Peelable blue gel and preparation method

A blue glue, curing resin technology, applied in the direction of coating, can solve the problems of cumbersome peeling process, high curing temperature, residue and other problems, and achieve the effect of easy control, simple process and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

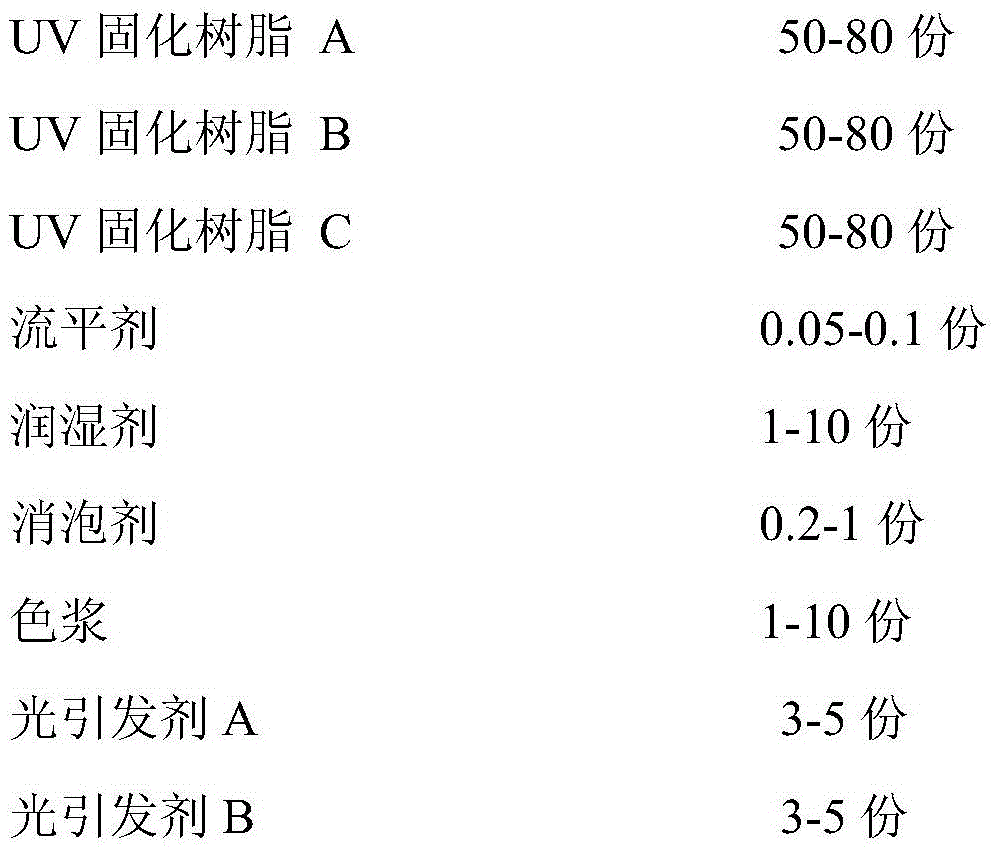

[0038] A peelable blue glue, calculated in parts by weight, its raw material composition and content are as follows:

[0039]

[0040]

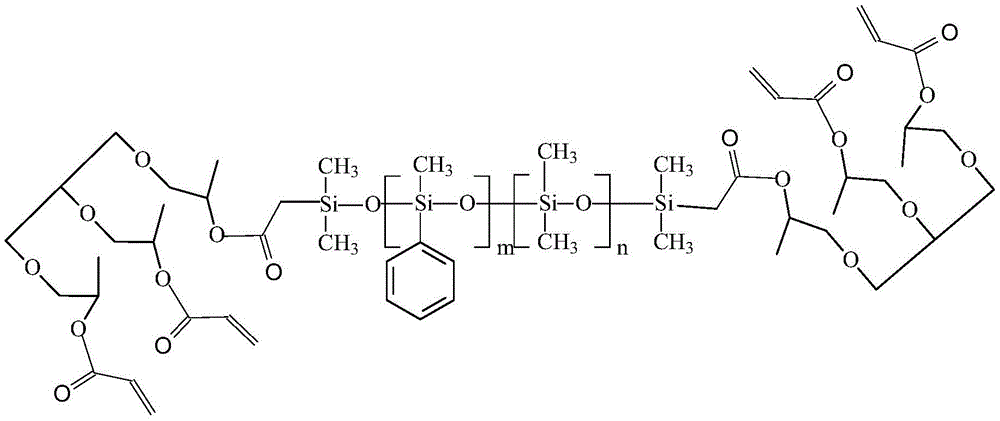

[0041] Wherein: The UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0042]

[0043] The UV curable resin A is prepared as follows: 20 parts of methyl phenyl hydrogen-containing silicone oil and 10 parts of propylene oxide glycerol triacrylate are added to a 500 ml three-necked flask, and then 0.005 of polymerization inhibitor p-hydroxybenzyl Ether, pass in protective gas, stir and heat, heat up to 60°C, add 0.03 parts of catalyst chloroplatinic acid / isopropanol solution, stir and keep at constant temperature for 3h, stop heating, when the temperature of the flask drops to room temperature, UV curable resin A is obtained .

[0044] The UV curable resin C is a mixture composed of dipentaerythritol hexaacrylate, diethylene glycol diacrylate, tetrahydrofuran acrylate, and pentaerythritol tetraacryl...

Embodiment 2

[0059] A peelable blue glue, calculated in parts by weight, its raw material composition and content are as follows:

[0060]

[0061] Wherein: The UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0062]

[0063] The UV curable resin A is prepared as follows: add 60 parts of methyl phenyl hydrogen-containing silicone oil and 20 parts of propylene oxide glycerol triacrylate into a 500 ml three-necked flask, and then add 0.01 part of polymerization inhibitor to hydroxyl Anisole, pass into the protective gas, stir and heat, increase the temperature to 80°C, add 0.05 parts of the catalyst chloroplatinic acid / vinyl double-head complex, keep the temperature for 5h under stirring, stop heating, and wait until the temperature of the flask drops to room temperature. The UV curable resin A is obtained.

[0064] The UV curable resin C is a mixture of dipentaerythritol hexaacrylate, diethylene glycol diacrylate, tetrahydrofuran acrylate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com