Stone-impact-resistant coating for low-density aluminum substrate

An aluminum substrate, anti-stone chip technology, applied in polyester coatings, polyamide coatings, coatings, etc., can solve the problems of not being able to meet the use requirements, easy to fall off, increase adhesion, etc., to meet the requirements of lightweight development, reduce The effect of vehicle weight and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

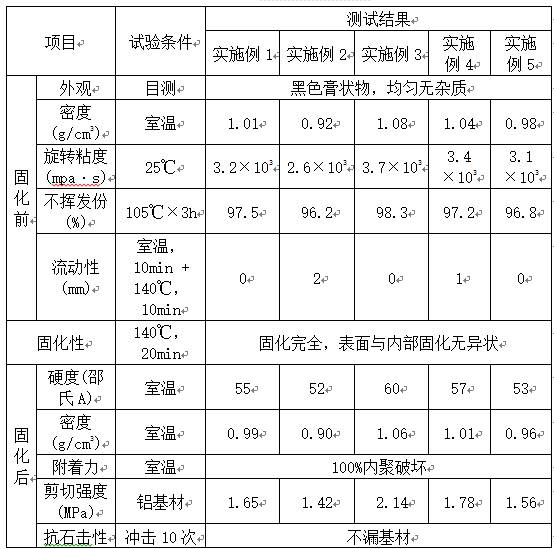

Examples

Embodiment 1

[0022] 20 parts of PVC paste resin, 8 parts of vinyl chloride-vinyl acetate-maleic anhydride ternary copolymer resin, 2 parts of adhesion promoting resin LTH, 1 part of polyamide resin, 32 parts of dioctyl phthalate, 2 parts of calcium oxide , 5 parts of odorless kerosene, 0.5 parts of carbon black, add to the high-speed disperser and stir at high speed to disperse evenly, then add 3.5 parts of hollow glass microspheres, 26 parts of nano-calcium carbonate and stir at high speed to disperse, stir evenly, pump the material to the aging tank for circulation , aging, that is, to obtain stone chipping-resistant coatings for low-density aluminum substrates. The coating was cured after being placed in an oven at 140°C for 20 minutes, and performance tests were performed after cooling to room temperature for 24 hours.

Embodiment 2

[0024] 15 parts of PVC paste resin, 12 parts of vinyl chloride-vinyl acetate-maleic anhydride ternary copolymer resin, 1 part of adhesion promoting resin LTH, 2 parts of polyamide resin, 35 parts of diisononyl phthalate, 1 part of calcium oxide , 8 parts of odorless kerosene, and 0.1 part of carbon black are added to the high-speed disperser and stirred at high speed to disperse evenly, then 5 parts of hollow glass microspheres and 21.9 parts of nano-calcium carbonate are added to disperse at high speed, stirred evenly, and then pumped into the aging tank for circulation. After aging, the anti-stone chip coating for low-density aluminum substrates can be obtained. The coating was cured after being placed in an oven at 140°C for 20 minutes, and performance tests were performed after cooling to room temperature for 24 hours.

Embodiment 3

[0026] 25 parts of PVC paste resin, 5 parts of vinyl chloride-vinyl acetate-maleic anhydride ternary copolymer resin, 2 parts of adhesion promoting resin LTH, 3 parts of polyamide resin, 32 parts of diisodecyl phthalate, 3 parts of calcium oxide 1 part, 3 parts of odorless kerosene, 1 part of carbon black, add to the high-speed disperser and stir at high speed to disperse evenly, then add 1 part of hollow glass microspheres, 25 parts of nano-calcium carbonate and stir at high speed to disperse, stir evenly and pump the materials into the aging tank Circulation and aging can obtain stone chip-resistant coatings for low-density aluminum substrates. The coating was cured after being placed in an oven at 140°C for 20 minutes, and performance tests were performed after cooling to room temperature for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com