Control method for enhancing organic solderability preservative (OSP) tin soldering property

A control method and process technology, applied in the field of OSP, can solve problems such as poor tin on PCB boards, and achieve the effect of maintaining tinning and good tinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

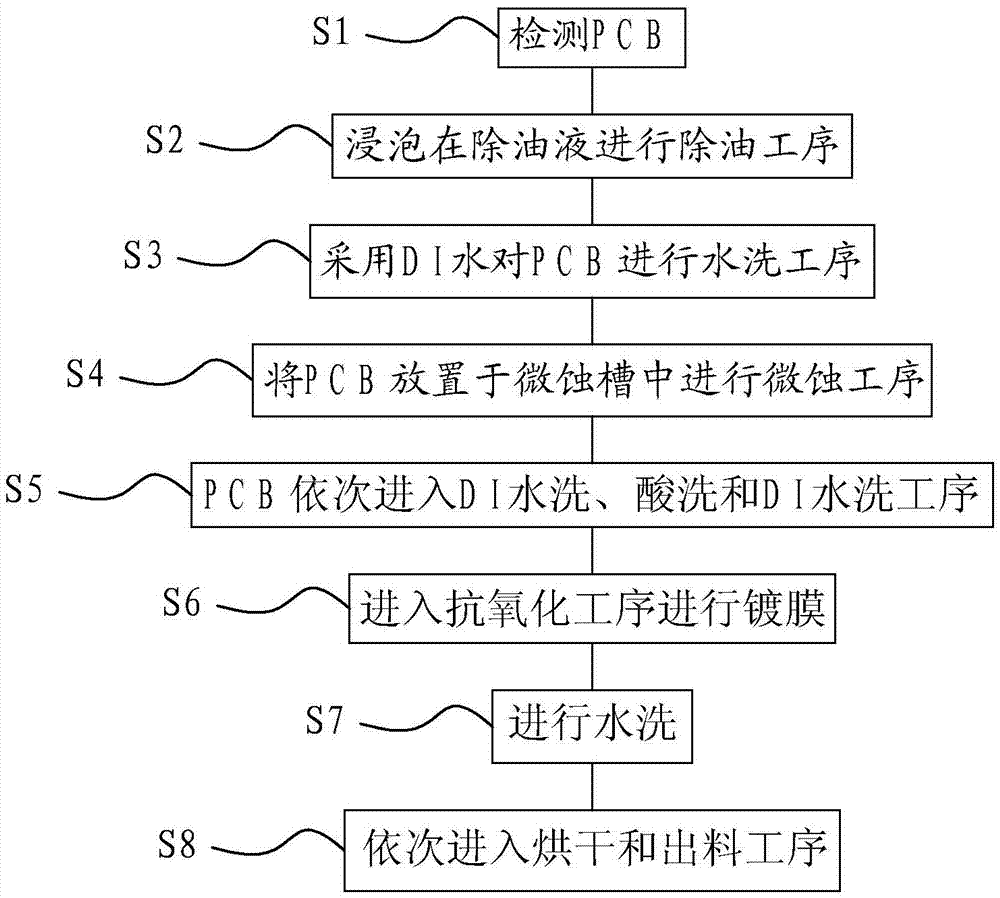

[0024] Such as figure 1 As shown, this embodiment discloses a control method for improving the tinning property of OSP, and the OSP process includes the following steps:

[0025] S1. Detect PCB

[0026] In this process, the good-quality PCB after the test is transferred to the final visual inspection to confirm the cleanliness of the PCB surface. At the same time, 10-20sets are taken from each batch for copper chloride test, and the cleanliness of the PCB surface does not meet the requirements. When the process is improved on the PCB, when the cleanliness of the PCB board surface meets the requirements, the PCB enters the degreasing process.

[0027] S2. Soak in degreasing liquid for degreasing process

[0028] The PCB with qualified cleanliness is soaked in a degreasing solution to perform a degreasing process, and the degreasing effect directly affects the film-forming quality. If the oil removal is not good, the thickness of the film will be uneven. On the one hand, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com