Epoxy resin microcapsule coated by tetraethyl orthosilicate, and preparation method of the epoxy resin microcapsule

A technology of tetraethyl orthosilicate and epoxy resin coating, applied in the field of tetraethyl orthosilicate coating epoxy resin microcapsules and its preparation, to achieve excellent thermal stability and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

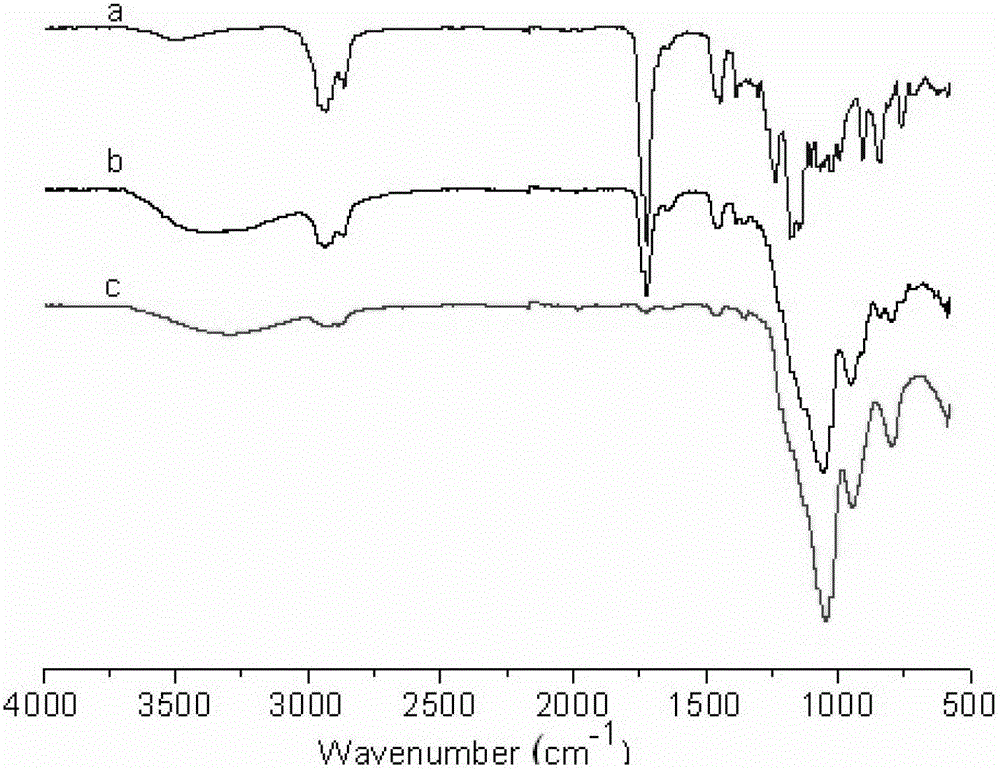

Embodiment 1

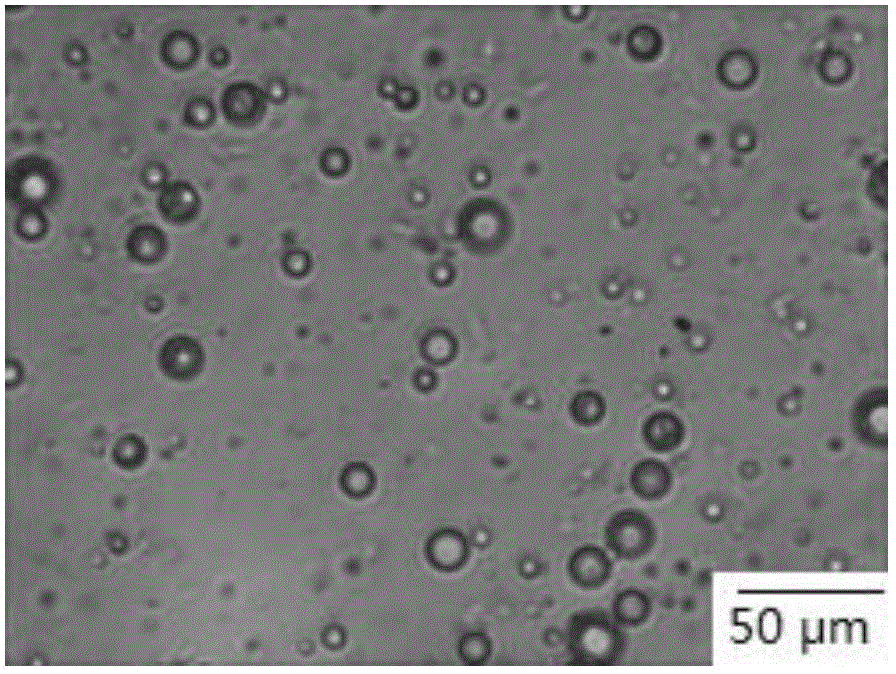

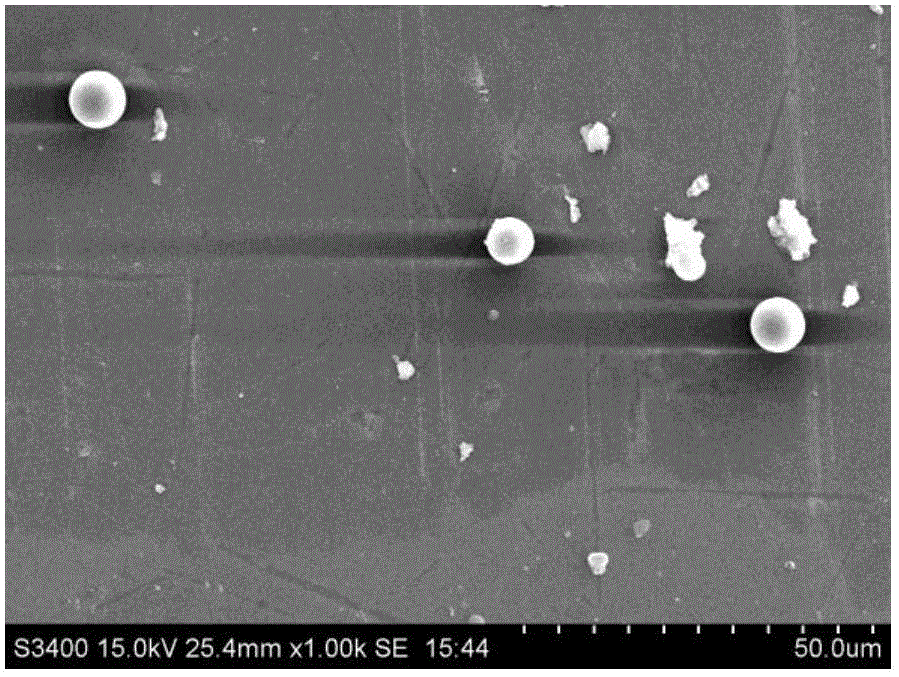

[0037] (1) Add 15 g of terpene-based epoxy resin and 3 g of terpene-based epoxy resin-polyethylene glycol 4000 nonionic surfactant into a four-neck flask equipped with a thermometer, agitator, and condenser tube, Heat to 60°C and stir evenly at 600 rpm. Slowly add 150 g of distilled water dropwise and continue stirring for 40 min to obtain an oil-in-water (O / W) emulsion.

[0038](2) Add 15 g tetraethyl orthosilicate (TEOS) and 30 g distilled water to the Erlenmeyer flask, add dropwise 2 mol / L acetic acid aqueous solution, adjust the pH value to 2.2, and place it in a water bath at 60 °C for 50 min for hydrolysis , to obtain a uniform and transparent hydrolyzate.

[0039] (3) Slowly add the prehydrolyzate in (2) to the O / W emulsion in (1), control the temperature at 55 ℃, and stir at 450 rpm. After the dropwise addition, the pH value was adjusted to 2.5±0.1, and the reaction was continued for 3 h. Cool to room temperature, wash with distilled water, suction filter and dry to...

Embodiment 2

[0041] (1) Add 15 g of terpene-based epoxy resin and 3 g of terpene-based epoxy resin-polyethylene glycol 4000 nonionic surfactant into a four-neck flask equipped with a thermometer, agitator, and condenser tube, Heat to 60°C and stir evenly at 600 rpm. Slowly add 150 g of distilled water dropwise and continue stirring for 40 min to obtain an oil-in-water (O / W) emulsion.

[0042] (2) Add 30 g tetraethyl orthosilicate (TEOS) and 60 g distilled water to the Erlenmeyer flask, add dropwise 2 mol / L acetic acid aqueous solution, adjust the pH value to 2.2, and place it in a water bath at 60 °C for 50 min for hydrolysis , to obtain a uniform and transparent hydrolyzate.

[0043] (3) Slowly add the prehydrolyzate in (2) to the O / W emulsion in (1), control the temperature at 55 ℃, and stir at 450 rpm. After the dropwise addition, the pH value was adjusted to 2.5±0.1, and the reaction was continued for 4 h. Cool to room temperature, wash with distilled water, suction filter and dry t...

Embodiment 3

[0045] (1) Add 15 g of rosin-based epoxy resin and 3 g of rosin-based epoxy resin-polyethylene glycol 4000 nonionic surfactant into a four-neck flask equipped with a thermometer, agitator, and condenser, and heat to 80°C, stirring evenly at 600 rpm. Slowly add 150 g of distilled water dropwise and continue stirring for 40 min to obtain an oil-in-water (O / W) emulsion.

[0046] (2) Add 15 g tetraethyl orthosilicate (TEOS) and 30 g distilled water to the Erlenmeyer flask, add dropwise 2 mol / L HCl aqueous solution, adjust the pH value to 2.2, and place it in a water bath at 60 °C for 50 min for hydrolysis , to obtain a uniform and transparent hydrolyzate.

[0047] (3) Slowly add the prehydrolyzate in (2) to the O / W emulsion in (1), control the temperature at 55 ℃, and stir at 450 rpm. After the dropwise addition, the pH value was adjusted to 2.5±0.1, and the reaction was continued for 4 h. Cool to room temperature, wash with distilled water, suction filter and dry to obtain pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com