PCB bonding pad/line connection structure

A PCB circuit board and circuit connection technology, applied in the direction of electrical connection of printed components, printed circuits, printed circuits, etc. Stable performance, ensuring the effect of finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

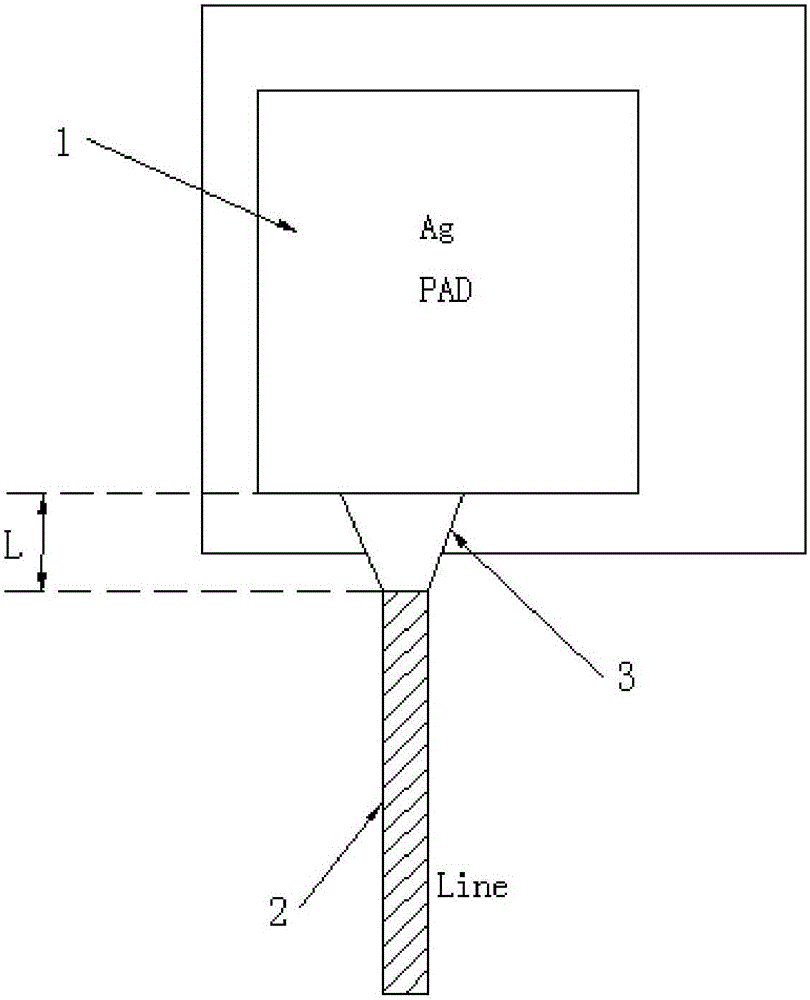

[0016] A pad / line connection structure of a PCB circuit board according to the present invention, the PCB circuit board includes a substrate, the substrate is provided with a connected pad 1 and a circuit 2; the connection between the pad and the circuit A teardrop structure 3 is also added, and the length of the teardrop structure satisfies the following formula:

[0017] L≥o+e+a

[0018] In the formula, L is the length of the added teardrop structure, o is the size of one side of the solder mask window, e is the offset of the solder mask, and a is the amount of side erosion of the ink.

[0019] This embodiment takes a PCB circuit board with a line spacing of less than 9mil as an example. In the above formula for calculating the length of the teardrop structure, the value of o is the maximum value on one side of the solder mask window, which is 1.5mil; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com