Organic solderability preservative (OSP) on surface of printed circuit board and presoaking stoste and method for manufacturing OSP

A printed circuit board, prepreg technology, applied in printed circuit parts, printed circuit secondary treatment, metal material coating process, etc., can solve the problems of replacement, prepreg solution aging, poor uniform density of OSP film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

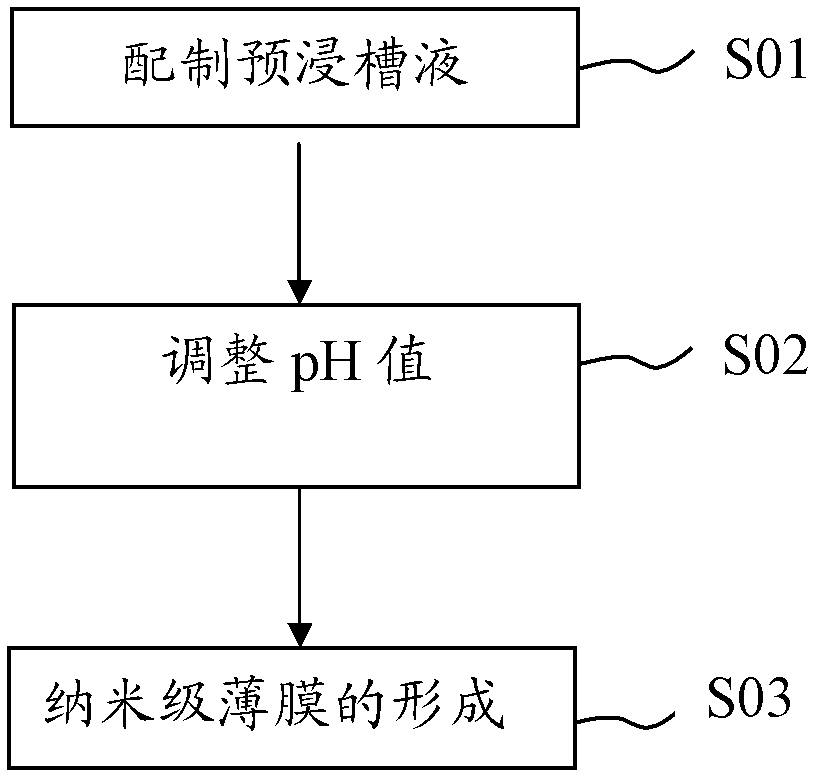

Method used

Image

Examples

Embodiment 1

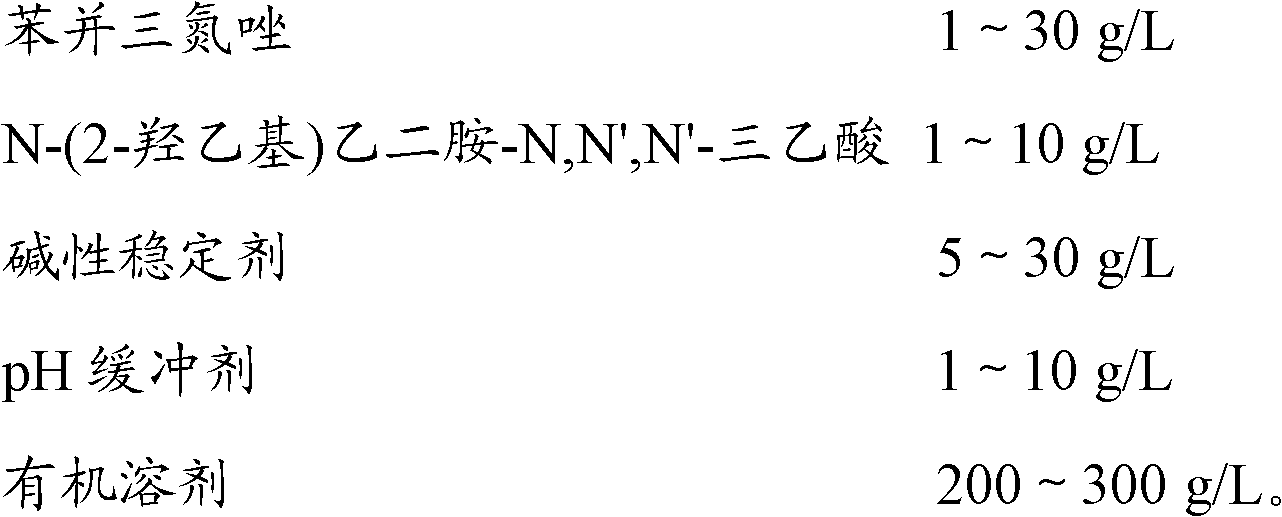

[0048] A kind of predipping dope that is used for the manufacture of OSP on the surface of printed circuit boards comprises the following formula components:

[0049]

Embodiment 2

[0051] A kind of predipping dope that is used for the manufacture of OSP on the surface of printed circuit boards comprises the following formula components:

[0052]

[0053]

Embodiment 3

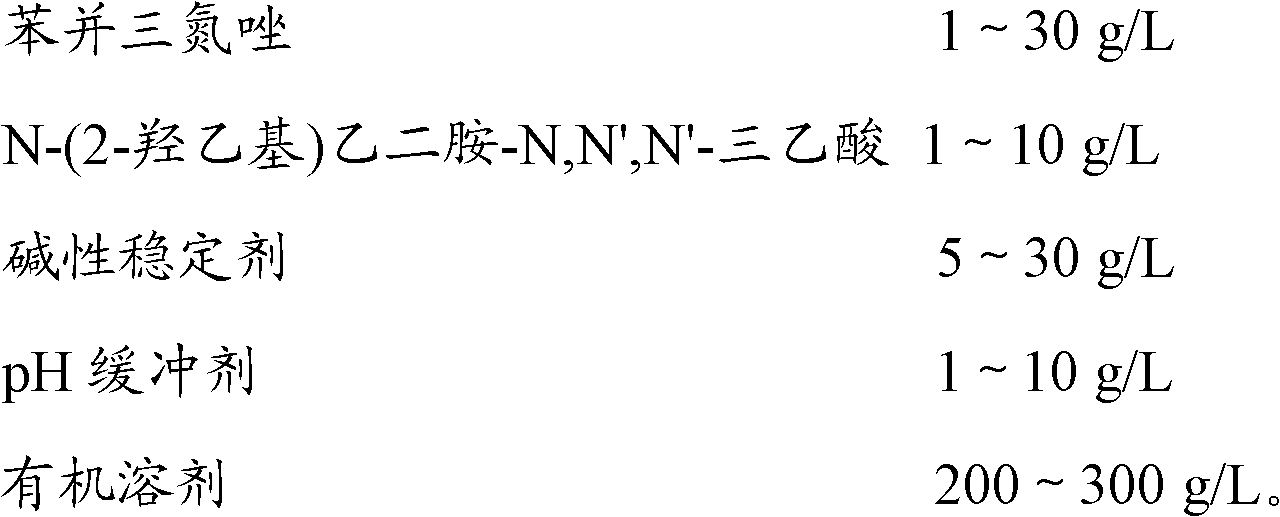

[0055] A kind of predipping dope that is used for the manufacture of OSP on the surface of printed circuit boards comprises the following formula components:

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com