Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

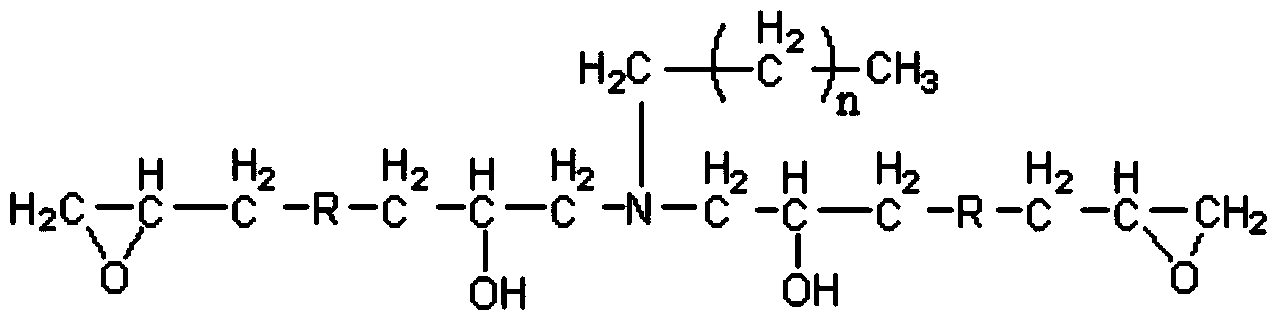

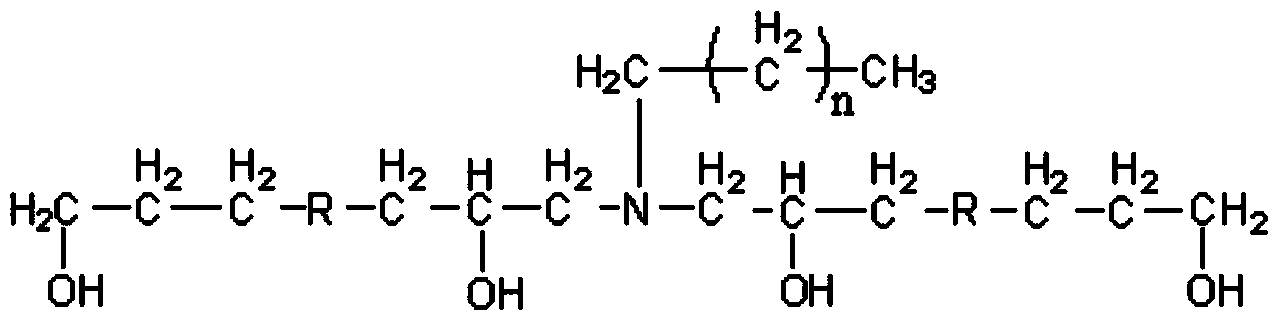

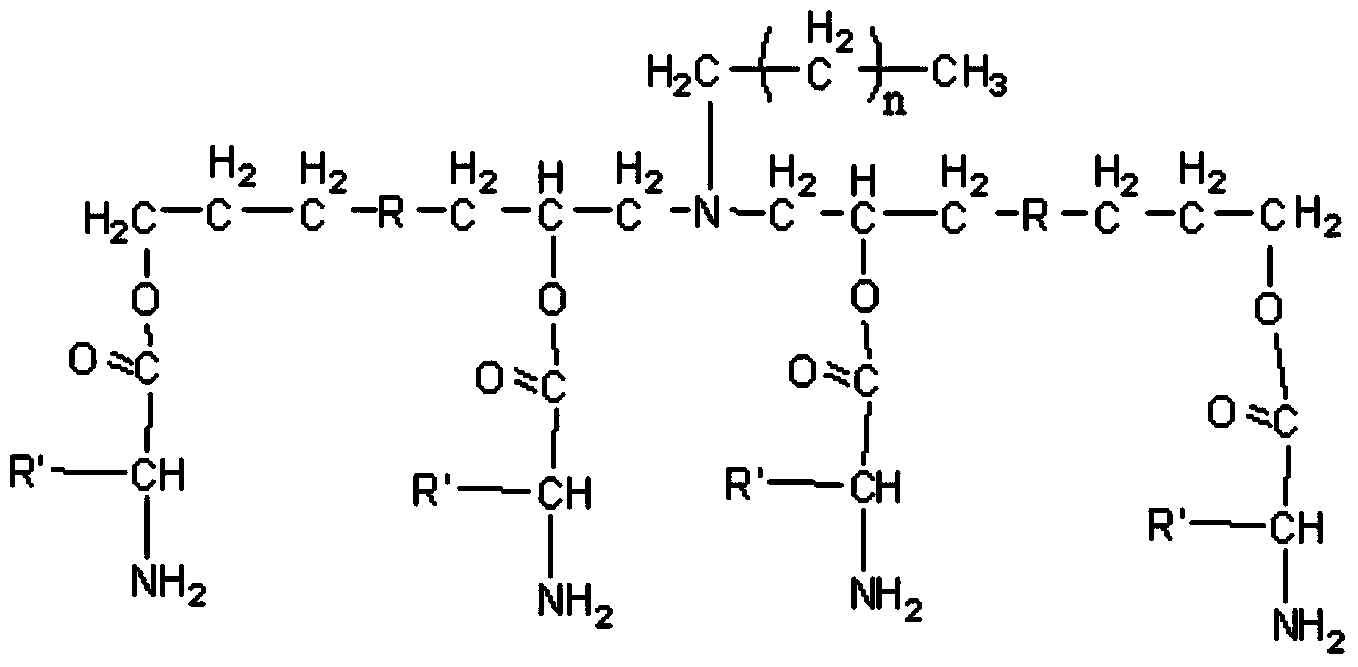

Non-ionic self-emulsifying aqueous epoxy hardener and preparation method and application thereof

InactiveCN101624385AGood self-emulsifying performanceGood flexibilityOrganic compound preparationEpoxy resin adhesivesEpoxyNitrogen

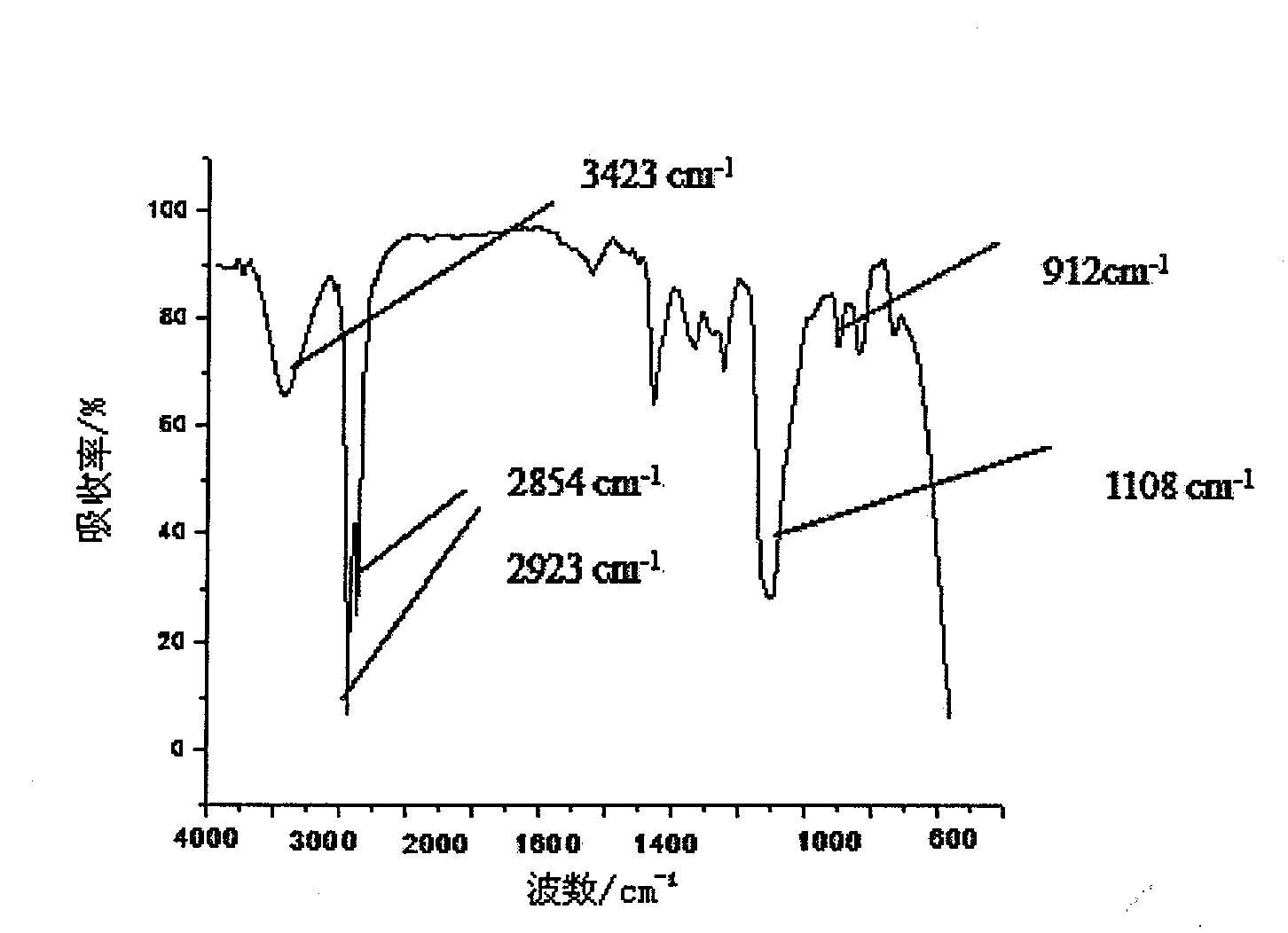

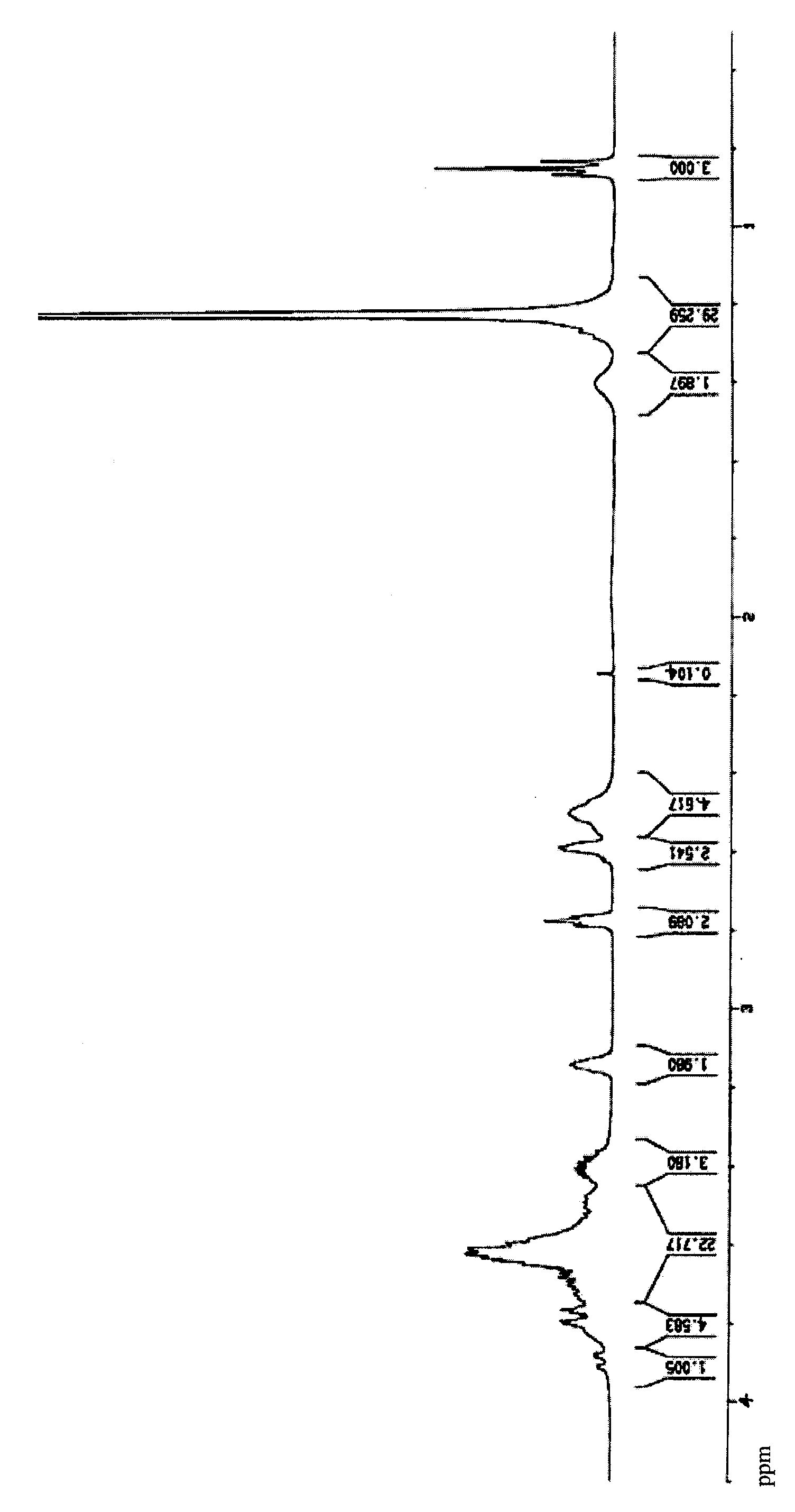

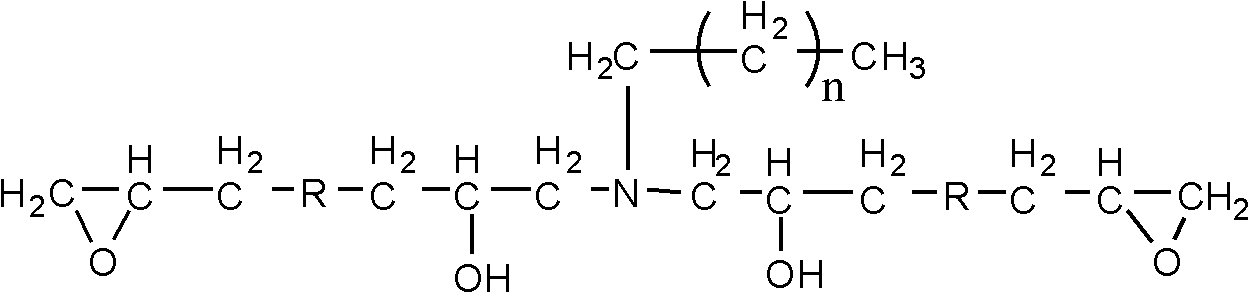

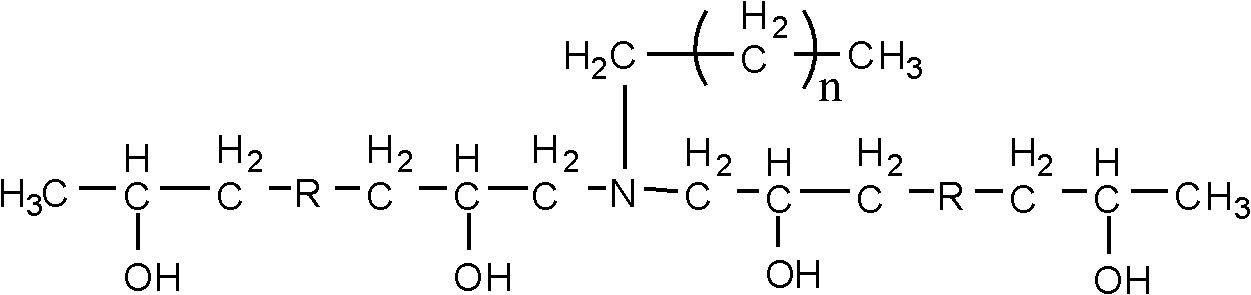

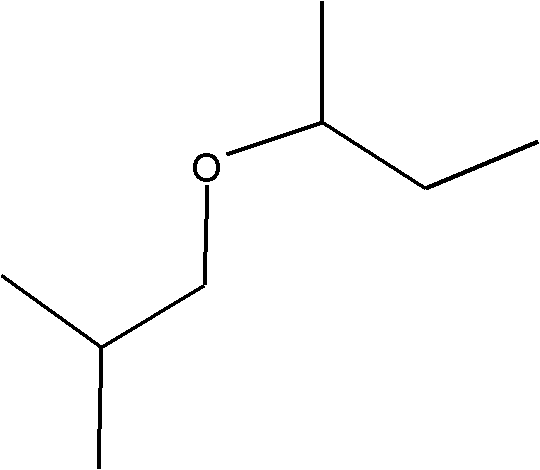

The invention relates to an epoxy hardener, in particular to a non-ionic self-emulsifying aqueous epoxy hardener. The hardener is prepared according to the following steps: adopting hydrophobic alkylamine and hydrophilic diglycidol ether with low molecular weight for reaction so as to obtain a diepoxy compound which has epoxy groups at two ends and a middle nitrogen atom linked with a long hydrophobic alkyl side chain; and adopting alicyclic amine for reaction for purpose of sealing the ends or respectively using the alicyclic amine and hydrophilic amine to seal the two ends, and finally obtaining the amino-terminated non-ionic self-emulsifying aqueous epoxy hardener similar to the structure of surfactant. The hardener can be further mixed with deionized water so that a light-yellow aqueous epoxy resin hardener with 50-60 percent of solids content can be obtained. The hardener has good self-emulsifying effect, is well compatible with epoxy resin and has high stability and good flexibility and surface activating function. The hardener can be widely applied in materials such as aqueous epoxy resin paint, epoxy resin binding agent, aqueous epoxy grouting materials, and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

InactiveCN102618045AGood emulsificationImprove hydrophilicityPaving detailsBuilding insulationsEpoxyRoad surface

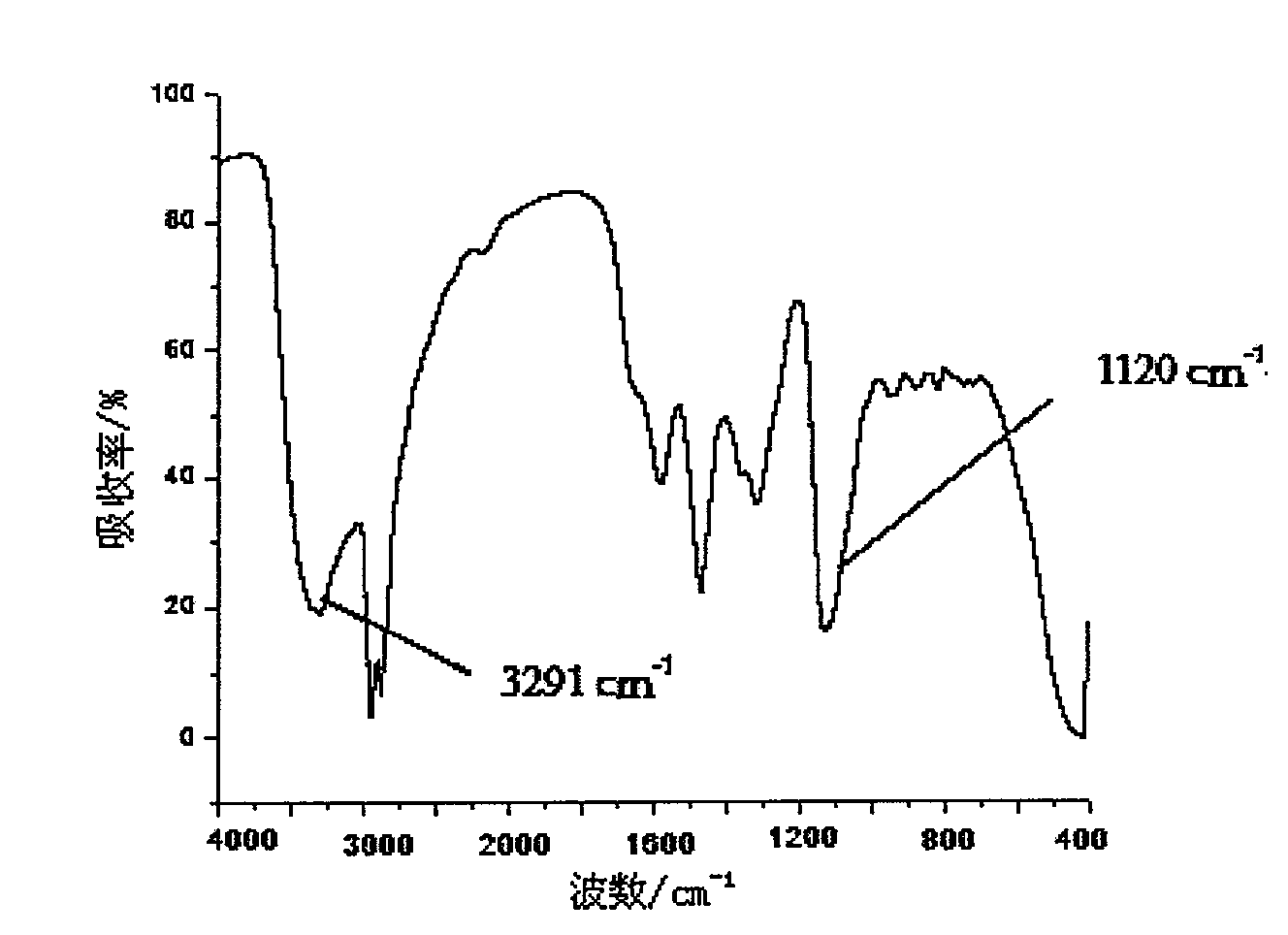

The invention discloses waterborne epoxy resin modified emulsified asphalt, which contains emulsified asphalt and self-emulsifying waterborne epoxy resin, wherein the volume ratio of the emulsified asphalt to the self-emulsifying waterborne epoxy resin is 1: (0.2-0.8); the emulsified asphalt is nonionic emulsified asphalt, anionic emulsified asphalt or cationic emulsified asphalt, and the solid content of the emulsified asphalt is 20 to 60 percent; and the self-emulsifying waterborne epoxy resin contains waterborne epoxy resin curing agent, water and liquid epoxy resin in a mass ratio of 1: (0.8-2): (2-5). The invention also discloses a preparation method for the waterborne epoxy resin modified emulsified asphalt and application in preparation of an asphalt type waterproof coating. After the common commercial emulsified asphalt is modified by the waterborne epoxy resin, the break elongation of the emulsified asphalt can be improved, and the modified emulsified asphalt has high adhesive strength with a base plane, certain strength and high waterproof property and ageing resistance; and the modified emulsified asphalt can be used for making the asphalt type waterproof coating, and can also be used for repairing road pavements.

Owner:重庆融极环保工程有限公司

Nonwoven fabric containing metal coating as well as product thereof

ActiveCN103552318ATougheningConductiveSynthetic resin layered productsMetal layered productsMetal coatingThin layer

The invention relates to a nonwoven fabric containing a metal coating as well as a product thereof. The nonwoven fabric containing the metal coating is mainly characterized in that the structural characteristic of the nonwoven fabric is that the nonwoven fabric is a thin layer which has a network structure and is formed by low-surface-density fibers; a metal layer of copper, silver, nickel, nickel coated copper or nickel-copper-nickel is coated on the surface of the nonwoven fabric and has the thickness of 100nm-5 micron m, so that the nonwoven fabric layer has electrical conductivity and keeps soft, also can obviously intensify the interlayer fracture toughness and electrical conductivity of laminated plates when being applied to intercalation compounding material lamination plates, and meanwhile a compound material is endowed with higher shock damage impedance and damage tolerance as well as higher electrical conductivity. Corresponding prepregs can be directly used for laying and covering so as to obtain a high-electrical-conductivity compound material, and the corresponding compound material product can be used for high-electrical-conductivity shock-resistant occasions and aircraft lightning protection structural bodies.

Owner:AVIC COMPOSITES

Zirconia ceramic as well as preparation method, shell and electronic equipment

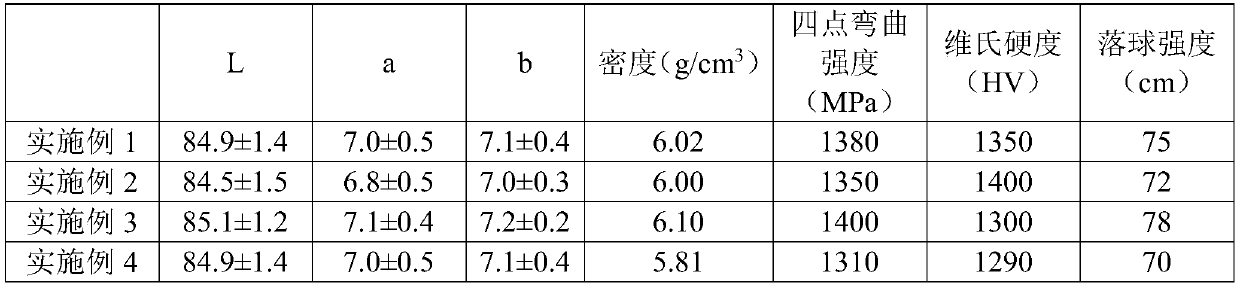

ActiveCN110304920ASolid solution avoidanceImprove mechanical propertiesElectrical apparatus casings/cabinets/drawersMixed materialsSilicon oxide

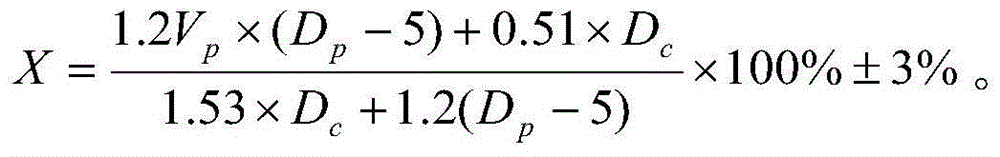

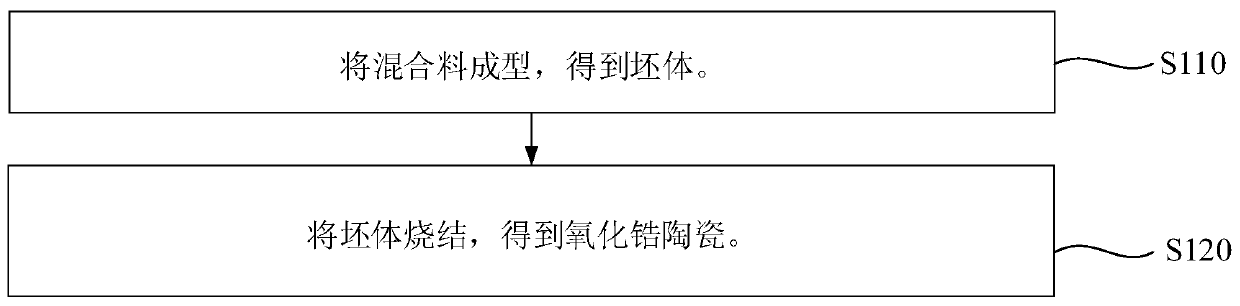

The invention relates to a zirconia ceramic as well as a preparation method, a shell and electronic equipment. The preparation method of the zirconia ceramic comprises the following steps: molding a mixed material so as to obtain a blank, wherein the mixed material comprises the following raw materials in percentage by mass: 85-90% of zirconium oxide, 1-4% of aluminum oxide, 2-3.8% of yttrium oxide, 2.1-4.1% of zinc oxide, 1.2%or less of titanium oxide, 1% or less of chromium hemitrioxide, 1% or less of silicon oxide and 1% or less of nickel oxide; and sintering the blank, so as to obtain thezirconia ceramic. The zirconia ceramic prepared by using the preparation method of the zirconia ceramic has a pink golden color and in addition has good mechanical properties.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

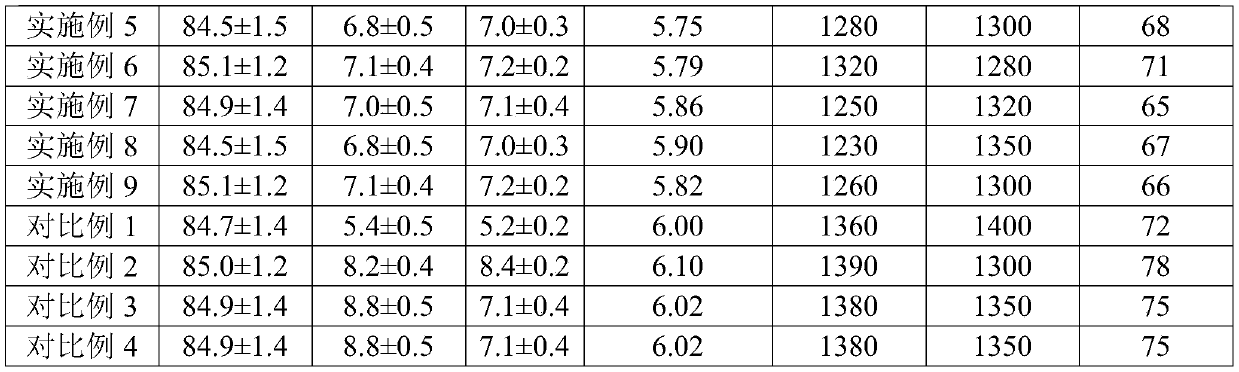

High-temperature resistant thermal shock resistant pipeline used in iron-making hot blast heater and preparation method of high-temperature resistant thermal shock resistant pipeline

The invention discloses a high-temperature resistant thermal shock resistant pipeline used in an iron-making hot blast heater, and relates to the technical field of refractory materials. The high-temperature resistant thermal shock resistant pipeline is prepared from bauxite chamotte clinker granules, andalusite, fine corundum powder, pure calcium aluminate cement, Al2O3 micro powder, SiO2 micro powder, a dispersing agent, organic anti-explosion fiber and stainless steel fiber, wherein andalusite consists of fine powder of 200 meshes and granules of 3-0.074mm; and the weight of the granules of 3-0.074mm is greater than 65% of the total weight of andalusite. A preparation method of the high-temperature resistant thermal shock resistant pipeline comprises the following steps: performing on-site casting or preparing the above raw materials into precast blocks, and subsequently combining and building the precast blocks on site. The mullitization of andalusite is a lasting process, columnar and needle-shaped mullite converted from andalusite can be formed into pilotaxitic texture with other raw materials and can be solidly combined, and when a raw material product is broken because of thermal stress and other mechanical stress, a bridging and toughening function is achieved, and the thermal shock resistance of the raw material product is improved.

Owner:ZHENGZHOU ANNEC IND

Easily-degradable ceramic materials and manufacturing method thereof

The invention is about a sort of one-off ceramic material. Which is easily degraded. It is made of major material degraded easily, binding admixture, the substance to puff, elasticizer, anti-friction material and water. The major material degraded easily is kaolin clay. The binding admixture is the mixture of innocuous organic and inorganic binding admixture. And the substance to puff is one or two of plant fiber, pearlstone and flotaftion bead. The elasticizer is plant fiber or glass fiber. The lubricant can be selected from plant oil, silicon oil, liquid wax, and polyglycol. The composition is proportioned by degratable major material 20-60%, binding admixture 20-35%, expanding agent 4-42%, toughness enhancing agent 5-10%, lubricant 1-3% and water 10-35%. It can be used for lableware, package lining, and flower pot, etc.

Owner:韩长玉

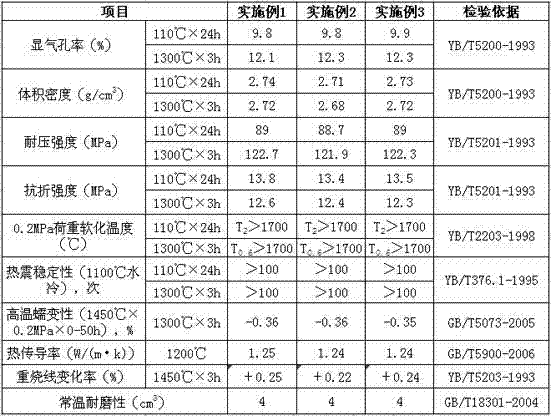

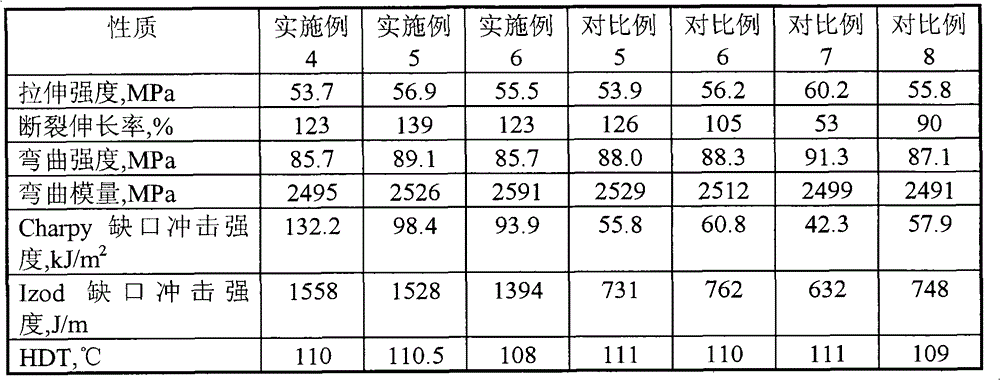

Polycarbonate/ABS (acrylonitrile, butadiene and styrene) resin plastic alloy

The invention relates to a polycarbonate / ABS resin plastic alloy to mainly solve a problem of low impact strength of polycarbonate / ABS plastic alloys prepared through previous technologies. The problem is well solved through adopting a technical scheme that the plastic alloy is composed of a polycarbonate resin, a bulk polymerization ABS resin, a compatilizer SMA resin, and auxiliary agents of an antioxidant and the like in the invention. The polycarbonate / ABS plastic alloy can be applied to the production of various plastic products needing the high impact strength, such as automobile bumpers, meter panels and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength and high-tenacity polypropylene composite materials and preparation method thereof

The invention discloses high-strength and high-tenacity polypropylene composite materials. The high-strength and high-tenacity polypropylene composite materials solve the problems that existing polypropylene is poor in tenacity and poor in strength. The high-strength and high-tenacity polypropylene composite materials are formed by the following components, by weight, 35-75% of polypropylene, 10-40% of calcium carbonate, 8-25% of calcium sulfate whisker masterbatch, 0.1-2% of coupling agents, 2-8% of compatilizer, 0.3-4% of lubricating agents and 0.2-0.8% of antioxygen. The invention further provides a preparation method of the high-strength and high-tenacity polypropylene composite materials. According to the preparation method of the high-strength and high-tenacity polypropylene composite materials, through the mode that calcium sulfate whiskers are made into masterbatch, the calcium sulfate whisker masterbatch is added to plastics to carry out co-extrusion mixing with the plastics and the like, thus, compared with powdery whiskers, material preparation can be evener and controllable, the problem that material preparation of the calcium sulfate whiskers is difficult is solved, meanwhile, the calcium sulfate whiskers are made to have better dispersity in plastic substrate, and the surfaces of products are smoother.

Owner:四川万润非金属矿物材料有限公司

Flame-retarding antistatic polyformaldehyde composite material and preparation method thereof

The invention discloses a flame-retarding antistatic polyformaldehyde composite material and a preparation method thereof. The flame-retarding antistatic polyformaldehyde composite material is prepared from the following components: 65 to 79.9 parts of polyformaldehyde, 12 to 20 parts of a nitrogen and phosphorus flame retardant, 3 to 8 parts of an antistatic agent, 0.1 to 0.5 part of an antioxidant, 1 to 3 parts of melamine and 4 to 8 parts of a compatibilizer. According to the flame-retarding antistatic polyformaldehyde composite material, a thermoplastic polyurethane elastomer is used as the compatibilizer and is used for cladding the flame retardant and the antistatic agent respectively to prepare a cladding material; then the cladding material, the polyformaldehyde and other auxiliaryagents are commixed through a double-screw extruder to prepare the flame-retarding antistatic polyformaldehyde composite material. According to the flame-retarding antistatic polyformaldehyde composite material, the nitrogen and phosphorus flame retardant with high carbon content is selected to be compounded with other flame retardants and the flame retarding effect is strengthened through char formation; a carbon material with high electric conductivity is compounded with carbon fibers to use and the dosage of the antistatic agent is reduced under the same electrical resistivity; the thermoplastic polyurethane elastomer is used as the compatibilizer between the antistatic flame-retarding auxiliary agent and the polyformaldehyde, so that the phase interface cohesiveness is effectively improved, and the prepared flame-retarding antistatic polyformaldehyde composite material keeps excellent mechanical strength.

Owner:KAILUAN ENERGY CHEM

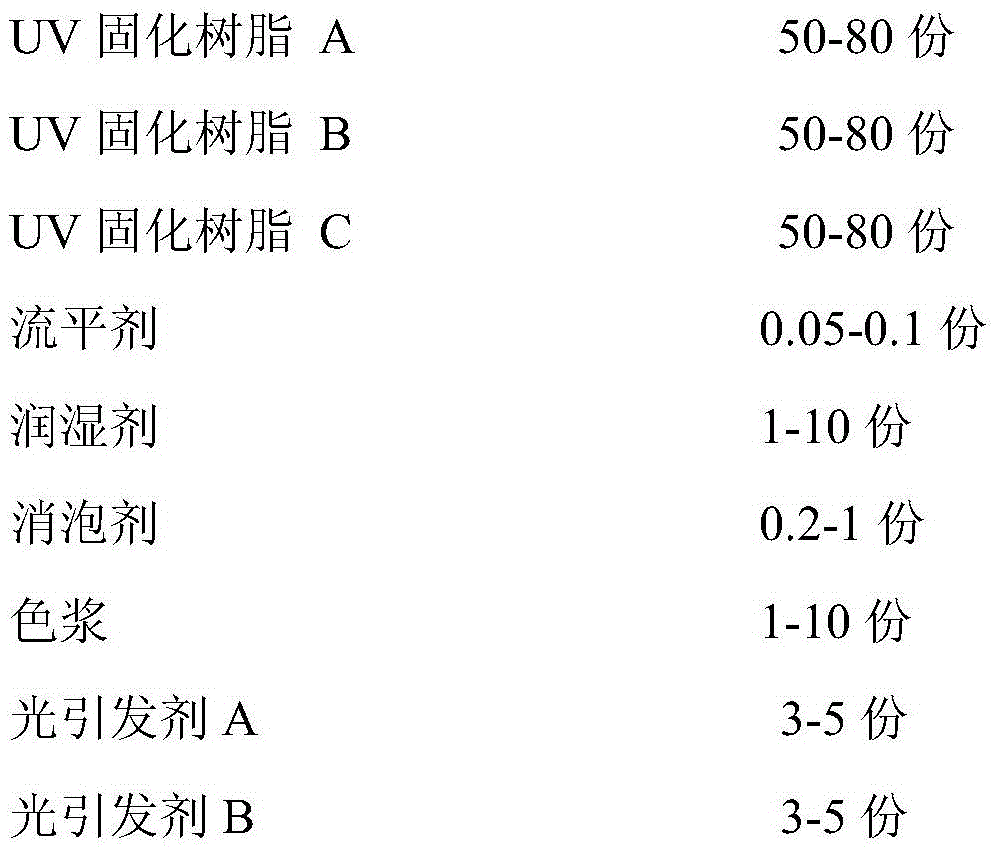

Peelable blue gel and preparation method

The invention discloses a peelable blue gel and a preparation method. The peelable blue gel comprises, by weight, 50-80 parts of UV cured resin A, 50-80 parts of UV cured resin B, 50-80 parts of UV cured resin C, 0.05-0.1 part of flatting agent, 1-10 parts of wetting agent, 0.2-1 part of defoamer, 1-10 parts of color paste special for UV nail polish, 3-5 parts of photoinitiator A and 3-5 parts of photoinitiator B. After being irradiated by a 365nm UV-LED light, the peelable blue gel can be cured rapidly, has good binding force without peeling off, is easy to peel completely without residue, and can be applied to insulation, damp proof, pollution prevention, scratch protection of materials such as PET and ITO conducting films, ITO glass, glass of cellphones and tempered glass windows.

Owner:SHANGHAI INST OF TECH

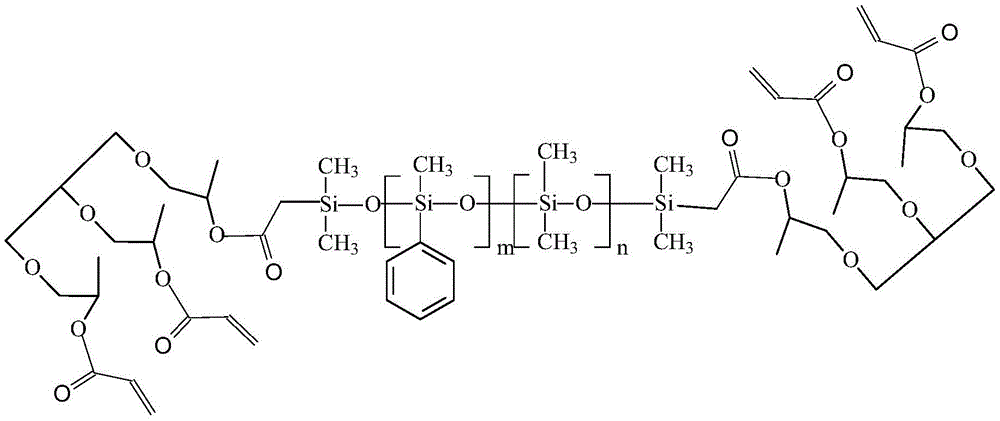

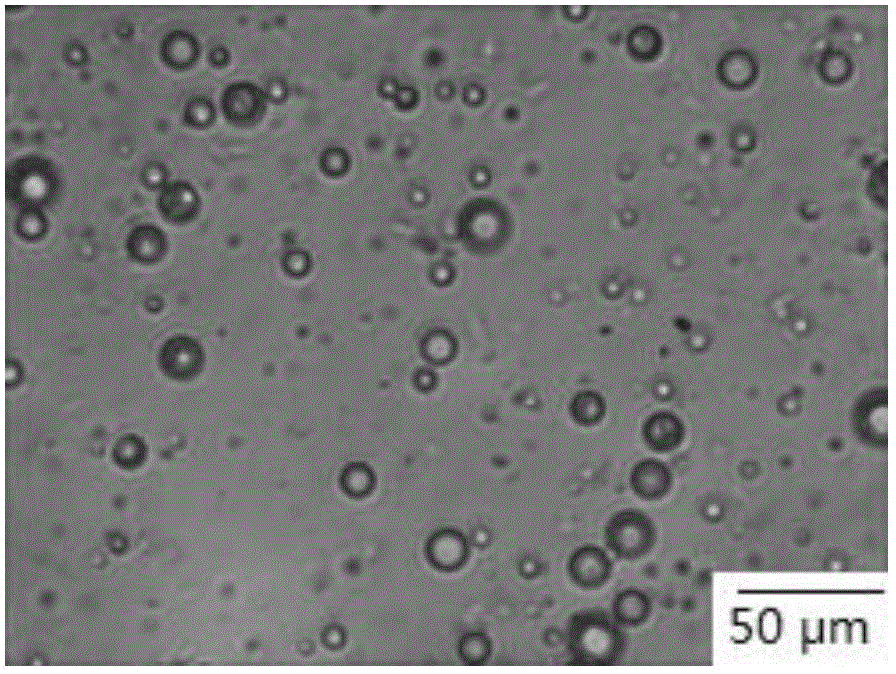

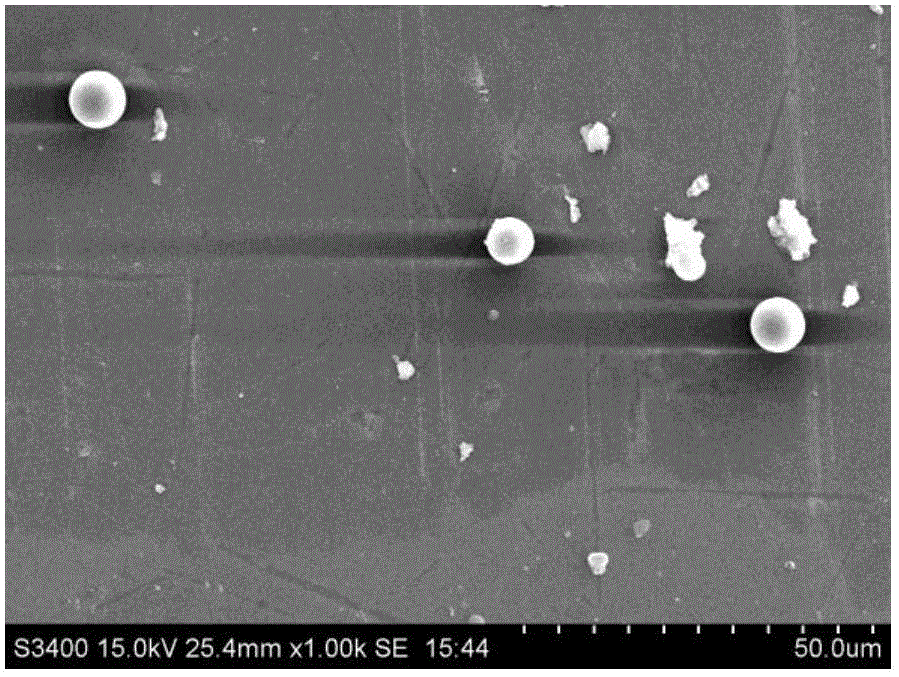

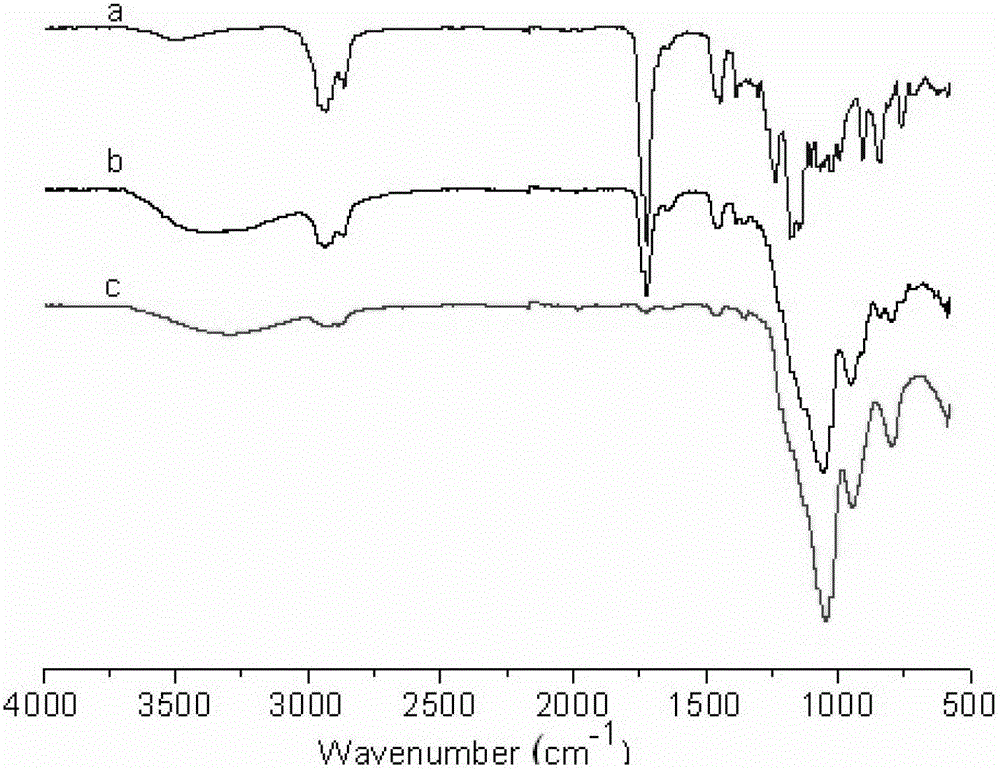

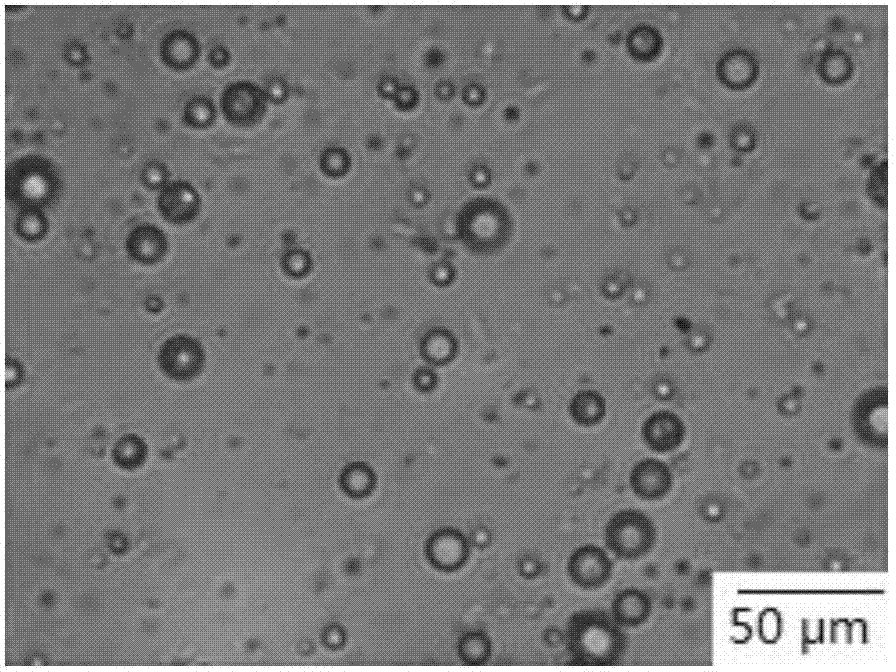

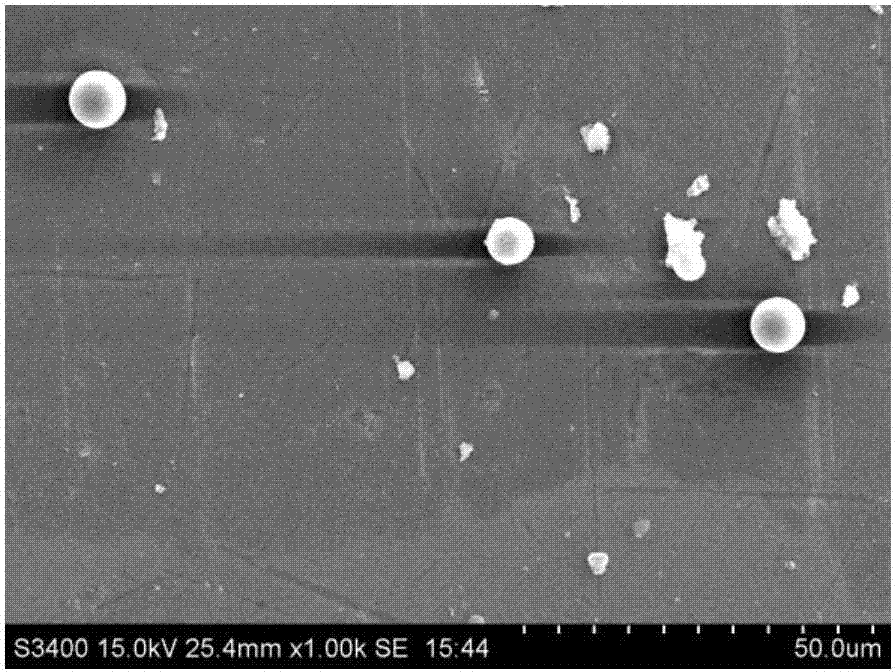

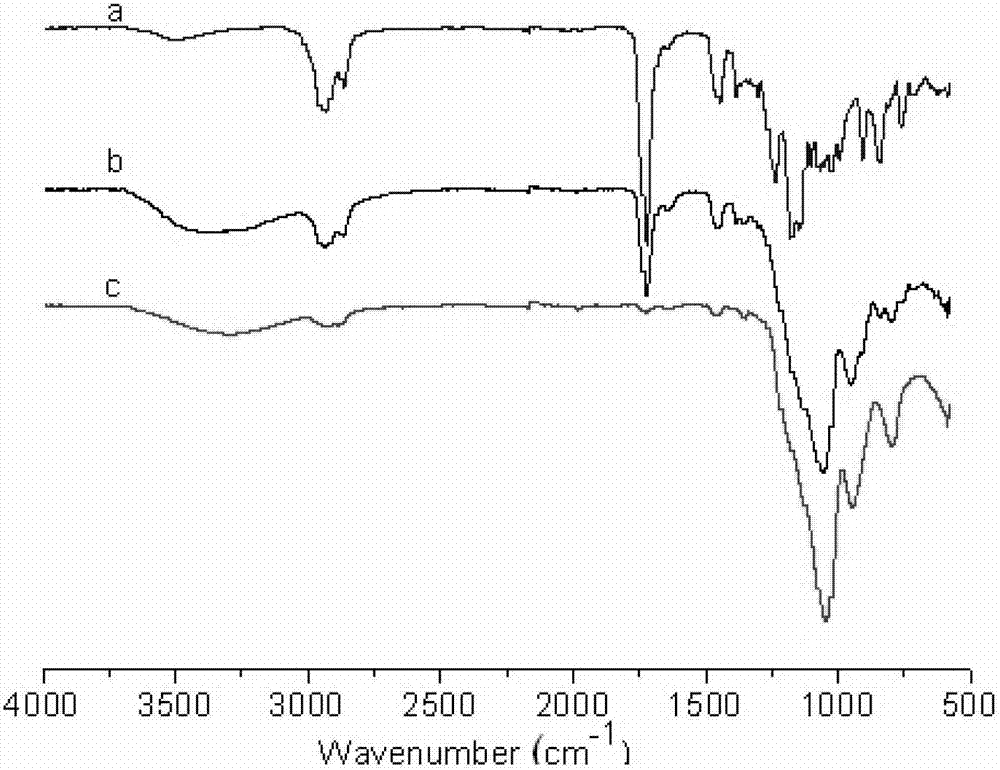

Epoxy resin microcapsule coated by tetraethyl orthosilicate, and preparation method of the epoxy resin microcapsule

InactiveCN103331134AImprove thermal stabilityGood storage stabilityMicroballoon preparationMicrocapsule preparationPolymer scienceInorganic materials

The invention discloses an epoxy resin microcapsule coated by tetraethyl orthosilicate, and a preparation method of the epoxy resin microcapsule. Epoxy resin is taken as a core material; and a wall material is formed by hydrolysis polycondensation reaction of the tetraethyl orthosilicate under an acid condition to coat the epoxy resin, so as to obtain the epoxy resin microcapsule; the core of the epoxy resin microcapsule is any one of bisphenol A epoxy resin, rosin epoxy resin and terpenyl epoxy resin; and the dosage of the tetraethyl orthosilicate is 0.5-2 times of mass of the epoxy resin. The epoxy resin microcapsule prepared by the method disclosed by the invention has the performances of organic and inorganic materials, and has excellent thermal stability and storage stability; the tetraethyl orthosilicate is free of poison or harm; the formed wall material of the epoxy resin microcapsule is friendly to the environment; and meanwhile, an organic silicon wall material of the epoxy resin microcapsule cracks in a curing process and is evenly distributed inside an epoxy resin system. Therefore, the toughness of cured epoxy resin can be improved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

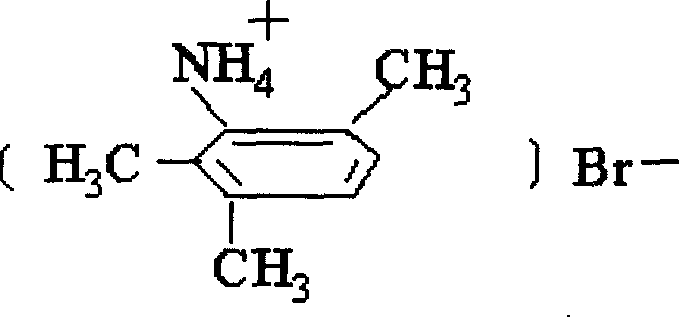

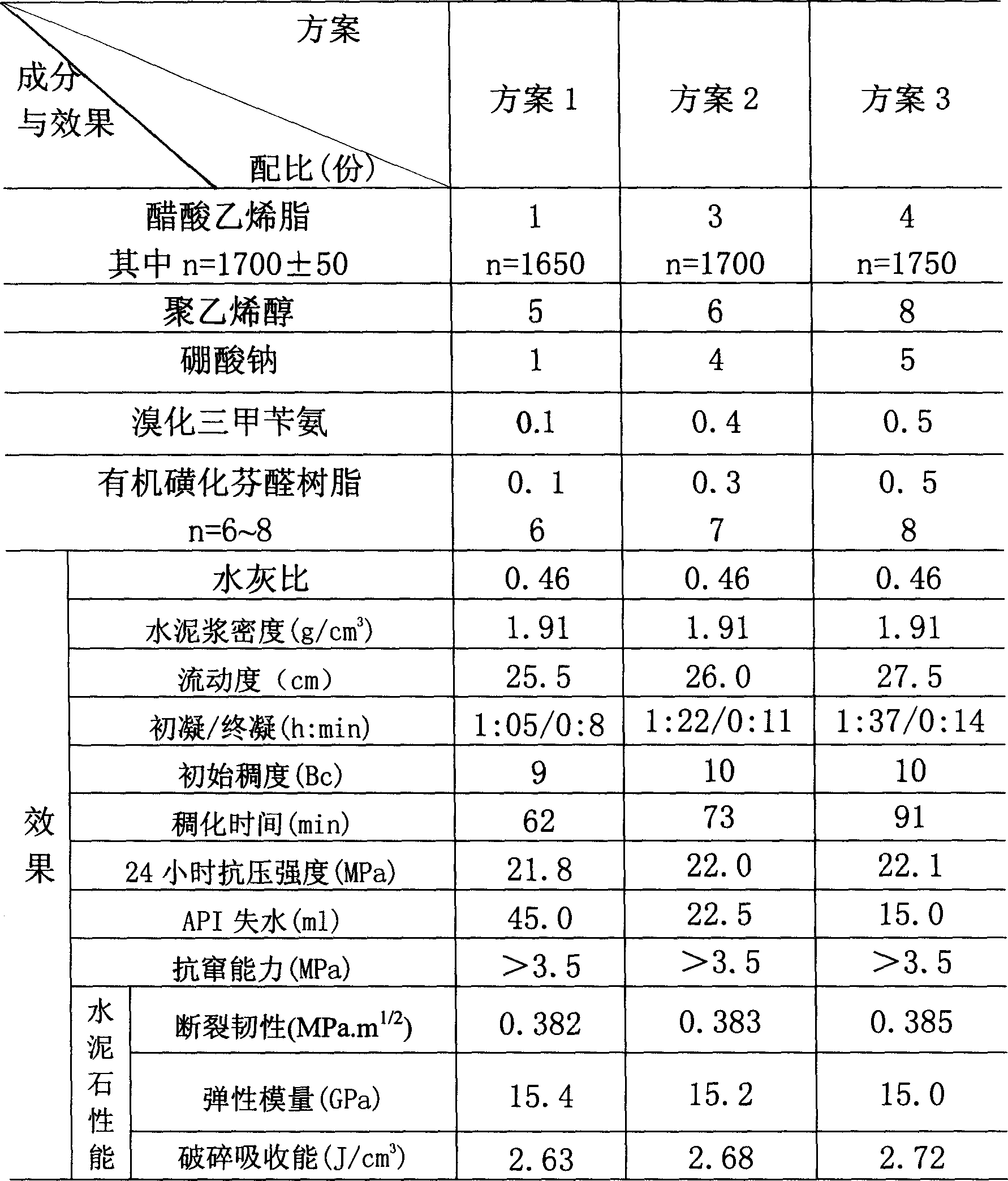

Tough impact admixture for oil well cement

The present invention relates to tough impact admixture for oil well cement for oil field well drilling and fixing. The present invention features that the tough impact admixture for oil well cement consists of vinyl acetate 1-4 (in weight portions, the same below), polyol 5-8, inorganic sodium salt 0.1-0.5, binary hydroxycarboxylic acid 0.1-0.3 and naphthalenesulfonate 0.1-0.5. The tough impact admixture has the features of fast solidification, waterproofing and antiseeping, low water loss, quick increase of coagulation strength, and powerful looseness resisting strength. It can raise the compact strength of cement ring and well fixing quality.

Owner:DAQING PETROLEUM ADMINISTRATION

Strippable nail polish gel and preparation method thereof

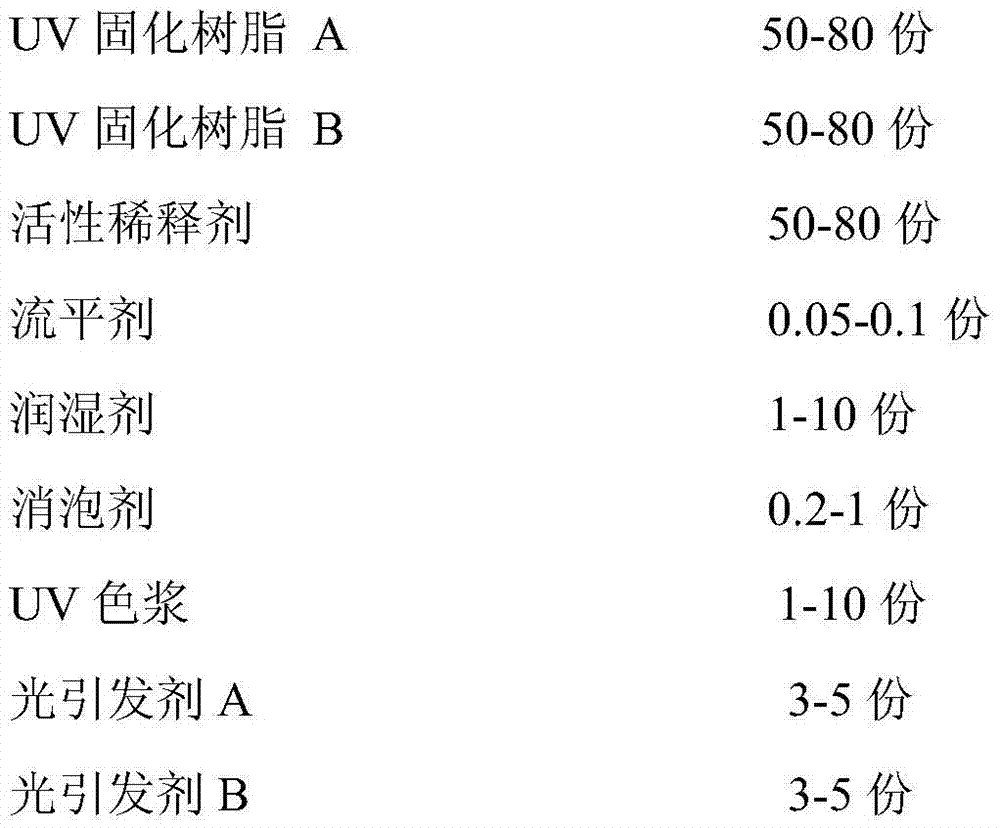

InactiveCN105434189AFinishing is convenient and quickBright and changeable colorsCosmetic preparationsToilet preparationsReactive diluentLED lamp

The invention discloses strippable nail polish gel and a preparation method thereof. The strippable nail polish gel is prepared from by weight, 50-80 parts of UV curing resin A, 50-80 parts of UV curing resin B, 50-80 parts of reactive diluents, 0.05-1 part of leveling agent, 1-10 parts of wetting agent, 0.2-1 part of antifoaming agent, 1-10 parts of UV color paste, 3-5 parts of photoinitiator A and 3-5 parts of photoinitiator B. The strippable nail polish gel has rapid curing capacity after being irradiated through 365 nm UV-LED lamps and can be widely applied to the technical field of nail care of various users.

Owner:SHANGHAI INST OF TECH

High-toughness and high-thermal-conductivity high-molecular material

The invention relates to the technical field of high-molecular materials, and in particular, relates to a high-toughness and high-thermal-conductivity high-molecular material comprising the components: 10-15 parts of glycidyl ester epoxy resin, 35-45 parts of epoxide polydibutene, 10-25 parts of polyethylene glycol, 60-75 parts of a composite thermal conductive filler, 3-8 parts of a flame retardant, 2.5-3.6 parts of a chain extender, 1-10 parts of a toughening filler, 0.3-1.3 parts of an antioxidant, and 0.5-4 part of a dispersant. The toughening filler and the chain extender have a toughening effect on the composite material, and the added toughening agent has good performance of low-temperature impact resistance, so the composite material has the advantages of high thermal conductivity and high toughness, also reduces the thermal conduction linear expansion coefficient, and avoids stress cracking of products.

Owner:ANHUI ELECTRIC GRP SHARES

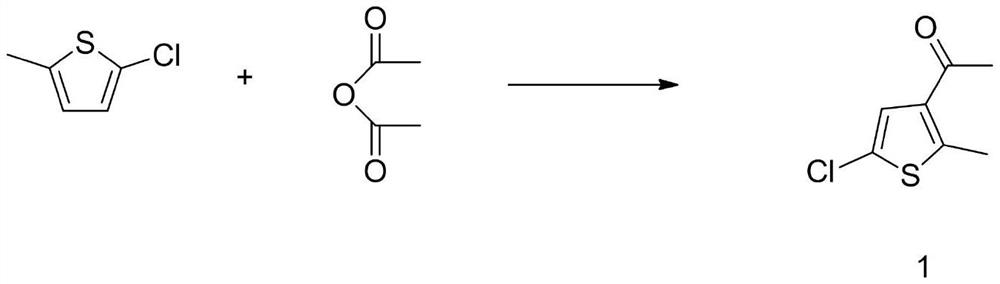

Halogen-free flame retardant epoxy resin used for electronic packaging material and preparation method of halogen-free flame retardant epoxy resin

InactiveCN104194703AIncrease multiplicityTougheningNon-macromolecular adhesive additivesMacromolecular adhesive additivesNano structuringPhosphorylation

The invention discloses a halogen-free flame retardant epoxy resin used for an electronic packaging material and a preparation method of the halogen-free flame retardant epoxy resin. The flame retardant epoxy resin comprises the following components in parts by weight: 50-70 parts of liquid epoxy resin, 2-10 parts of a reactive diluent, 5-15 parts of a curing agent, 0.2-2 parts of a curing accelerator and 2-20 parts of phosphoric acid doped polyaniline nanometer material, wherein the phosphoric acid doped polyaniline nanometer material has the inflaming retarding effect in the epoxy resin, and a large number of P-N bond intermediates generated during the combustion process of the phosphoric acid doped polyaniline nanometer material is a phosphorylation agent which has better inflaming retarding effect than the conventional phosphorus compound; the nitrogen content of the prepared epoxy resin is 0.8-5 wt%, and the phosphorus content of the prepared epoxy resin is 0.2-3 wt%. According to the invention, the flame resistance of an aromatic nucleus, the flame retardance of a nitrogen heterocyclic ring and organic phosphorus as well as the toughening effect of a polyaniline nano-structure are combined, so that the synchronous improvement of the multiple properties of the material is realized, and further, the requirements on the toughness and halogen-free flame retardance of the electronic component packaging material are met.

Owner:JIANGNAN UNIV +1

Epoxy resin microcapsule coated by tetraethyl orthosilicate, and preparation method of the epoxy resin microcapsule

InactiveCN103331134BImprove thermal stabilityGood storage stabilityMicroballoon preparationMicrocapsule preparationPolymer scienceInorganic materials

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

A kind of non-woven fabric containing metal coating and its products

ActiveCN103552318BTougheningConductiveSynthetic resin layered productsMetal layered productsFiberMetal coating

The invention relates to a nonwoven fabric containing a metal coating as well as a product thereof. The nonwoven fabric containing the metal coating is mainly characterized in that the structural characteristic of the nonwoven fabric is that the nonwoven fabric is a thin layer which has a network structure and is formed by low-surface-density fibers; a metal layer of copper, silver, nickel, nickel coated copper or nickel-copper-nickel is coated on the surface of the nonwoven fabric and has the thickness of 100nm-5 micron m, so that the nonwoven fabric layer has electrical conductivity and keeps soft, also can obviously intensify the interlayer fracture toughness and electrical conductivity of laminated plates when being applied to intercalation compounding material lamination plates, and meanwhile a compound material is endowed with higher shock damage impedance and damage tolerance as well as higher electrical conductivity. Corresponding prepregs can be directly used for laying and covering so as to obtain a high-electrical-conductivity compound material, and the corresponding compound material product can be used for high-electrical-conductivity shock-resistant occasions and aircraft lightning protection structural bodies.

Owner:AVIC COMPOSITES

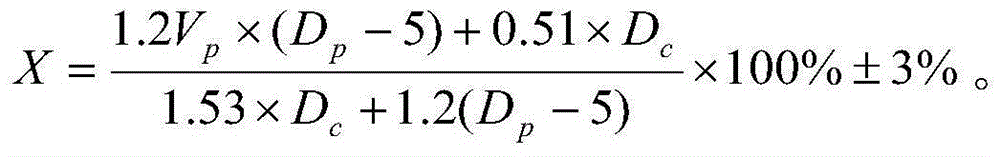

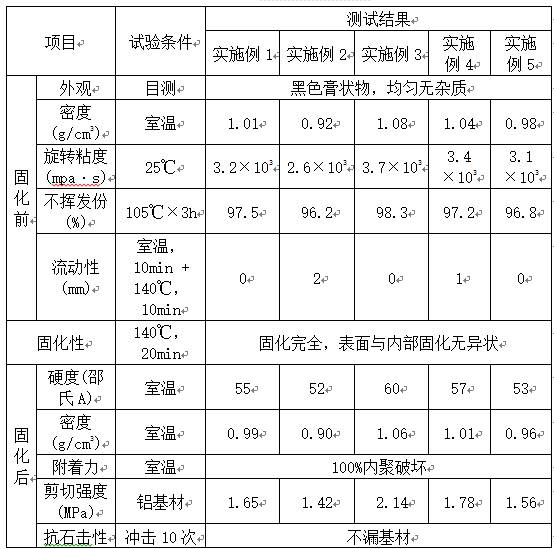

Stone-impact-resistant coating for low-density aluminum substrate

InactiveCN112409854AStrong adhesionReduce weightPolyamide coatingsPolyester coatingsPlasticizerAluminum substrate

The invention discloses a stone-impact-resistant coating for a low-density aluminum substrate. The stone-impact-resistant coating is prepared from the following raw materials in parts by weight: 15-25parts of PVC paste resin, 5-15 parts of ternary vinyl chloride-vinyl acetate resin, 1-5 parts of adhesion promoting resin LTH, 1-5 parts of tackifying resin, 30-40 parts of plasticizer, 1-3 parts ofmoisture-proof agent, 3-8 parts of diluent, 0.1-1 part of carbon black, 1-5 parts of hollow glass beads and 20-30 parts of filler. The stone-impact-resistant coating can be baked and cured at 140 DEGC for 20 min, compared with a common PVC type stone-impact-resistant coating, the stone-impact-resistant coating has the advantages that a cured product and an aluminum base material have good adhesive force, the density after baking is 0.9-1.1 g / cm<3>, the weight of a vehicle body can be effectively reduced, and the weight is reduced by 35% or above compared with that of the common PVC type stone-impact-resistant coating.

Owner:三友(天津)高分子技术有限公司

Wear-resistant and scratch-resistant modification method of leather for bags and suitcases

InactiveCN111138937AGood dispersionImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceAniline

The invention discloses a wear-resistant and scratch-resistant modification method of leather for bags and suitcases. The production process comprises the following steps: (1) dispersing white carbonblack and silicon micro powder in an ethanol medium, carrying out ultrasonic treatment, stirring in a water bath, carrying out suction filtration, and carrying out vacuum drying to obtain a wear-resistant hybrid filler; (2) adding graphene into hydrochloric acid, carrying out ultrasonic mixing, then adding an aniline monomer, continuously carrying out ultrasonic treatment, adding absolute ethyl alcohol and water, stirring, slowly adding an ammonium persulfate aqueous solution in a dropwise manner, stirring in an ice-water bath, standing, washing with water, carrying out suction filtration until filtrate is colorless, and drying to obtain a scratch-resistant filler; and (3) dissolving bisphenol A aniline benzoxazine and an alicyclic epoxy resin in acetone, carrying out ultrasonic oscillation to completely dissolve, adding the wear-resistant hybrid filler and the scratch-resistant filler, carrying out ultrasonic uniform mixing, pouring the obtained mixture into a cleaned spray gun, uniformly spraying the mixture on the surface of cleaned leather at room temperature, and curing to prepare the wear-resistant scratch-resistant coating.

Owner:安徽省高雅家居有限公司

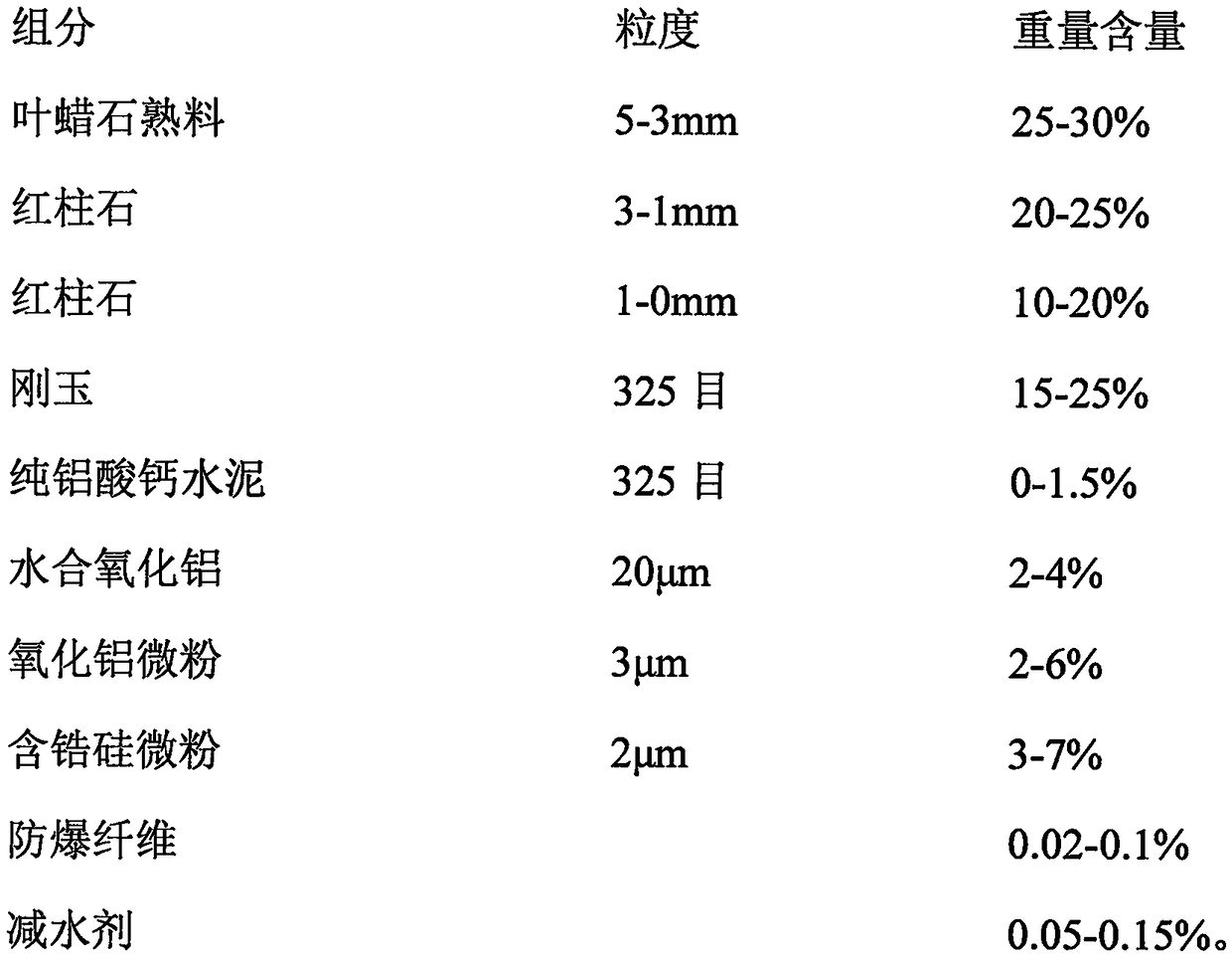

Castable for reducing atmosphere kiln

InactiveCN109503181AStrong room temperature hardening abilityHigh temperature strengthPyrophylliteThermal shock

The invention specifically relates to a castable for a reducing atmosphere kiln. The castable is prepared from low iron pyrophyllite clinker, low iron andalusite and high-purity corundum as main raw materials, and calcium aluminate cement-hydrated alumina-silica micropowder is used as a composite bonding agent. The castable has higher room temperature hardening performance and higher high-temperature strength. The thermal shock performance of the castable is improved greatly through zirconia in the silica powder. The raw materials used in the castable have low iron content and higher CO corrosion resistance, so that a furnace liner can be effectively prevented from getting tremendously loose, and the service life of the reducing atmosphere kiln is prolonged greatly.

Owner:LUOYANG KECHUANG NEW MATERIAL CO LTD

Nonionic self-emulsifying water-based epoxy curing agent and its preparation method and application

InactiveCN101624385BLow viscosityImprove hydrophilicityOrganic compound preparationEpoxy resin adhesivesPolymer scienceActive agent

The invention relates to an epoxy curing agent, and specifically provides a non-ionic self-emulsifying water-based epoxy curing agent. The curing agent is first reacted with a hydrophobic alkylamine and a low molecular weight hydrophilic bisglycidyl ether to prepare a A kind of diepoxy compound with epoxy groups at both ends and a long hydrophobic alkyl side chain connected to the middle nitrogen atom, and then reacted with fatty amines or both ends are blocked with fatty amines and hydrophilic amines respectively, An amino-terminated nonionic self-emulsifying water-based epoxy curing agent with a structure similar to that of a surfactant is prepared. The curing agent can be further mixed with deionized water to prepare a light yellow water-based epoxy resin curing agent with a solid content of 50% to 60%. The curing agent prepared by the invention has good self-emulsification effect, good compatibility with epoxy resin, high stability, good flexibility and surface activity. It can be widely used in water-based epoxy resin coatings, epoxy resin adhesives and water-based epoxy grouting materials.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

InactiveCN102618045BGood emulsificationImprove hydrophilicityPaving detailsBuilding insulationsEpoxyAging resistance

The invention discloses waterborne epoxy resin modified emulsified asphalt, which contains emulsified asphalt and self-emulsifying waterborne epoxy resin, wherein the volume ratio of the emulsified asphalt to the self-emulsifying waterborne epoxy resin is 1: (0.2-0.8); the emulsified asphalt is nonionic emulsified asphalt, anionic emulsified asphalt or cationic emulsified asphalt, and the solid content of the emulsified asphalt is 20 to 60 percent; and the self-emulsifying waterborne epoxy resin contains waterborne epoxy resin curing agent, water and liquid epoxy resin in a mass ratio of 1: (0.8-2): (2-5). The invention also discloses a preparation method for the waterborne epoxy resin modified emulsified asphalt and application in preparation of an asphalt type waterproof coating. After the common commercial emulsified asphalt is modified by the waterborne epoxy resin, the break elongation of the emulsified asphalt can be improved, and the modified emulsified asphalt has high adhesive strength with a base plane, certain strength and high waterproof property and ageing resistance; and the modified emulsified asphalt can be used for making the asphalt type waterproof coating, and can also be used for repairing road pavements.

Owner:重庆融极环保工程有限公司

Method for preparing polystyrene-based phase change microcapsule heat-storage composite material

InactiveCN106554577AReduce heat transfer rateLow thermal conductivityHeat-exchange elementsMicroballoon preparationPolymer scienceBulk polymerization

The invention relates to a method for preparing a polystyrene-based phase change microcapsule heat-storage composite material. The method for preparing the polystyrene-based phase change microcapsule heat-storage composite material includes the following steps of (1) preparation of a phase change microcapsule and (2) preparation of the phase change microcapsule composite material. By the adoption of the method, the polystyrene-based phase change microcapsule heat-storage composite material is prepared through a mass polymerization method, the heat storage function is obvious, the heat transfer speed is decreased, the heat conductivity coefficient is lowered remarkably and is lower than the specification value about the heat conductivity coefficient of an efficient thermal insulation material in the national standard on the whole, and thus the polystyrene-based phase change microcapsule heat-storage composite material belongs to a good thermal insulation material.

Owner:SHAANXI SHENGMAI PETROLEUM

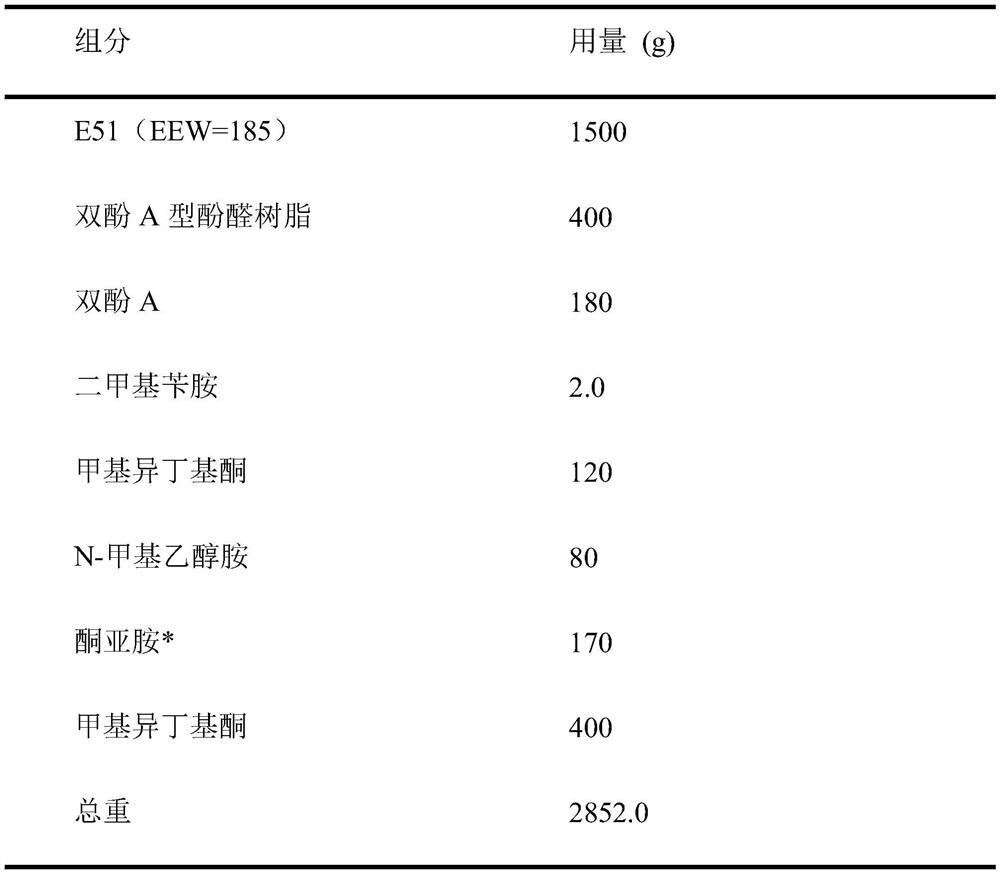

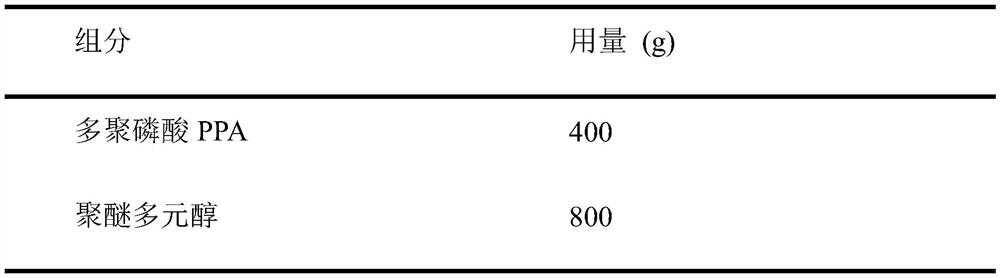

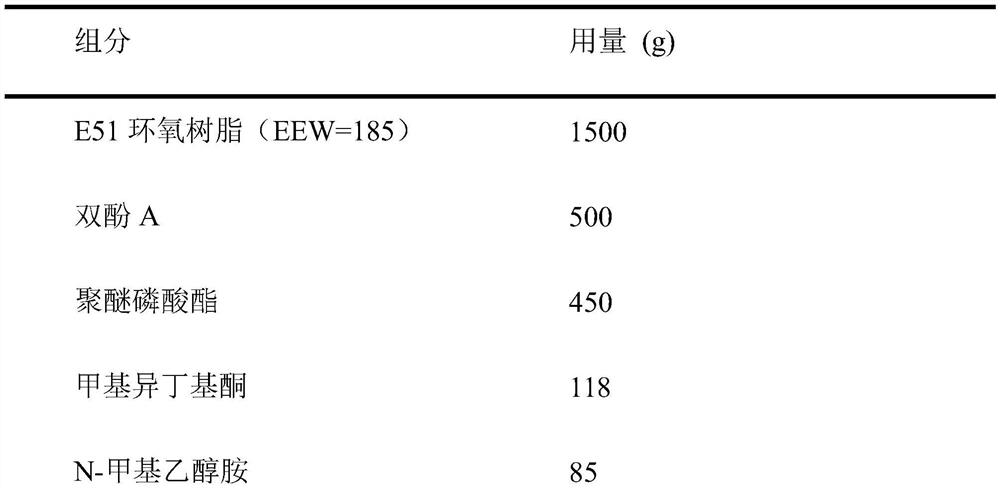

Cathode electrophoretic paint with environment-friendly pretreatment and high matching property and preparation method thereof

InactiveCN112266723AImprove wet film resistanceImproved wet adhesionPaints for electrolytic applicationsPolymer chemistryElectrophoreses

The invention relates to cathode electrophoretic paint with environment-friendly pretreatment and high matching performance and a preparation method. The electrophoretic paint mainly comprises phenolic resin modified epoxy resin and phosphate ester modified epoxy resin. The preparation method has the beneficial effects that epoxy resin is introduced by adopting phenolic resin, so that the wet filmresistance is improved. The polyether phosphate is adopted to modify the epoxy resin, so that the wet adhesive force of a paint film can be effectively improved, and the epoxy resin can be toughenedto adapt to environment-friendly pretreatment. Through a method of mixing two kinds of modified epoxy resin, the electrophoretic paint with environment-friendly pretreatment and high matching performance is prepared.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

Preparation method of composite diatom ooze wall coating material

The invention relates to a preparation method of a composite diatom ooze wall coating material. The method comprises the following steps: collecting and processing kieselguhr; preparing foamed cement powder; preparing short bamboo fibers; and preparing the composite diatom ooze wall coating material. The wall coating material is prepared by compounding the kieselguhr, the foamed cement powder and the short bamboo fibers, wherein the foamed cement powder has the porosity, so that the foamed cement powder has the performance of adsorbing particles in air; the short bamboo fibers have the anti-cracking performance, so that the short bamboo fibers can perform a toughening function and can be used for absorbing and regulating the air moisture at the same time. Thus, compared with the existing pure diatom ooze, the composite diatom ooze wall coating material provided by the invention is high in strength, strong in air moisture regulating ability, low in cost and easy in material selection, and can generate the effect of natural textures. As a result, the method provided by the invention is suitable for being applied to the preparation of the composite wall coating material taking the diatom ooze as a main body.

Owner:啄木鸟漆业集团有限公司

Preparation method of anti-cracking unsaturated polyester varnish

ActiveCN109517502AGood flexibilityImprove adhesionFireproof paintsPolyester coatingsDiluentAccelerant

The invention relates to a preparation method of anti-cracking unsaturated polyester varnish. The preparation method comprises the following steps: modified filler preparation, main varnish raw material preparation and proportioning, and weighing and subpackaging. The anti-cracking unsaturated polyester varnish comprises 100 parts of main varnish, 1.5-2.5 parts of an initiator, 1-2 parts of an accelerant and 30-40 parts of a diluent. The main varnish comprises an anti-cracking agent and modified filler. By adding the anti-cracking gent and the modified inorganic filler, the film has a good adhesive force, dryness and cracks induced by construction of thick film are avoided, and the construction efficiency is improved.

Owner:广东百川化工有限公司

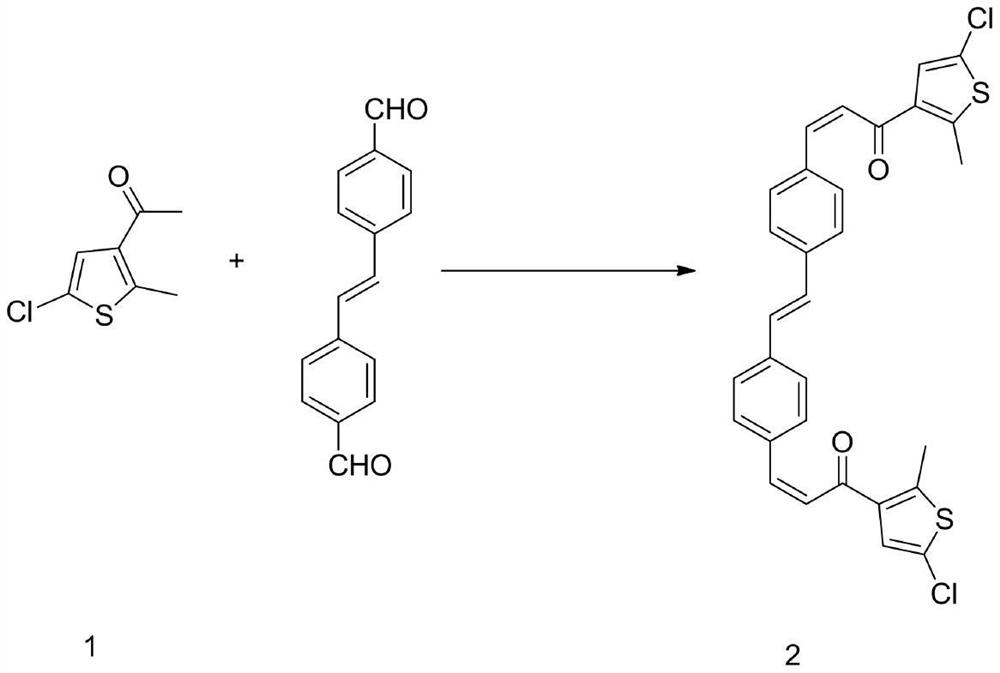

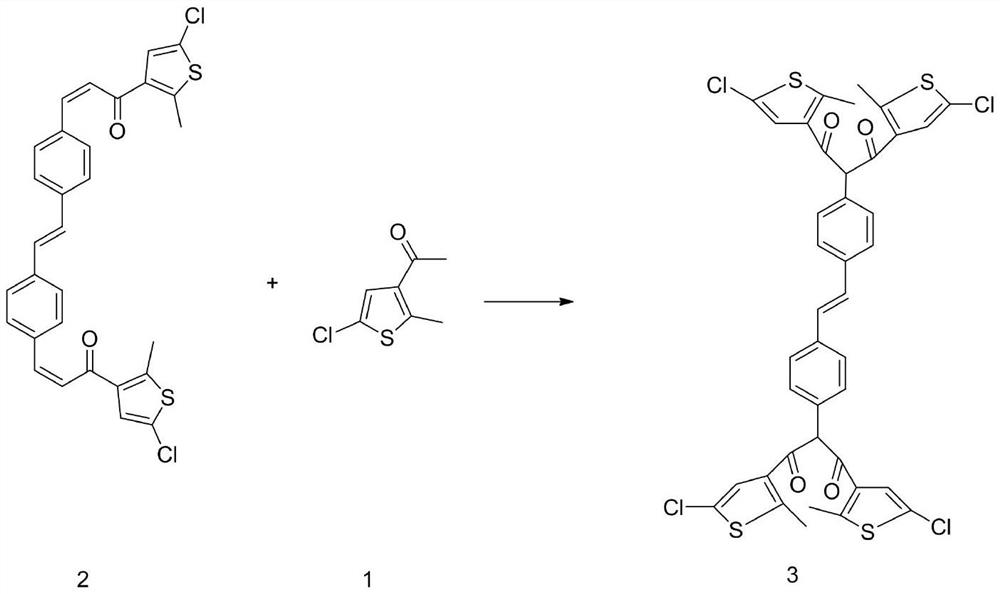

Color-changing garment fabric and preparation method thereof

InactiveCN112921437AWith the singular function of changing colorMaintain photochromic reactivityOrganic chemistryMonocomponent synthetic polymer artificial filamentElectrospinningSodium carboxymethylcellulose

The invention discloses a color-changing garment fabric. The color-changing garment fabric is prepared from color-changing fibers through a knitting weaving method; the color-changing fibers are prepared from 15-20 parts of polyvinyl alcohol, 6-8 parts of deionized water, 2-3 parts of carboxymethyl cellulose, 1 part of color-changing agent, 1 part of absolute ethyl alcohol and 1 part of self-cleaning filler through electrostatic spinning, wherein the color-changing agent is subjected to a ring-closing reaction under ultraviolet irradiation, and the color changing agent becomes blue from a achromatic color, and is subjected to reversible ring-opening reaction under irradiation of visible light to recover the achromatic color, so that the fiber has the fantastic function of color changing; and the self-cleaning filler contains nano titanium dioxide and cuprous oxide, has the photocatalytic self-cleaning function and also has the antibacterial property, and therefore, the garment fabric prepared by the invention not only has a lasting color-changing function, but also has the characteristics of antibiosis, self-cleaning and good air permeability, and has huge utilization value in the preparation of color-changing clothing.

Owner:安徽天一新型纤维科技有限公司

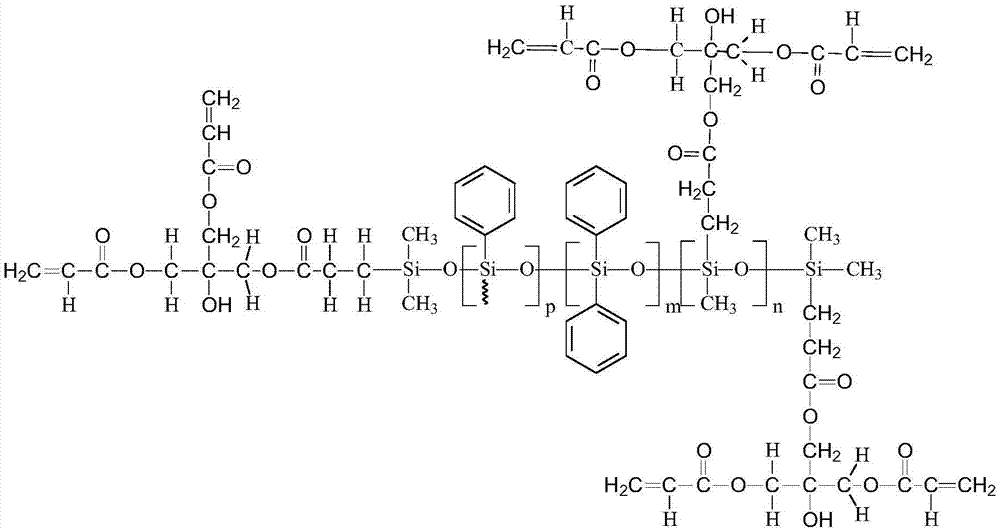

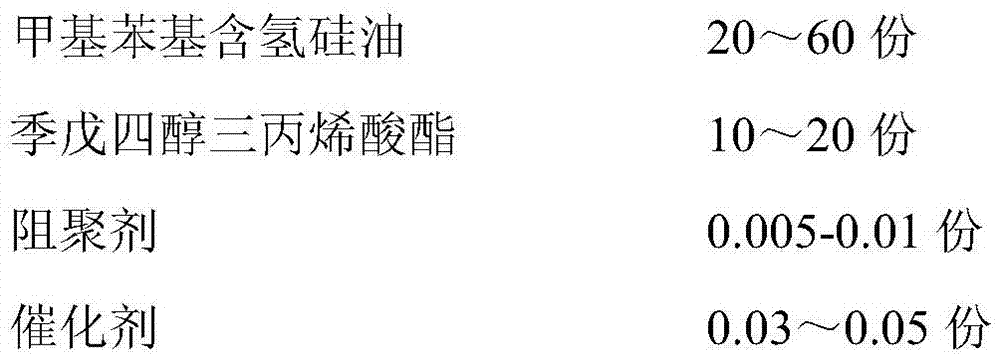

Peelable nail polish gel and synthesis process thereof

InactiveCN105496817AResilientTougheningCosmetic preparationsToilet preparationsLED lampPhotoinitiator

The invention discloses peelable nail polish gel and a synthesis process thereof. The peelable nail polish gel is prepared from the following components in parts by weight: 50-80 parts of UV curing resin A, 50-80 parts of UV curing resin B, 50-80 parts of UV curing resin C, 0.05-0.1 part of a flatting agent, 1-10 parts of a wetting agent, 0.2-1 part of a defoaming agent, 1-10 parts of mill base, 3-5 parts of photoinitiator A and 3-5 parts of photoinitiator B. The peelable nail polish gel has a quick-curing capability after being applied and irradiated by a 365nm UV-LED lamp, and can be widely applied to technical fields of manicure and the like for various populations.

Owner:SHANGHAI INST OF TECH

Recycled modified PP and PE automotive trim special material and preparation method thereof

The invention discloses a recycled modified PP and PE automotive trim special material and a preparation method thereof. The recycled modified PP and PE automotive trim special material comprises thefollowing raw materials in parts by weight: 80-100 parts of recycled particles, 40-45 parts of a reinforcing agent, 0.2-0.4 part of isophthalic acid, 4-6 parts of bis(triazinyl)aminostilbene, 1-3 parts of an antioxidant and 1-3 parts of a light stabilizer. The preparation method comprises the following steps: 1, adding the recycled particles, the reinforcing agent, the isophthalic acid, the bis(triazinyl)aminostilbene, the antioxidant and the light stabilizer into a high-speed mixer, and conducting mixing for 15 minutes to obtain a premix; and 2, pouring the premix into a hot mixing machine, discharging the premix to a cold mixing machine when the premix is subjected to hot mixing to 100-110 DEG C, then starting cold mixing to room temperature to obtain a dry mixture, and carrying out meltblending on the dry blend at 145-155 DEG C, conducting treatment through a twin-screw extruder, and conducting granulating to obtain the recycled modified PP and PE automotive trim special material.

Owner:ANHUI GUANHONG PLASTIC IND

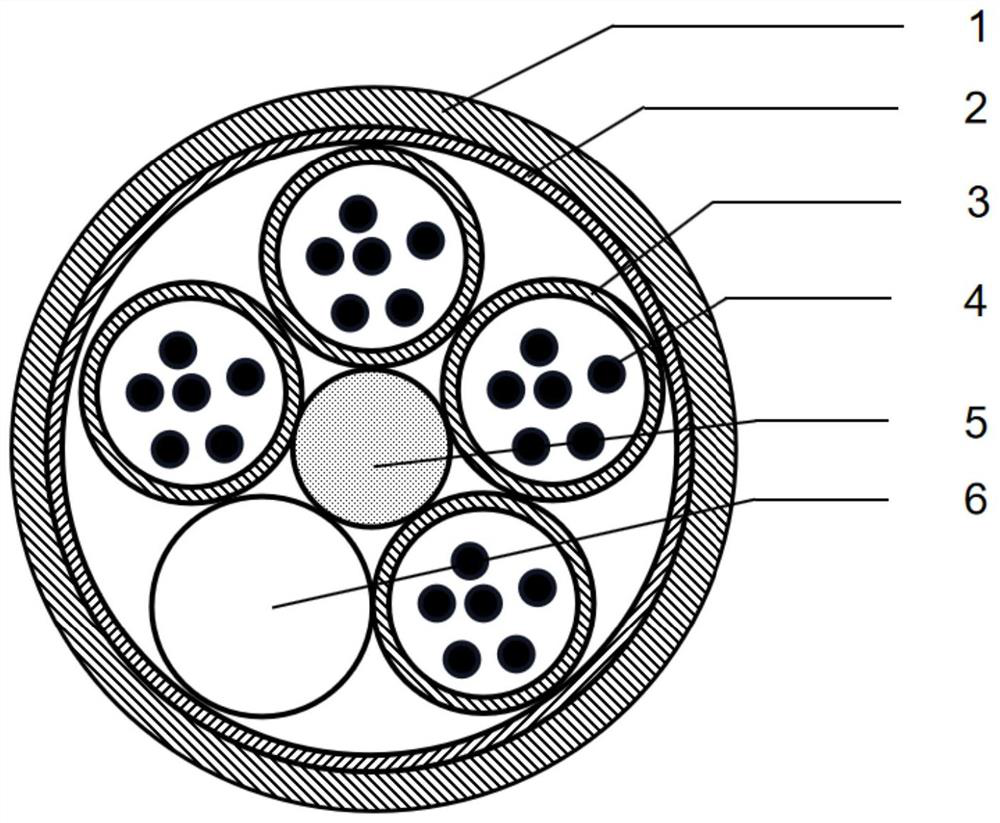

Enhanced layer-stranded optical cable and preparation process thereof

InactiveCN111856681AReduce coefficient of frictionImprove slipperinessFibre mechanical structuresPolytetramethylene terephthalatePolymer chemistry

The invention discloses an enhanced layer-stranded optical cable and a preparation process thereof, and relates to the field of layer-stranded optical cables. The enhanced layer-stranded optical cablecomprises an outer sheath (1) wrapping a plurality of loose tubes (3), optical fibers (4) are arranged in the loose tubes (3), a reinforcer (5) is arranged in the center of the optical cable, and theloose tubes (3) are arranged around the reinforcer (5). The polyethylene composite material for preparing the outer sheath (1) comprises the following components in percentage by weight: 75-85% of polyethylene, 15-25% of glass fibers and 0.1-5% of an additive. The polybutylene terephthalate composite material for preparing the loose tubes (3) is prepared from the following components in percentage by weight: 70-80% of a polybutylene terephthalate material, 20-30% of glass fibers and 0.1-5% of an additive. According to the invention, shrinkage of the high-molecular material is reduced, influence of stress on the optical fibers caused by shrinkage of the high-molecular material is reduced, the influence on the service life and performance of the optical fibers is reduced, and stretch resistance and impact resistance of the optical cable are enhanced.

Owner:四川天府江东科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com