Tough impact admixture for oil well cement

An oil well cement and anti-shock technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of low cementing quality rate, poor impact resistance performance, and poor cementation quality, etc., and achieve Rapid gelling strength, strong channeling resistance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

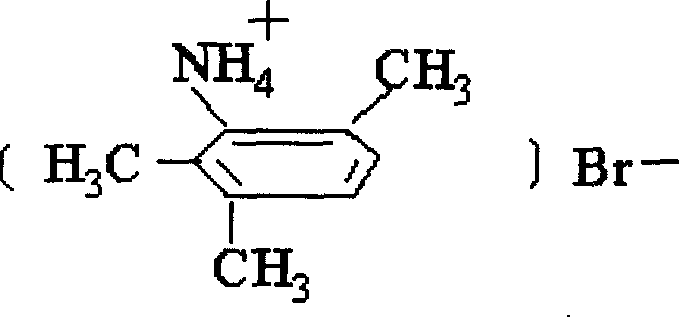

Method used

Image

Examples

Embodiment 1

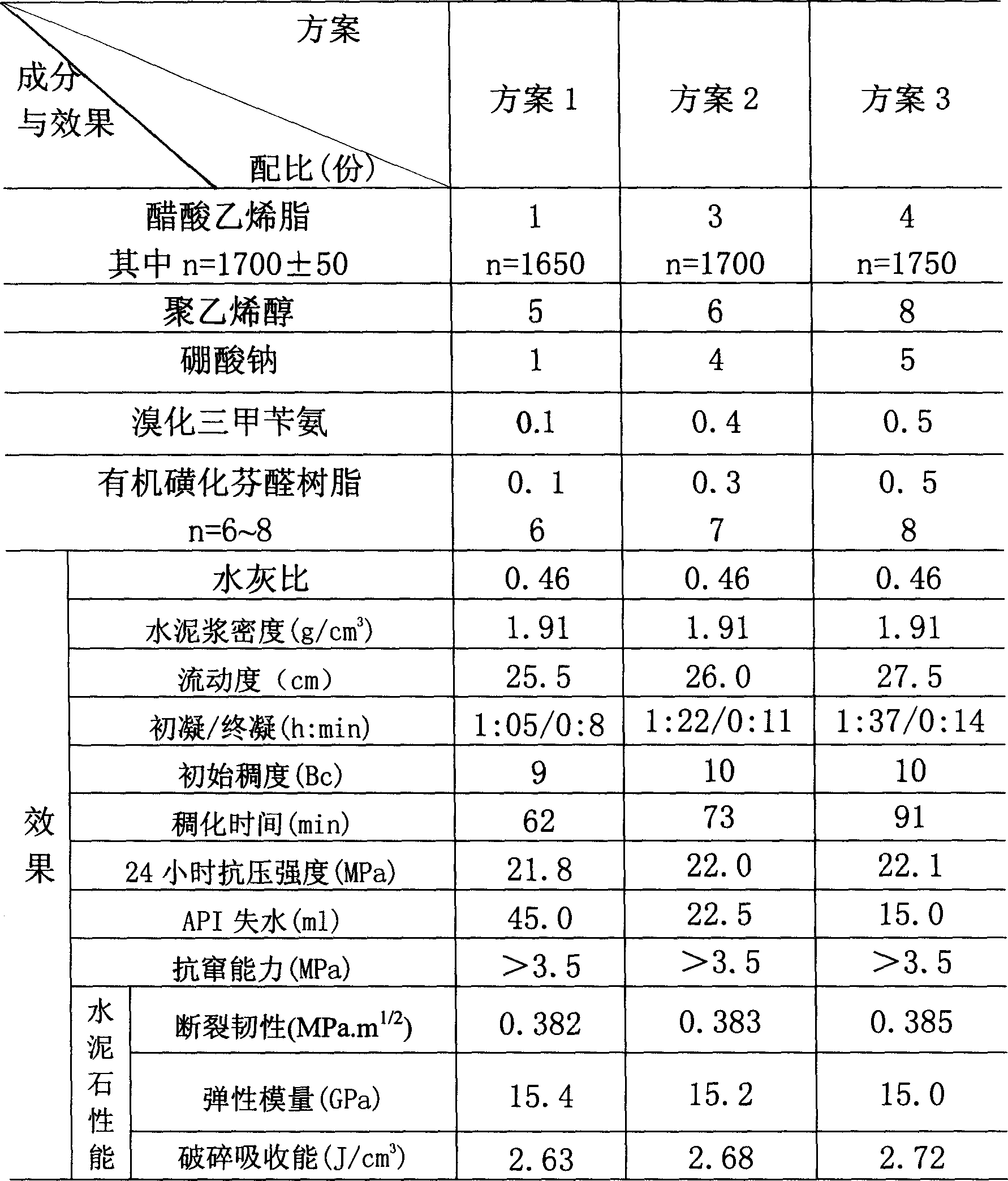

[0015] Example 1: Well Xing 7-21-635 in Daqing is located in the abnormally high-pressure area of Xingbei. The wells in this block are wells in off-surface reservoirs. The cementing rate is high, the interlayer pressure difference is large, and a thick floating mud cake is formed, which is not clean enough to replace it, thus affecting the cementing quality. The cement slurry prepared by the cement admixture of the above scheme 1 was applied on site for well cementing. Compared with the clean slurry, the cement slurry prepared by the cement admixture has better cement performance and fracture toughness of 0.382MPa.m 1 / 2 , the specific pulp fracture toughness is 0.087MPa.m 1 / 2 Large; the elastic modulus is 15.4GPa, which is smaller than the elastic modulus of the clean slurry which is 19.72GPa; the crushing absorption energy is 2.63J / cm 3 ; Specific pulp crushing absorption energy is 1.37J / cm 3 Small; after perforation and fracturing, the percentage of the fully cemented p...

Embodiment 2

[0016] Example 2: Daqing Xing 3-31-648 oil well is cemented using the cement slurry prepared by the cement admixture prepared in the above scheme 2. Compared with the clean slurry, the cement slurry prepared by the cement admixture has better cement performance and fracture toughness. 0.383MPa.m 1 / 2 , the specific pulp fracture toughness is 0.087MPa.m 1 / 2 Large; the elastic modulus is 15.2GPa, which is smaller than the elastic modulus of the clean slurry which is 19.72GPa; the crushing absorption energy is 2.68J / cm 3 , the crushing absorption energy of the pure pulp is 1.37J / cm 3 Small, with a daily liquid production of 24 tons, a daily oil production of 9 tons, and a water content of 62.5%. The 8 wells put into production in this block at the same time all adopt clean slurry cementing, the production method is the same, the production layer is the same, the average daily liquid production is 31 tons, the oil production is 3-4 tons, and the average water content reaches more...

Embodiment 3

[0017] Example 3: Well Xing 2-341-30 is an adjustment well for the third infill in Xing 1-3 area. Casing damage wells in this block account for 30% of the total number of oil and water wells, and high pressure layers are easy to form in casing damage layers. Fault shielding, lithology lame pressure zones, high formation pressure at the top and low at the bottom, and large pressure difference between layers. These complicated geological conditions make it difficult to guarantee the cementing quality. Compared with the clean slurry, the cement slurry prepared with this cement admixture in this well has a cement stone performance and fracture toughness of 0.385MPa.m 1 / 2 , the specific pulp fracture toughness is 0.087MPa.m 1 / 2 Large; the elastic modulus is 15.0GPa, which is smaller than the elastic modulus of the clean slurry which is 19.72GPa; the crushing absorption energy is 2.72J / cm 3 , the crushing absorption energy of the pure pulp is 1.37J / cm 3 High, the transition time f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com