Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

A water-based epoxy resin, emulsified asphalt technology, applied in asphalt coatings, building components, coatings, etc., can solve the problems affecting the performance and properties of emulsified asphalt, short service time, small extension length, etc., to achieve excellent emulsification effect, improve Performance, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Synthesis of water-based epoxy resin curing agent

[0062] (1) Preparation of diepoxy compounds:

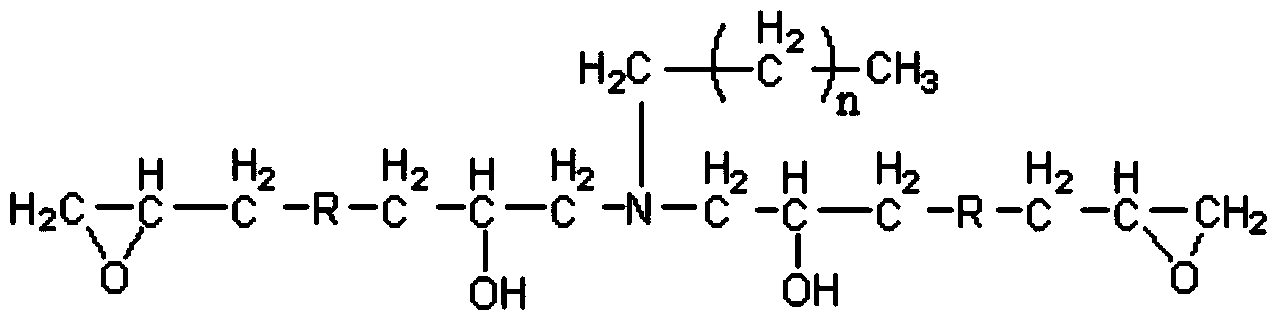

[0063] In a four-necked flask filled with nitrogen, equipped with a stirrer, a thermometer, a reflux condenser, and a constant pressure funnel, add 0.24 moles of SY-669 (ethylene glycol bisglycidyl ether), raise the temperature to 65 ° C, and dissolve 0.1 moles of SY-669 Octadecylamine was dissolved in 40g of propylene glycol methyl ether, placed in a constant pressure funnel, and then slowly dropped into the flask. Control the dropwise addition within 1 to 1.5 hours, then raise the temperature to 70° C., react for about 3 to 4 hours, and measure the reaction end point by hydrochloric acid acetone method. The product is taken out, and the product is cooled, and its structure is as follows:

[0064] (2) Hydrolysis of epoxy group: add dilute hydrochloric acid solution in the diepoxy group compound that makes in the step (1), wherein the mass percentage concentration of ...

Embodiment 2

[0079] 1. Synthesis of water-based epoxy resin curing agent

[0080] (1) Preparation of Diepoxides:

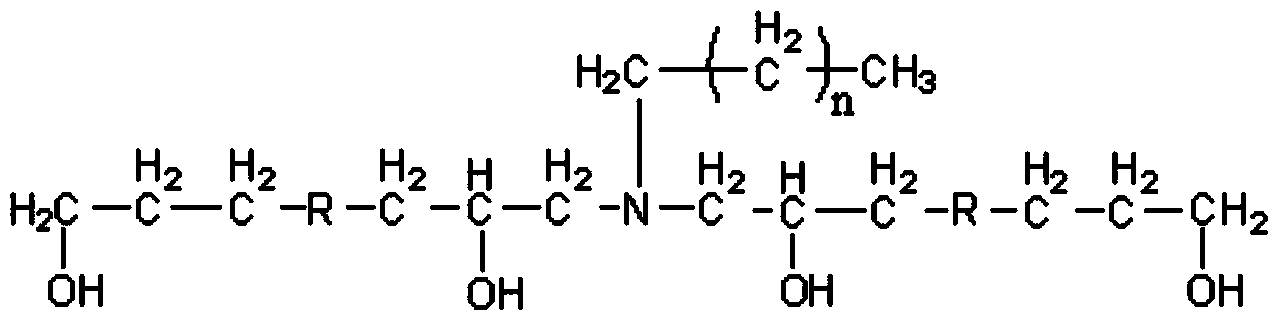

[0081] In a four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, and a constant pressure funnel, add 0.24 moles of SY-669 (ethylene glycol bisglycidyl ether), raise the temperature to 65 ° C, and add 0.1 moles of hexadecylamine Dissolve in 40g of propylene glycol methyl ether, place in a constant pressure funnel and slowly drop into the flask. Control the dropwise addition within 1 hour, then raise the temperature to 70°C, react for about 4 hours, and measure the reaction end point by the hydrochloric acid acetone method. The product was removed and cooled. Its structural formula is:

[0082]

[0083] (2) Hydrolysis of epoxy group: add dilute hydrochloric acid solution in the diepoxy group compound that makes in the step (1), wherein wherein the mass percent concentration of hydrochloric acid is 5%, between dilute hydrochloric acid and diepoxy grou...

Embodiment 3

[0098] 1. Synthesis of water-based epoxy resin curing agent

[0099] (1) Preparation of Diepoxides:

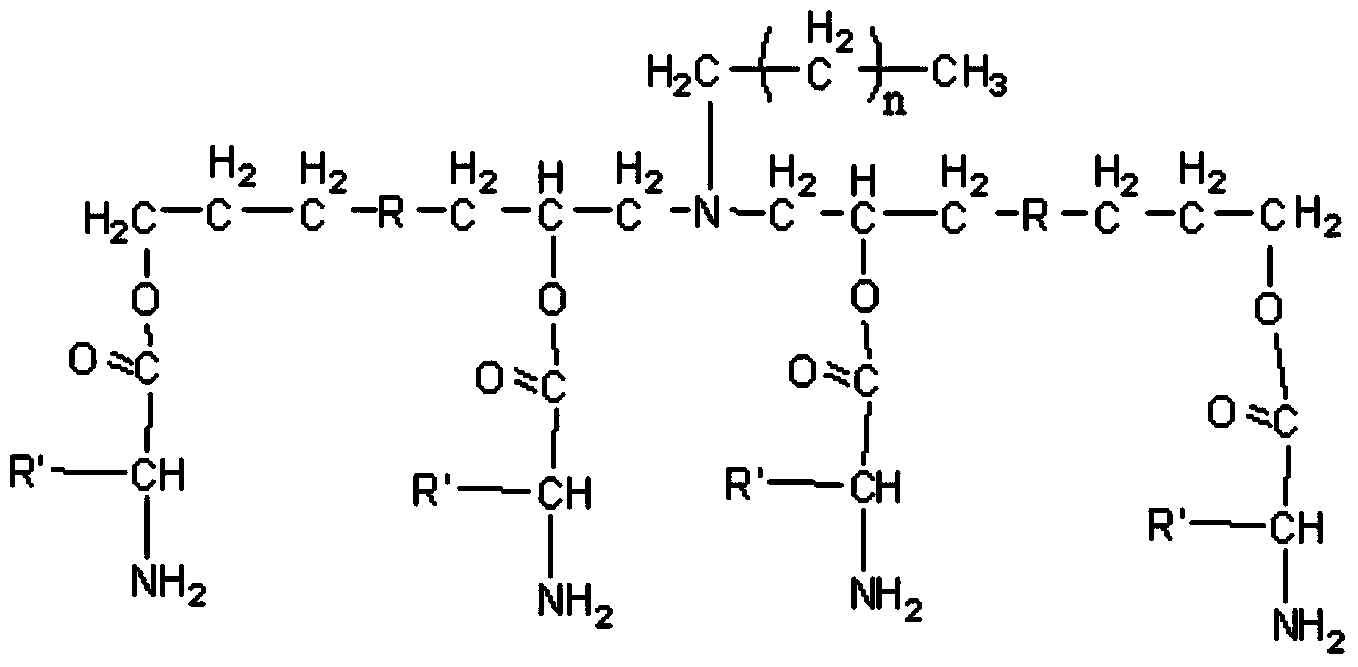

[0100] In a four-neck flask filled with nitrogen, equipped with a stirrer, a thermometer, a reflux condenser, and a constant pressure funnel, add 0.24 moles of polyethylene glycol bisglycidyl ether (m=1), raise the temperature to 65 ° C, and 0.1 One mole of tetradecylamine was dissolved in 40g of propylene glycol methyl ether, placed in a constant pressure funnel, and then slowly dropped into the flask. Control the dropwise addition within 1.5 hours, then raise the temperature to 70°C, react for about 4 hours, and measure the reaction end point by hydrochloric acid acetone method. The product was taken out, and the product was cooled. Its structure is as follows:

[0101]

[0102] in:

[0103] n is an integer of 12;

[0104] R stands for -O-A-O-,

[0105] A is:—(CH 2 —CH 2 ) m —, m=1

[0106] (2) Hydrolysis of epoxy group: add dilute hydrochloric acid solution in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com