Enhanced layer-stranded optical cable and preparation process thereof

A preparation process, layer twisting technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of affecting the life and performance of optical fibers, and the thermal expansion coefficient is very different, so as to enhance mechanical properties, improve smoothness, and enhance resistance. stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

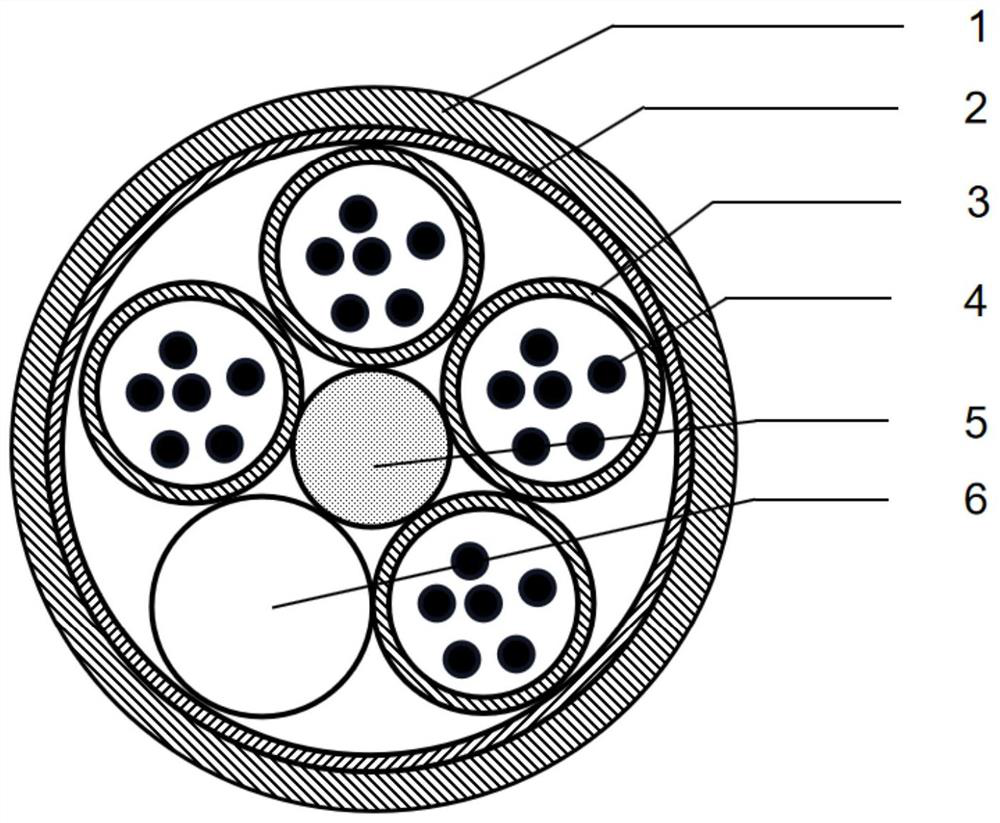

Image

Examples

preparation example Construction

[0064] A preparation process for an enhanced layer-stranded optical cable, including the process for preparing the described enhanced layer-stranded optical cable is as follows:

[0065] Prepare outer sheath 1 and prepare loose tube 3;

[0066] Wherein, the percentage by weight of the polyethylene composite material for preparing the outer sheath 1 is as follows: 75-85% polyethylene, 15-25% glass fiber, and 0.1-5% additive;

[0067] Wherein, the percentage by weight of the polybutylene terephthalate composite material for preparing the loose tube 3 is as follows: polybutylene terephthalate material 70-80%, glass fiber 20-30%, additive 0.1 -5%.

Embodiment 1

[0068] Embodiment 1, the weight percent of the polybutylene terephthalate composite material that prepares described loose tube 3 is as follows:

[0069] Polybutylene terephthalate 78%;

[0070] 20% glass fiber, the specification of glass fiber is TCR736;

[0071] Silicone resin 2%, the specification of silicone resin is 100A;

[0072] Antioxidant 0.5%, the trade mark that antioxidant adopts is 1010.

Embodiment 2

[0073] Embodiment 2, the weight percent of the polybutylene terephthalate composite material that prepares described loose tube 3 is as follows:

[0074] Polybutylene terephthalate 83%;

[0075] 15% glass fiber, the specification of glass fiber is TCR736;

[0076] Silicone resin 1.5%, the specification of silicone resin is 100A;

[0077] Antioxidant 0.5%, the trade mark that antioxidant adopts is trade mark 168.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com