A tinning device for gear-lifting bus bar joints

A busbar connector and lift-type technology is applied in the field of gear-lifting copper busbar connector tinning devices, which can solve the problems of unstable tinning surface treatment effect, outstanding safety problems of tinning surface, easy to burn the human body, etc. Good effect, low production cost, good for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

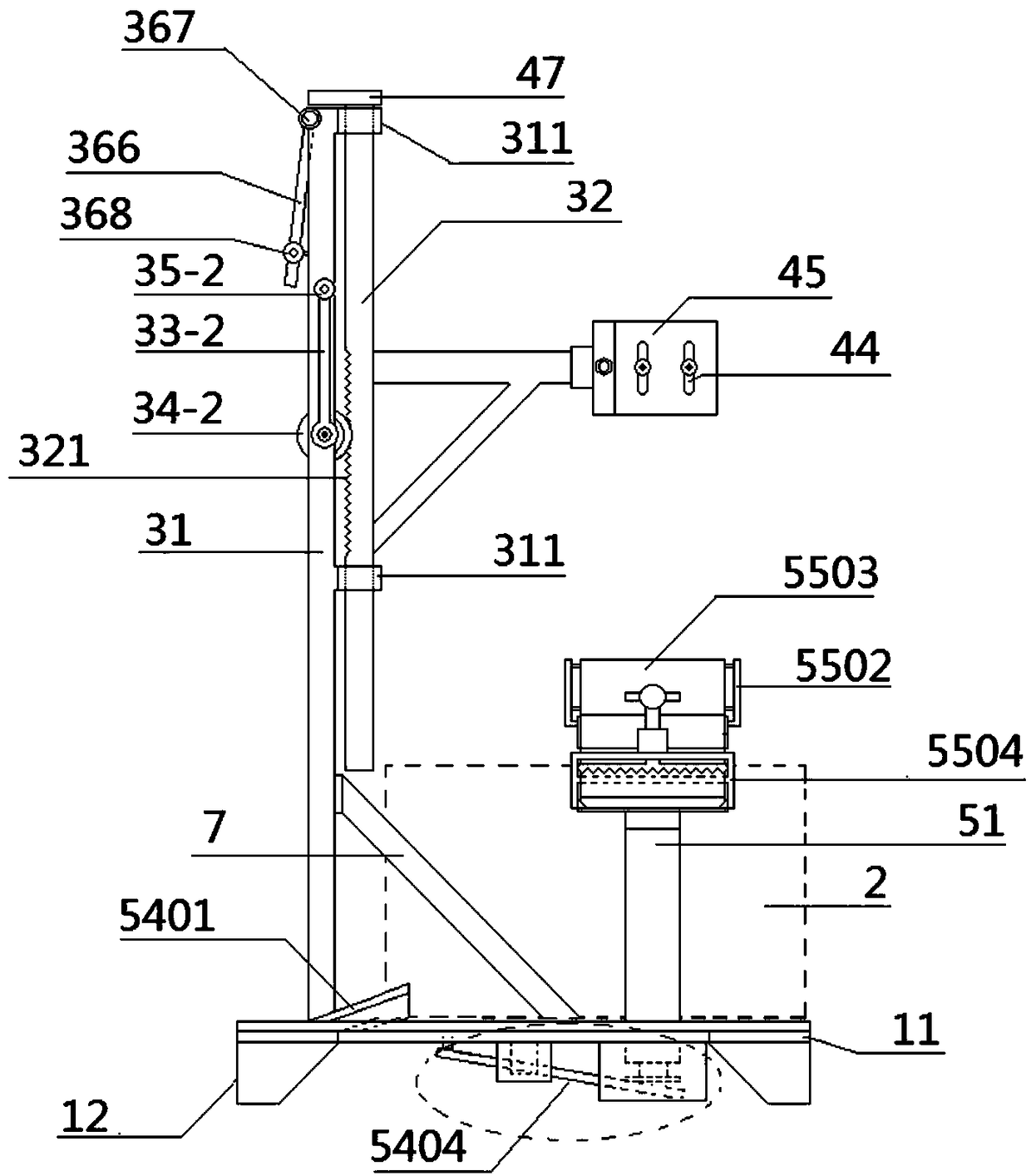

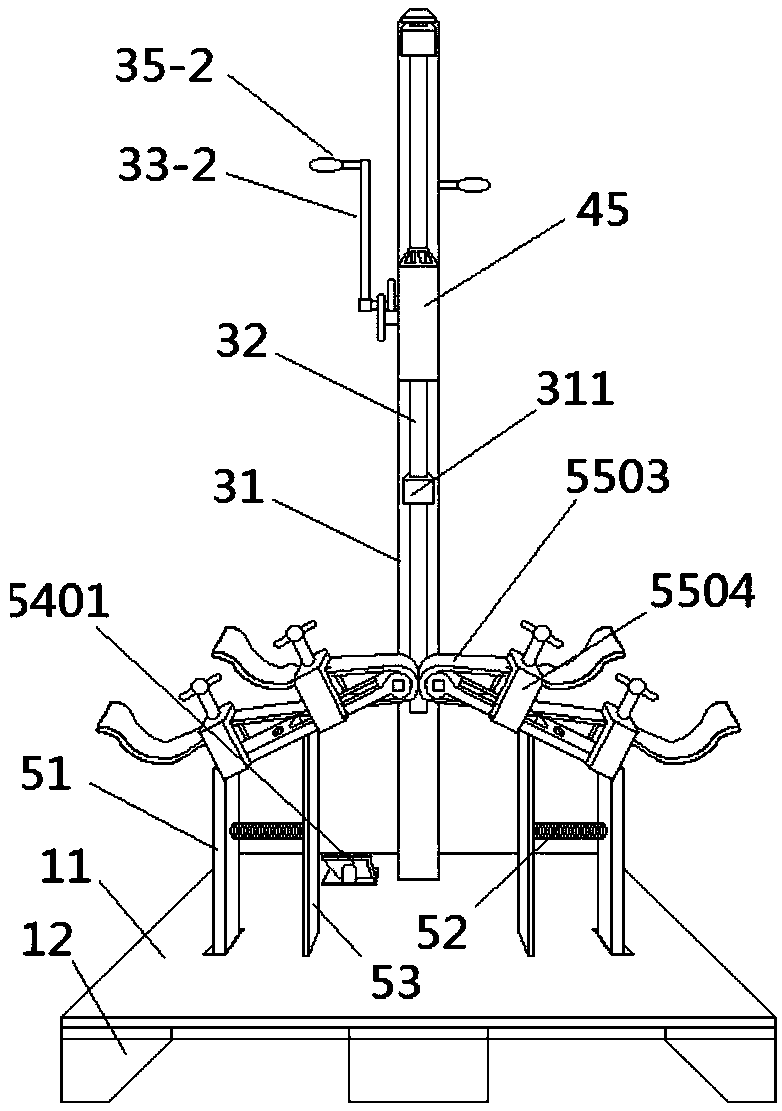

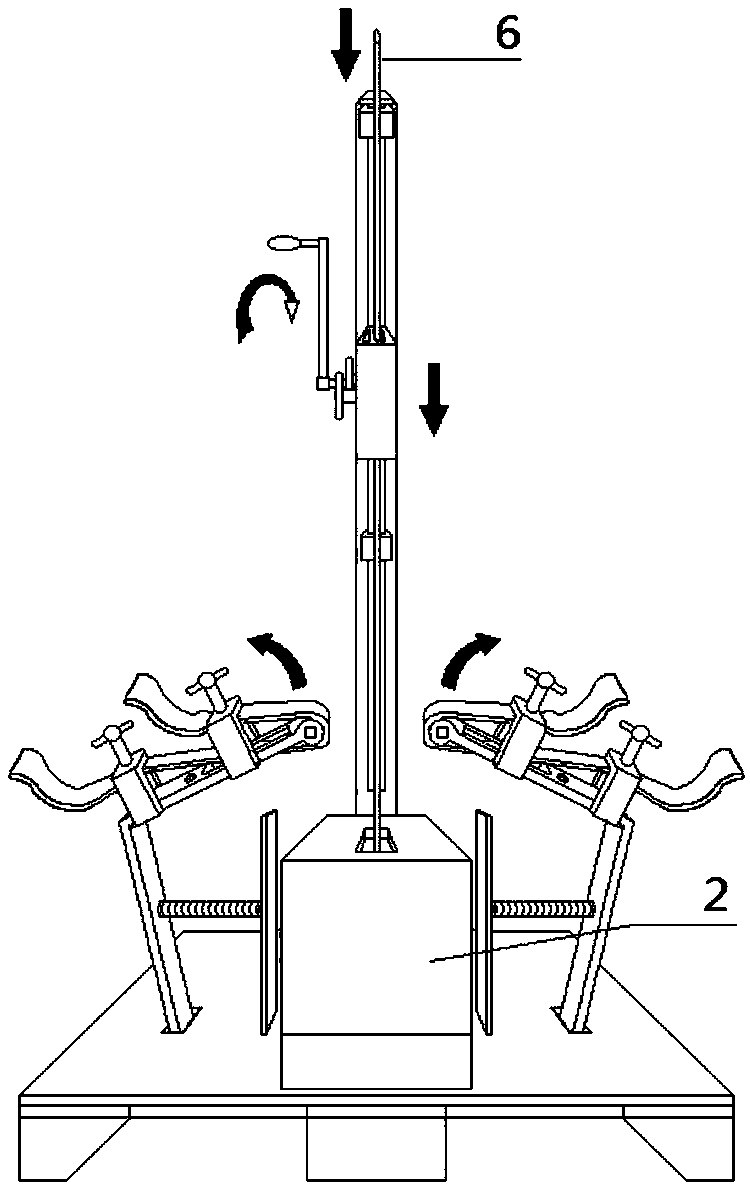

[0072] Such as Figure 1-4 As shown, a gear lifting type copper bar bus joint tinning device includes a base, a tin melting mechanism 2, a gear type copper bar lifting mechanism, a copper bar fixing mechanism and a copper bar wiping mechanism.

[0073] The base includes a base plate 11 and feet 12 provided at the bottom of the base plate.

[0074] Such as figure 1 As shown, the gear-type copper bar lifting mechanism includes a main load-bearing column 31, a lift-type main support frame 32 and a gear-type lifting adjustment mechanism; the main load-bearing column is erected on the base plate, and the main load-bearing column is connected to the base plate. There are reinforcing ribs 7 . The gear-type lifting adjustment mechanism is installed on the main load-bearing column, and it includes a lifting handle 33-2, a hand handle coaxial pinion 34-2 and a hand handle handle 35-2. The lifting hand crank and the coaxial pinion of the hand crank are coaxially installed on the main ...

Embodiment 2

[0082] Such as Figure 11 As shown, a gear lifting type copper bar bus joint tinning device includes a base, a tin melting mechanism 2, a gear type copper bar lifting mechanism, a copper bar fixing mechanism and a copper bar wiping mechanism.

[0083] The difference between this embodiment and embodiment 1 is:

[0084] (1) Gear type lifting adjustment mechanism: such as figure 1 , Figure 14-16 As shown, the gear-type lifting adjustment mechanism includes a lifting wheel 33-1, a wheel coaxial pinion 34-1 and a lifting wheel handle 35-1. The lifting wheel and the coaxial pinion of the wheel are coaxially installed on the main load-bearing column, and the lifting wheel and the coaxial pinion of the wheel are coaxially rotated synchronously, and the coaxial pinion of the wheel meshes with the rack. The lift wheel handle is fixed on the lift wheel. The ratio of the radius of the lifting wheel to the radius of the wheel coaxial pinion is 4:1.

[0085] (2) The positioning metho...

Embodiment 3

[0087] Such as Figure 17 As shown, a gear lifting type copper bar bus joint tinning device includes a base, a tin melting mechanism 2, a gear type copper bar lifting mechanism, a copper bar fixing mechanism and a copper bar wiping mechanism.

[0088] The difference between this embodiment and embodiment 1 is:

[0089] (1) Gear type lifting adjustment mechanism: such as Figure 17 As shown, the gear-type lifting adjustment mechanism includes a lifting wheel 33-1, a wheel coaxial pinion 34-1 and a lifting wheel handle 35-1. The lifting wheel and the coaxial pinion of the wheel are coaxially installed on the main load-bearing column, and the lifting wheel and the coaxial pinion of the wheel are coaxially rotated synchronously, and the coaxial pinion of the wheel meshes with the rack. The lift wheel handle is fixed on the lift wheel. The ratio of the radius of the lifting wheel to the radius of the wheel coaxial pinion is 6:1.

[0090] (2) The positioning method of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com