Method for evaluating galvanic corrosion under thin liquid film

A technology for galvanic corrosion and evaluation methods, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as poor accuracy, cumbersome steps, and high cost, and achieve accurate evaluation. The method is simple, easy to operate, and convenient The effect of objective comparison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following specific examples illustrate the present invention in further detail. In the following examples, aluminum alloy 6005A is selected as material A, and galvanized steel SP791-370Q is selected as material B.

[0047] The evaluation method of galvanic corrosion under a kind of thin liquid film provided by the invention comprises the following steps:

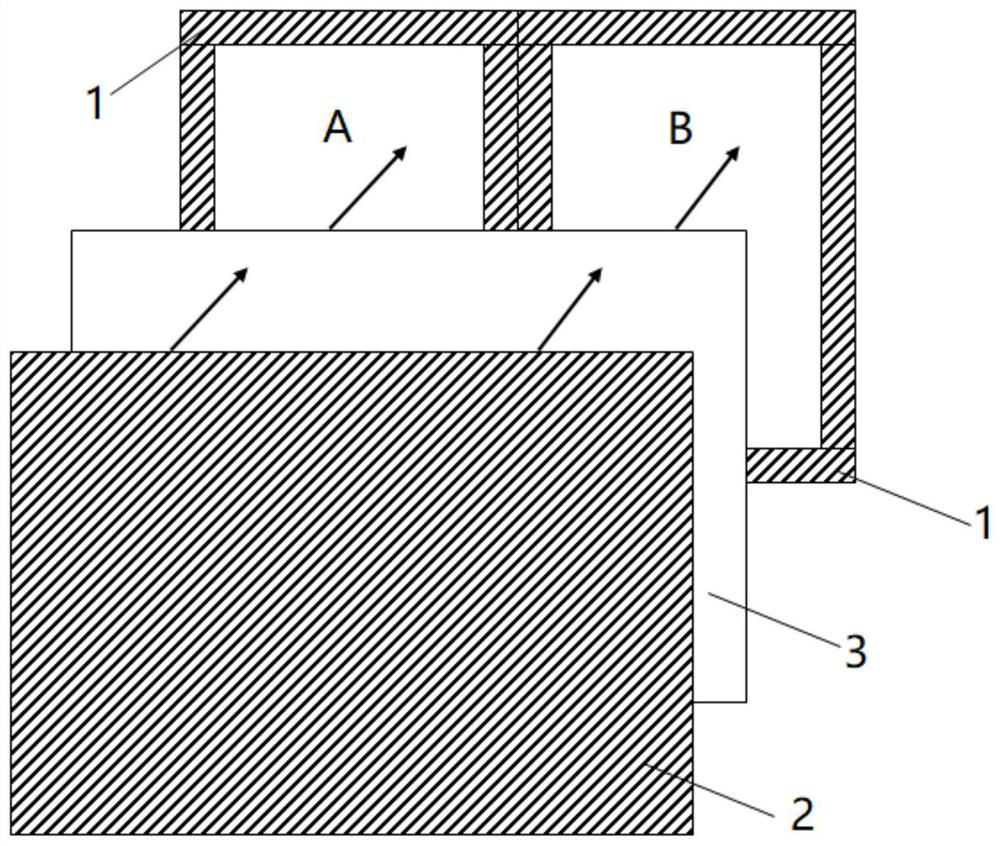

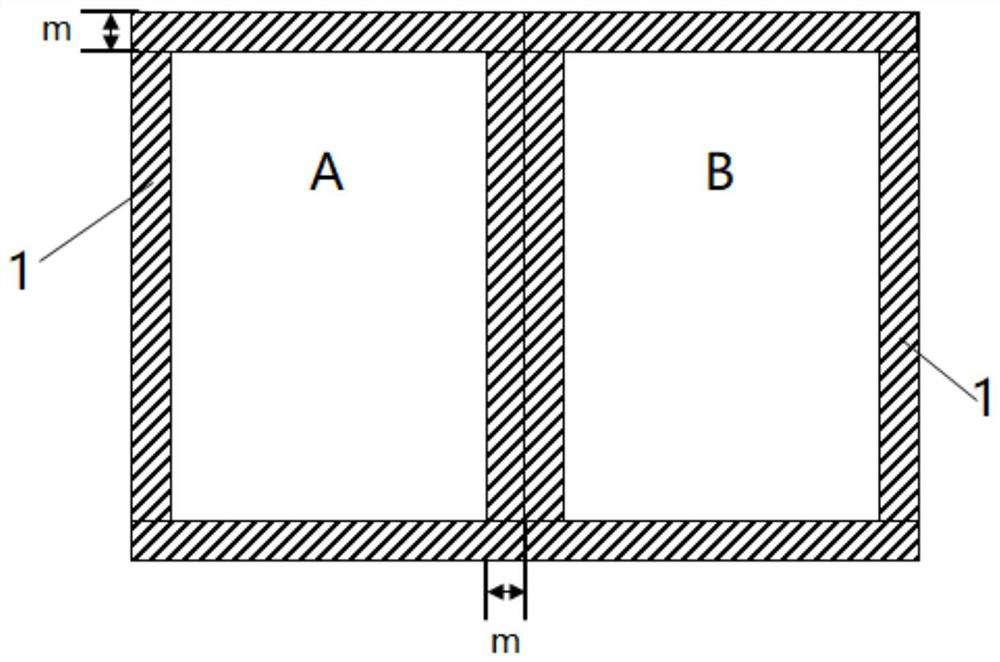

[0048] (1) Preparation of lap joint samples

[0049] Two kinds of materials A and B to be evaluated for galvanic corrosion are made into sample A to be tested and sample B to be tested respectively, and the edges of the two samples to be tested are sealed and insulated to make lap joint samples. In this embodiment, All the edges of the sample A to be tested and the sample B to be tested are sealed and insulated with insulating tape to form the edge sealing tape 1 around the sample A and the sample B to be tested, and the edge sealing tape 1 is on the front side of the sample and The sealing width m of the back s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com