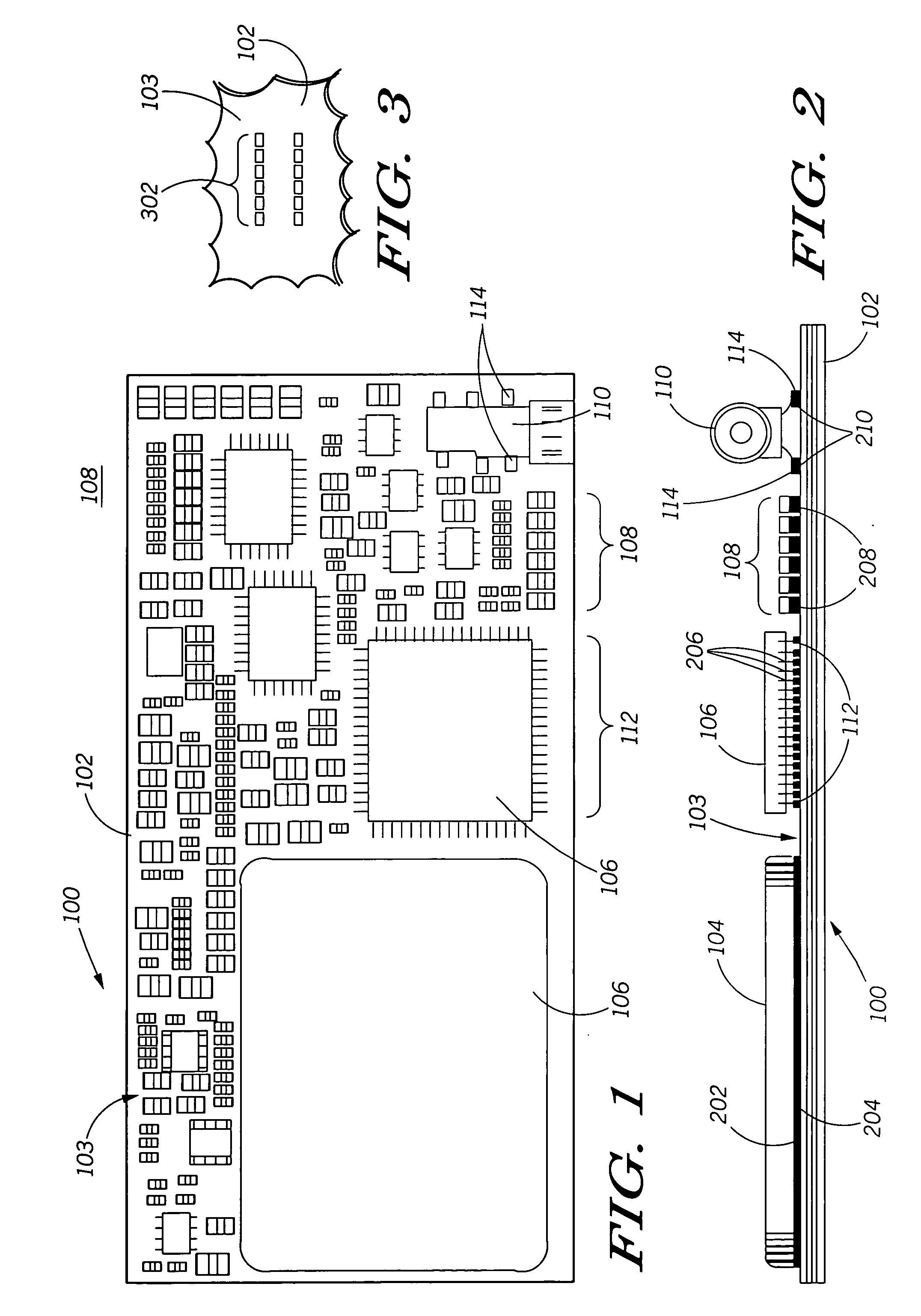

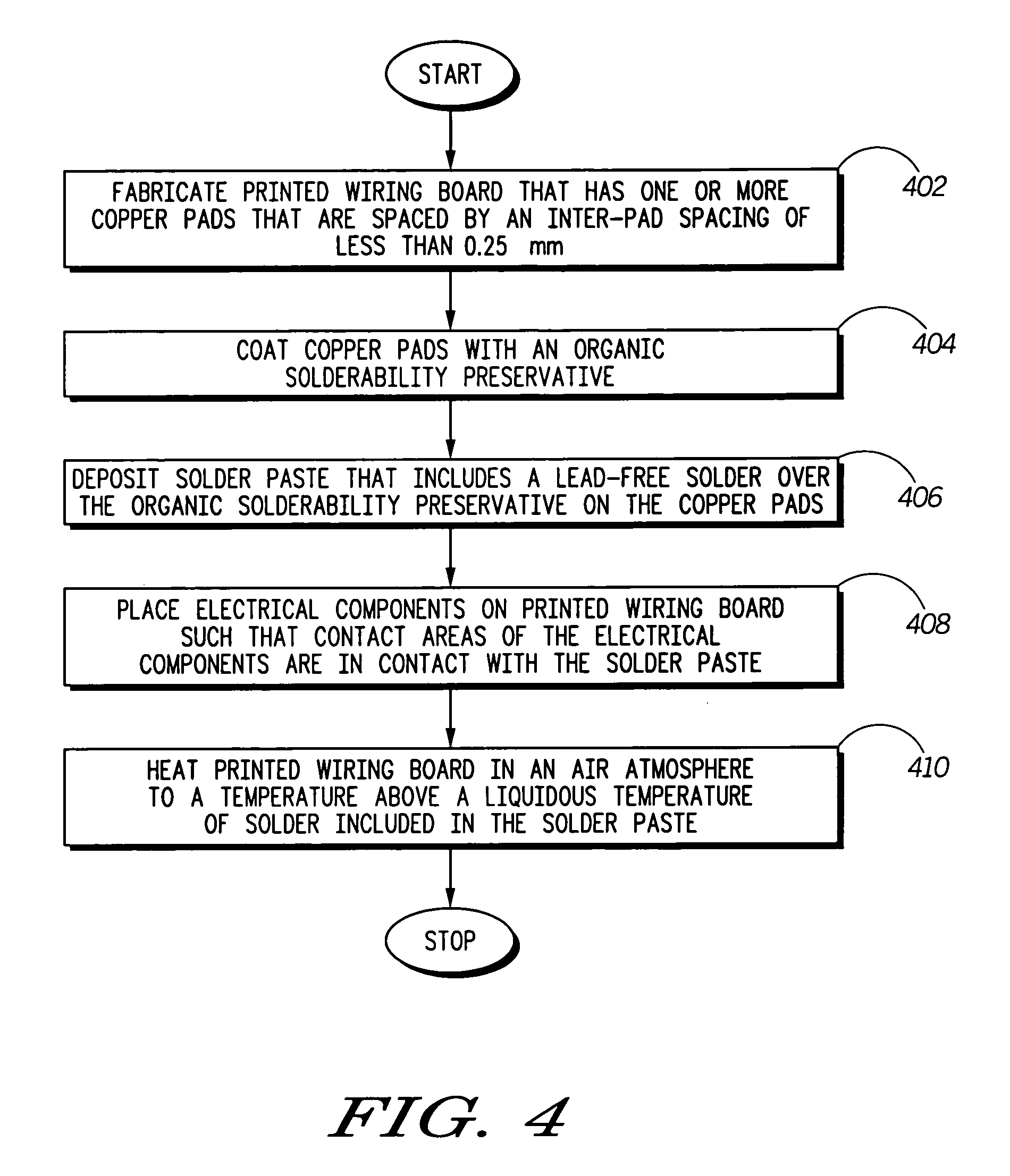

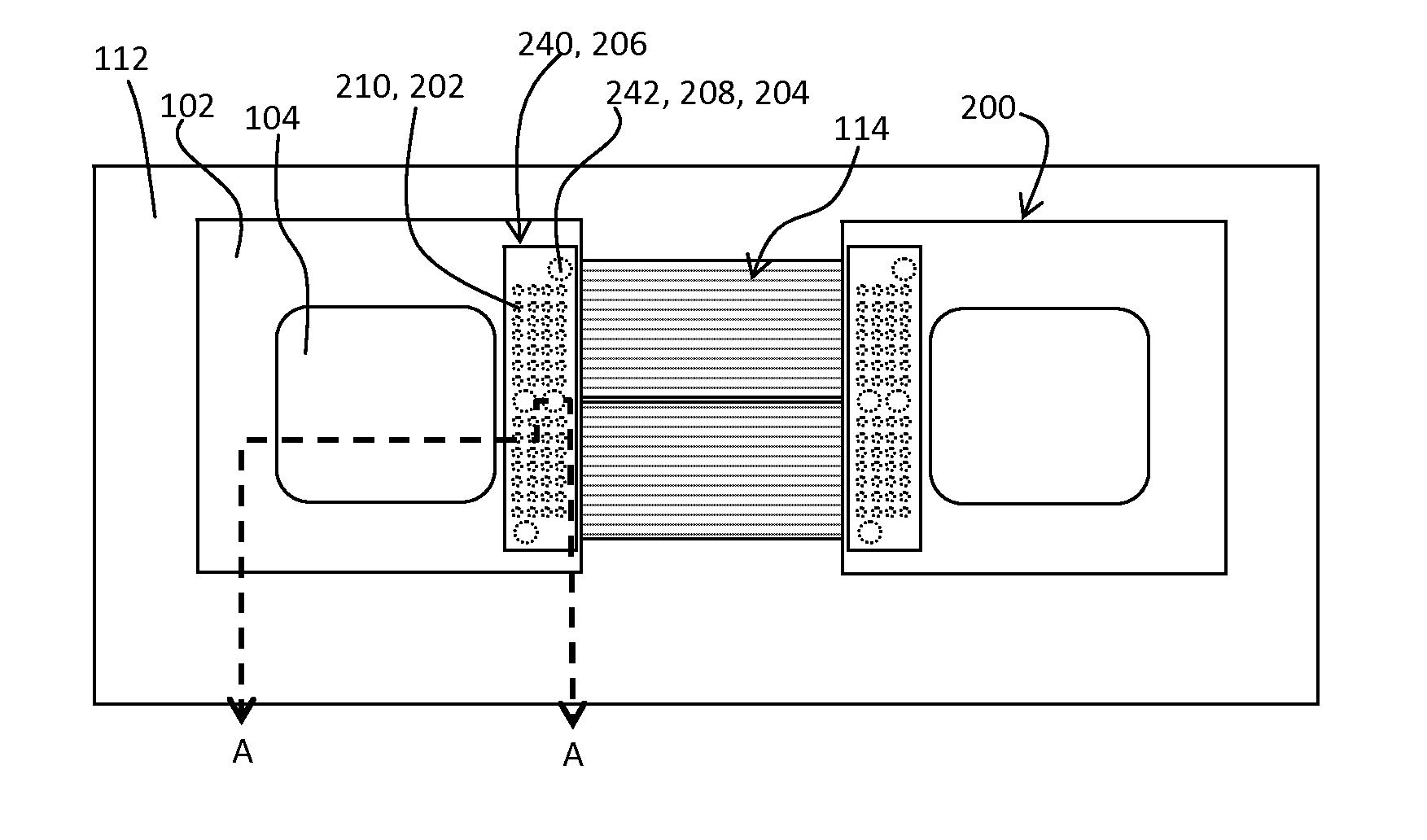

Populated printed wiring board and method of manufacture

A populated printed wiring board (PWB) (100) and method of manufacturing the populated PWB are taught. The populated PWB is manufactured by fabricating a PWB (102, 402) with exposed copper pads (302), coating the copper pads with an organic solderability preservative (OSP) (404), depositing a solder paste that includes lead-free solder on the OSP covered copper pads (406), placing components (408) and heating the PWB above a liquidous temperature of the lead-free solder in an air atmosphere (410). The process allows very close spacing of components and component leads while forming reliable solder joints to components that are mechanically stressed and components that have non-negligible planarity or coplanarity tolerances.

Owner:GOOGLE TECH HLDG LLC

Organic solderability preservative pre-soaking treating agent and organic solderability preservation film forming method

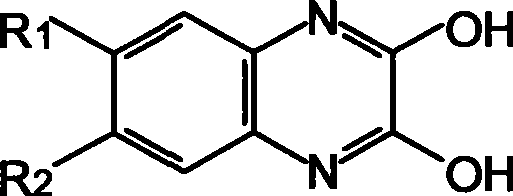

InactiveCN101508051AFast film formationShort duration of actionArc welding apparatusMetallic material coating processesQuinoxalineBuffering agent

The invention relates to the technical field of printed circuit board solderability preservation, in particular to an organic solderability preservative preimpregnation finishing agent and an organic solderability preservative forming method. The adopted organic solderability preservative preimpregnation finishing agent comprises the following components in percentage by weight: 0.05 to 6.0 percent of nanometer accelerating agent, 0.01 to 2.0 percent of quinoxaline compound, 0.05 to 2.0 percent of inorganic base, 0.001 to 15.0 percent of ammonia or amine buffering agent, 0.001 to 0.5 percent of metallic salts, and 0.01 to 5.0 percent of halide. The invention firstly forms a nano material active layer on the copper face, and can increase the thickness of the organic solderability preservative by more than 20 percent in the same reaction time, reduce metal pollution speed of tank liquor, double the service life of the tank liquor, prevent galvanic effect, ensure good appearance of a printed circuit board, reduce the thickness of intermetallic compounds (IMC) after soldering, and guarantee the shear strength of welding joints and reliability of welding spots.

Owner:林原标 +1

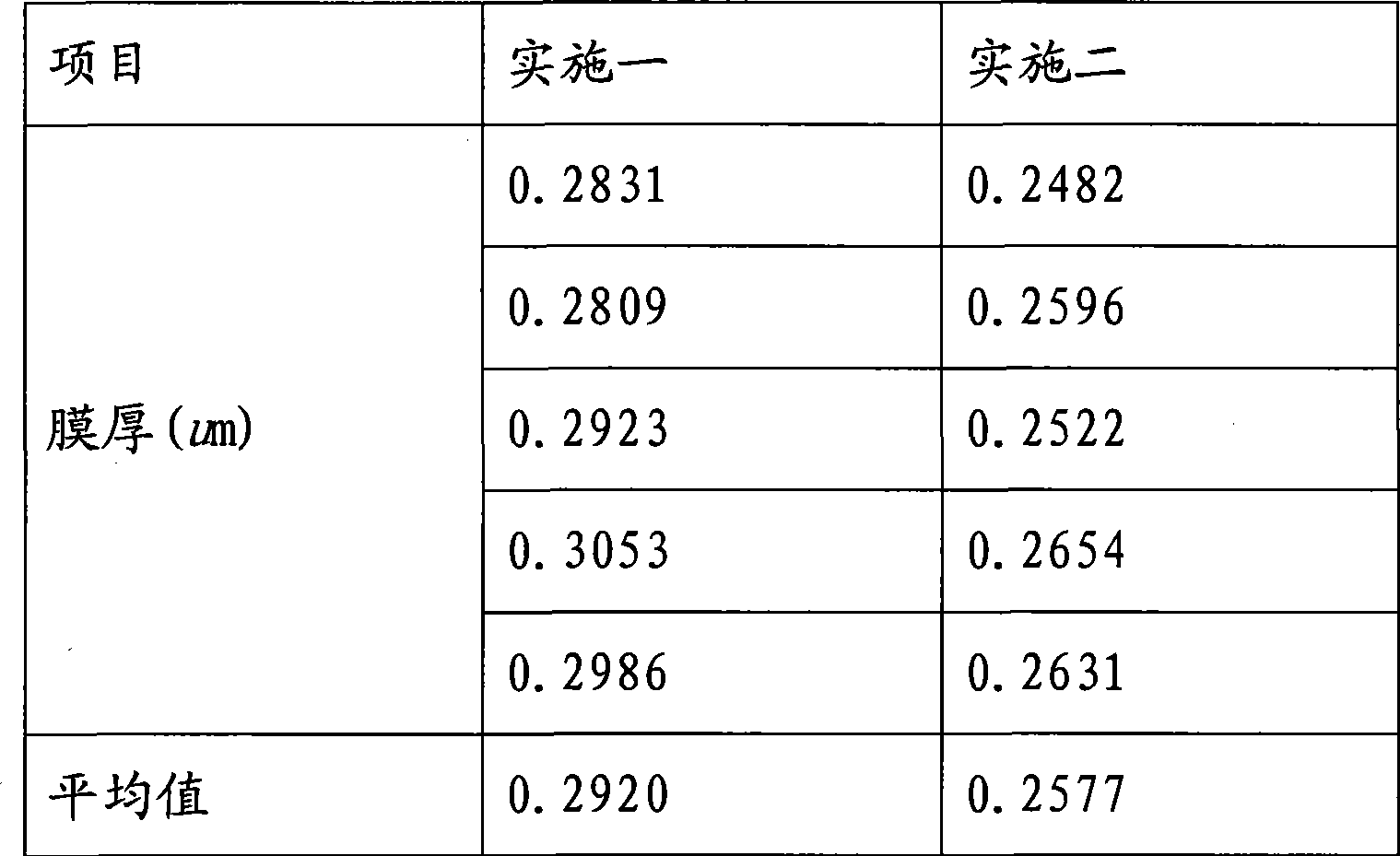

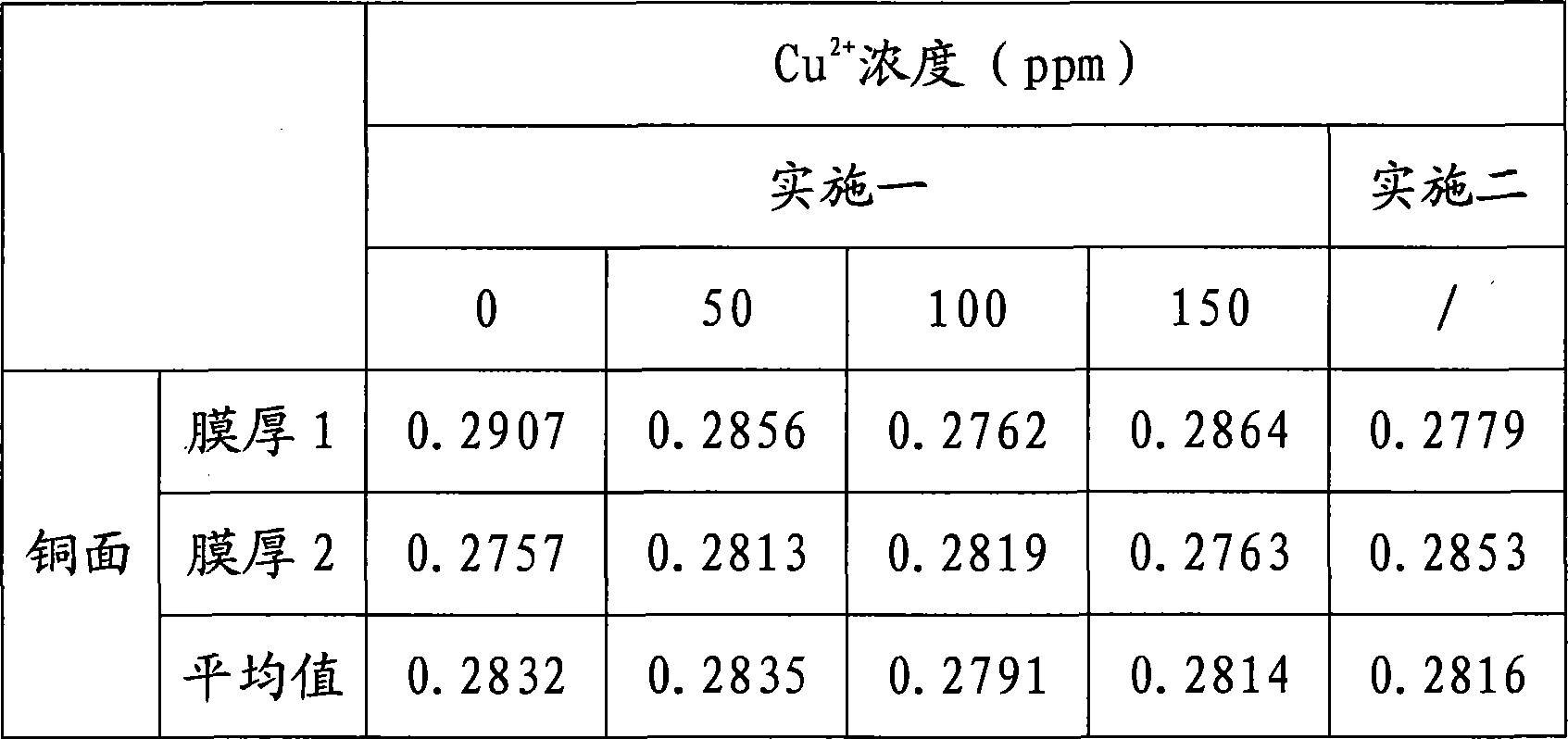

Method for producing organic solderability preservative on surface of circuit board

InactiveCN104918417AModerate roughnessUniform colorNon-metallic protective coating applicationOrganic filmEtching

The invention belongs to the circuit board production technical field and relates to a method for producing an organic solderability preservative on the surface of a circuit board. According to the method of the invention, sand blasting and board grinding procedures are omitted in a pretreatment process, and technological parameters of pickling and micro-etching are adjusted, and therefore, the problem of the smash of fine sands onto a board surface and the problem of high roughness and unevenness of a copper surface when a grinding brush is adopted to perform board grinding can be solved, and the roughness of the copper surface of the circuit board can be moderate and uniform, and the thickness of a formed organic film can be basically consistent with the thickness of etched copper; the circuit board is arranged in an antioxidant cylinder before the production of the organic film, a cylinder dragging plate is adopted to perform cylinder dragging processing at first, so that impurities in an antioxidant solution can be removed, and production parameters can be stabilized, and the concentration of Cu<2+> in the solution is controlled below 15ppm, and therefore, the organic film can be effectively prevented from blackening or color difference of the organic film can be effectively prevented, and yield can be improved; technological methods and parameters in various links are modified, and optimal parameter combinations can be explored, and therefore, the color of the organic film formed on the copper surface can be uniform.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Combined solderable multi-purpose surface finishes on circuit boards and method of manufacture of such boards

A circuit board, in one embodiment a printed wiring board (PWB); in a second embodiment a substrate for an ASIC (Application Specific Integrated Circuit) or Chip Carrier; and a method of manufacturing the same. In one embodiment, the PWB, ASIC or Chip Carrier includes: (1) a substrate having a conductive trace located thereon and (2) a combined, multi-purpose surface finish utilizing an electroless or electrolytically deposited nickel under-plate finished with a coating of an organic solderability preservative (OSP) and is located on at least a portion of the conductive areas (trace, pad, fingers, etc), which forms both a non-contact finish and a contact finish for the PWB, ASIC or Chip Carrier.

Owner:BARBETTA MICHAEL +1

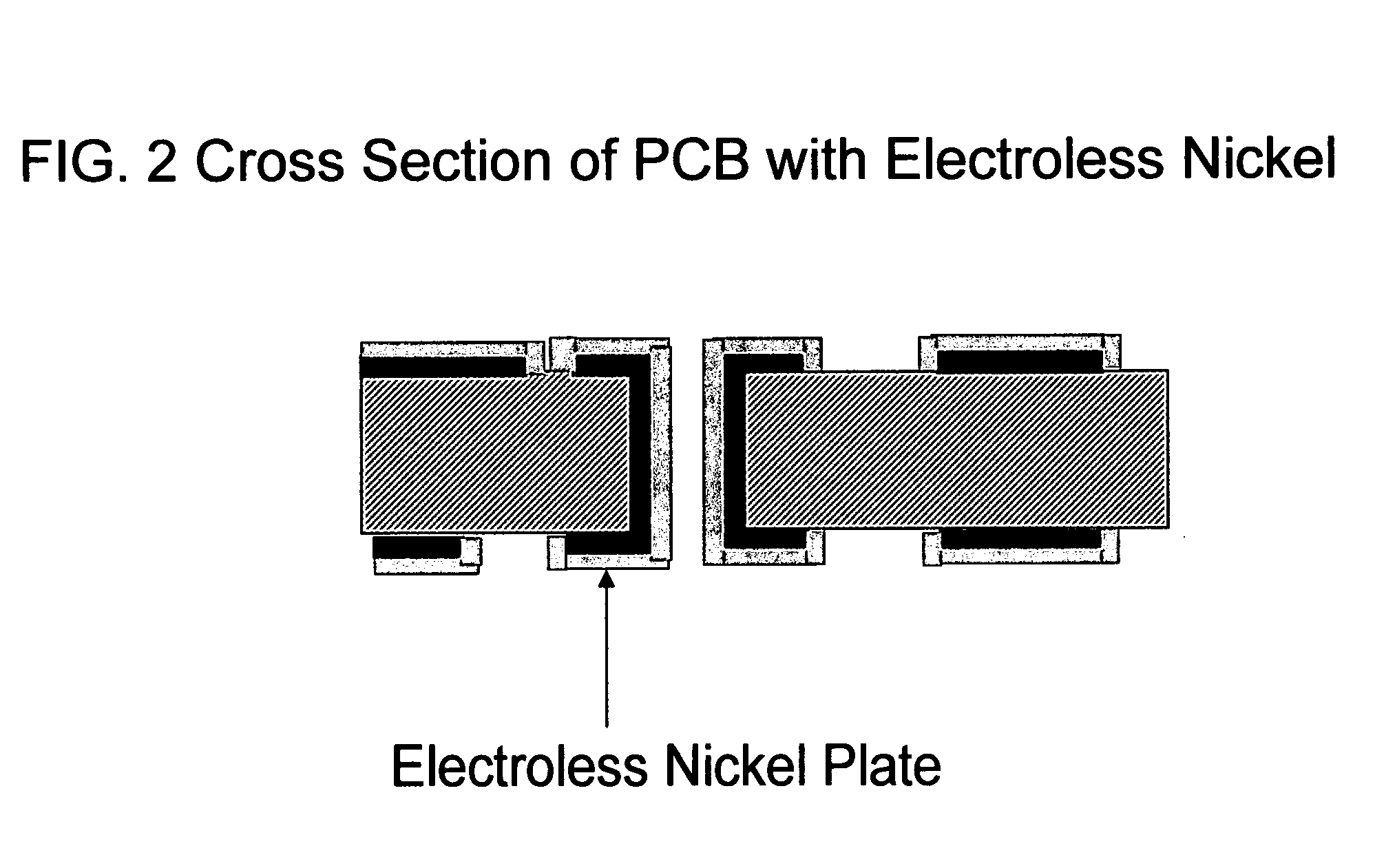

Polymer thermal interface materials

In some embodiments, polymer thermal interface materials are presented. In this regard, a thermal interface material is introduced comprising a polymer matrix, a matrix additive, wherein the matrix additive comprises a fluxing agent, and a spherical filler material, wherein the spherical filler material comprises a metallic core with an organic solderability preservative coating. Other embodiments are also disclosed and claimed.

Owner:INTEL CORP

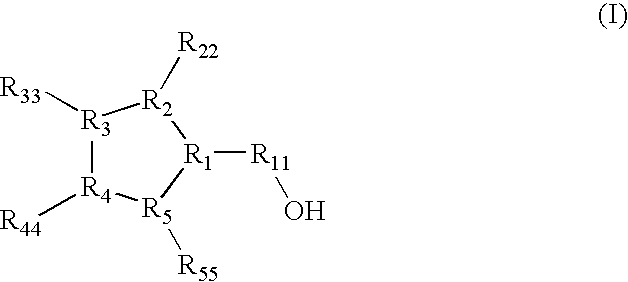

Organic solderability preservative comprising high boiling temperature alcohol

ActiveUS20080163787A1Improve stabilityOrganic non-polymeric coatingOther chemical processesPhysical chemistryCyclic alcohol

An organic solderability preservative (OSP) composition comprising an alkyl cyclic alcohol and an azole compound having enhanced composition stability against crystallization of the azole compound.

Owner:MACDERMID ENTHONE INC

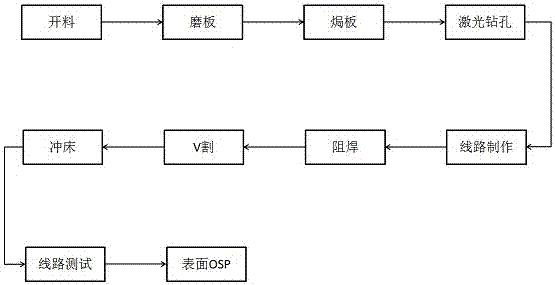

Method for optimizing the manufacturing technique of single-sided aluminum substrate

InactiveCN107072048AImprove reliabilityGood dimensional stabilityCircuit precursor manufactureCooking & bakingResist

The invention relates to the technical field of circuit board manufacturing and in particular to a method for optimizing the manufacturing technique of a single-sided aluminum substrate. The method comprises following steps of: cutting: cutting the single-sided aluminum substrate into a prescribed dimension in accordance with a production requirement of the single-sided aluminum substrate; baking: stacking the aluminum substrates together and baking the aluminum substrates for 3 to 5 hours at the temperature from 140 to 148 degrees centigrade, wherein the thickness of each stack is 40 to 48 cm; C, laser drilling: processing holes on the aluminum substrates by using laser drilling technology; D, line production: subjecting the aluminum substrates to film pasting, exposure, development and etching; E, solder resist: protecting the line not required to be soldered and preventing the entry of tin from causing short circuit; F, V cutting: cutting the surface of the aluminum substrate by using a V cutting machine to form a semi-V groove; G, punching: processing the outline of the aluminum substrate by using a punch press to form holes and a specified shape; H, line test: detecting whether the completed lines operate normally; and I, surface OSP: forming an organic solderability preservative on the aluminum substrate by using reactive resin.

Owner:ANHUI LINCHI ELECTRONICS CO LTD

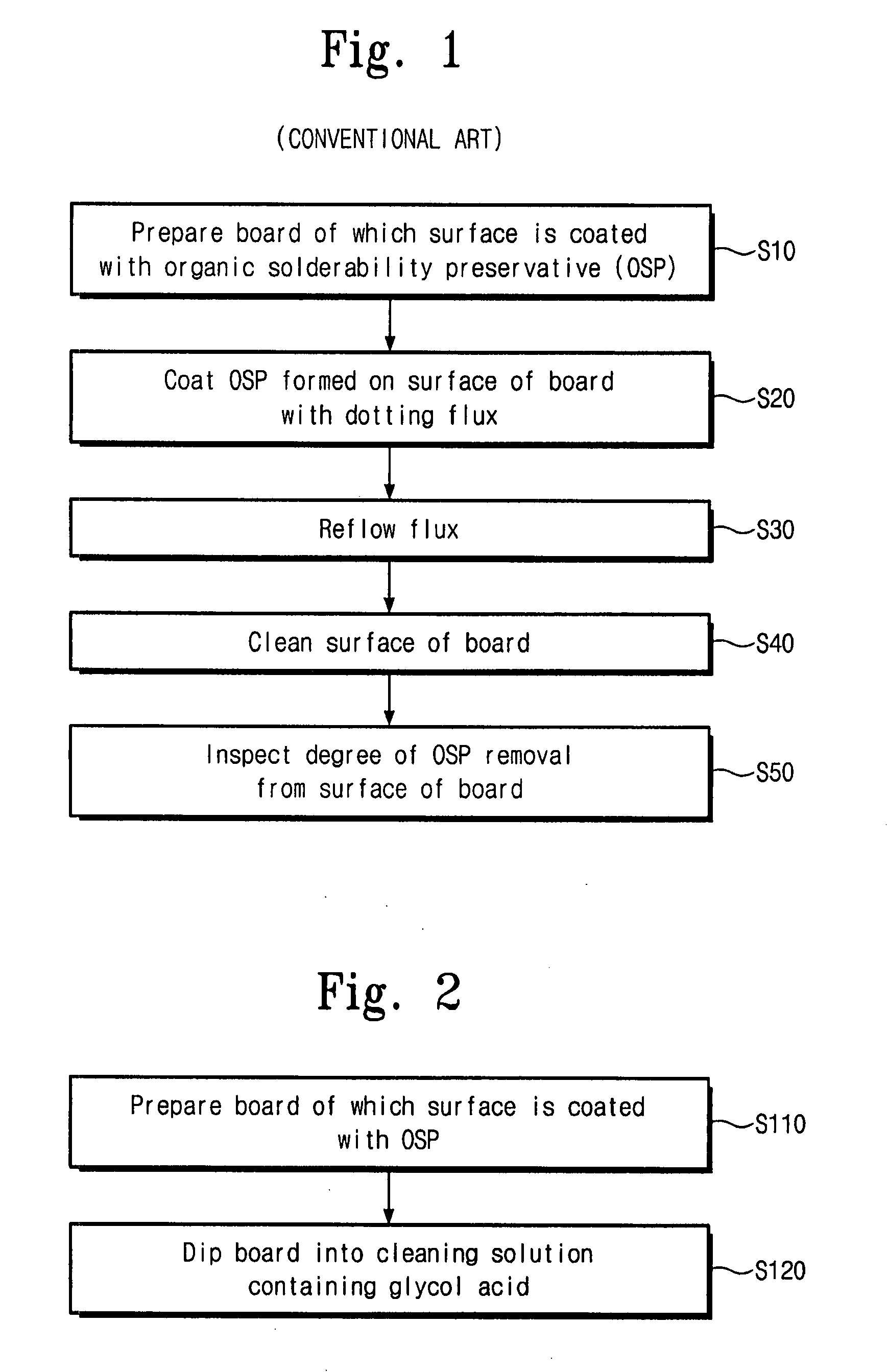

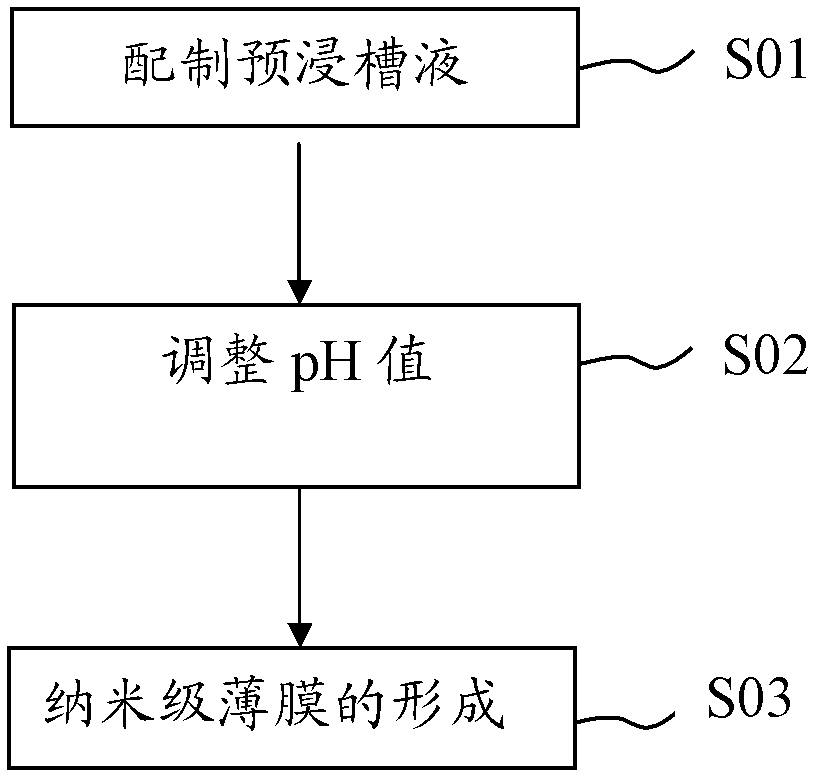

Cleaning solutions and methods of cleaning boards using the same

InactiveUS20080110477A1Easy to cleanDetergent mixture composition preparationSemiconductor/solid-state device manufacturingGlycollic acidSURFACTANT BLEND

A method of cleaning a board includes dipping a board having a surface on which an organic solderability preservative (OSP) is provided into a cleaning solution having glycolic acid, a surfactant and water.

Owner:SAMSUNG ELECTRONICS CO LTD

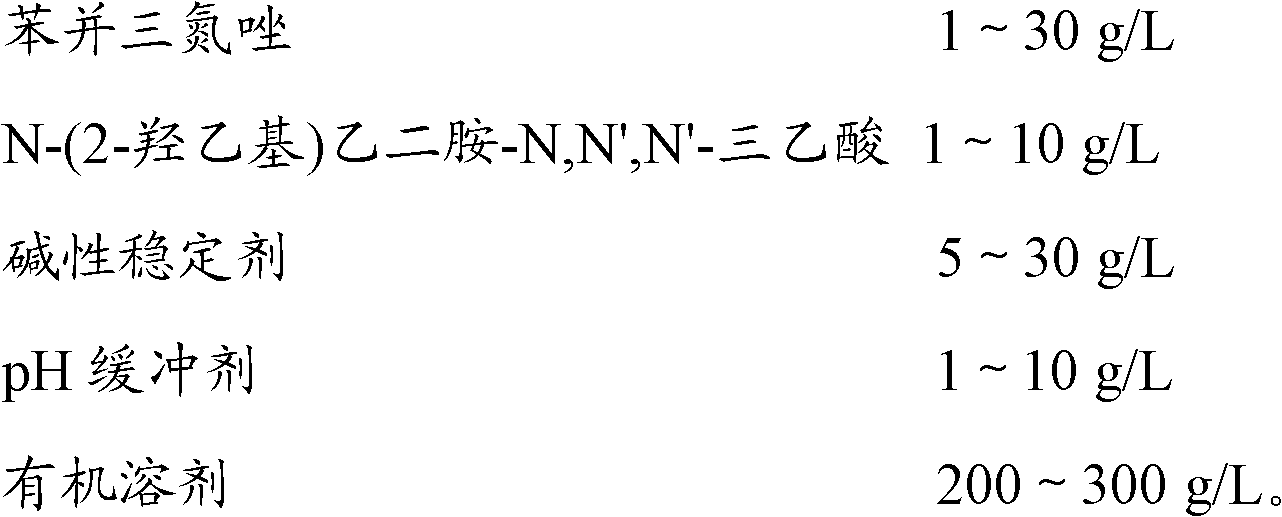

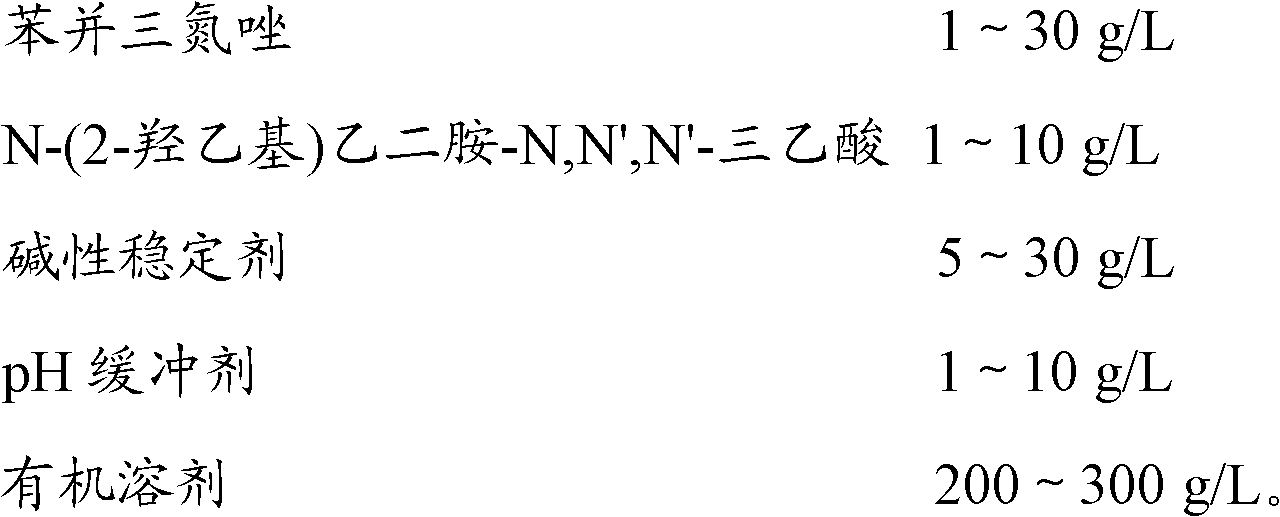

Organic solderability preservative (OSP) on surface of printed circuit board and presoaking stoste and method for manufacturing OSP

InactiveCN102523680AStrong adhesionImprove antioxidant capacityPrinted circuit detailsMetallic material coating processesPh bufferingOrganic solvent

The invention discloses an organic solderability preservative (OSP) on the surface of a printed circuit board and a presoaking stoste and a presoaking method for manufacturing the OSP. The presoaking stoste for manufacturing the OSP on the surface of the printed circuit board comprises the following components of: 1 to 30 g / L of benzotriazole, 1 to 10 g / L of N-(2-ethoxy)quadrol-N,N',N'-nitrilotriacetic-acid, 5 to 30 g / L of alkaline stabilizer, 1 to 10 g / L of pH buffering agent and 200 to 300 g / L organic solvent. The presoaking method for manufacturing the OSP on the surface of the printed circuit board comprises the following steps of: preparing a presoaking bath solution, adjusting the pH value and forming a nano thin film. The OSP on the surface of the printed circuit board is prepared by presoaking by the presoaking method for manufacturing the OSP on the surface of the printed circuit board, and then forming an OSP film. The presoaking stoste for manufacturing the OSP on the surface of the printed circuit board is high in stability and long in service life; the presoaking method for manufacturing the OSP on the surface of the printed circuit board is simple in process, and the conditions are easy to control; the obtained OSP has high adhesive force and high temperature resistance, and is uniform and compact, so that the solderability of the finished printed circuit board is improved.

Owner:深圳市华傲创表面技术有限公司

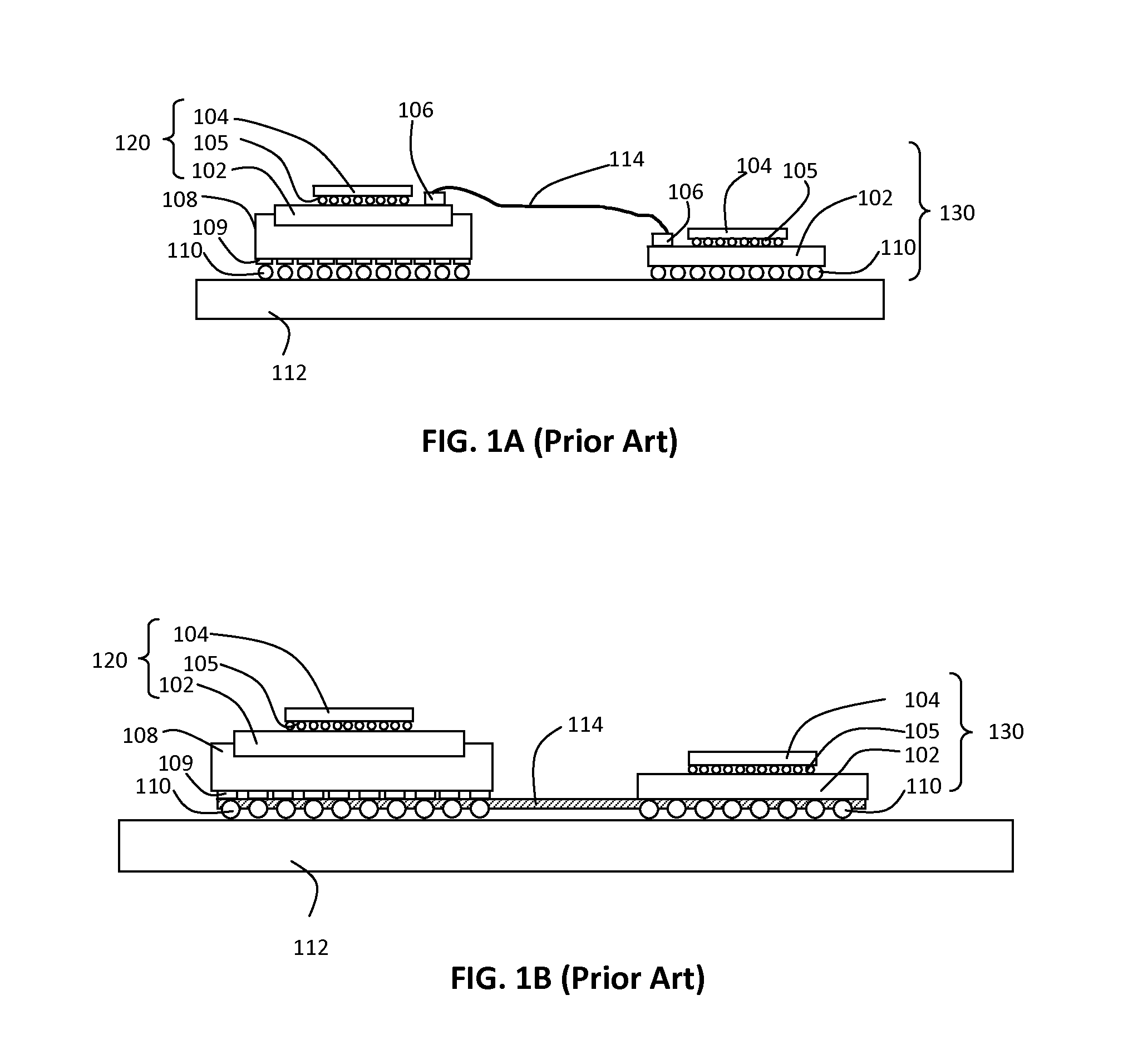

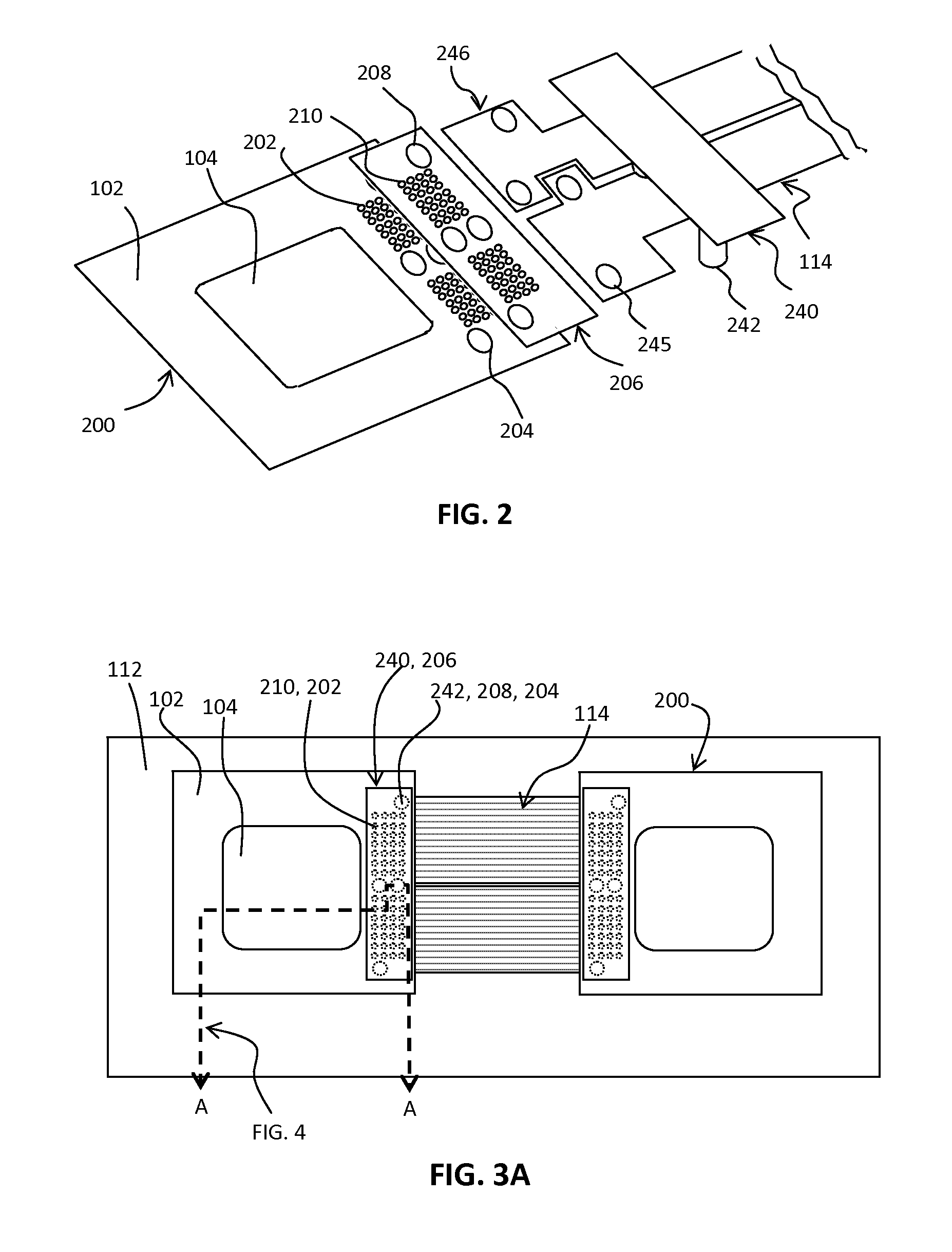

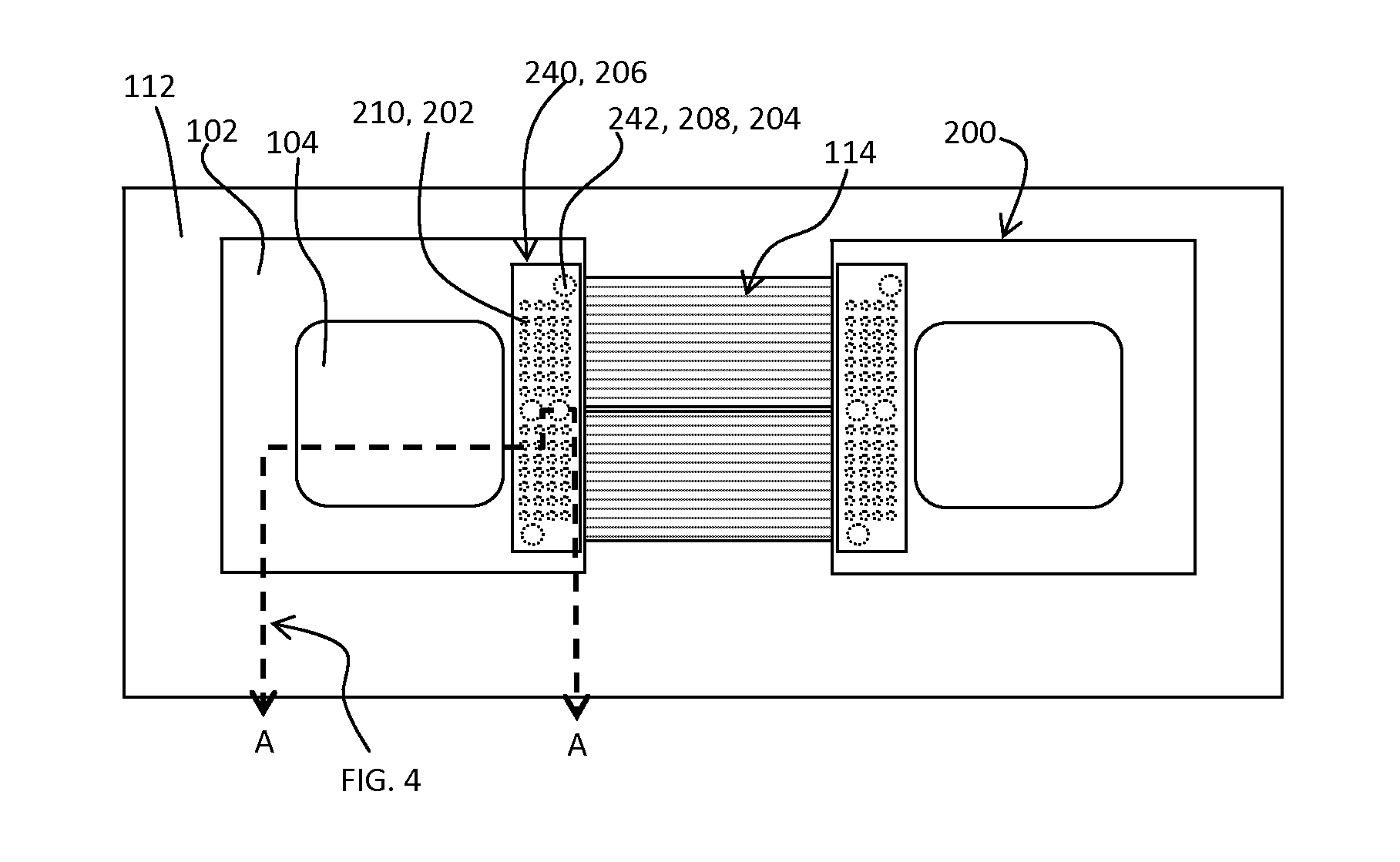

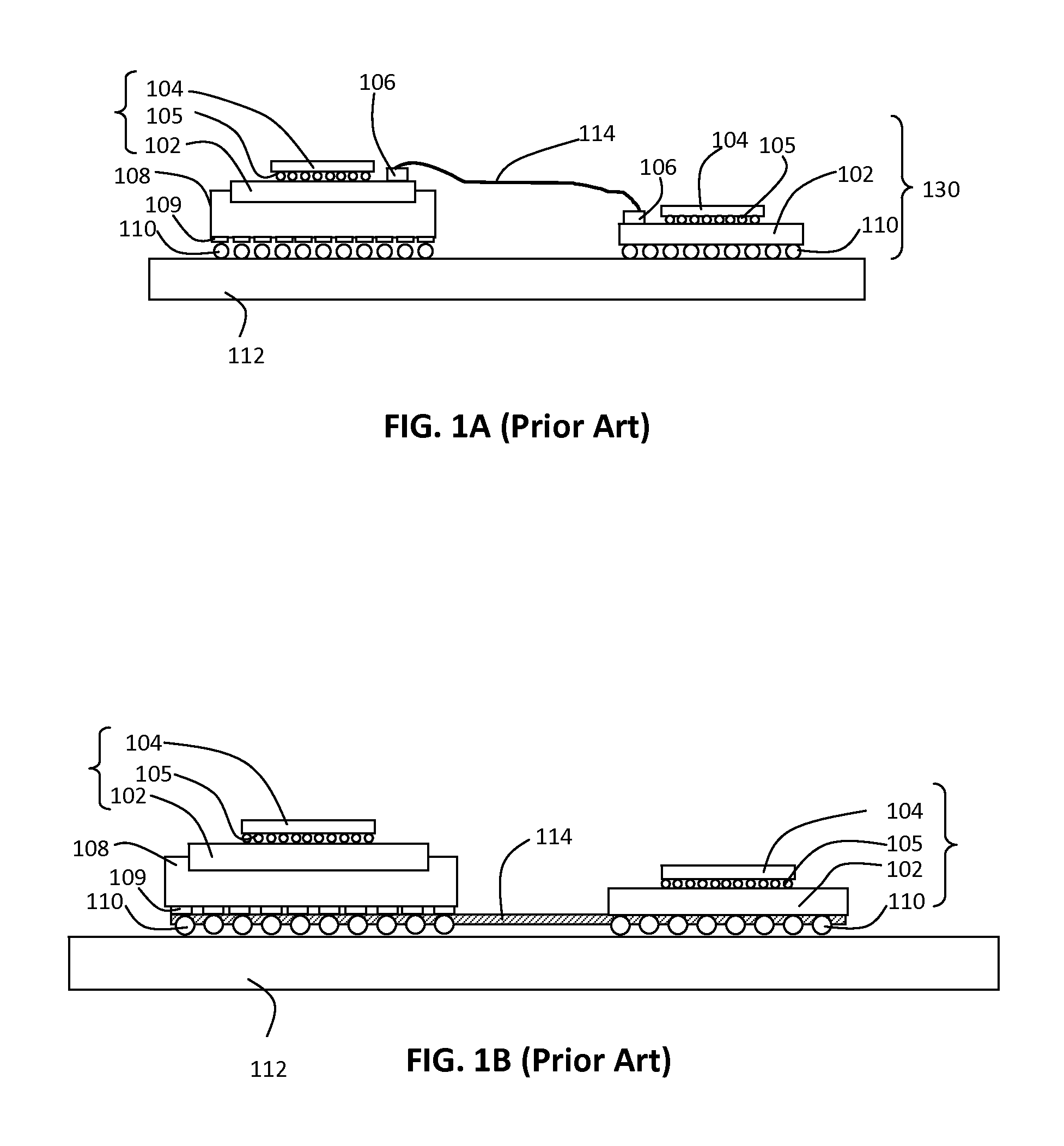

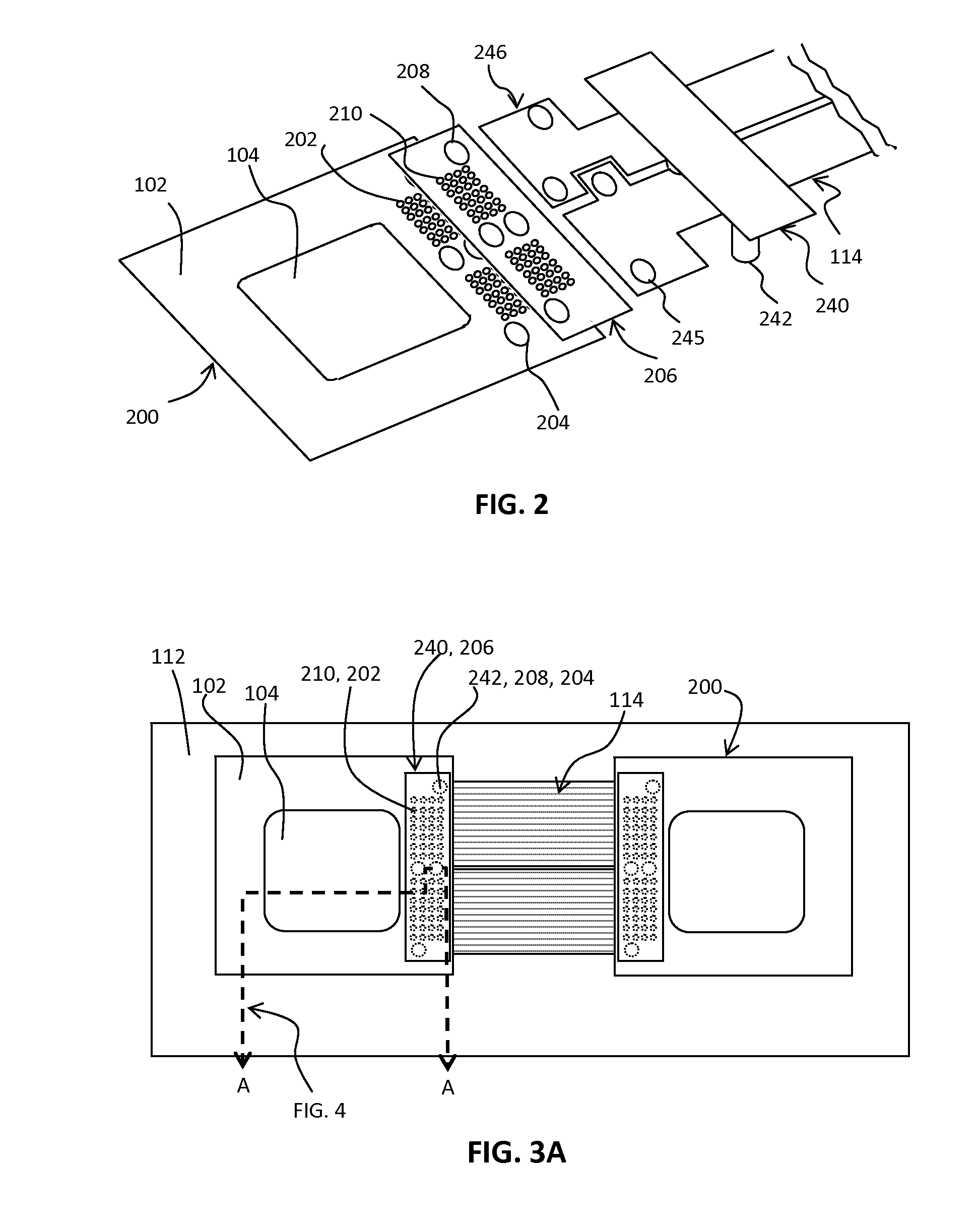

Flex cable and method for making the same

An assembly of substrate packages interconnected with flex cables. The assembly allows input / output (I / O) signals to be speedily transmitted between substrate packages via flex cable and without being routed through the motherboard. Embodiments relate to a substrate package providing detachable inter-package flex cable connection. The flex cable comprises a transmission region that includes a plurality of signal traces and a ground plane. A plurality of solder mask strips are disposed on the plurality of signals traces to provide anchoring for the signal traces. The solder mask strips intersect the signals traces. The exposed signal traces and the ground plane are coated with organic solderability preservative material. Hermetically-sealed guiding through holes are provided on the substrate package as a mechanical alignment feature to guide connection between flex cables and high speed I / O contact pads on the substrate package. Embodiments of the method of fabrication relate to simultaneously forming hermetically-sealed guiding through holes and I / O contact pads.

Owner:TAHOE RES LTD

Organic solderability preservative and method

InactiveUS20140174322A1Good anticorrosion property and thermal stabilityMaintain solderabilitySemiconductor/solid-state device manufacturingMetallic material coating processesElectrical connectionSolderability

An organic solderability preservative solution includes pyrazine derivatives which inhibit corrosion of metal. The solution is applied to metal surfaces of components for electronic apparatus to improve solderability of electrical connections between the components in the electronic apparatus.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

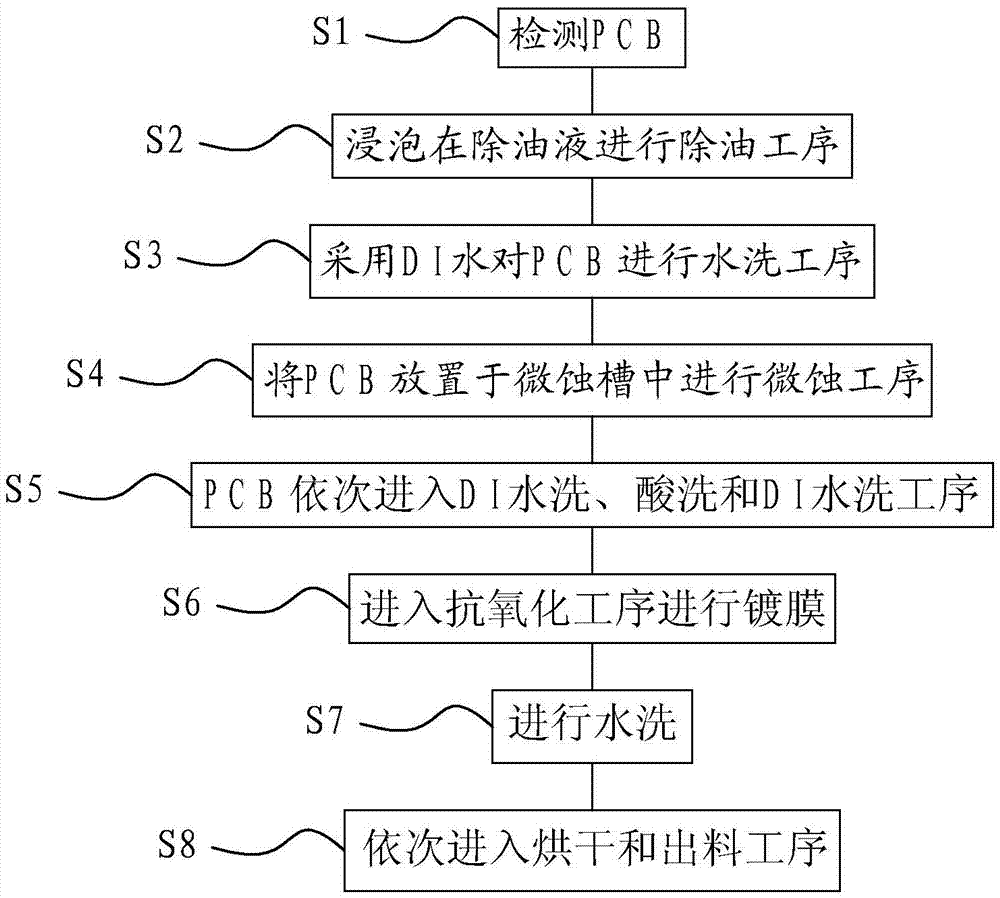

Control method for enhancing organic solderability preservative (OSP) tin soldering property

InactiveCN105451457AGood tinning effectGuaranteed cleanlinessNon-metallic protective coating applicationSolderabilityEngineering

The invention relates to the technical field of organic solderability preservatives (OSPs), in particular to a control method for enhancing an organic solderability preservative (OSP) tin soldering property. According to the technical scheme provided by the invention, a printed circuit board (PCB) is detected firstly in order to ensure the cleanliness of a copper surface before coating of an OSP film. A film is formed under a good OSP condition, and the formed film is protected in inspection, conveying and packaging processes. Conditions which tend to occur before, during and after an OSP procedure are controlled to prevent hidden troubles, so that the technical problem of poor tin soldering property of the PCB due to poor OSP film control is solved, and good tin soldering property of the PCB treated with the OSP is kept.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

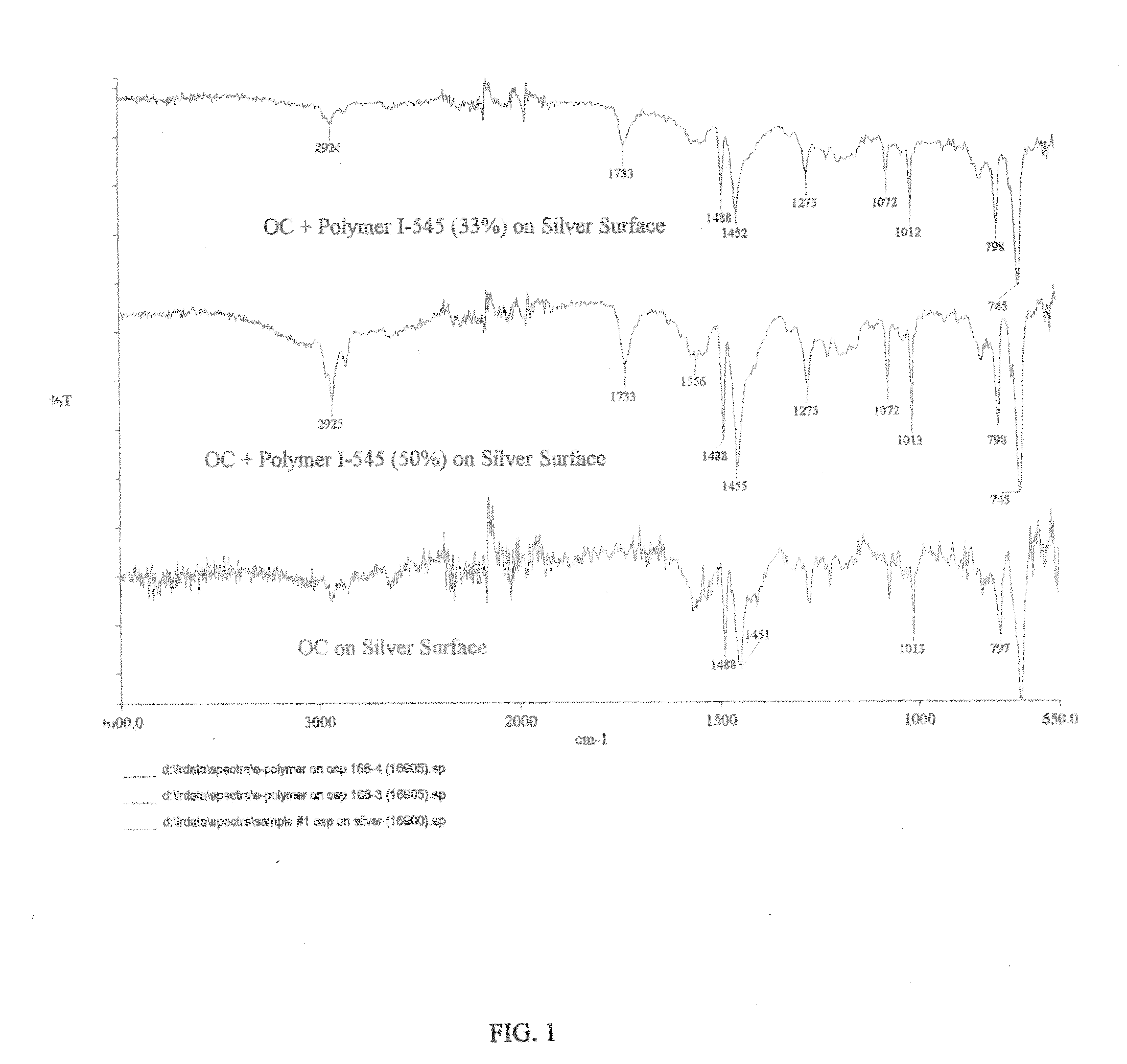

Organic polymer coating for protection against creep corrosion

InactiveUS20100243301A1Improve corrosion resistanceImproved creep corrosion resistanceAnti-corrosive paintsLiquid/solution decomposition chemical coatingSurface finishChemical reaction

A process is described for treating metal surfaces printed wiring boards and similar substrates to provide improved creep corrosion resistance on such surfaces. A modified organic solderability preservative composition is used in combination with an emulsion polymer to provide a modified polymer coating on the metal surface finish via a chemical reaction to provide enhanced corrosion protection of the surface.

Owner:MACDERMID ACUMEN INC

Combined Solderable Multi-Purpose Surface Finishes on Circuit Boards and Method of Manufacture of Such Boards

InactiveUS20080173470A1Faster ratePrinted circuit manufactureMetallic pattern materialsSurface finishEngineering

A circuit board, in one embodiment a printed wiring board (PWB); in a second embodiment a substrate for an ASIC (Application Specific Integrated Circuit) or Chip Carrier; and a method of manufacturing the same. In one embodiment, the PWB, ASIC or Chip Carrier includes: (1) a substrate having a conductive trace located thereon and (2) a combined, multi-purpose surface finish utilizing an electroless or electrolytically deposited nickel under-plate finished with a coating of an organic solderability preservative (OSP) and is located on at least a portion of the conductive areas (trace, pad, fingers, etc), which forms both a non-contact finish and a contact finish for the PWB, ASIC or Chip Carrier.

Owner:BARBETTA MICHAEL

Organic solderability preservative comprising high boiling temperature alcohol

ActiveUS7794531B2Improve stabilityOrganic non-polymeric coatingOther chemical processesPhysical chemistryCyclic alcohol

An organic solderability preservative (OSP) composition comprising an alkyl cyclic alcohol and an azole compound having enhanced composition stability against crystallization of the azole compound.

Owner:MACDERMID ENTHONE INC

Low-temperature solubilizer of organic solderability preservative and application method thereof

InactiveCN101758338AImprove solubilityEnhanced pH adjustmentPrinted circuit manufactureWelding/cutting media/materialsOrganic filmSolubility

The invention discloses low-temperature solubilizer of organic solderability preservative (OSP), which is mainly used for the technologies of anti-oxidation and soldering in manufacturing industry of printed-circuit boards. A layer of organic film is chemically grown on the surface of cleaning bare copper, wherein the film has oxidation resistance, thermal shock resistance and wet fastness for protecting the surface of copper. With the volatility of dissolvent of the organic solderability preservative and the dissolubility of main agent, low-temperature precipitated crystalloid is generated in the process of production to influence the practical use of the OSP technology. The patent improves the problems that the OSP has worse stability under low temperature and is easily crystallized, and the like. By adding the low-temperature solubilizer, the invention increases the low-temperature dissolubility of the main agent of the OSP, so that the OSP still has good stability when the temperature is reduced below 5 DEG C.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Semiconductor device and fabrication method thereof

InactiveUS20070001295A1Avoid crackingSemiconductor/solid-state device detailsStacked resist layersDevice materialEngineering

A semiconductor device and a method of fabricating the same may be provided. The semiconductor device may include an insulation material as a base frame of a PCB, including an opening penetrating the insulation material with sidewalls plated with a gold (Au) layer. The semiconductor device may further include a printed circuit board for use in a module, having a pad whose surface may be coated with an organic solderability preservative (OSP) and an opening whose sidewalls may be plated with a nickel (Ni) layer and a gold (Au) layer, and a semiconductor device mounted on the PCB via the pad. During a temperature cycling reliability test on the semiconductor device, no defects, for example, cracks may form inside the opening.

Owner:SAMSUNG ELECTRONICS CO LTD

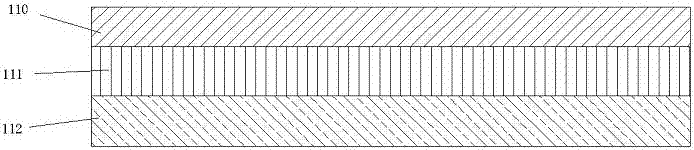

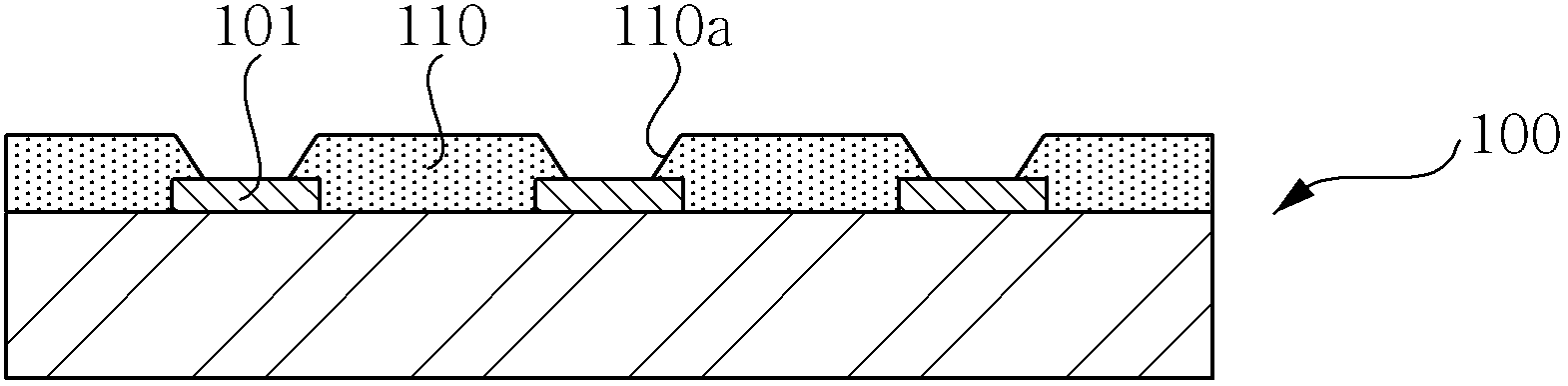

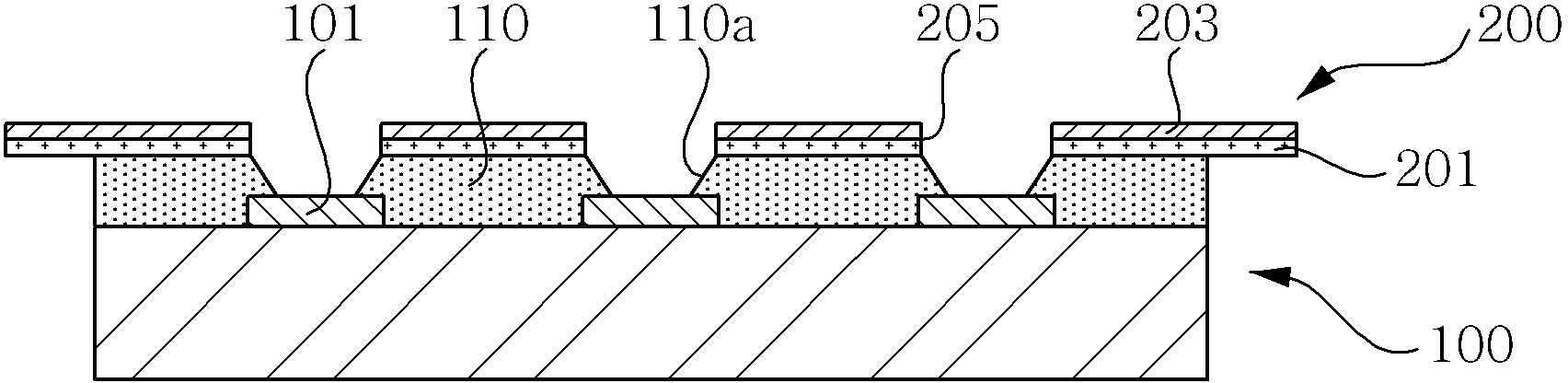

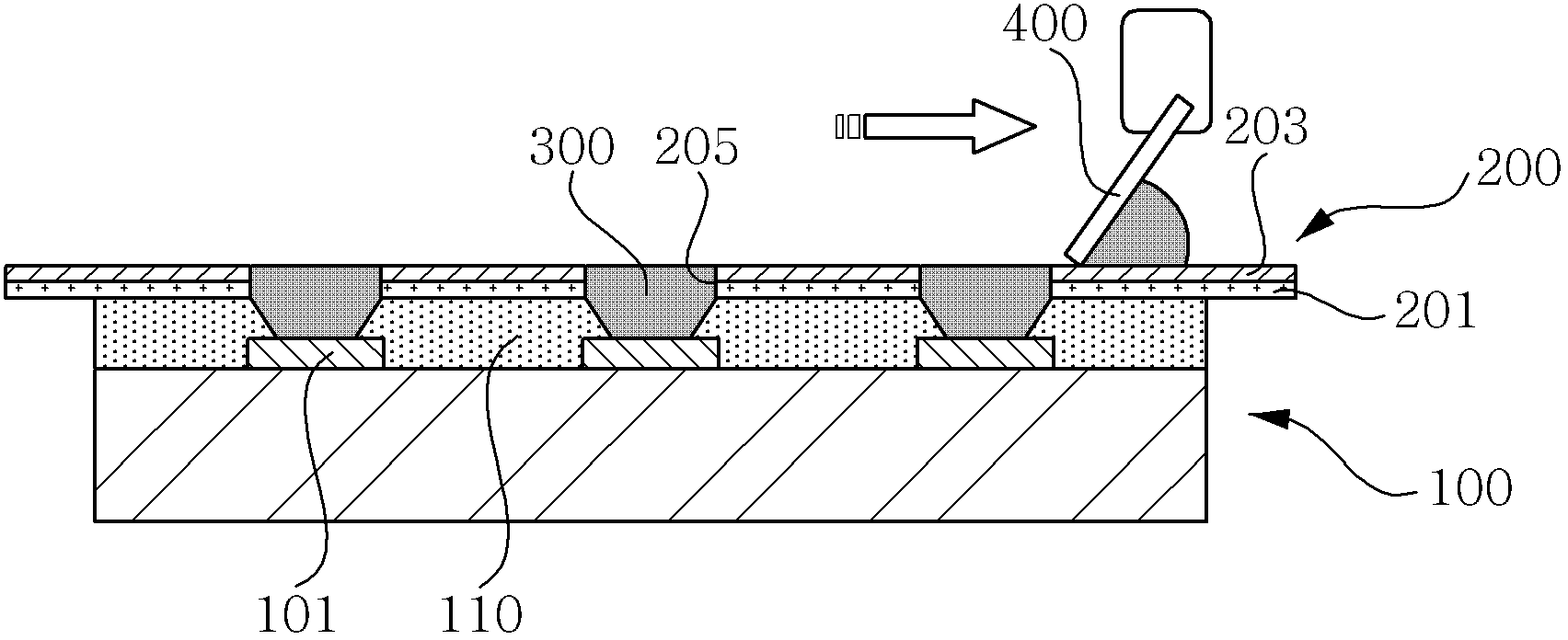

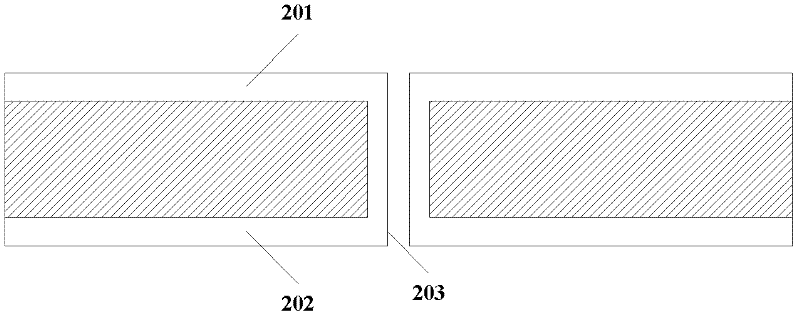

Method for manufacturing of circuit board

InactiveCN103188885APrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringOrganic solderability preservative

A manufacturing method of a circuit substrate is provided to form a surface processing layer by coating with an OSP(Organic Solderability Preservative) liquid and reducing an organic exhausting volume. A base substrate(100) having a connection pad(101) is prepared. A mask(200) having an opening part(205) on the base substrate is arranged. A surface treatment liquid(300) is charged in the opening part. The surface processing layer is formed on the connection pad with a step of heating. The mask is removed.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

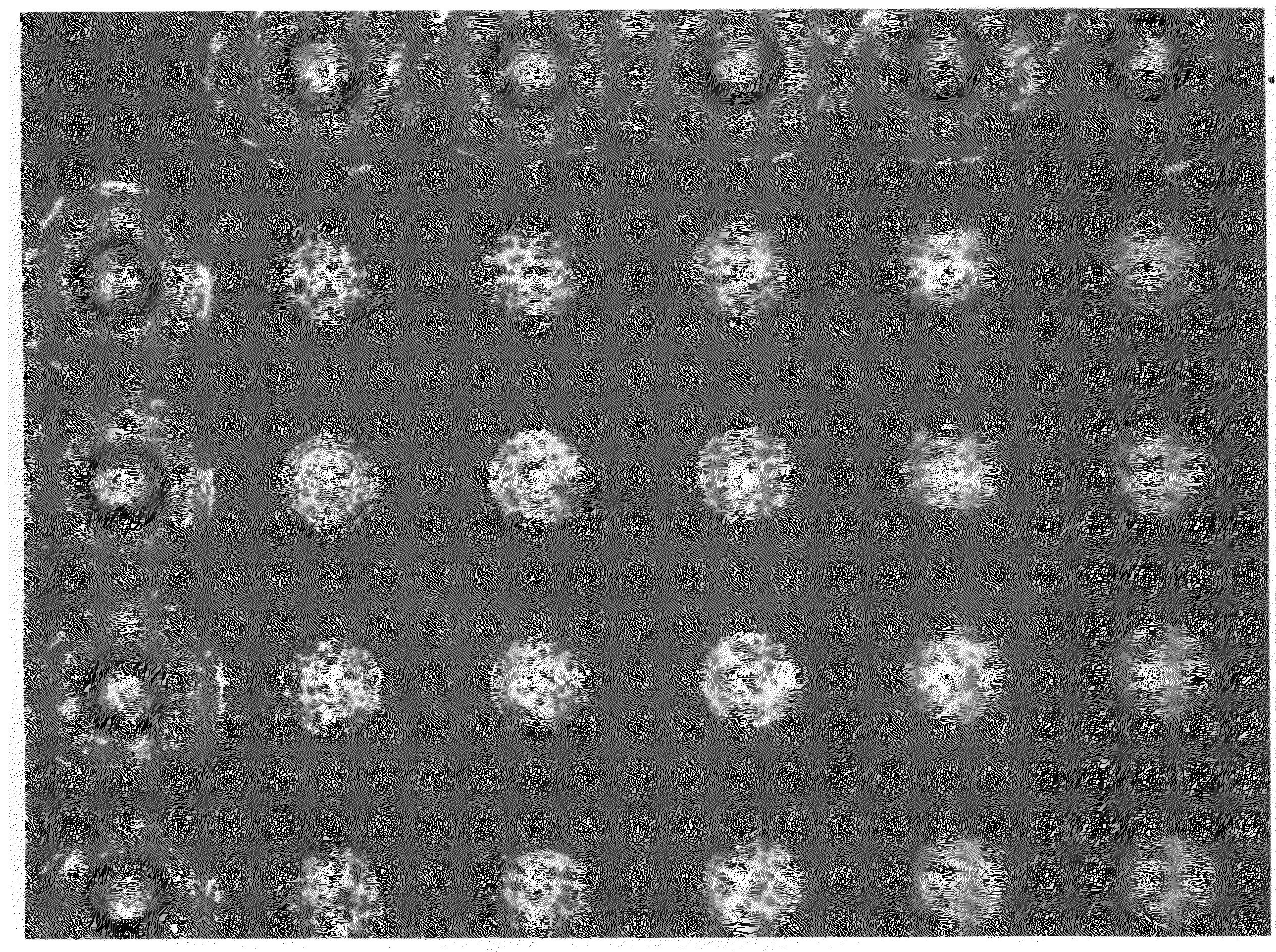

Precoat composition for organic solderability preservative

InactiveUS20070221503A1Simple coating processImprove solderabilityPrinted circuit manufactureSolderabilityCarboxylic acid

An improved method of enhancing the solderability of a copper surface comprising the steps of contacting one or more copper surfaces with a pretreatment composition comprising a dilute solution of an aliphatic carboxylic acid and an additive selected from the group consisting of amines and ammonia and thereafter contacting the one or more surfaces with an organic solderability preservative composition. The improved organic solderability preservative process of the invention forms a more uniform coating that has a better appearance and color.

Owner:MACDERMID INC

Precoat composition for organic solderability preservative

The present invention provides an improved method of enhancing the solderability of a copper surface comprising the steps of contacting one or more copper surfaces with a pretreatment composition comprising a dilute solution of an aliphatic carboxylic acid and an additive selected from the group consisting of amines and ammonia and thereafter contacting the one or more surfaces with an organic solderability preservative composition. The improved organic solderability preservative process of the invention forms a more uniform coating that has a better appearance and color.

Owner:MACDERMID INC

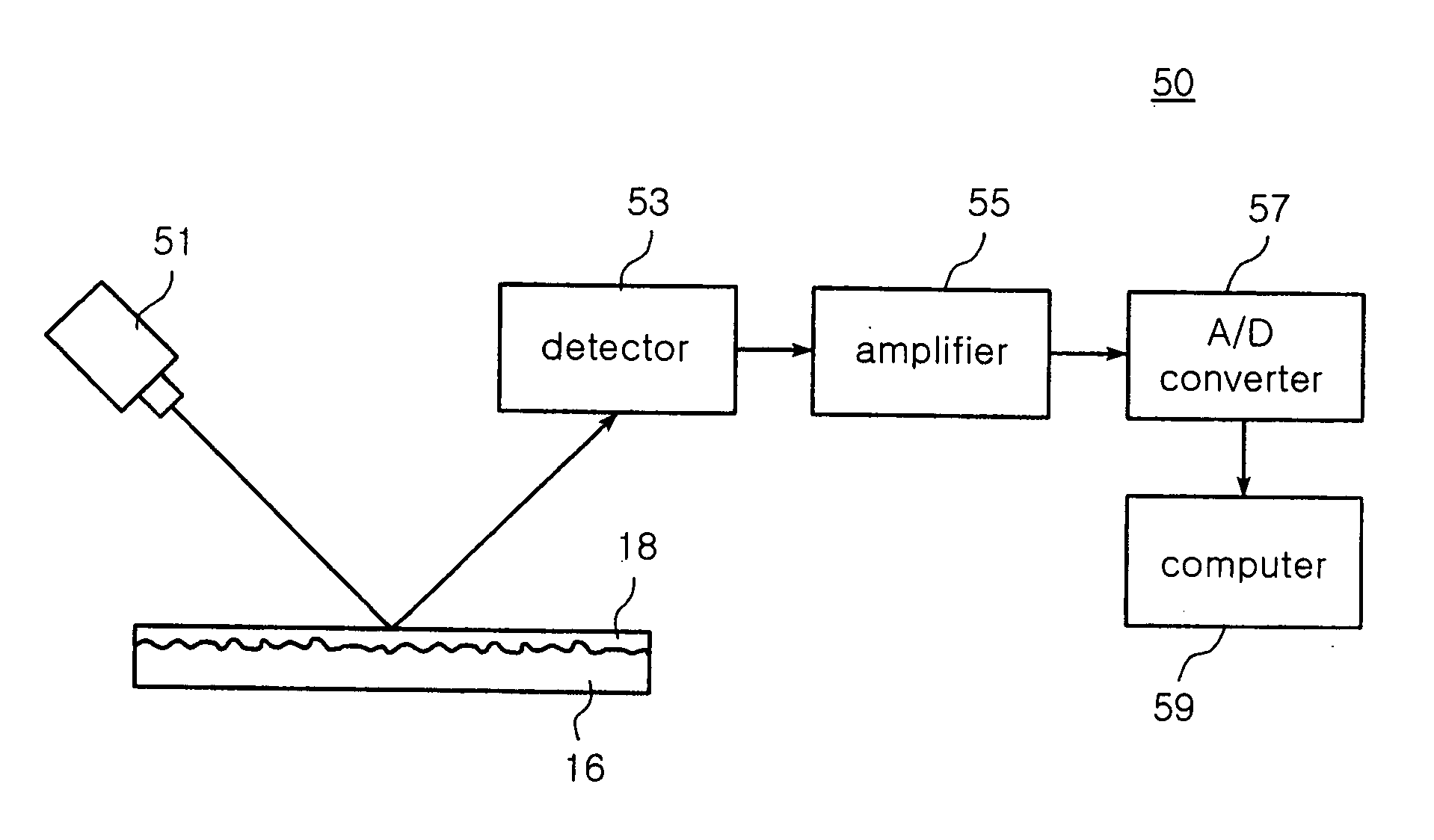

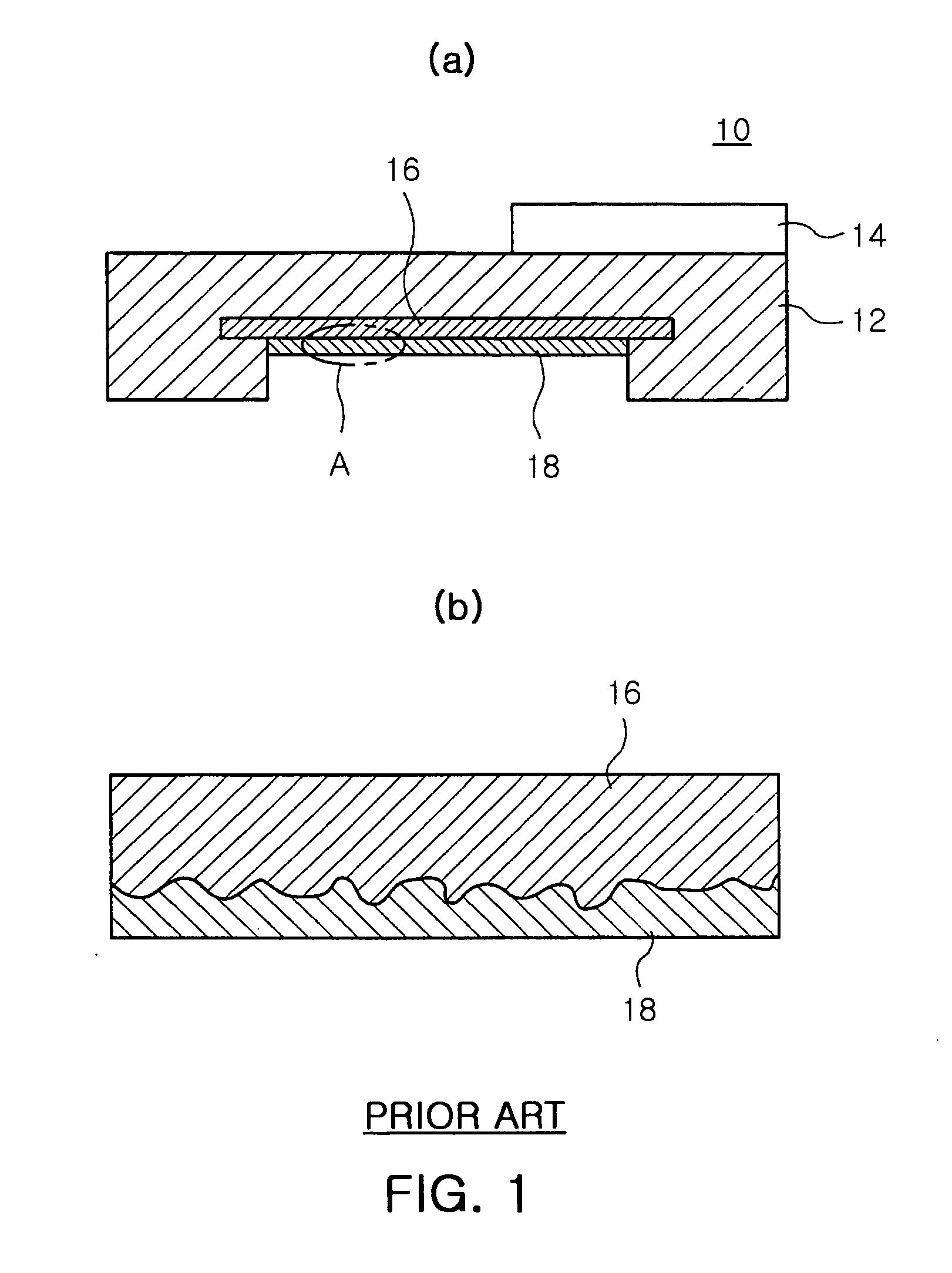

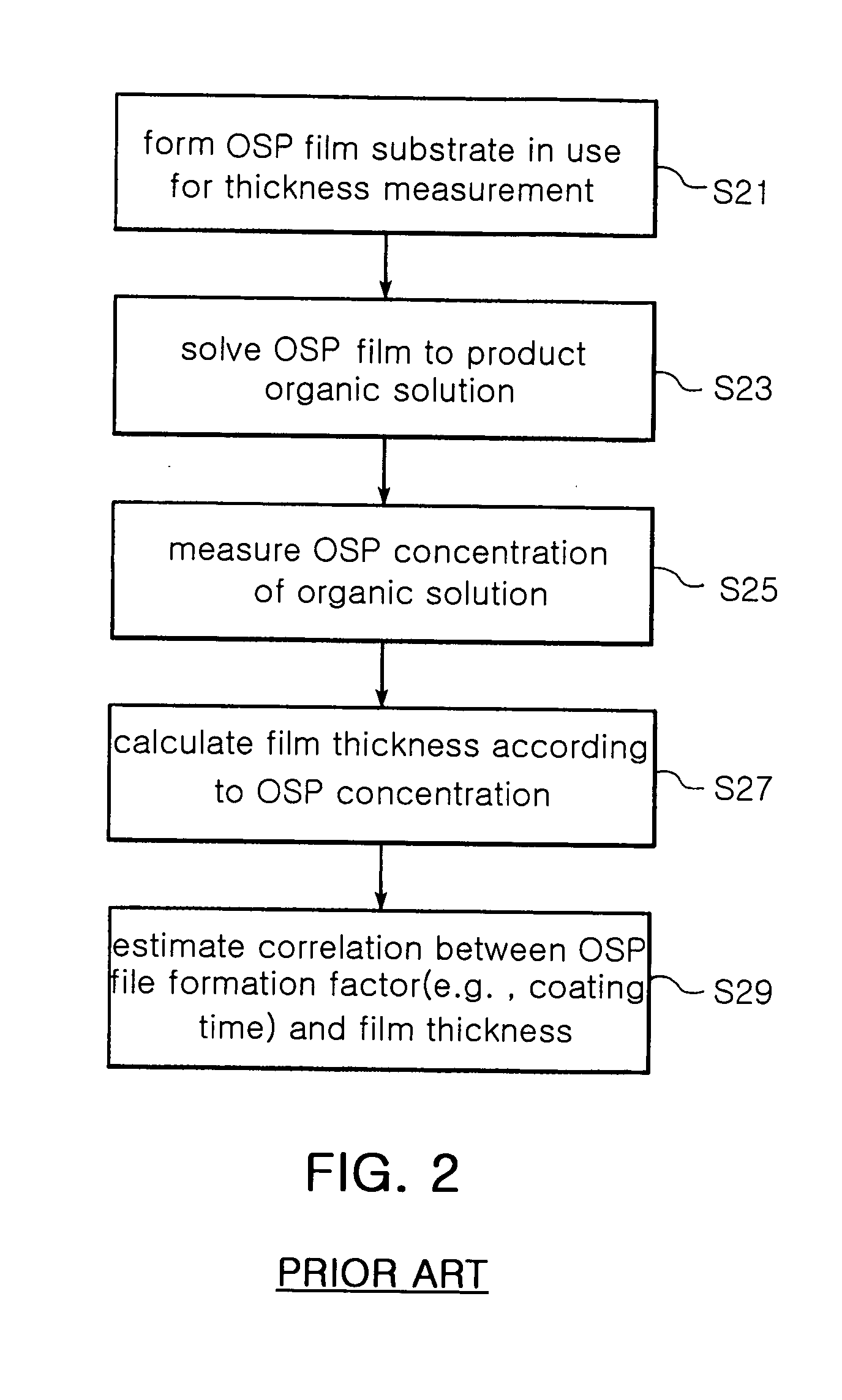

Thickness measuring method for organic coating film on metal surface

InactiveUS20060119867A1Reduce errorsAny errors caused by external influence can be decreased effectivelyLiquid/solution decomposition chemical coatingColor/spectral properties measurementsUltimate tensile strengthOrganic solderability preservative

The invention relates to a thickness-measuring method for an organic coating film such as an organic solderability preservative film formed on a metal film. In the method, an absorption spectrum of at least one reference organic coating film formed on a first metal surface is measured and absorption intensity in a predetermined wavelength range is calculated from the absorption spectrum. The thickness of the reference organic coating film is measured by destructive measurement. Then, correlation is defined based upon the absorption intensity and measured thickness of the reference organic coating film. An absorption spectrum of an organic coating film to be measured. Absorption intensity in the predetermined wavelength range is calculated from the absorption spectrum of the organic coating film to be measured, and the thickness of the organic coating film is calculated from the absorption intensity thereof based upon the correlation.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

A circuit board producing method for preventing golden fingers from exposing copper

ActiveCN103619131AEfficient removalIncrease surface tensionPrinted element electric connection formationEngineeringCopper

The invention provides a circuit board producing method for preventing golden fingers from exposing copper. The circuit board producing method is characterized in that the OSP process of the method comprises following processing: removing spots residing on a circuit board; micro-etching the copper surfaces of lines on the circuit board; and coating the copper surfaces with an organic solderability preservative, wherein micro-etching the copper surfaces of lines on the circuit board means that the circuit board is immersed in a micro-etching liquid in order that the copper surfaces are etched 80 to 100 [mu] " at a rate of 30 to 60 [mu] " / min. With the micro-etching operation, micro-etching liquid medicine, and the optimization of a gold plating process and a nickel plating process, the method effectively prevents a phenomenon of exposed golden finger copper which is commonly generated in a circuit board producing process and guarantees the quality of produced circuit boards. Compared with a method in the prior art in which the golden fingers are shielded by insulating material to be prevented from exposing copper, the method makes progress in operational simplification and increase in efficiency, and is especially suitable for large-scale industrialized popularization.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

Flex cable and method for making the same

An assembly of substrate packages interconnected with flex cables. The assembly allows input / output (I / O) signals to be speedily transmitted between substrate packages via flex cable and without being routed through the motherboard. Embodiments relate to a substrate package providing detachable inter-package flex cable connection. The flex cable comprises a transmission region that includes a plurality of signal traces and a ground plane. A plurality of solder mask strips are disposed on the plurality of signals traces to provide anchoring for the signal traces. The solder mask strips intersect the signals traces. The exposed signal traces and the ground plane are coated with organic solderability preservative material. Hermetically-sealed guiding through holes are provided on the substrate package as a mechanical alignment feature to guide connection between flex cables and high speed I / O contact pads on the substrate package. Embodiments of the method of fabrication relate to simultaneously forming hermetically-sealed guiding through holes and I / O contact pads.

Owner:TAHOE RES LTD

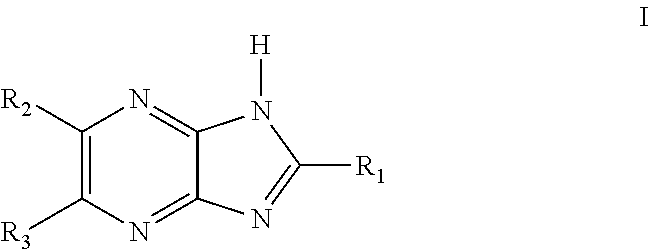

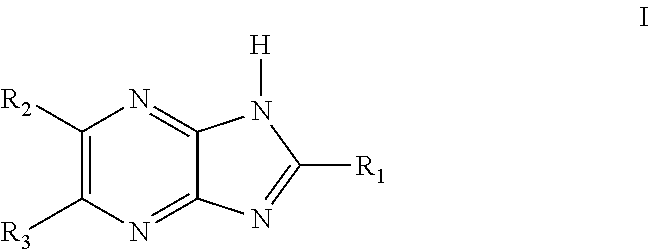

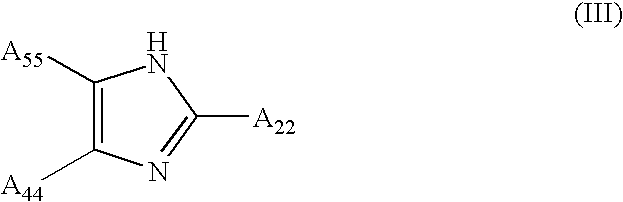

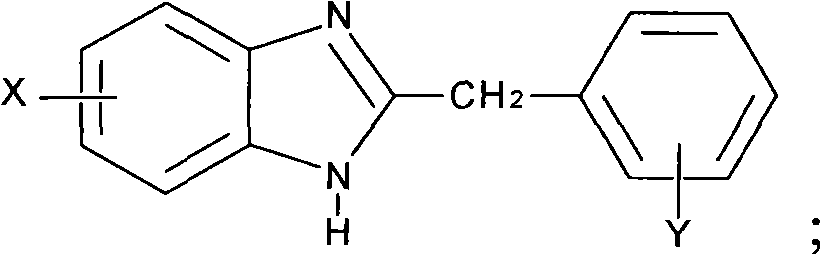

Imidazole derivative solution capable of being used as organic solderability preservative

ActiveCN101780614AImprove solderabilityImprove high temperature resistancePrinted circuit manufactureWelding/cutting media/materialsTemperature resistanceOrganic solderability preservative

The invention relates to organic solderability preservative technology, in particular to imidazole derivative solution capable of being used as an organic solderability preservative, which is used for the organic solderability preservative process of copper or copper alloy on a printed circuit board. The solution comprises the following components in percentage by weight: 0.05 to 10 percent of imidazole derivatives, 0.01 to 30 percent of acidic materials and 0.0001 to 10 percent of water-soluble metal salt. Compared with the prior art, the solution has the advantages that: a layer of organic solderability preservative film with the thickness of 0.1 to 1.0 micrometer is uniformly formed on the surface of the copper or the copper alloy of the printed circuit board, so that the printed circuit board has excellent solderability and has excellent high temperature resistance and oxidation resistance in a high-temperature high-humidity environment.

Owner:林原标

OSP (organic solderability preservative) preimpregnation agent

InactiveCN105081614AShort duration of actionFast film formationWelding/cutting media/materialsSoldering mediaMetal contaminationOrganic solderability preservative

The invention relates to the technical field of printed circuit board shielded welding, in particular to an OSP (organic solderability preservative) preimpregnation agent. The OSP preimpregnation agent comprises 30 g / L-50 g / L of cyclic ketone compound, 1 g / L-5 g / L of amine compound and the balance water. According to the OSP preimpregnation agent, an active layer can be firstly formed on a copper surface, the forming speed of an organic solderability preservative film is increased, and the thickness of the organic solderability preservative film can be increased by more than 20% within the same reaction time. The OSP preimpregnation agent is alkaline preimpregnation treating agent liquid medicine with a higher pH value, corrosion to the copper surface can be reduced, the metal contamination speed of tank liquor is lowered, and the service life of the copper surface can be prolonged by one time. The galvanic effect can be avoided, and the good appearance of a printed circuit board can be ensured. The thickness of intermetallic compounds obtained after tin soldering can be lowered, and the shear strength of a welding connector and the reliability of welding points are guaranteed.

Owner:东莞市富默克化工有限公司

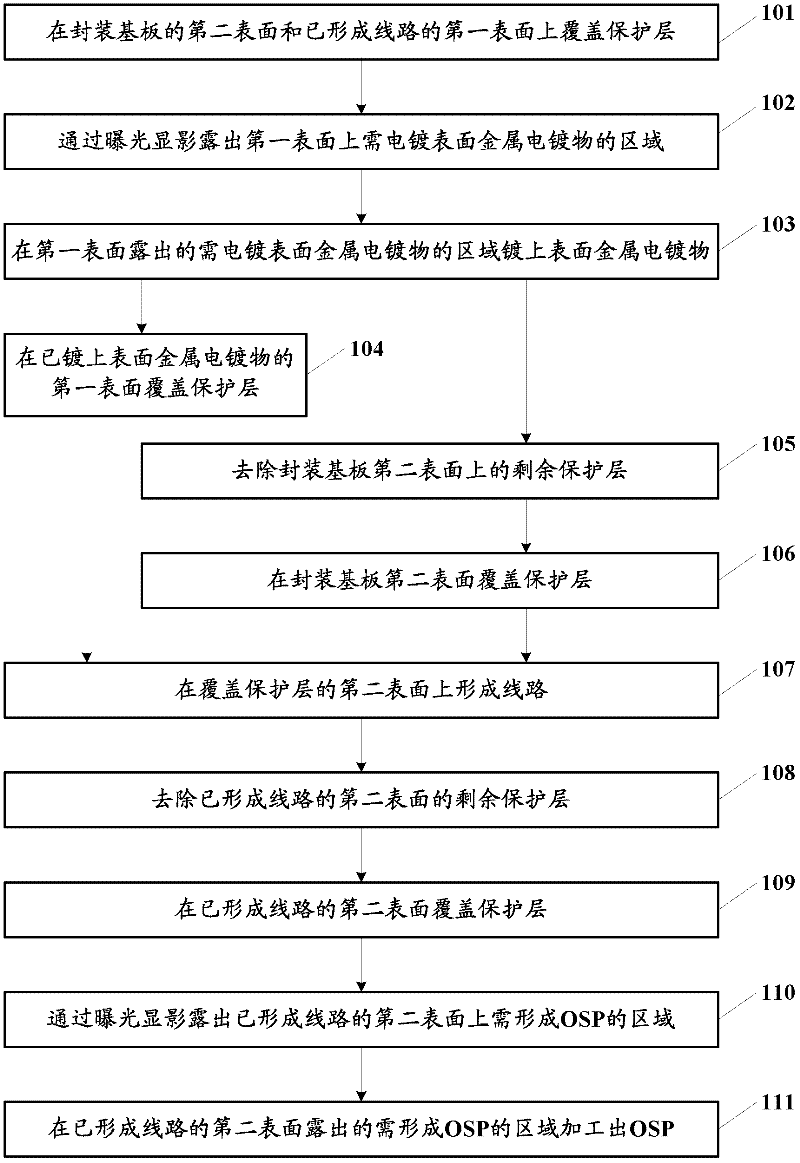

Manufacturing method of package substrate

ActiveCN102543780AReduce processing costsExpand the effective wiring spaceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProtection layer

The embodiment of the invention discloses a manufacturing method of a package substrate, which comprises steps of respectively covering a protection layer on a second surface and a first surface of the package substrate, wherein a circuit is formed on the first surface, and providing at least one via hole between the first surface and the second surface of the package substrate; exposing an area needed to be electroplated with a surface metal electroplate by exposure development on the first surface; electroplating the area needed to be electroplated with the surface metal electroplate on the first surface; covering another protection layer on the firs surface; removing the residual protection layer on the second surface; covering another protection layer on the second surface; forming another circuit on the second surface; removing the another residual protection layer on the second surface where the circuit is formed; covering a protection layer on the second surface and exposing an area where an OSP (organic solderability preservative) is needed to form on, wherein the area is on the second surface; and manufacturing the OPS on the area where an OSP is needed to form, wherein the area is on the second surface. The method of the embodiment of the invention is helpful for avoiding or reducing electroplated lead usage in the substrate electroplating process as much as possible.

Owner:SHENNAN CIRCUITS

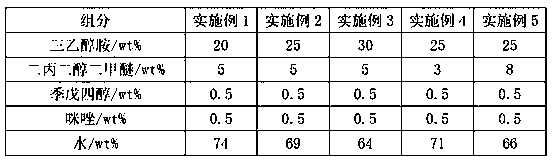

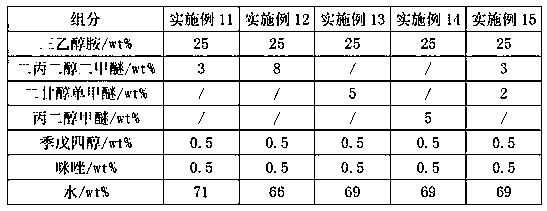

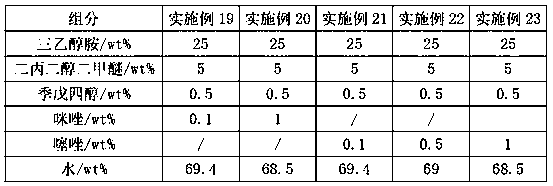

Halogen-free PCB board special-purpose solder mask stripping agent, and preparation method and applications thereof

ActiveCN109880432AGood swelling and dissolving effectEffective peelingChemical paints/ink removersSolder maskOrganic solvent

The invention discloses a halogen-free PCB board special-purpose solder mask stripping agent, and a preparation method and applications thereof. The halogen-free PCB board special-purpose solder maskstripping agent comprises, by mass, 20 to 30% of an organic base, 3 to 8 % of an organic solvent, 0.1 to 1.0 % of a surfactant, 0.1 to 1.0 % of an organic solderability preservative, and the balance water. The halogen-free PCB board special-purpose solder mask stripping agent possesses excellent stripping effect, is suitable for stripping of a plurality of kinds of PCB board solder masks, and is especially excellent in stripping effect on halogen-free PCB board solder mask; when the halogen-free PCB board special-purpose solder mask stripping agent is adopted for solder mask peeling, texture exposure and white spot are not easily caused, after processing, PCB board cooper surface damage is avoided, no blacking is caused, halogen-free PCB board solder mask stripping reworking qualified yield is increased greatly, no obvious solid residue is detected in waste liquid obtained through processing, no obvious residue attached onto liquid tank internal walls is detected, production equipmentcleaning maintenance cost is reduced greatly. The invention also discloses the preparation method and applications of the halogen-free PCB board special-purpose solder mask stripping agent.

Owner:上海富柏化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com