A Method for Evaluation of Galvanic Corrosion Under Thin Liquid Film

A technology for galvanic corrosion and evaluation methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of cumbersome steps, poor accuracy, high cost, etc., and the method is simple and easy to operate, accurate evaluation, and convenient The effect of objective comparison

Active Publication Date: 2022-05-31

DONGFENG MOTOR GRP

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The above-mentioned patents have the following defects: 1. The processing procedure of the sample to be corroded is complicated. First, the polarity of the two materials must be distinguished, and then an anodic plate with holes is made according to the polarity, and cathodic bolts and nuts are made, and then a connection test is formed. 2. The accuracy is poor, galvanic corrosion only occurs in a limited area, and the weight loss caused by galvanic corrosion before and after the test is very small, and the weight loss by corrosion is used for evaluation. The level of galvanic corrosion cannot be accurately evaluated; 3. The risk level of galvanic corrosion between mechanical structures can only be qualitatively obtained, and the degree of galvanic corrosion at the same risk level cannot be compared

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0046] The following specific embodiment will further describe the present invention in detail. In the following examples, aluminum alloy 6005A was selected

[0059] If Z

[0063] If there is Z

[0069]

[0070]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

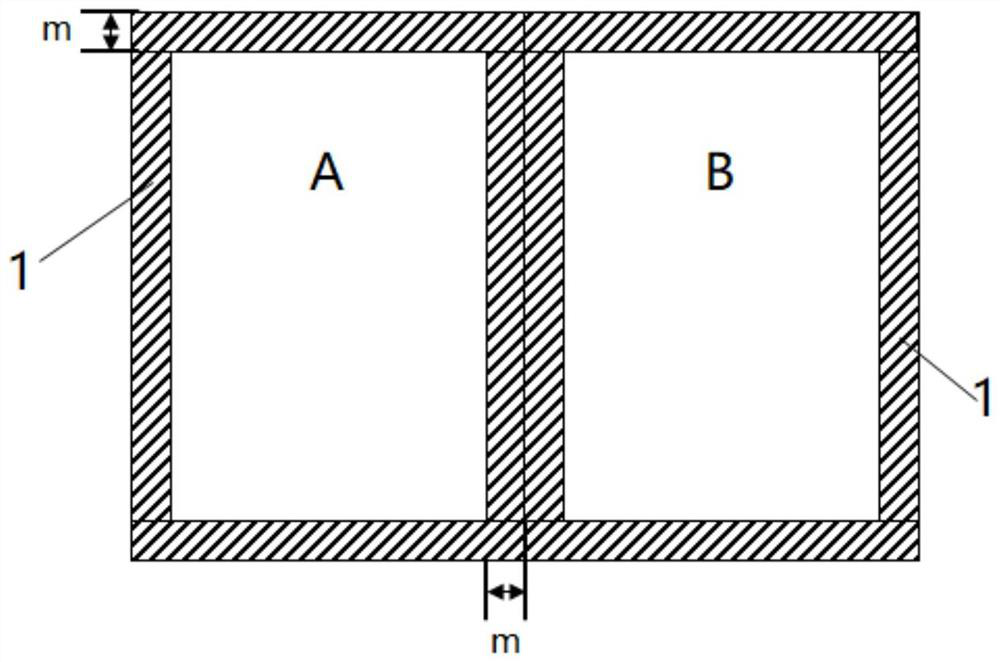

The invention discloses a method for evaluating galvanic corrosion under a thin liquid film, which comprises the following steps: (1) preparing a lap joint sample; (2) preparing a control sample; (3) salt spray test; (4) evaluating corrosion , the test sample A, the test sample B, and the control sample A were determined. 0 , control sample B 0 The respective average corrosion depths, respectively Z tst‑A ,Z tst‑B ,Z ref‑A ,Z ref‑B , according to the statistical t test to judge Z tst‑A Is it significantly different from Z ref‑A ,Z tst‑B Is it significantly different from Z ref‑B , if Z tst‑A Significantly different from Z ref‑A And Z tst‑B Significantly different from Z ref‑B , then calculate the respective galvanic effect values of material A and material B. The invention uses the corrosion depth data to quantify the description of the corrosion degree, can more accurately evaluate the galvanic effect between different metals, and is convenient for objective comparison.

Description

A method for evaluating galvanic corrosion under thin liquid films technical field [0001] The present invention relates to metal materials, and specifically refers to a method for evaluating galvanic corrosion under a thin liquid film. Background technique [0002] With the tightening of energy saving and emission reduction requirements, the application ratio of lightweight materials in industrial products is increasing day by day. brought by this The galvanic corrosion problem between different materials has also attracted the attention of many engineers. Therefore, how to evaluate economically and effectively The level of the galvanic effect between the galvanic combination in the atmospheric environment has become one of the concerns of the industry, especially the automotive industry. one. [0003] Chinese invention patent CN111141661A discloses a kind of dissimilar metal sheet mechanical connection structure galvanic couple in automobile Corrosion evaluation met...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N17/00

CPCG01N17/006

Inventor 齐叶龙付益平秦兴国刘昱李勇

Owner DONGFENG MOTOR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com