Etching liquid capable of effectively retarding galvanic effect

A Giavani effect and etchant technology, applied in the field of etchant that can effectively slow down the Giavani effect, can solve the problems of high-frequency and high-speed applications that cannot load consumer electronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

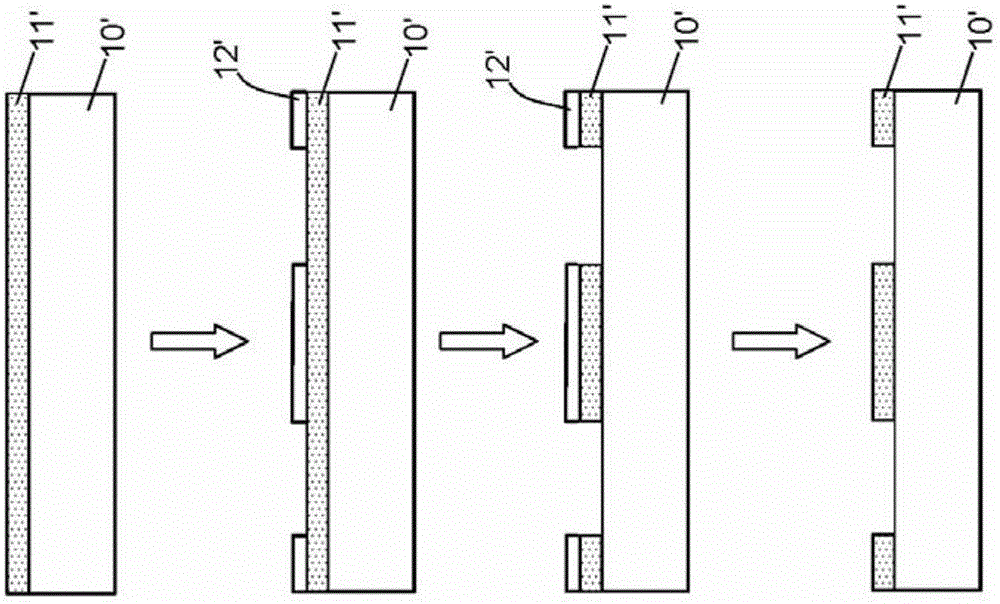

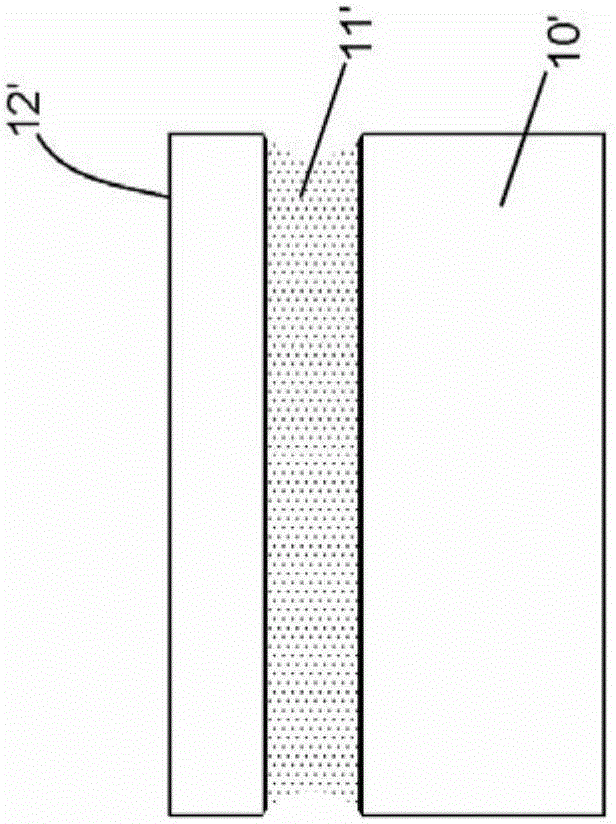

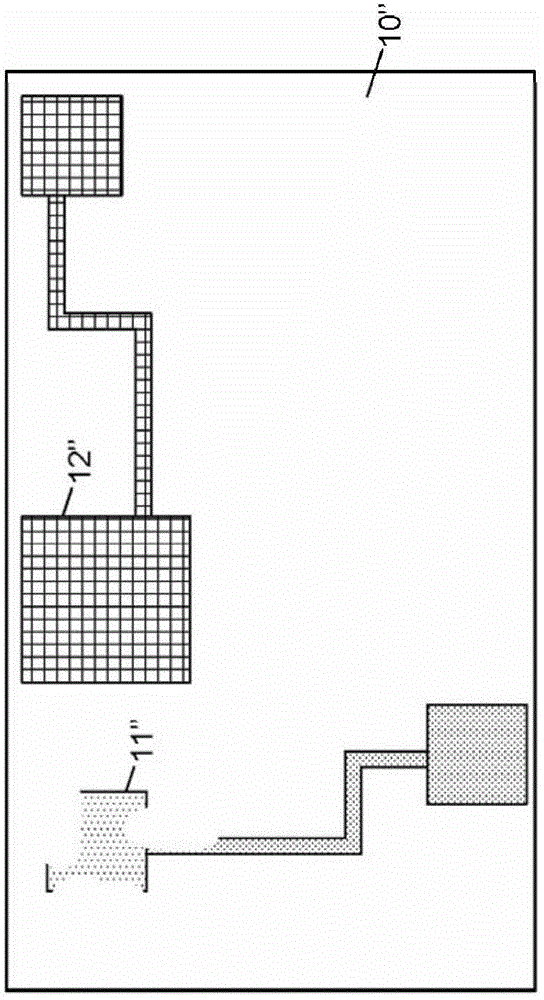

[0054] In order to more clearly describe an etching solution proposed by the present invention that can effectively mitigate the Giavani effect, preferred embodiments of the present invention will be described in detail below with reference to the drawings.

[0055] The etchant that can effectively slow down the Giavanni effect of the present invention is applied to a substrate comprising at least one first metal and at least one second metal in a wet etching manufacturing process; wherein, due to the reduction potential of the first metal (Reduction Potential) is greater than the reduction potential of the second metal, therefore, the first metal can be gold (Au), platinum (Pt), silver (Ag), copper (Cu), tin (Sn), nickel (Ni), and aluminum (Al); and correspondingly, the second metal can be aluminum (Al), nickel (Ni), tin (Sn), copper (Cu), silver (Ag), platinum (Pt), titanium (Ti) , iron (Fe), cobalt (Co) and chromium (Cr); as for the substrates, they are common printed circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com