Method for manufacturing of circuit board

A technology of circuit boards and substrates, which is applied in the direction of secondary processing of circuits, printed circuits, and assembly of printed circuits with electrical components, and can solve problems such as increased volume of organic emissions, increased equipment footprint, and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

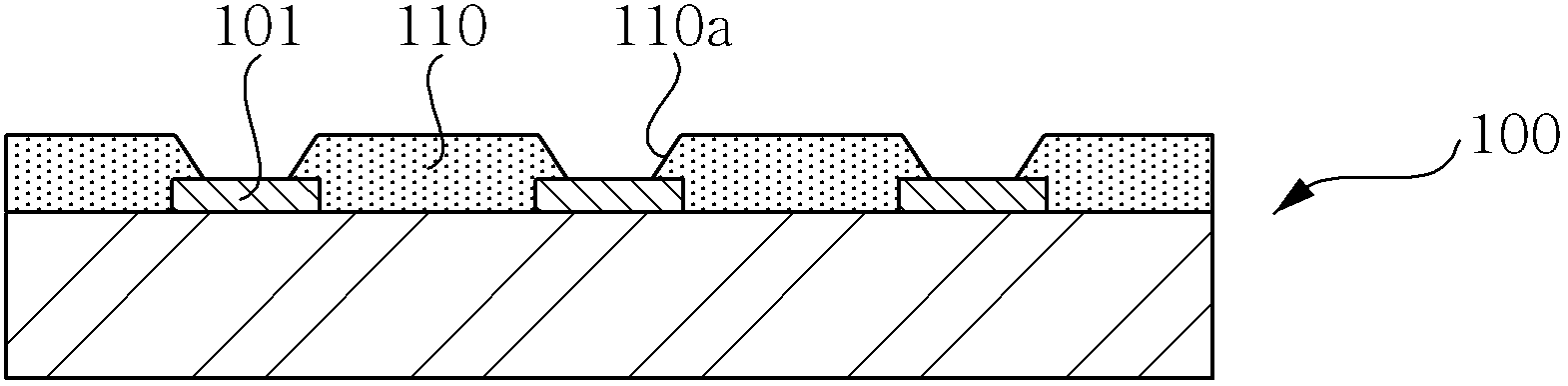

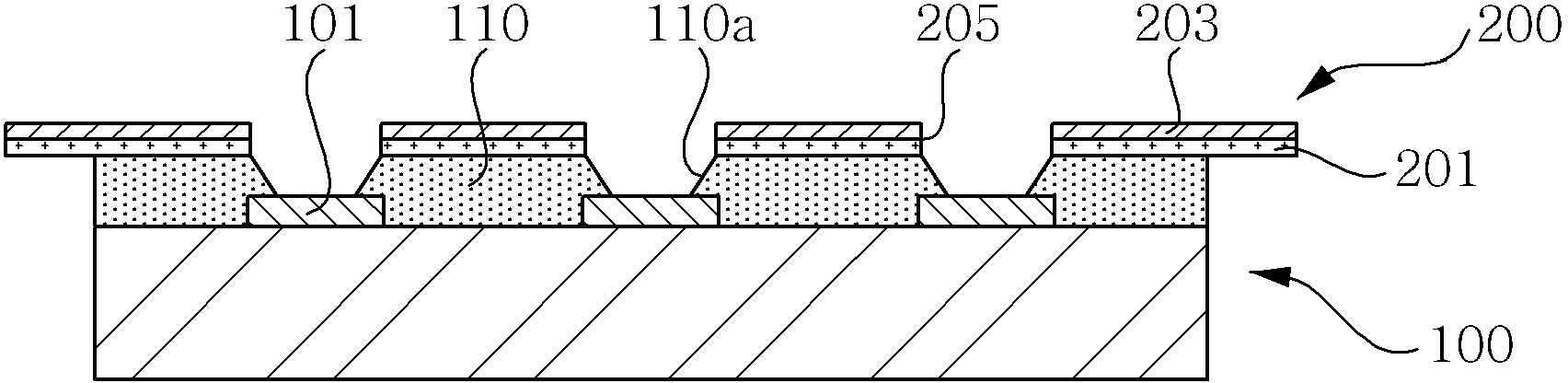

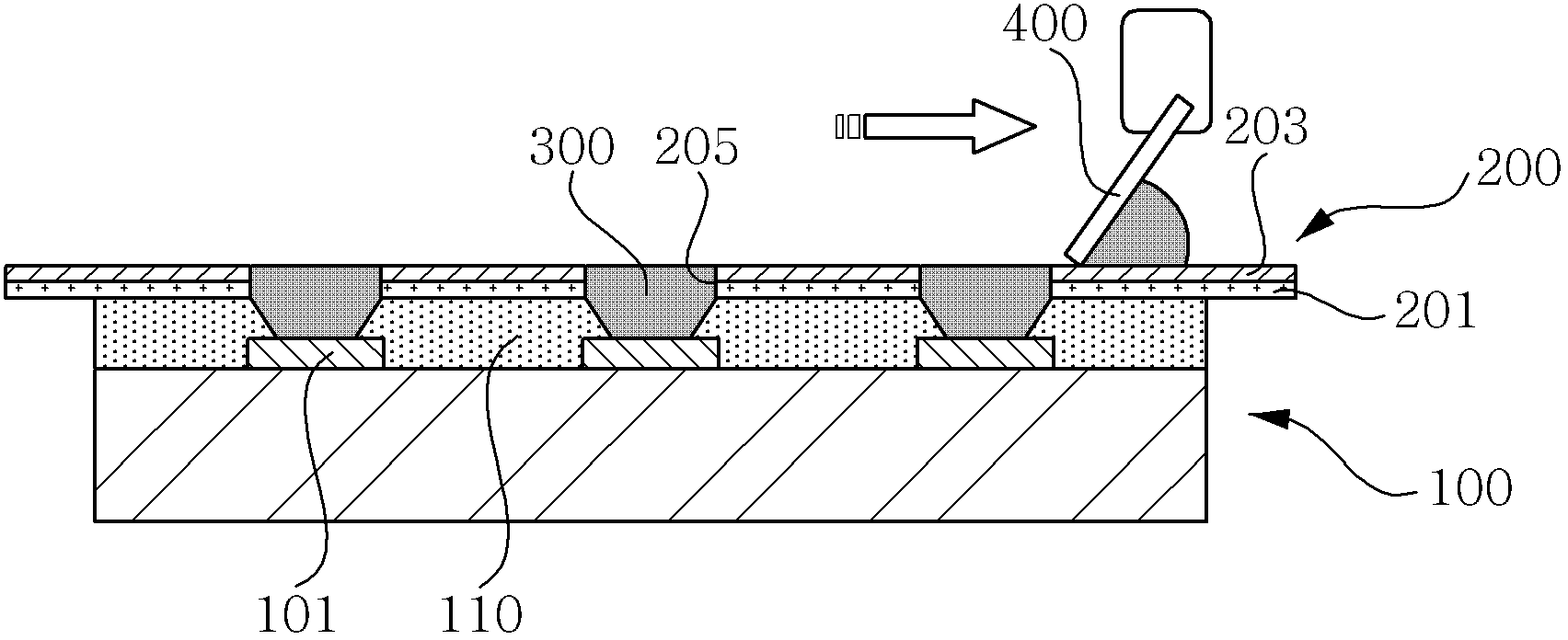

[0030] The features and advantages of the present invention will be more clearly understood from the following detailed description and embodiments. Throughout the drawings, the same reference numerals are used to designate the same or similar elements. Furthermore, even if known arts are related to the present invention, when they would make the characteristics and description of the present invention unclear, their descriptions are considered unnecessary and may be omitted. In the description, the terms 'first', 'second', etc. are used to distinguish one element from another element, and the elements are not defined by the above terms.

[0031] In addition, the terms and words used in this specification and claims should not be construed as limited to the ordinary meanings and dictionary definitions, but should be based on the inventor's ability to properly define the concepts implied by the terms with the best The rules according to describing the method known to him or he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com