Zirconia ceramic as well as preparation method, shell and electronic equipment

A technology of zirconia ceramics and zirconia, which is applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, etc., and can solve the problems of warping of ceramic sheets, low yield rate, and difficulty in obtaining pink gold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

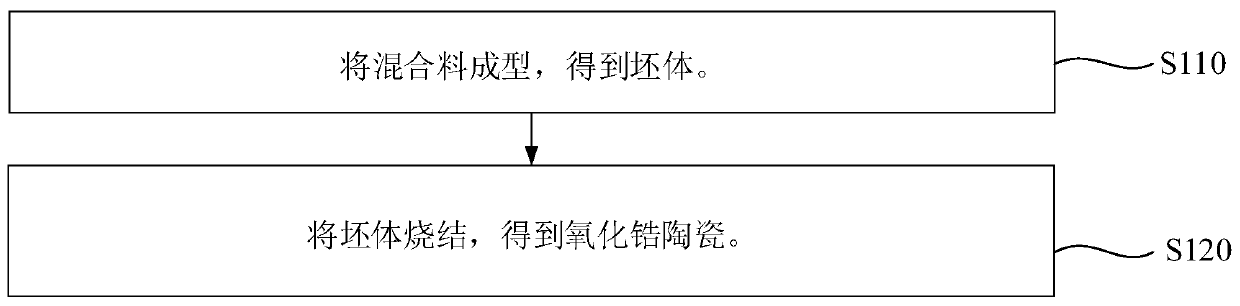

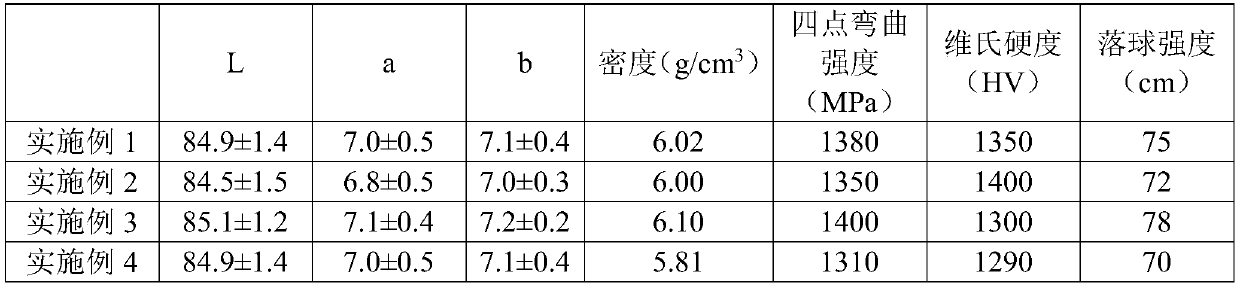

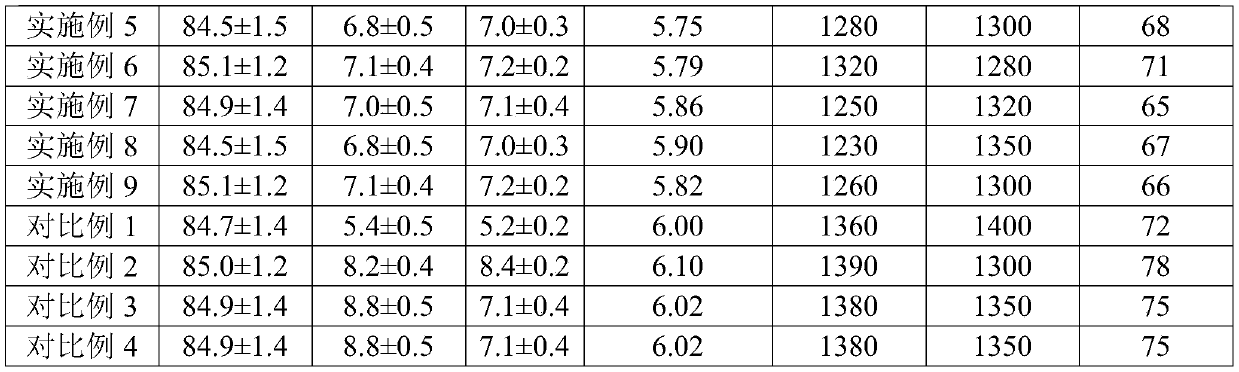

[0022] Such as figure 1 As shown, the preparation method of zirconia ceramics according to the first embodiment, the zirconia ceramics prepared by this method can be used to process and manufacture housings (such as the back cover of electronic equipment, such as mobile phones and tablet computers), decorative parts, Appearance parts, etc. The zirconia ceramic prepared by the method is pink gold, and its LAB value is as follows: the L value is 83-87, the a value is 6-8, and the b value is 6-8. L stands for Luminosity, equivalent to brightness, a stands for the range from red to green, and b stands for the range from blue to yellow. The preparation method of the zirconia ceramics comprises the following steps:

[0023] Step S110: molding the mixture to obtain a green body.

[0024] Among them, the mixture includes raw materials, and according to the mass percentage, the raw materials include: 85% to 90% of zirconia, 1% to 4% of aluminum oxide, 2% to 3.8% of yttrium oxide, 2....

Embodiment 1

[0066] The preparation process of the pink gold zirconia ceramics of the present embodiment is as follows:

[0067](1) Mix and ball-mill raw materials, binders, defoamers, plasticizers and solvents to obtain a mixture. Among them, according to the mass percentage, the raw material is composed of the following components: 88% zirconia, 2% aluminum oxide, 2.5% yttrium oxide, 2.8% zinc oxide, 1% titanium oxide, 0.5% Chromium, 0.5% silicon oxide, 0.5% nickel oxide and 2.2% hafnium oxide. And the median particle size of the raw material is 500 nm to 1200 nm; the binder is polymethyl methacrylate (PMMA); the solvent is a mixture of toluene and ethylene glycol with a mass ratio of 7:3. The defoamer is dimethylsiloxane; the plasticizer is dibutyl phthalate (DBP); in the mixture, the mass percentage of the defoamer is 3%, and the mass percent of the plasticizer is The component content is 8%, the mass percentage content of the binder is 8%, and the mass percentage content of the solv...

Embodiment 2

[0071] The preparation process of the pink gold zirconia ceramics of the present embodiment is as follows:

[0072] (1) Mix and ball-mill raw materials, binders, defoamers, plasticizers and solvents to obtain a mixture. Among them, according to the mass percentage, the raw material is composed of the following components: 85% zirconia, 4% aluminum oxide, 3.8% yttrium oxide, 2.1% zinc oxide, 1.2% titanium oxide, 1% oxide Chromium, 1% silicon oxide, 1% nickel oxide and 0.9% hafnium oxide. And the median particle size of the raw material is 500 nanometers to 1200 nanometers; the binder is polymethyl methacrylate (PMMA) and polyvinyl butyral (PVB) with a mass ratio of 1:1; the solvent is absolute ethanol The defoamer is dimethylsiloxane; the plasticizer is dioctyl phthalate (DOP) and butyl benzyl phthalate (BBP) with a mass ratio of 1:1; in the mixture, The mass percentage of the defoamer is 2%, the mass percentage of the plasticizer is 5%, the mass percentage of the binder is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Four point bending strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com