Sealing agent and its preparation method and application

A technology of sealing agent and solvent, which is applied in the fields of printed circuit manufacturing, liquid chemical plating, and coating of non-metallic protective layers, etc., which can solve the problems of Giavani effect, unsatisfactory Giavani effect, PCB Eliminate metal reactivity, avoid Giavani effect, and improve corrosion resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

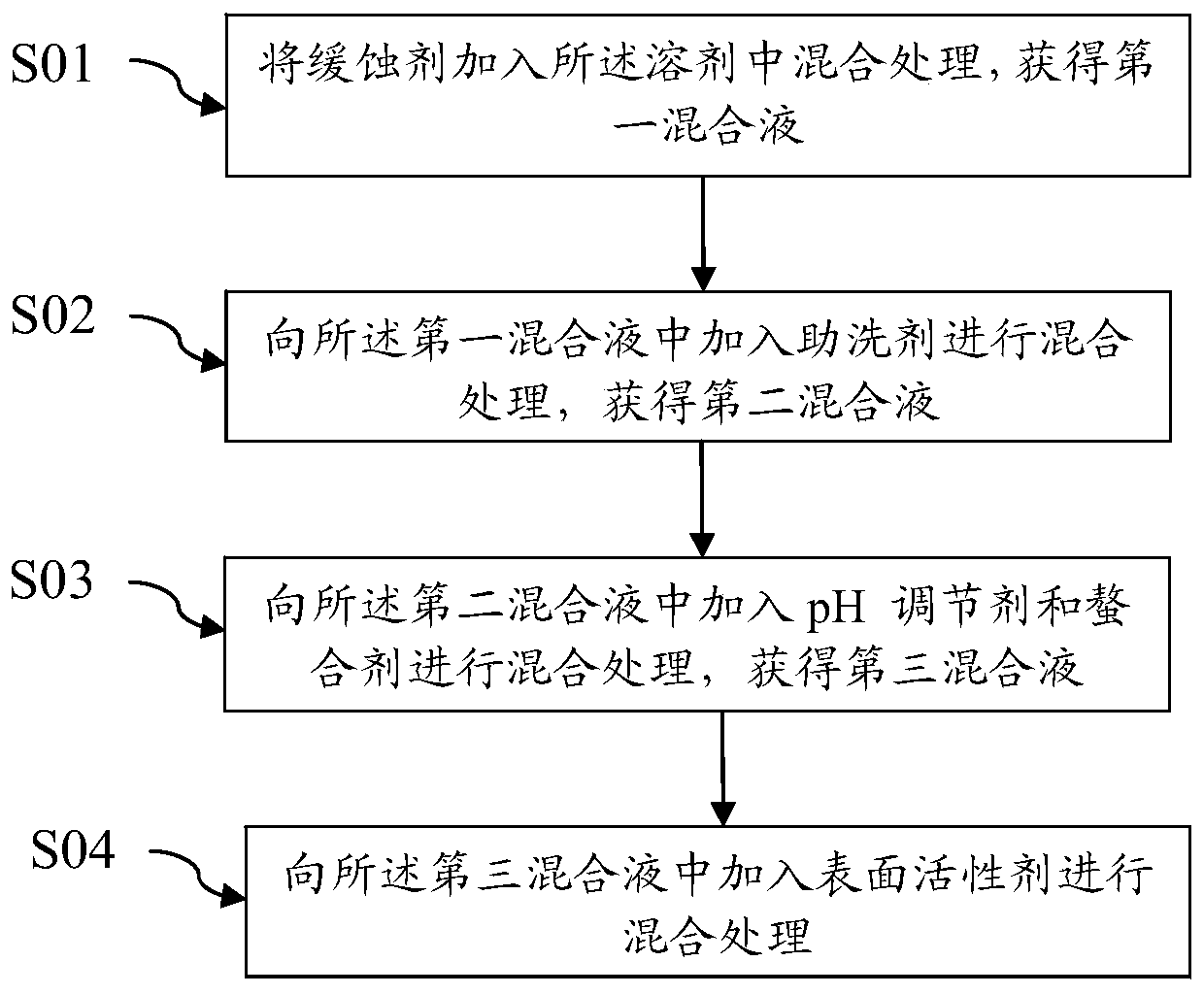

[0036] On the basis of the sealing agent described above, the embodiment of the present invention also provides a preparation method of the sealing agent. The preparation method flow process of the sealing agent is as follows figure 1 shown, including the following steps:

[0037] S01: Adding the corrosion inhibitor into the solvent for mixed treatment to obtain the first mixed solution;

[0038] S02: adding a builder to the first mixed liquid for mixing treatment to obtain a second mixed liquid;

[0039] S03: adding a pH regulator and a chelating agent to the second mixed solution for mixing treatment to obtain a third mixed solution;

[0040] S04: adding a surfactant to the third mixed solution for mixing treatment.

[0041] Wherein, in the step S01, in order to effectively dissolve the corrosion inhibitor in the solvent, in one embodiment, the solvent may be heat-treated to improve the solubility of the corrosion inhibitor. Such as heating the solvent to above 60°C.

...

Embodiment 11

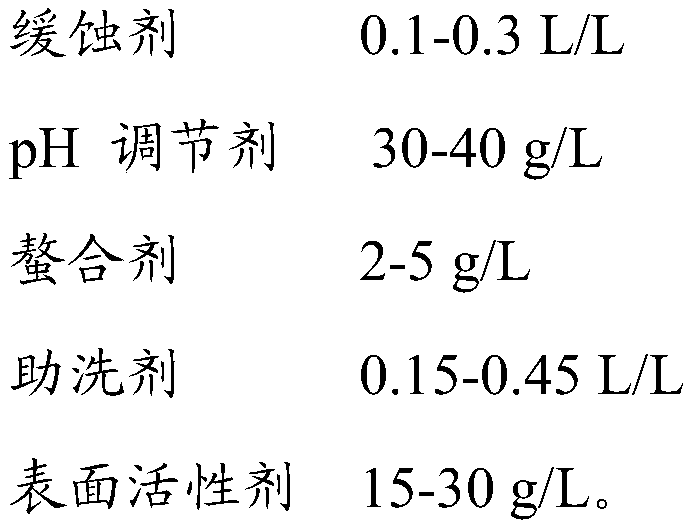

[0053] This embodiment provides a sealing agent composition. The sealant composition comprises the following components:

[0054]

[0055] The sealing agent composition described in this embodiment is prepared according to the following steps:

[0056] S11: Add 10 liters of pure water and 5 liters of polyethylene glycol 200 to the container, and raise the temperature to not lower than 60 degrees;

[0057] S12: Add 7.5 liters of OP-10 emulsifier, stir to dissolve;

[0058] S13: Add 800 grams of stearyl mercaptan and 80 grams of cetyl mercaptan, and heat to dissolve;

[0059] S14: Add nickel acetate NiAC2.4H 2 O content 500g;

[0060] S15: add sodium fluoride NaF content 120g;

[0061] S16: replenish water and stir evenly, pack after cooling.

Embodiment 12

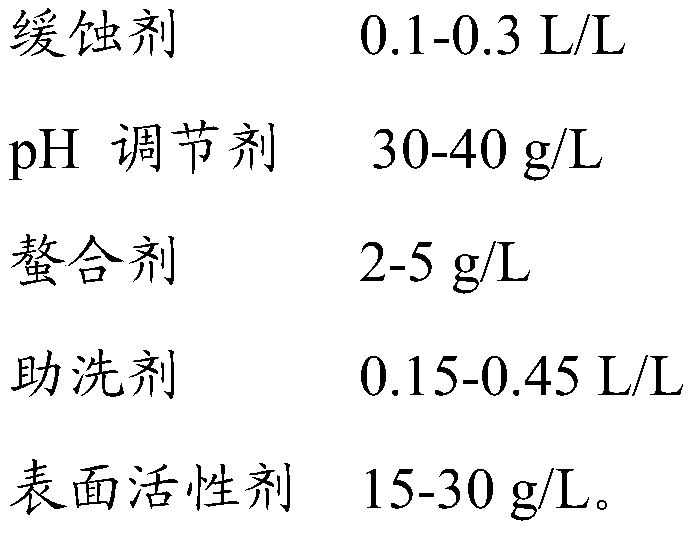

[0063] This embodiment provides a sealing agent composition. The sealant composition comprises the following components:

[0064]

[0065] Wherein, the surfactant includes nickel acetate and sodium fluoride, and the mass ratio of nickel acetate and sodium fluoride is 1:1.

[0066] The preparation method of the sealing agent composition described in Example 12 is to prepare according to the preparation method in Example 11 according to the formula of this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com