Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Strong leakage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portland blast furnace slag cement and preparation method thereof

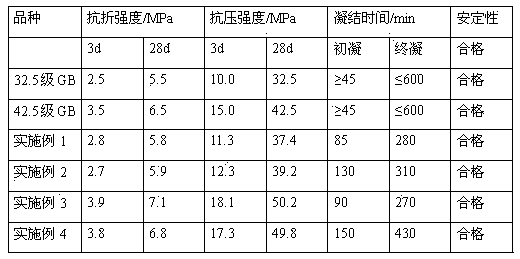

The invention relates to a portland blast furnace slag cement and a preparation method thereof. The portland blast furnace slag cement is prepared from the following raw materials by weight percent: 12%-30% of at least one of slag, coal gangue, boiling slag, liquid slag, cinerite, kiln dust and crushed tile, 10%-42% of mineral waste residue, steel slag or silicomanganese slag, 0-12% of limestone, 2%-8% of gypsum, 0-10% of zeolite, 0-17% of boiling slag, 0-10% of coal ash, and 10%-50% of silicate series cement. The preparation method comprises steps of putting the slag, mineral waste residue, gypsum, zeolite, boiling slag, and coal ash into a pulverizer to be smashed, grinding by a ball mill to achieve the fineness of 0.08mm, sieving by a square hole sieve with 2% left, and then mixing with the silicate series cement. The portland blast furnace slag cement has the advantages of having a simple preparation method, needing no cement clinker, guaranteeing the strength and stability of the cement, fully using industrial residue resources like slag and mineral waste residue, lowering production cost, and reducing the pollution of industrial residue to the environment.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE

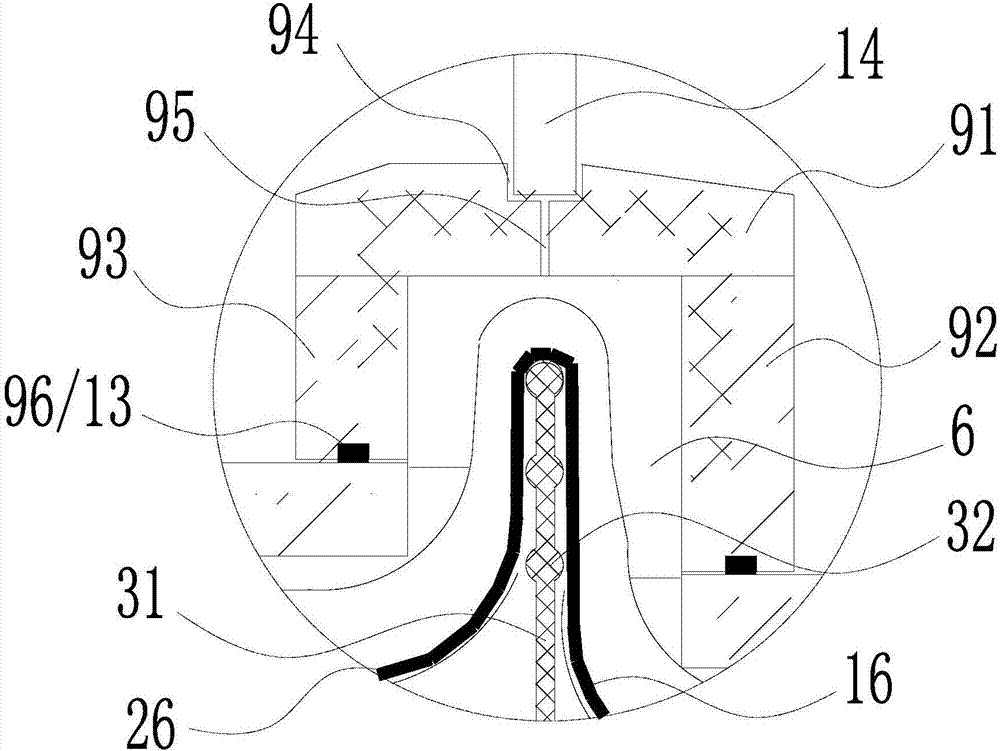

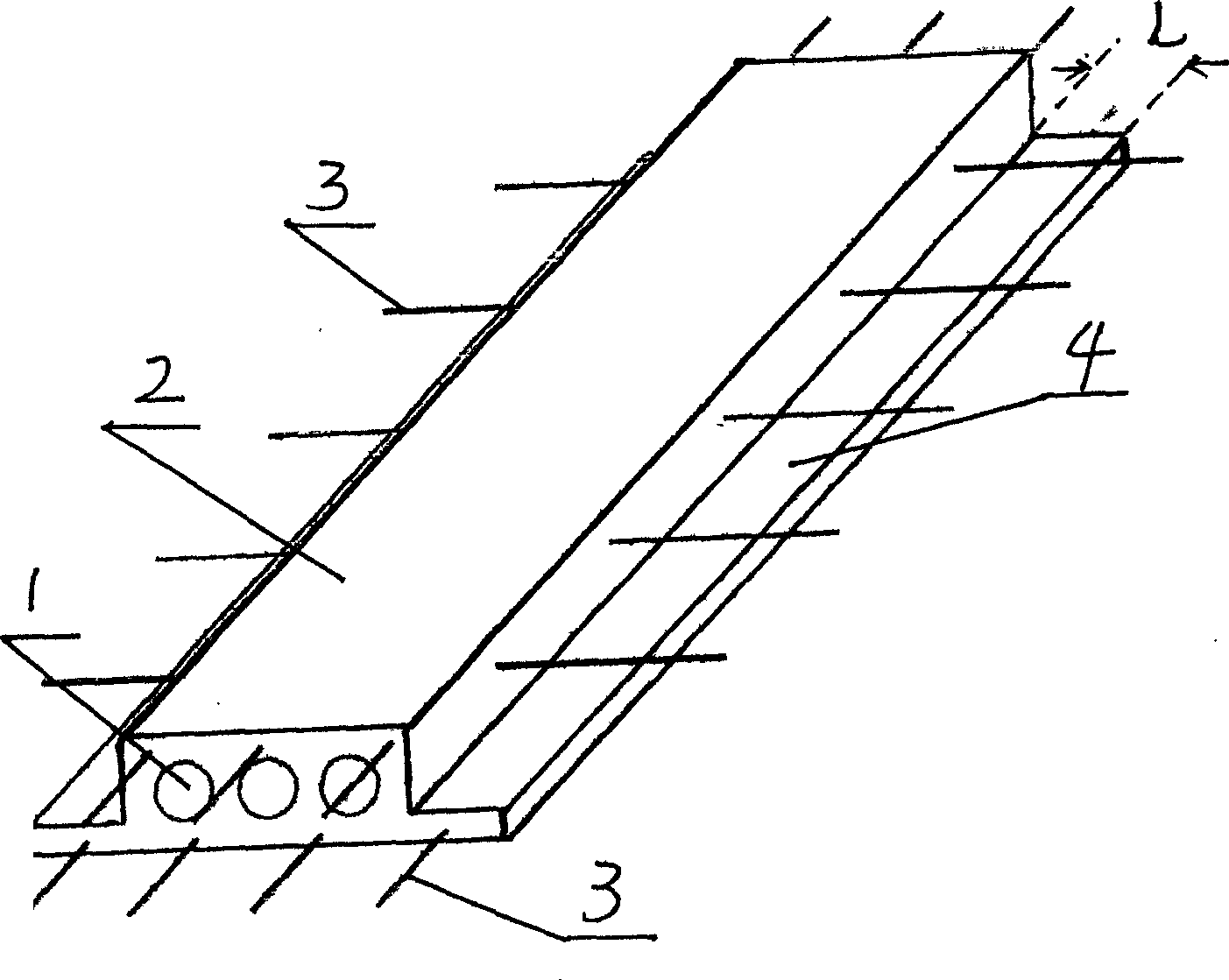

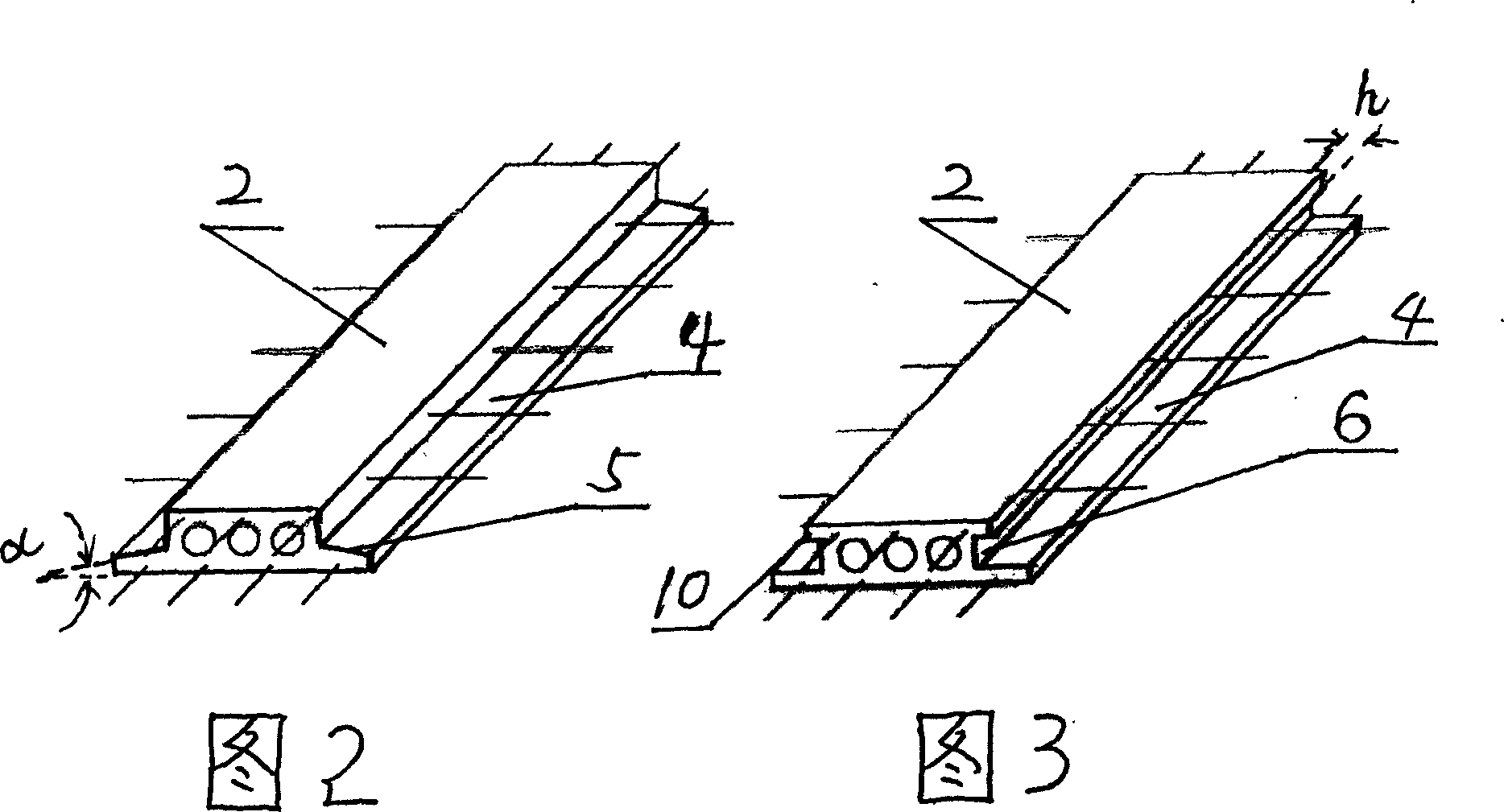

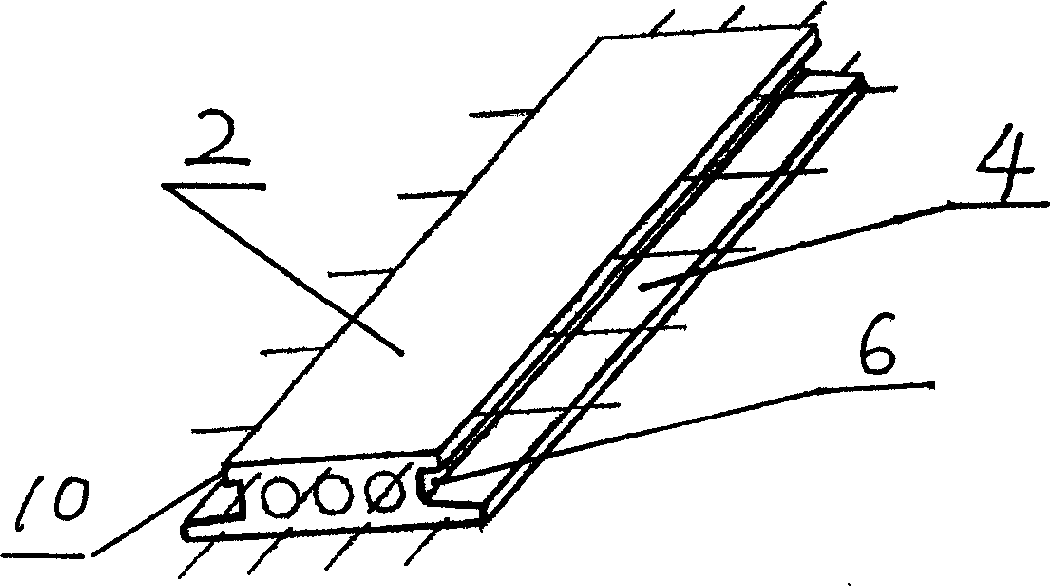

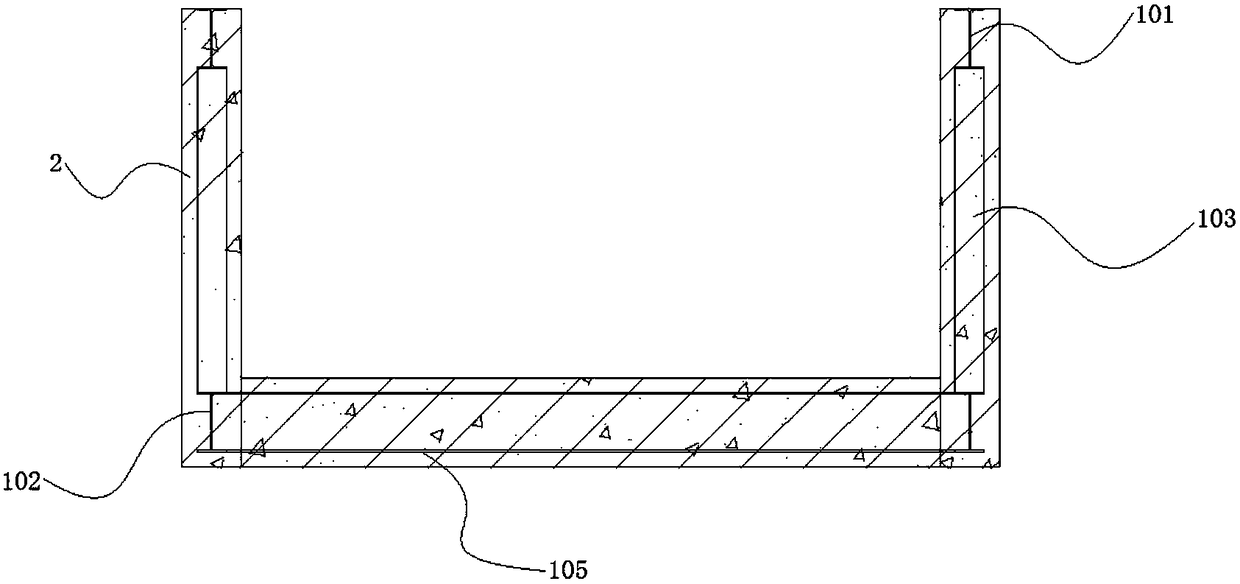

Underground continuous wall construction method of city-across pipeline

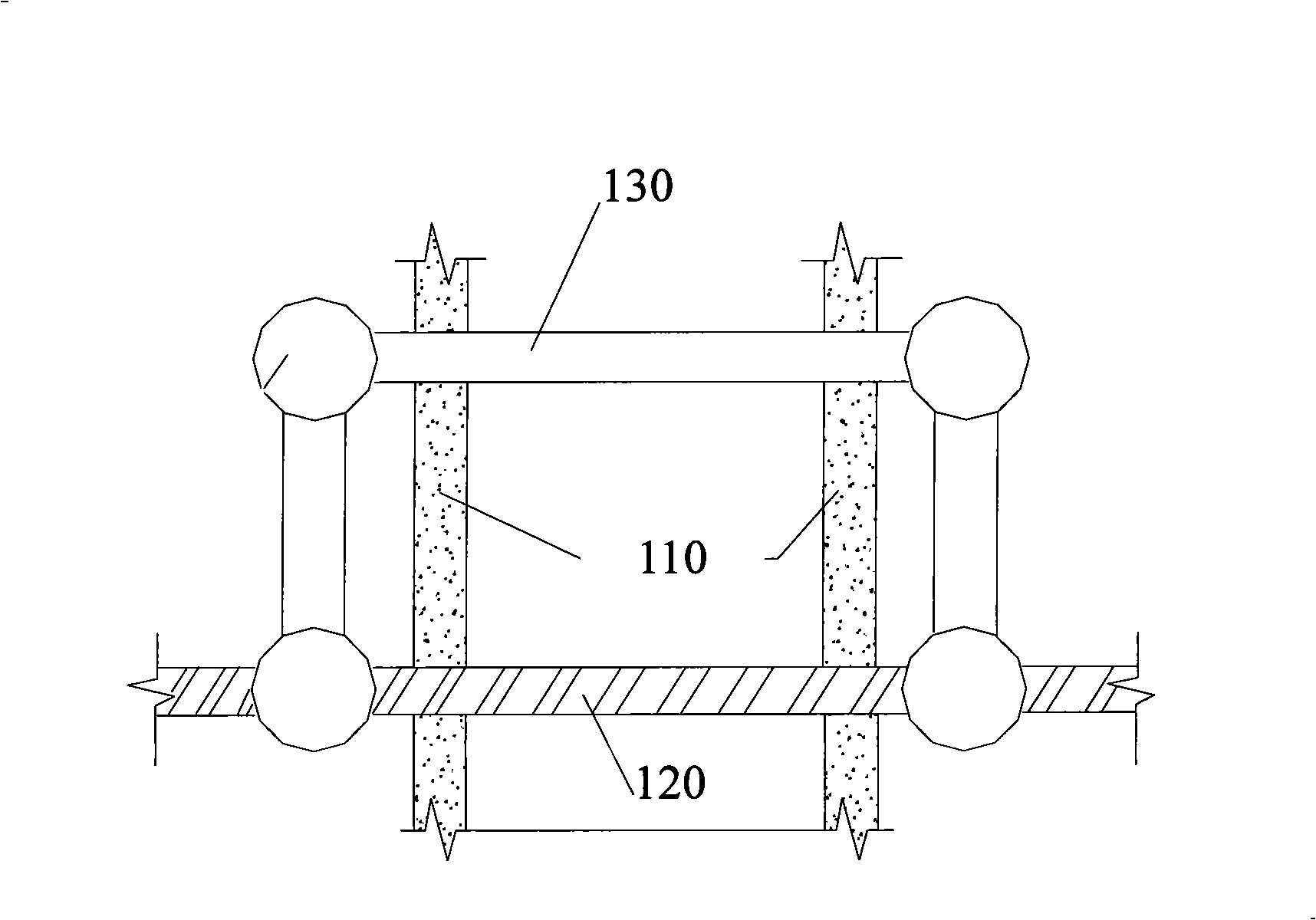

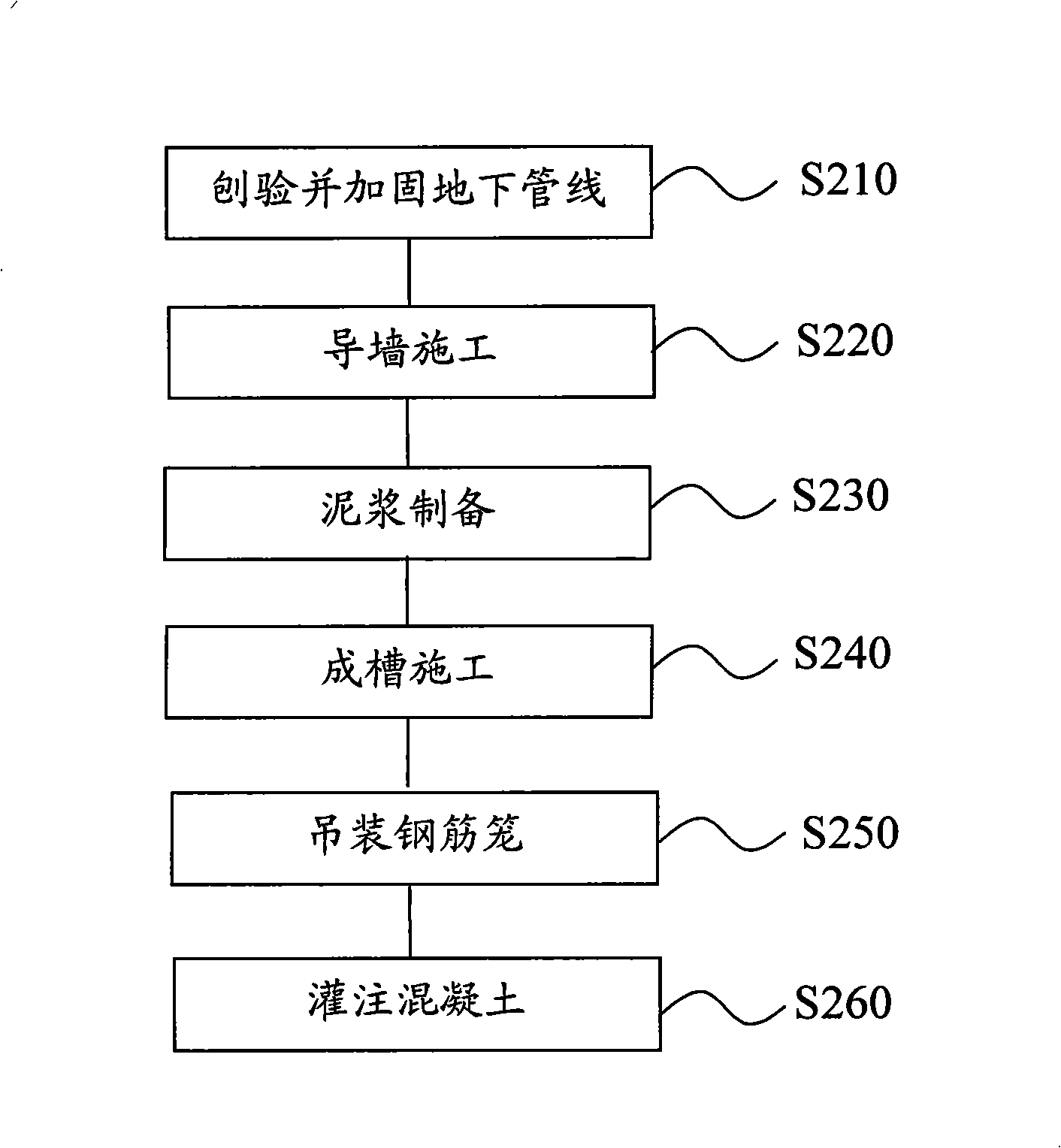

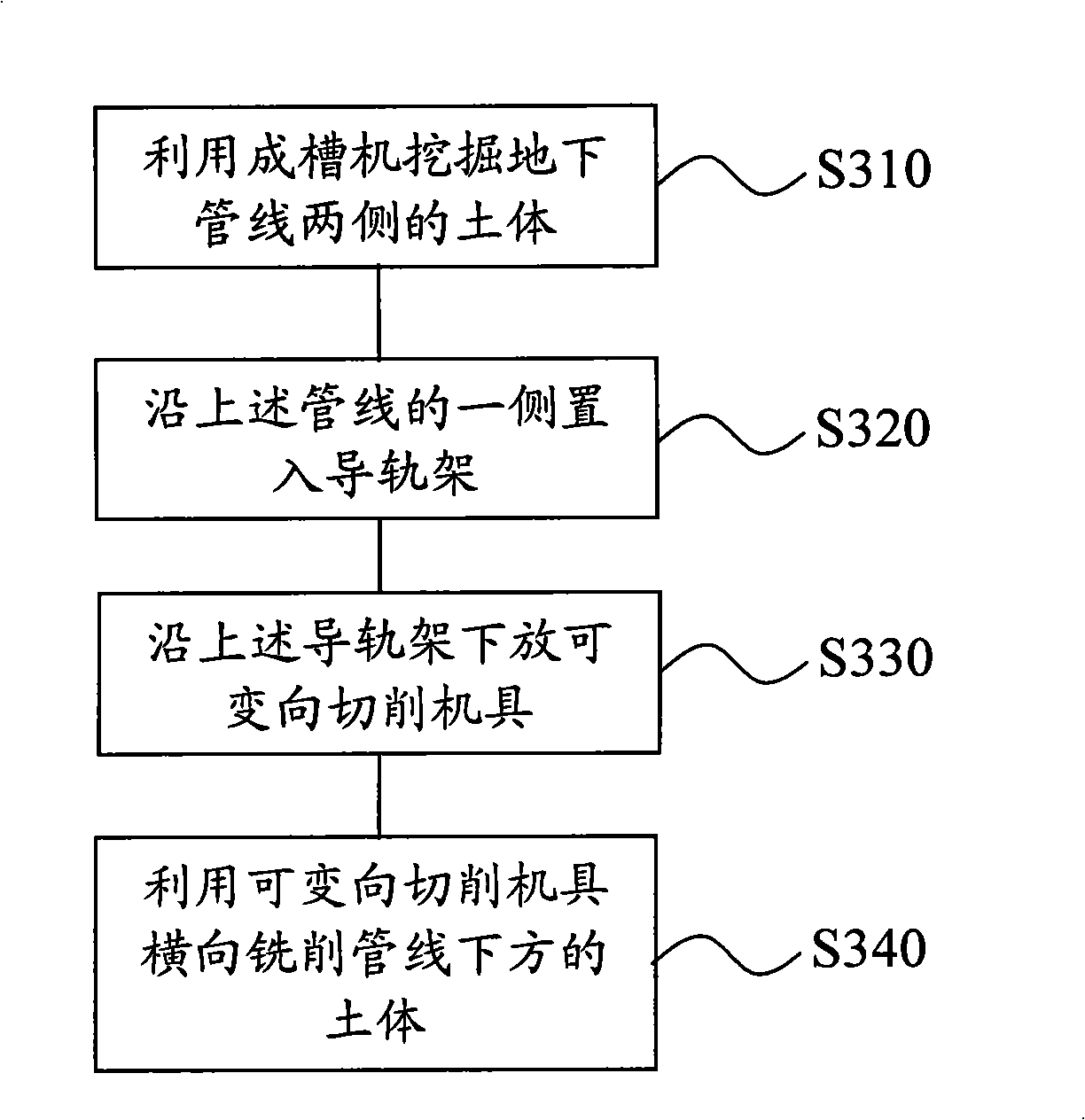

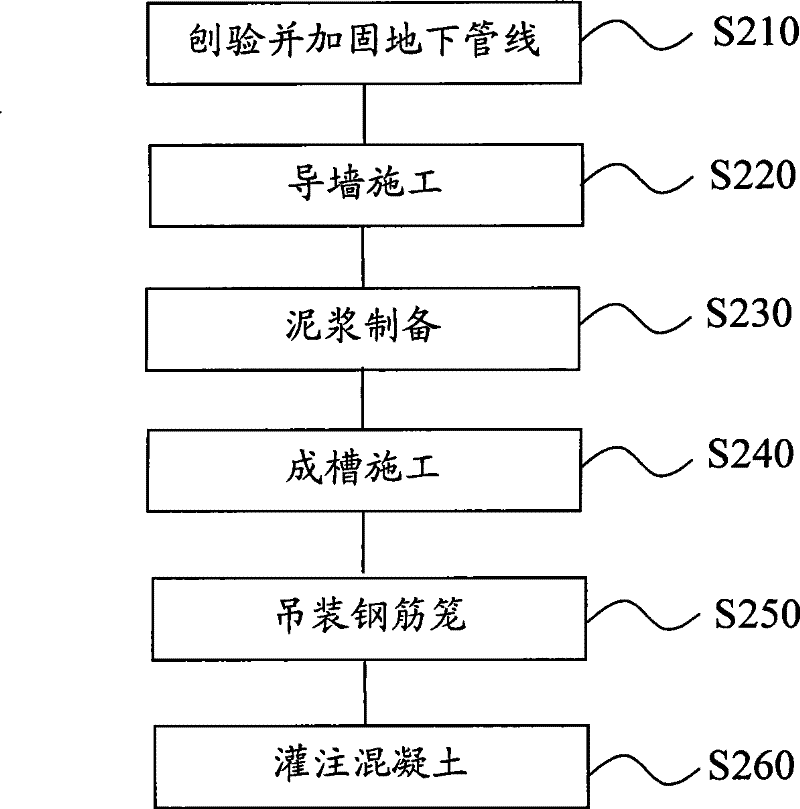

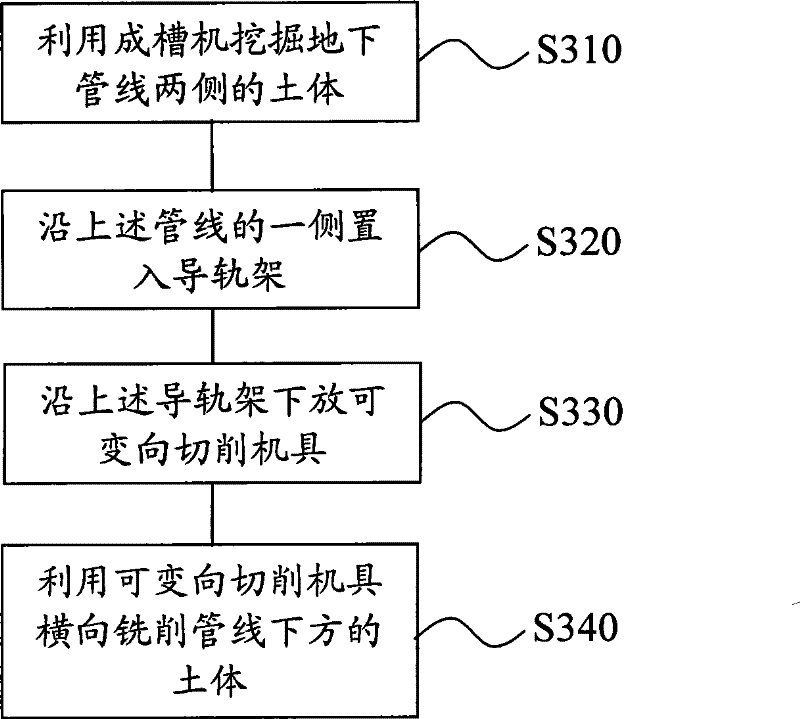

The invention provides an inter-city pipeline underground continuous wall construction method. Through the adoption of the method in the construction, the integrity of the underground continuous wall is good, the verticality is high, the anti-penetration performance is good, the wall body can be successfully sealed, the pollution to the surrounding environment is less, and the underground structures can be better protected. The inter-city pipeline underground continuous wall construction method comprises the following steps: the pipeline is dug, examined and reinforced; wall guiding construction is performed in the pipeline scope; groove building construction is performed, which comprises: firstly, soil masses at both sides of the pipeline are dug with a groove milling machine; secondly, a guiding track frame is arranged along one side of the pipeline; thirdly, a reversible cutting machine is placed in the track guiding frame; and fourthly, the soil masses under the pipeline are laterally milled with the reversible cutting machine; after the groove is milled, a reinforcement cage is hanged in; and the concrete is poured into the pipe.

Owner:SHANGHAI CONSTRUCTION GROUP

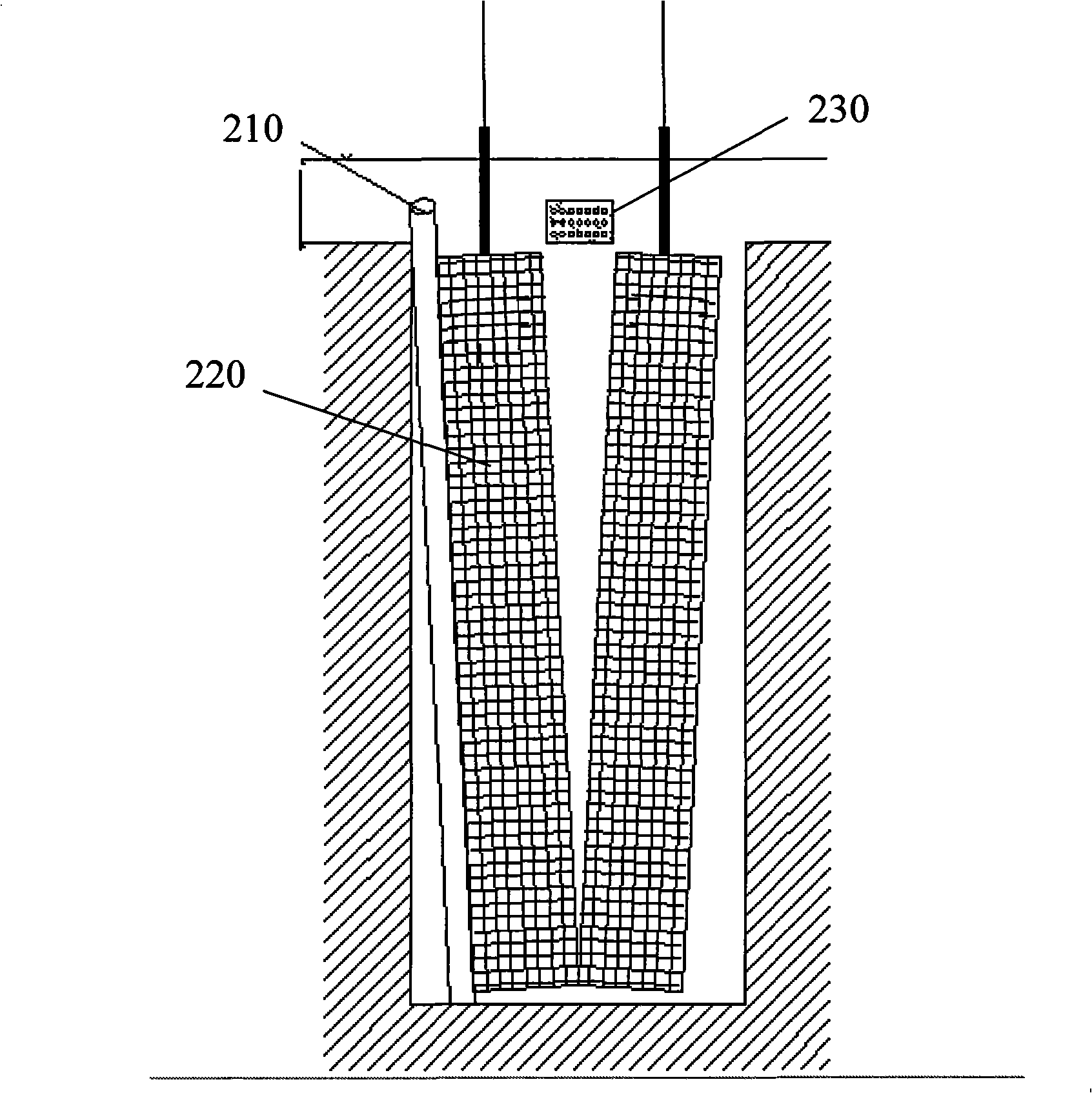

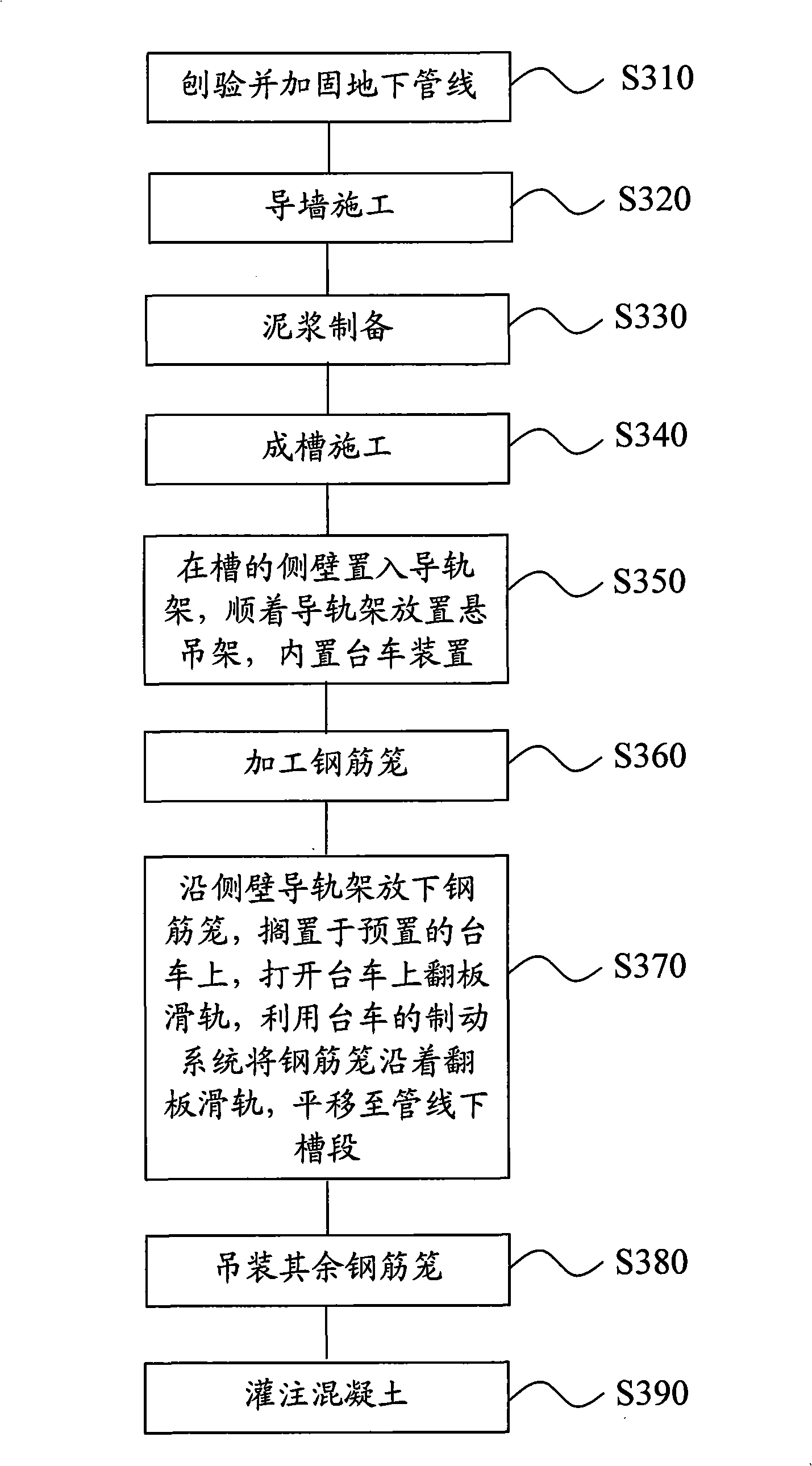

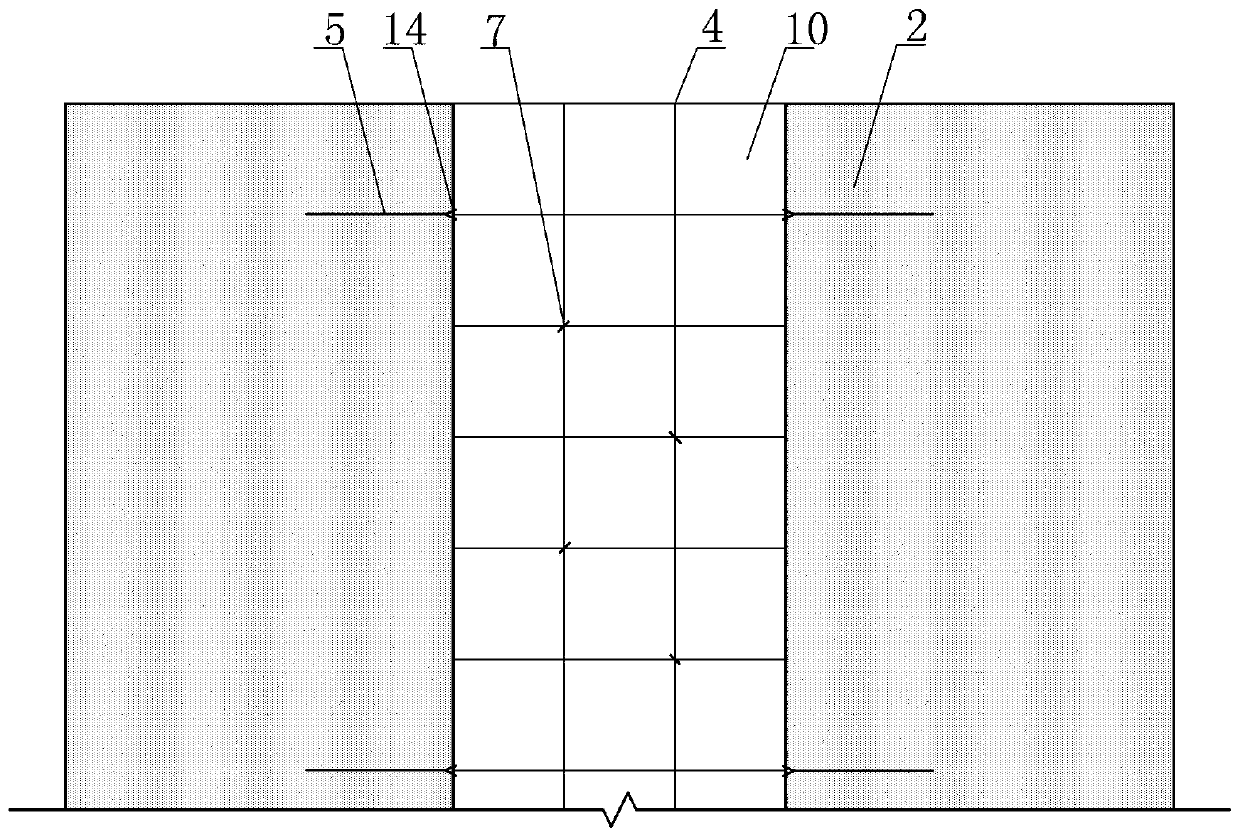

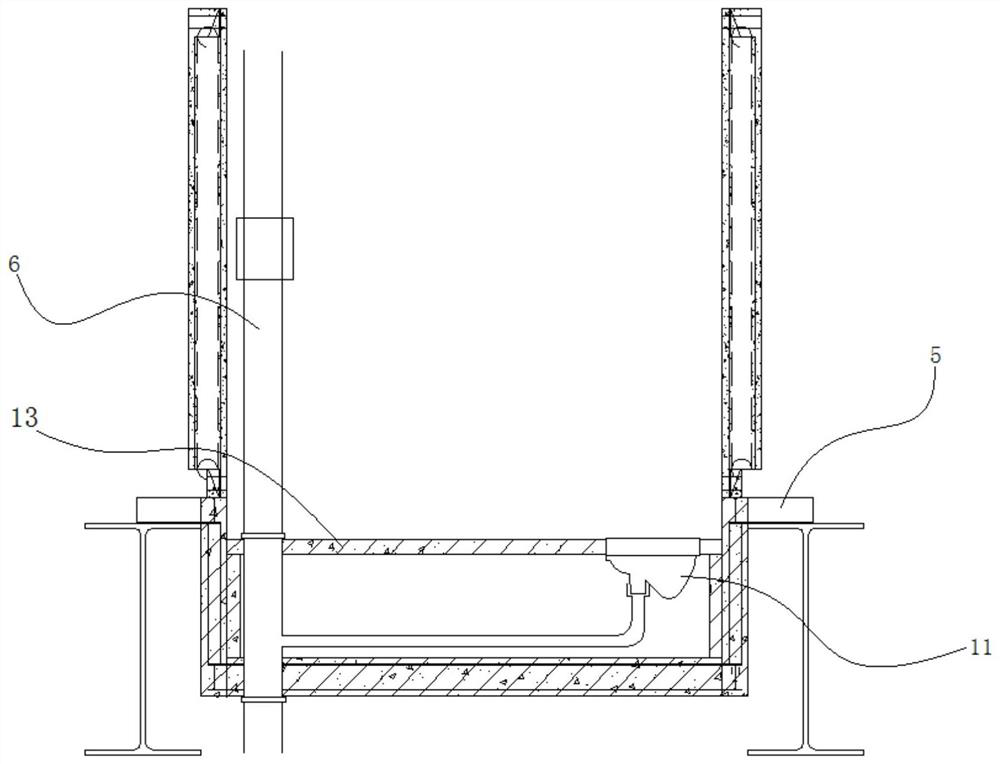

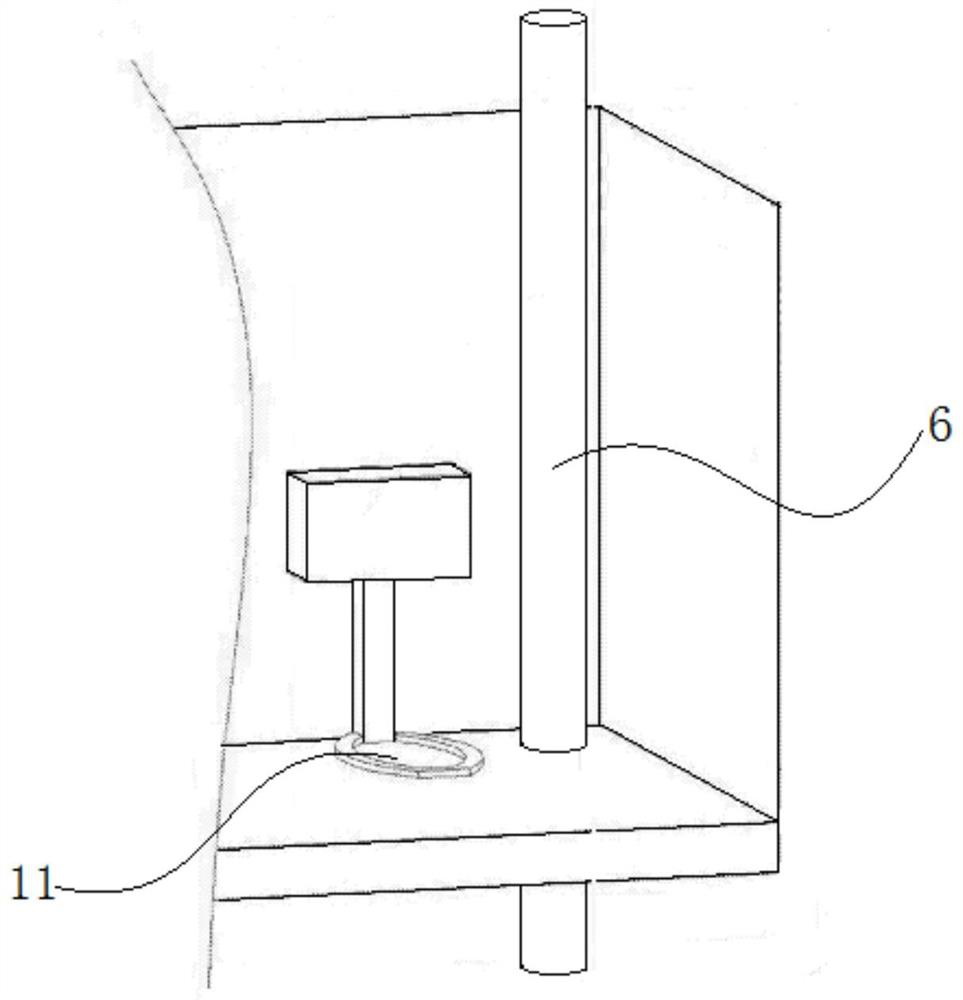

Underground continuous wall construction method crossing city pipelines

The invention provides a method for constructing an underground continuous wall traversing an urban pipeline; and the method is utilize to make the underground continuous wall have good integrality, high verticality, good anti-seepage performance and small influence on ambient environment, thereby well protecting underground buildings. The construction method comprises the following steps: a pipeline is planed, tested and reinforced; the guide wall is constructed; slurry is prepared; a groove is formed and constructed; after groove forming is completed, a guide rail rack is positioned in one sidewall of the groove; a suspension rack is positioned along the guide rail rack, wherein the suspension rack is provided with a trolley device inside; a trolley is provided with a braking system and a slide rail for a turned plate; a steelwork cage is processed, put down along the guide rail rack and positioned on the trolley; the slide rail of the turned plate is opened; the braking system of the trolley is utilized to translate the steelwork cage to the lower groove section of the pipeline along the slide rail of the turned plate; and the other steelwork cages are lifted and filled with concrete.

Owner:SHANGHAI CONSTRUCTION GROUP

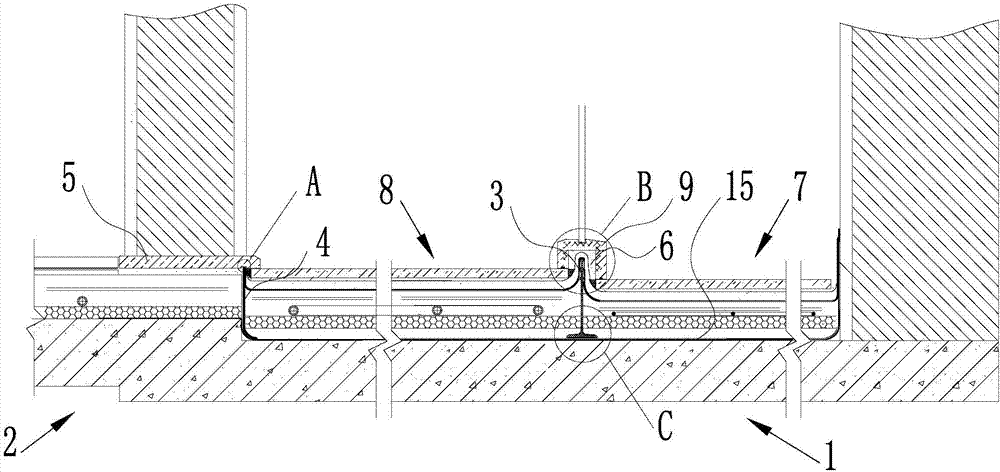

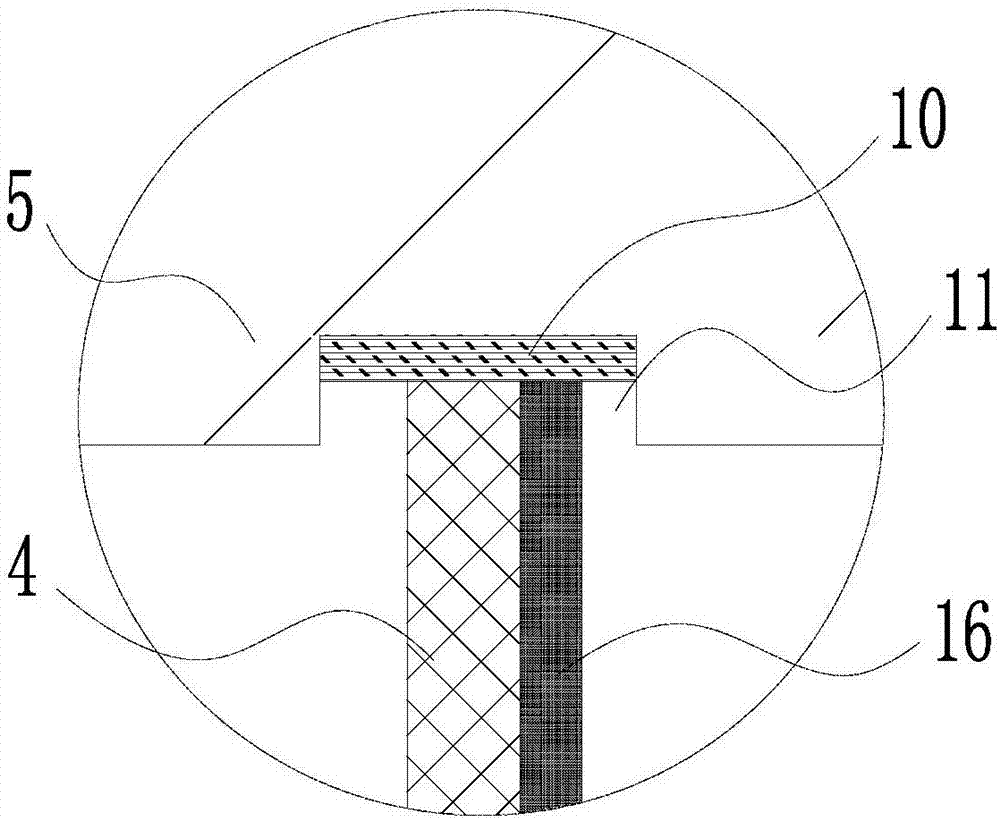

Bathroom waterproof system and construction method

ActiveCN106978856AEasy to pour constructionEasy to fixSills/thresholdBuilding insulationsEngineeringCement mortar

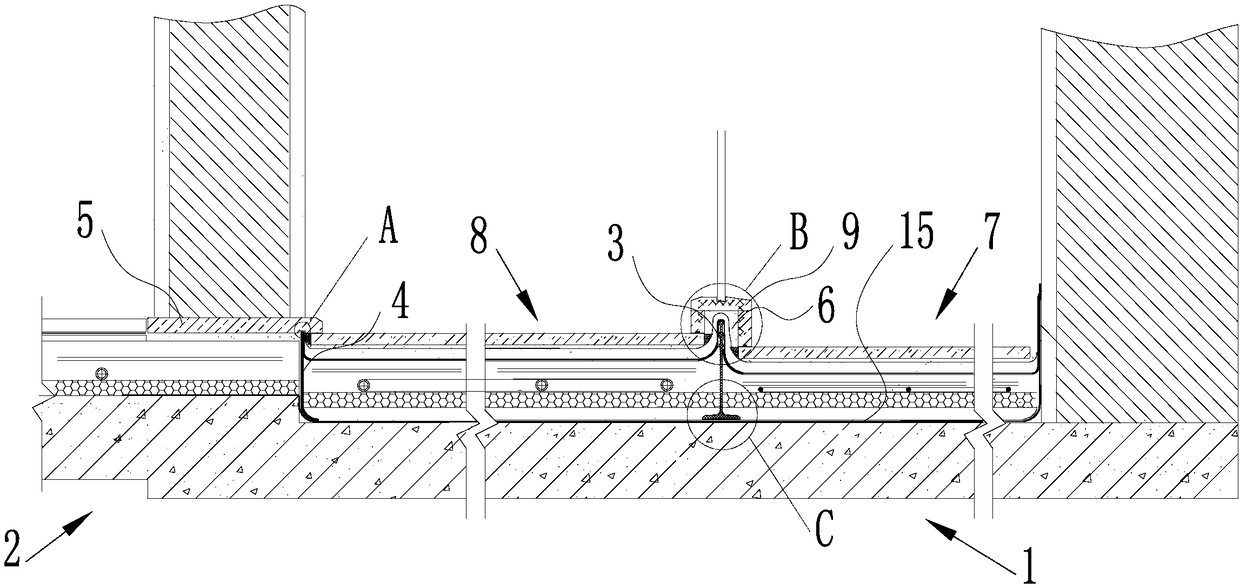

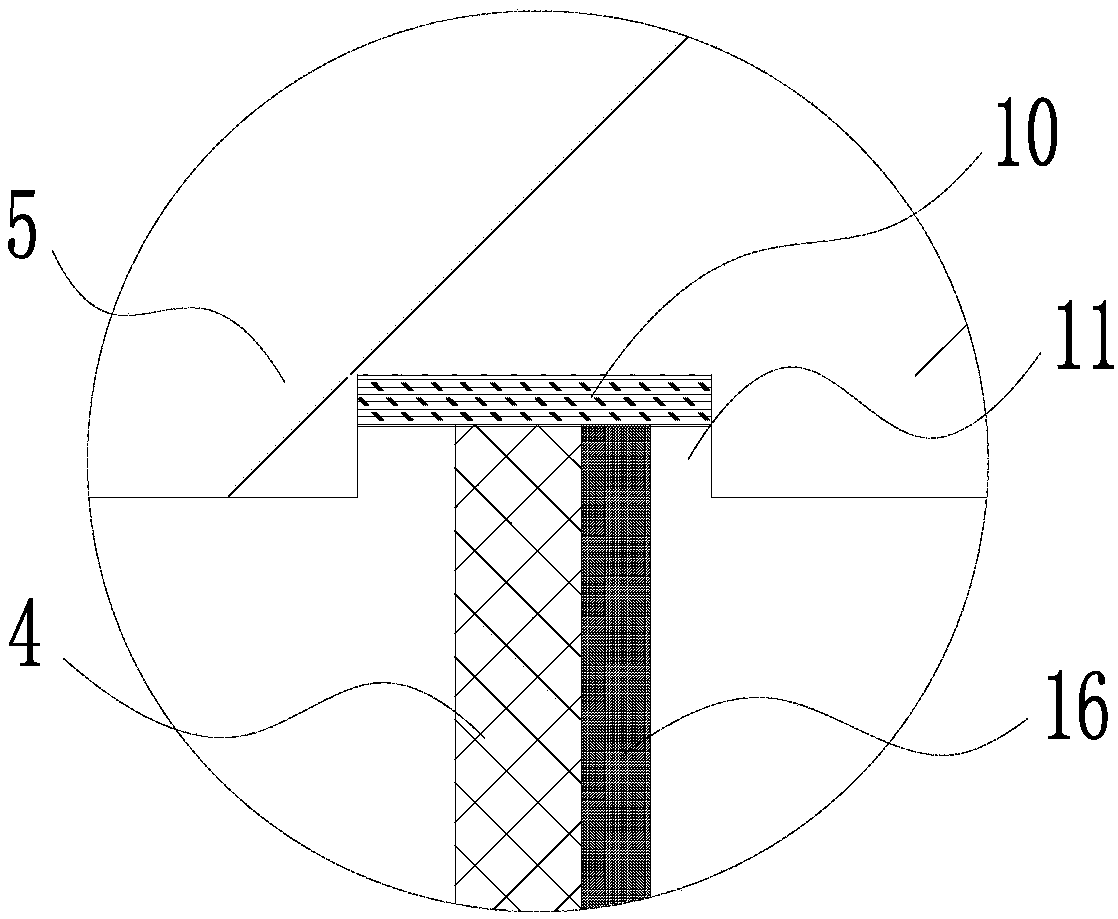

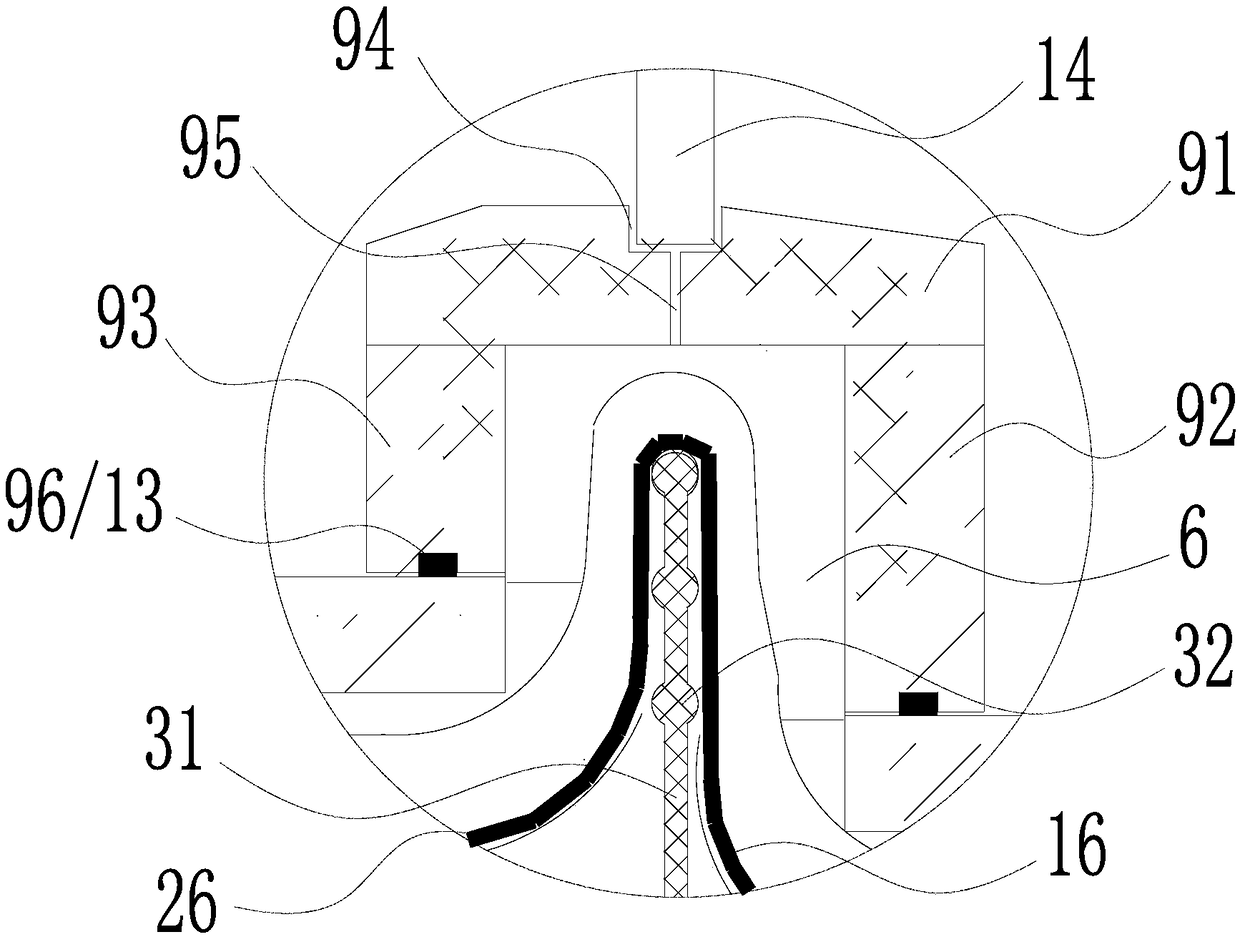

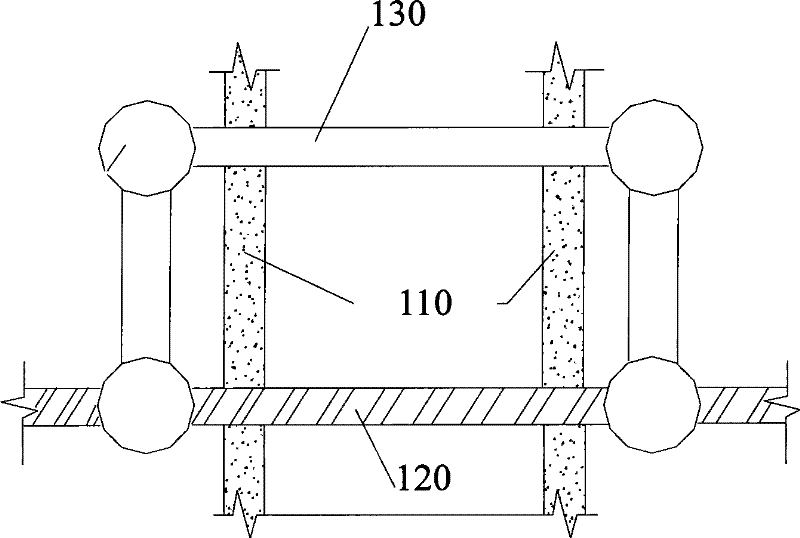

The invention relates to the field of building decoration and provides a bathroom waterproof system which is simple in structure can convenient to construct and can effectively prevent water molecules in a bathroom from leaking outward and a construction method. The technical problems that in the prior art, the leakage proof effect of the bathroom is poor, the situation that a floor, a door sleeve and the like in a dry area mould and decay is quite prone to occurring, and the attractive degree of overall decoration is reduced are solved. The bathroom waterproof system comprises a bathroom floor base layer and a dry area floor base layer connected with the bathroom floor base layer. Ground decoration paving layers are laid on the surfaces of the bathroom floor base layer and the dry area floor base layer correspondingly. An elastic water retaining plate and the lower end of an elastic water retaining strip are arranged between the bathroom floor base layer and the corresponding ground decoration paving layer in a clamped mode, wherein the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected on the bottom face of a doorsill plate in a closed mode, and the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected with a cement mortar retaining strip in an airtight mode. The cement mortar retaining strip divides the corresponding floor decoration paving layer into a bathing area and a rest area.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

Thermal-insulation waterproof building paint and preparation method thereof

InactiveCN106634334AGood insulation performanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesWeather resistanceEmulsion

The invention discloses a thermal-insulation waterproof building paint and a preparation method thereof. The thermal-insulation waterproof building paint is prepared from the following raw materials in parts by weight: 25-35 parts of water-based silicone-acrylic emulsion, 20-30 parts of Kalmatron KFA, 18-25 parts of phenethyl phenol polyoxyethylene ether, 10-15 parts of sodium silicate, 15-20 parts of zinc oxide, 10-15 parts of titanium white, 10-15 parts of 1-hydroxy-cyclohexyl-phenyl, 15-25 parts of zinc white, 2-4 parts of neopentyl glycol, 5-8 parts of aid, 3-6 parts of kaolin, 4-6 parts of polyacrylonitrile fiber and 2-5 parts of nano aluminum oxide. By effectively proportioning the water-based silicone-acrylic emulsion, Kalmatron KFA, phenethyl phenol polyoxyethylene ether, sodium silicate, zinc oxide, titanium white, 1-hydroxy-cyclohexyl-phenyl, zinc white, neopentyl glycol and aid, the prepared building paint has the advantages of favorable thermal-insulation property, favorable weather resistance and high acid / alkali resistance, which are respectively greatly enhanced as compared with the common commercially-available thermal-insulation paints. The thermal-insulation waterproof building paint has the characteristics of favorable corrosion resistance, excellent seepage resistance, simple preparation method and wide application prospects.

Owner:芜湖浩权建筑工程有限公司

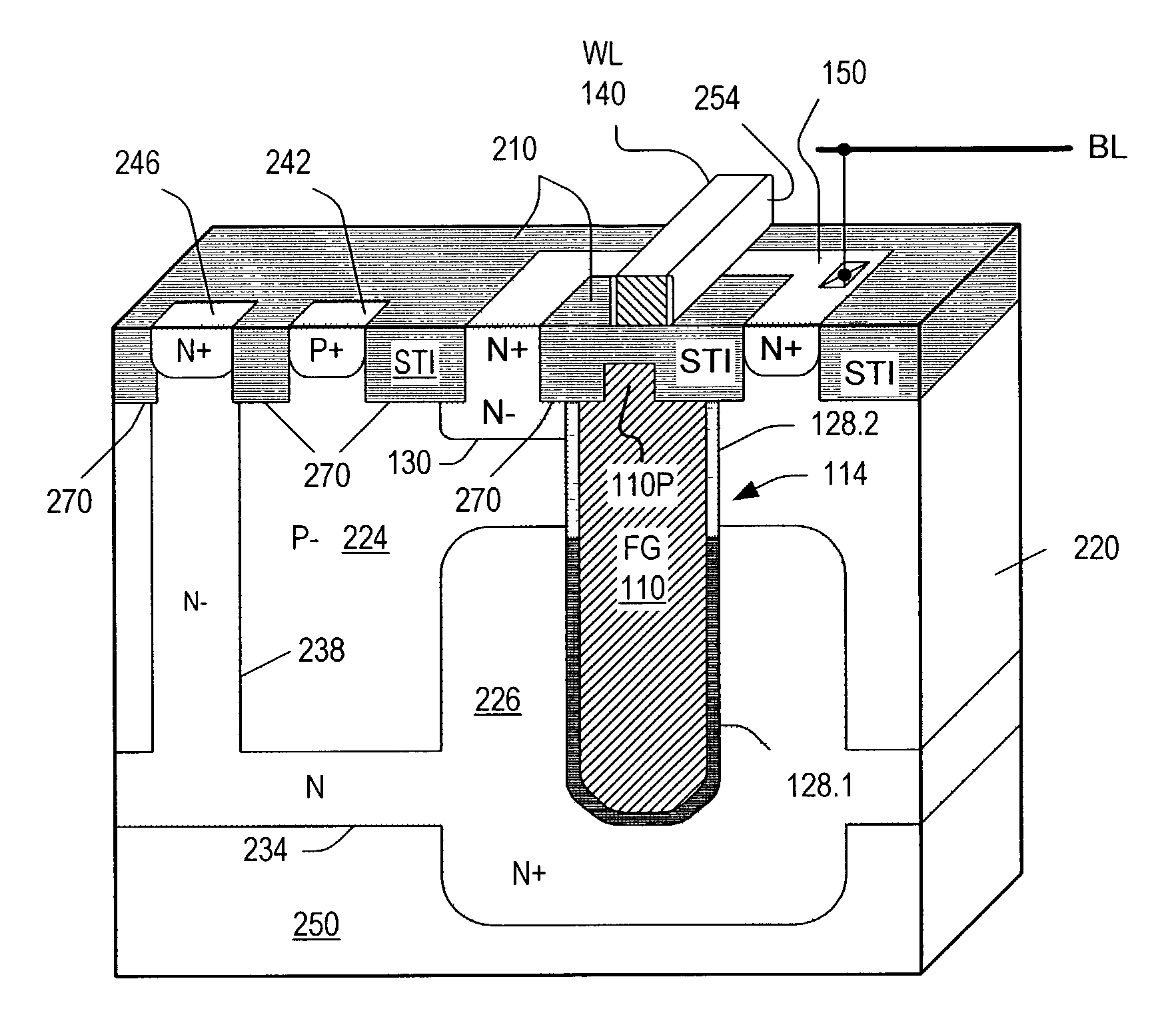

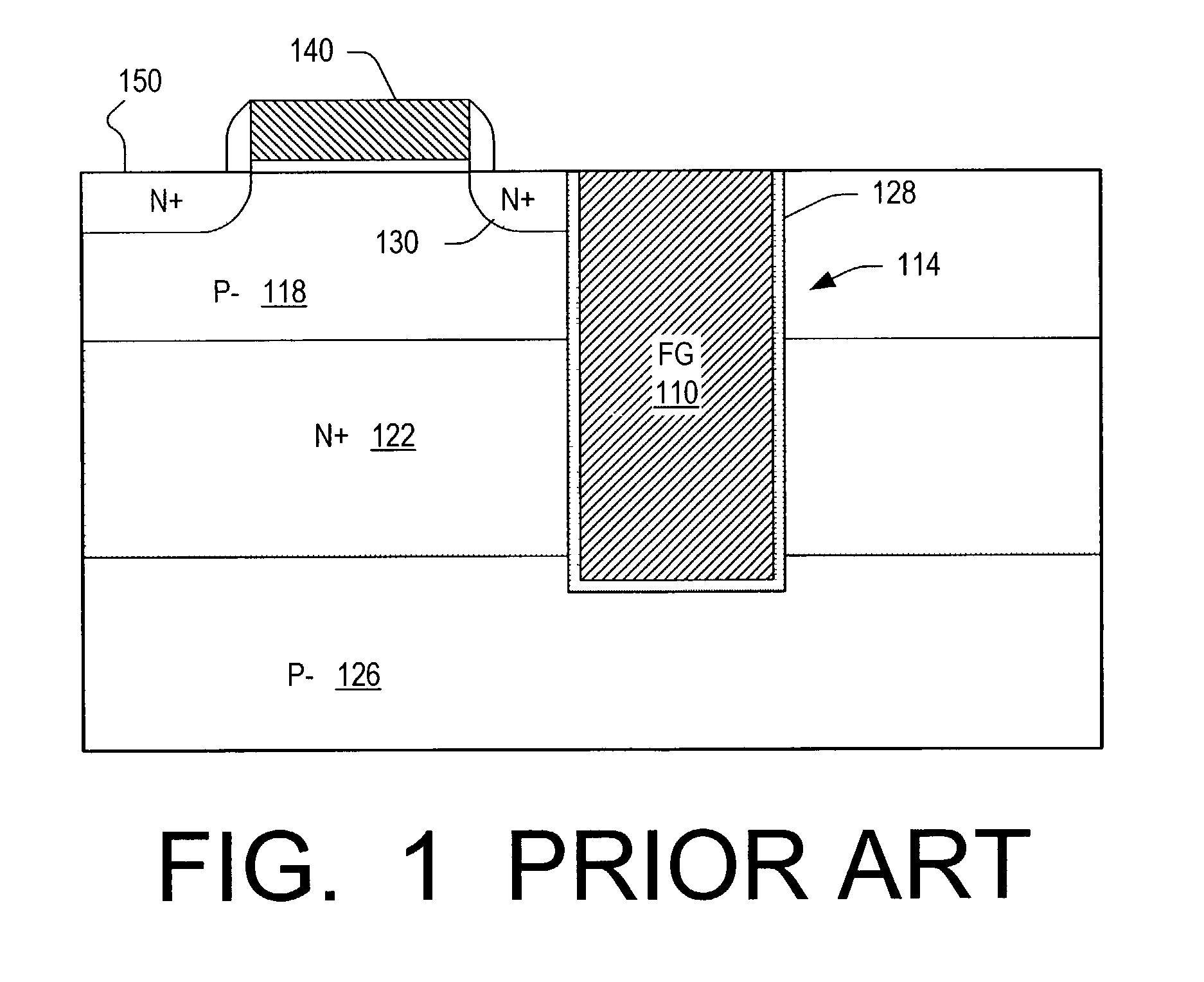

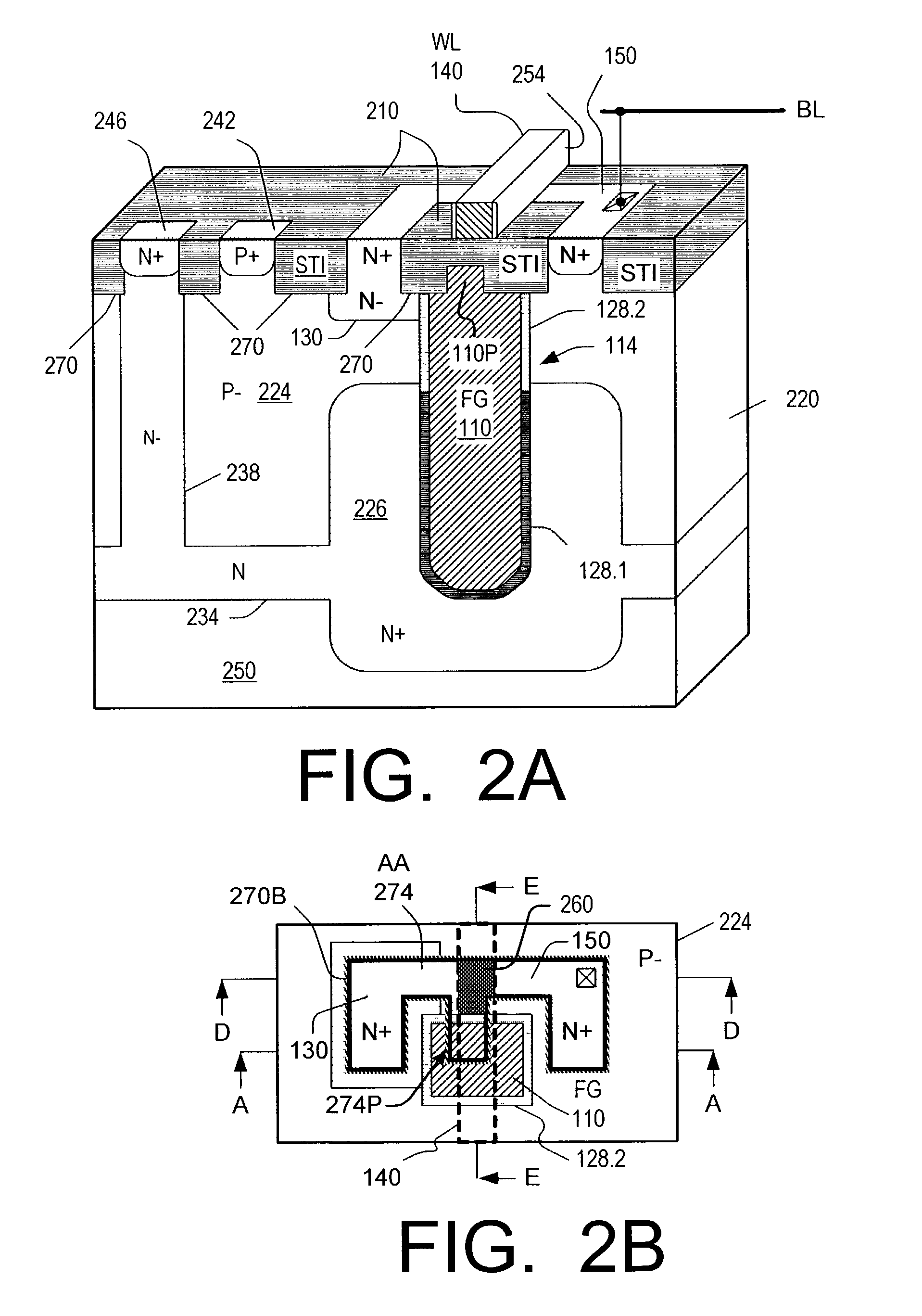

Nonvolatile memory cell with a floating gate at least partially located in a trench in a semiconductor substrate

InactiveUS7005338B2Avoid less flexibilityIncrease vertical FET channel widthTransistorSolid-state devicesDielectricCapacitance

A floating gate (110) of a nonvolatile memory cell is formed in a trench (114) in a semiconductor substrate (220). A dielectric (128) covers the surface of the trench. The wordline (140) has a portion overlying the trench. The cell's floating gate transistor has a first source / drain region (226), a channel region (224), and a second source / drain region (130). The dielectric (128) is stronger against leakage near at least a portion of the first source / drain region (122) than near at least a portion of the channel region. The stronger portion (128.1) of the additional dielectric improves data retention without increasing the programming and erase times if the programming and erase operations do not rely on a current through the stronger portion. Additional dielectric (210) has a portion located below the top surface of the substrate between the trench and a top part of the second source / drain region (130). The second source / drain region has a part located below the additional dielectric and meeting the trench. The additional dielectric can be formed with shallow trench isolation technology. The additional dielectric reduces the capacitance between the second source / drain region (130) and the floating gate.

Owner:PROMOS TECH INC

Environment-friendly waterproof paint

ActiveCN104119734AImprove waterproof performanceStrong leakage resistanceCoatingsSodium metasilicateEtidronic acid

The invention discloses environment-friendly waterproof paint which consists of the following raw materials in parts by weight: 62-70 parts of styrene-acrylic emulsion, 0.4-1 part of pyromellitic dianhydride, 1-2 parts of guaiacol, 1-2 parts of mannitol, 0.1-0.2 part of potassium titanate, 6-10 parts of fluorapatite, 4-6 parts of talcum powder, 1-2 parts of 1,2-dimethylimidazole, 2-3 parts of dioctyl azelate, 1-2 parts of sodium metasilicate, 0.5-1 part of polypropylene glycol diglycidyl ether, 0.5-1 part of coco fatty acid diethanol amide, 0.3-0.6 part of etidronic acid, 5-7 parts of coalescing agent and 10-16 parts of deionized water. The waterproof paint is good in waterproof effect, high in leakage resistance, excellent in ageing resistance, high in adhesive force, high in material extensibility, high in constructability, safe and environment-friendly and does not have any toxic or side effect.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

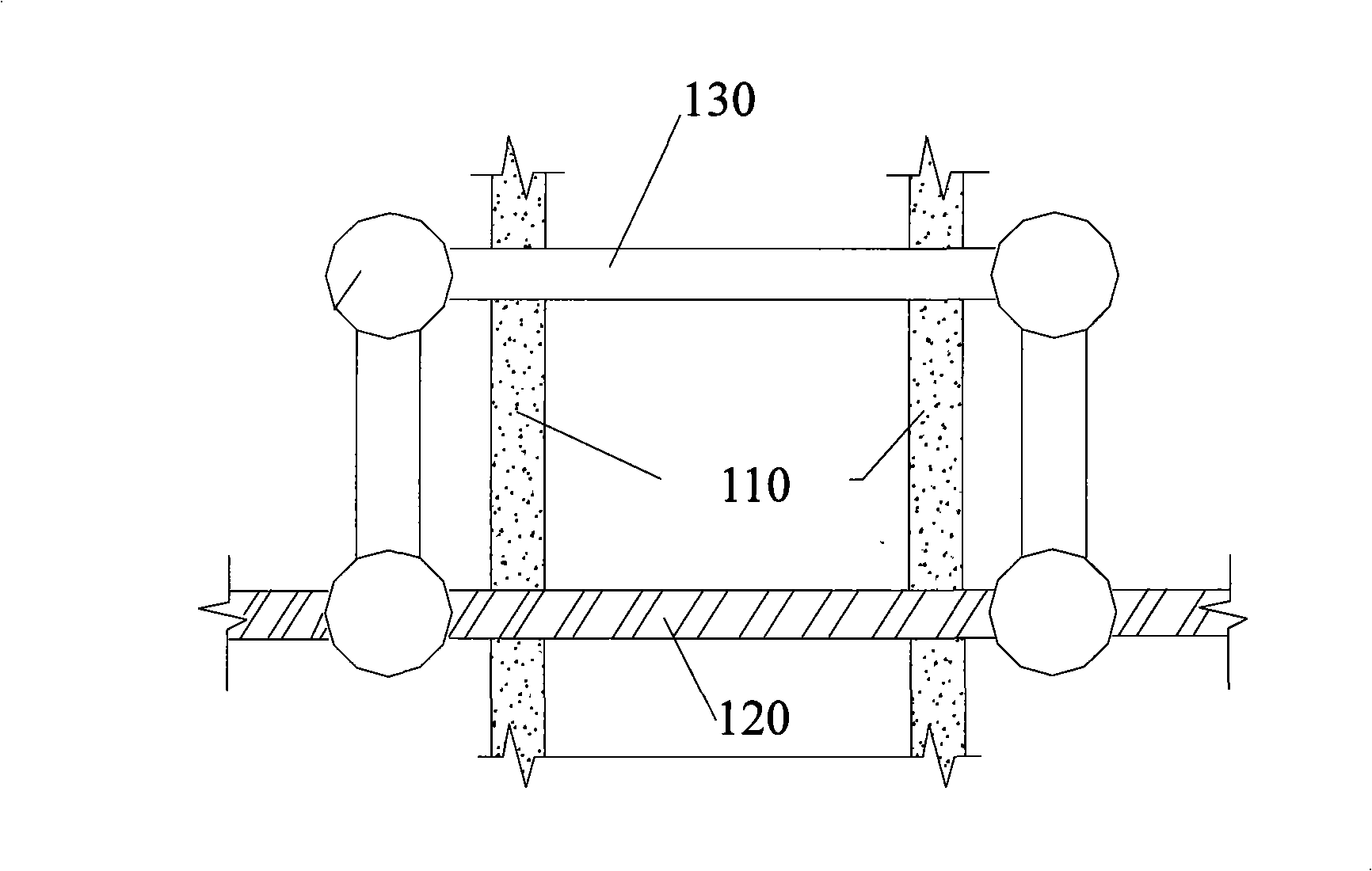

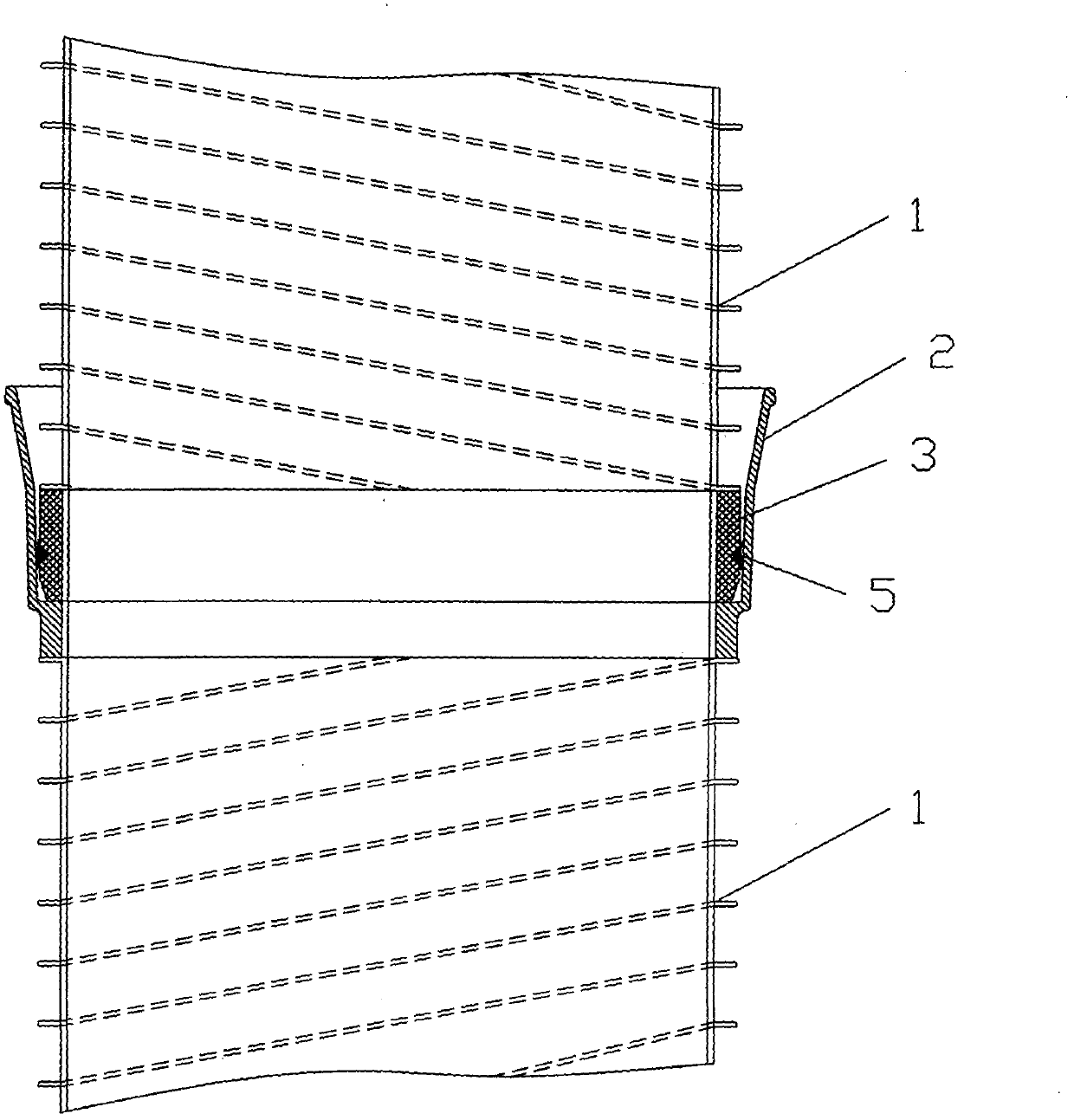

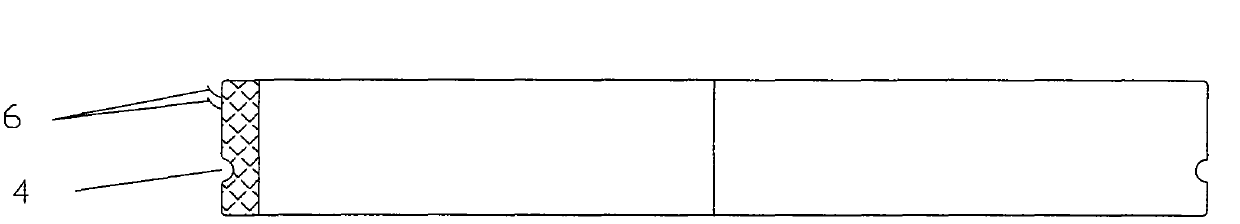

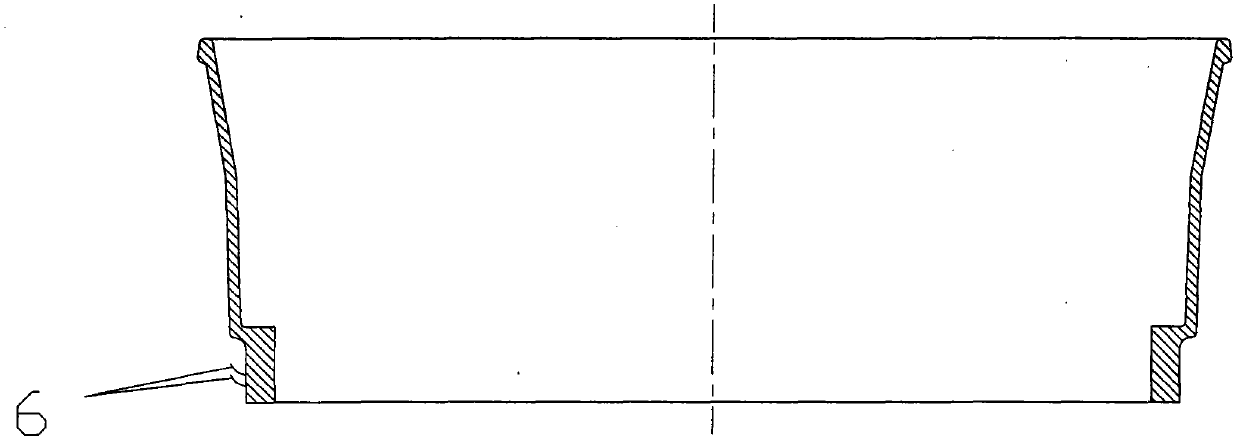

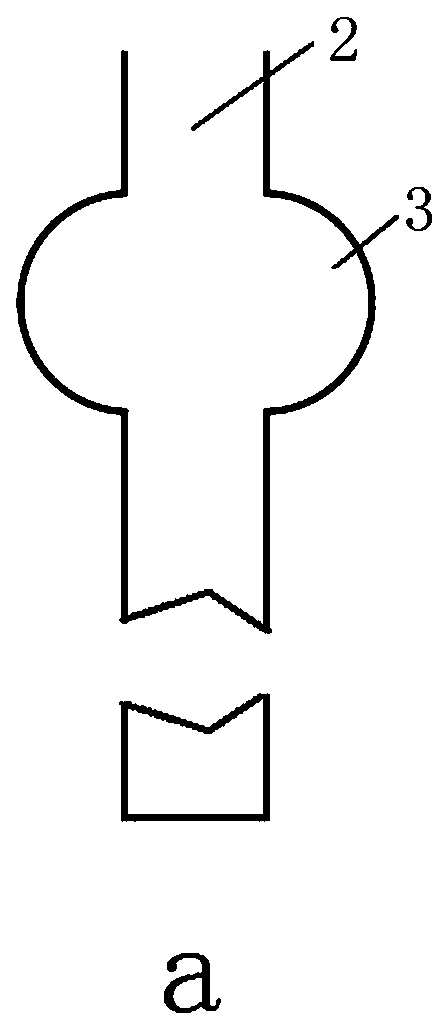

Socket structure for plastic steel twined piles

InactiveCN102384327AImprove sealingStrong leakage resistancePipe connection arrangementsSmall caliberMaterials science

The invention relates to a socket structure for plastic steel twined piles, belonging to the field of pollution discharge and drainage facilities. The socket structure of the plastic steel twined piles comprises two sections of the plastic steel twined piles with spiral outer surfaces; the two sections of the plastic steel twined piles are connected with an electro-thermal melting sleeve through an electro-thermal melting jacket; the electro-thermal melting jacket is in a shape of step; the section with a small caliber of the electro-thermal melting jacket is sleeved on the periphery of one end of one plastic steel twined pile, and the plastic steel twined pile sleeve is sleeved on the periphery of one end of the other plastic steel twined pile; and the electro-thermal melting sleeve is annular and is arranged in the section with a large caliber of the electro-thermal melting jacket. The socket structure provided by the invention has the advantages of stronger sealing performance and anti-leakage property, simple structure and convenience for rapid installation and connection; furthermore, because the plastic steel twined piles, the electro-thermal melting jacket and the electro-thermal melting sleeve are made of the same material or similar materials, the socket structure is integrated in appearance.

Owner:SUZHOU XINGHE PLASTIC MACHINERY

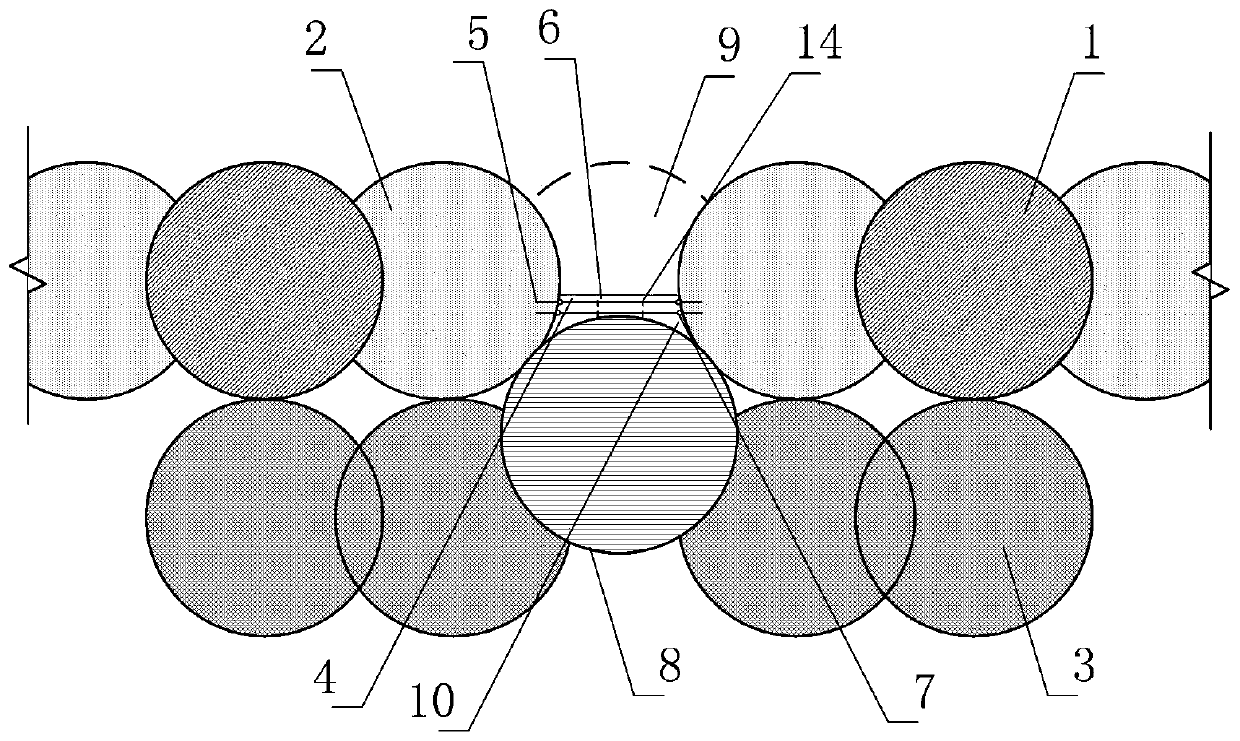

Reinforced concrete hollow prefabricated component plate

The hollow reinforced concrete slab includes reinforced concrete slab body and its two sides have two stretched blocks in the lower part and stretched steel bars. When constructing floor, after the hollow reinforced concrete slabs are set on support, trough will formed between two adjacent slabs, the stretched steel bars are connected and the trough is deposited with concrete to constitute integral floor. The floor has high anti-cracking performance and anti-seepage performance, strengthened connection between adjacent floor slabs and raised floor entirety.

Owner:吴方伯

Waterproof and wear-resistant composite coating for buildings and preparation method thereof

InactiveCN108219547AGood heat insulationGood weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedCellulose

The invention discloses a waterproof and wear-resistant composite coating for buildings and a preparation method thereof. The waterproof and wear-resistant composite coating is prepared from the following raw materials in parts by weight: 25 to 35 parts of maleic anhydride modified rosin glyceride, 20 to 30 parts of epoxy acrylic resin, 18 to 25 parts of portland cement, 10 to 15 parts of polyurethane rigid foam powder, 15 to 20 parts of trimethylol triacrylate, 10 to 15 parts of modified nano-silica, 10 to 15 parts of water-based silicone-acrylic emulsion, 15 to 25 parts of asphalt, 2 to 4 parts of calcined kaolin, 5 to 8 parts of additive, 3 to 6 parts of filler, 4 to 6 parts of modified nano slurry, and 2 to 5 parts of cellulose ether thickener. The coating for buildings prepared from the maleic anhydride modified rosin glyceride, epoxy acrylic resin, portland cement, polyurethane rigid foam powder, trimethylol triacrylate, modified nano-silica, water-based silicone-acrylic emulsion, asphalt, and calcined kaolin according to an effective ratio has excellent weather resistance and strong acid and alkali resistance, which are greatly improved compared with the thermal insulation coatings sold in the general market; and the anticorrosion performance is good, and the preparation method is simple.

Owner:安徽嘉中金属材料有限公司

Nano water-resistant paint

The invention discloses a nano water-resistant paint which is prepared from the following raw materials in parts by weight: 71-80 parts of silicone-acrylic emulsion, 1-2 parts of polyvinyl pyridine, 2-3 parts of locust bean gum, 1-2 parts of N-ethyl-ortho-para-toluene sulfonate, 10-13 parts of nano calcium carbonate, 1-2 parts of zinc borate, 4-6 parts of fluorapatite, 0.1-0.2 part of succinic acid, 2-3 parts of butyl epoxy oleate, 1-2 parts of sodium sulfite, 0.1-0.3 part of ethylene glycol monobutyl ether, 1-2 parts of glycerol triglyceride, 0.5-1 part 2,6-di-tert-butyl-para-cresol, 4-5 parts of film formation assistant and 14-20 parts of deionized water. The nano raw material added into the water-resistant paint can effectively enhance the compatibility among the raw materials, enhances the leveling property of the coating surface, and has the advantages of favorable smoothness, high hardness, wear and scratch resistance, favorable leakage resistance and high weather resistance.

Owner:ANHUI SUNROAD ENVIRONMENT PROTECTIVE NEW MATERIALS

Secant pile construction cold joint treatment structure and method

PendingCN110670598AStrong leakage resistanceImprove the stability of actionExcavationsBulkheads/pilesArchitectural engineeringMesh reinforcement

The invention belongs to the technical field of constructional engineering, and relates to a secant pile construction cold joint treatment structure and method. Concrete is subjected to mesh sprayingto the position between formed plain piles, Y connecting pieces are connected with reinforcing mesh joints, U connecting parts enable combination of reinforcing meshes and a sprayed face to be more tight, dual layers of reinforcing meshes are adopted for improving anti-permeability and stability at a secant pile construction cold joint, reinforcing piles are arranged on the outer side, jet grouting piles are added to be secant with the reinforcing piles, and according to the geology, a grouting floral tube is added among the jet grouting piles, the reinforcing piles and the secant piles for further improving the leakage-resisting capacity of a foundation pit. The secant pile cold joint has high leakage-resisting capacity, whole stability is high, the foundation pit bracing safety is improved, safety hidden danger is reduced, the structure is suitable for subway foundation pit engineering, and secant pile construction cold joint treatment of the building foundation pit engineering has the wide application prospects.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

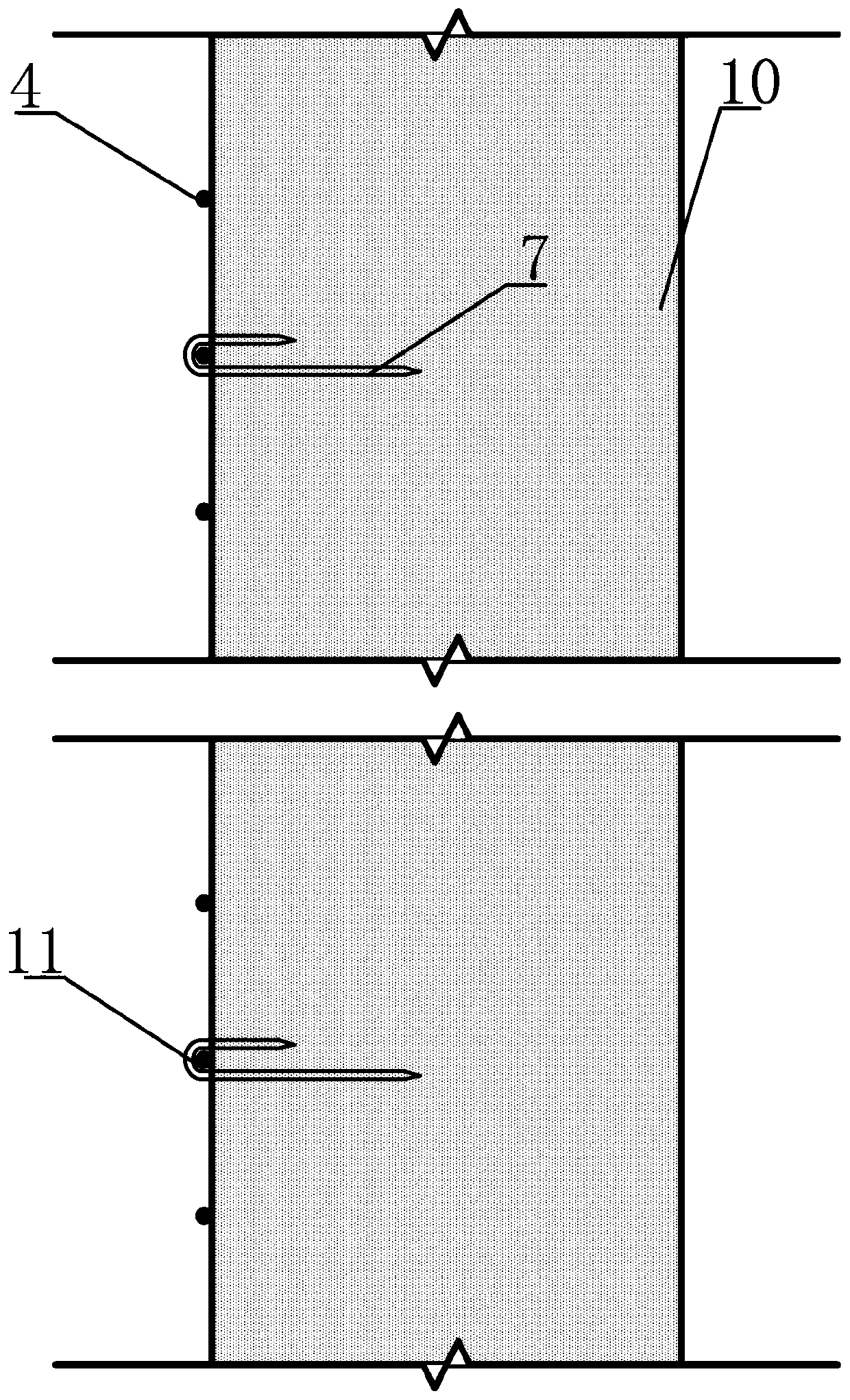

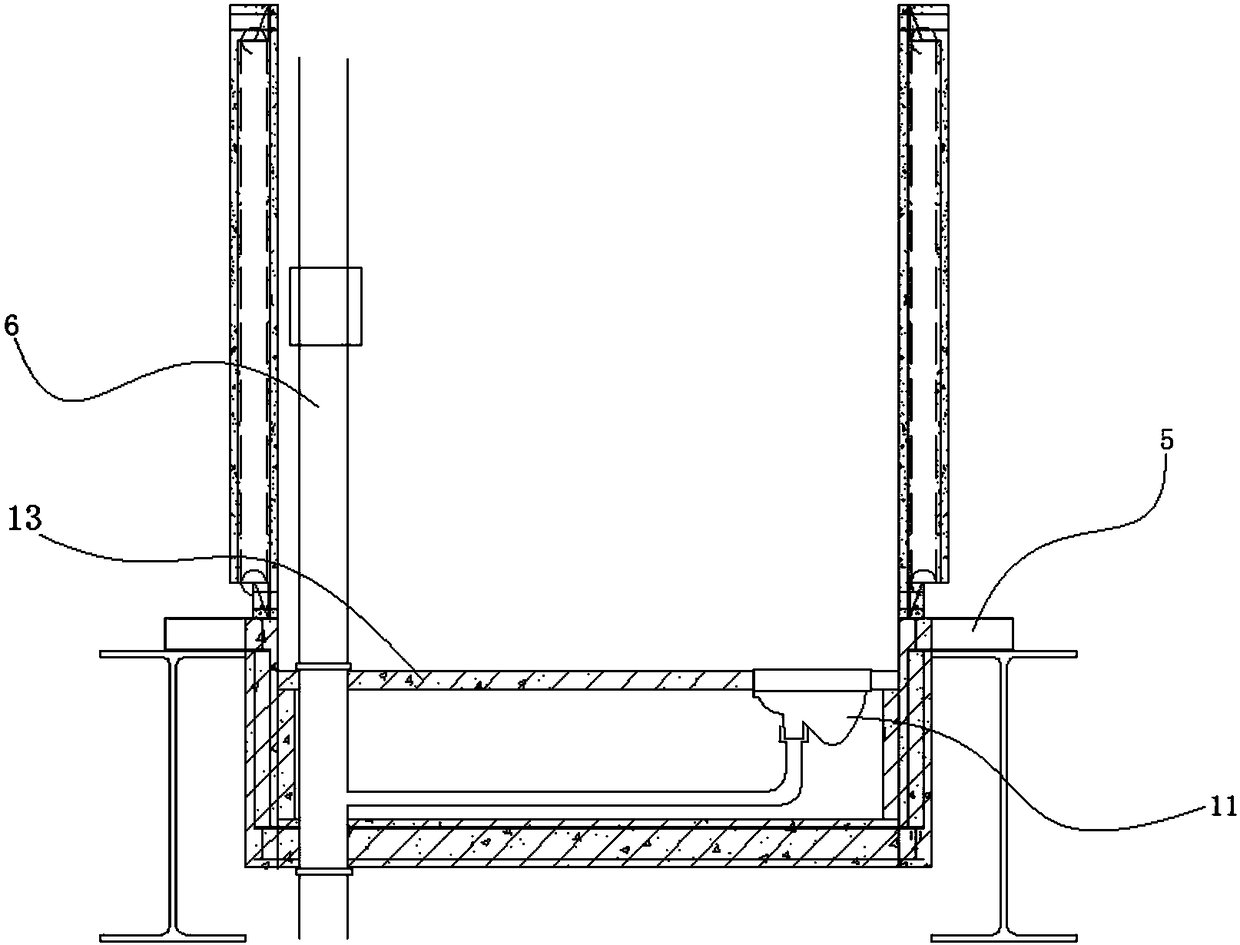

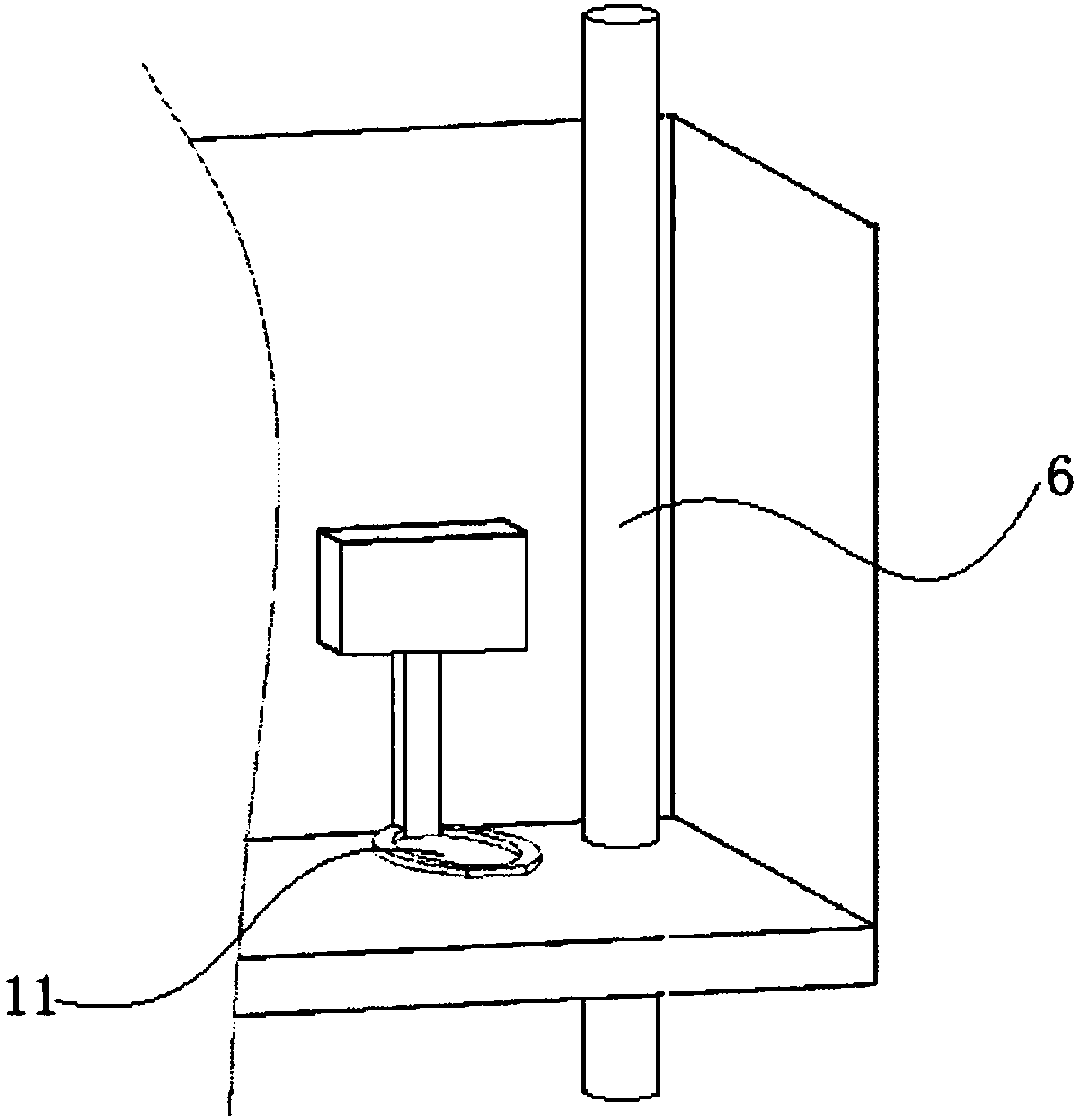

Prefabricated hybrid structure prefabricated toilet and manufacturing method thereof

ActiveCN108612345AGuaranteed Quality ControlReduce construction difficultiesWallsSpecial buildingEngineeringSewage

The invention provides a hybrid structure prefabricated toilet for a prefabricated building and a manufacturing method thereof. The toilet comprises a wall unit, a sewage main riser, and a bottom plate unit fixedly connected with a steel beam or a superposed beam. During operation, the bottom plate unit is fixedly connected with the steel beam or the superposed beam through connecting pieces I. The bottom plate unit is connected with a floor through cast-in-place nodes. A wallboard is fixedly connected with the bottom plate unit through the matching of a connecting plate II and a correspondingconnecting plate I. The sewage main riser penetrates through and is fixedly connected to the bottom plate unit. The manufacturing method of the toilet includes the steps of scheme design, prefabricating the bottom plate unit, prefabricating the wallboard, transportation to the site, assembling and pouring floors and the like. The toilet can reduce construction difficulties caused by weather changes, is convenient and quick to install, and has good anti-leakage performance.

Owner:重庆宜府住工科技有限公司

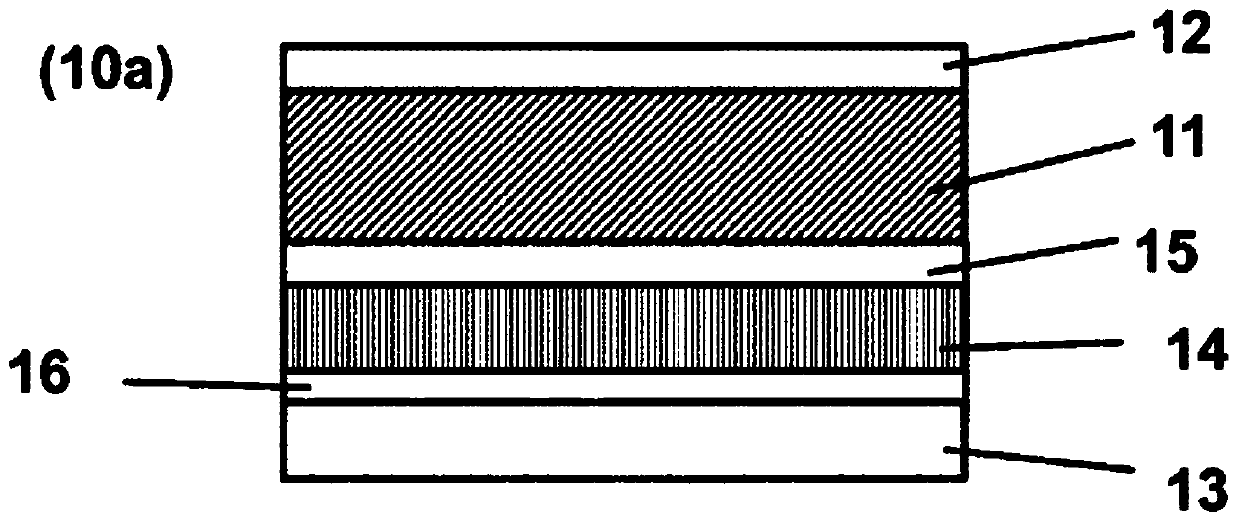

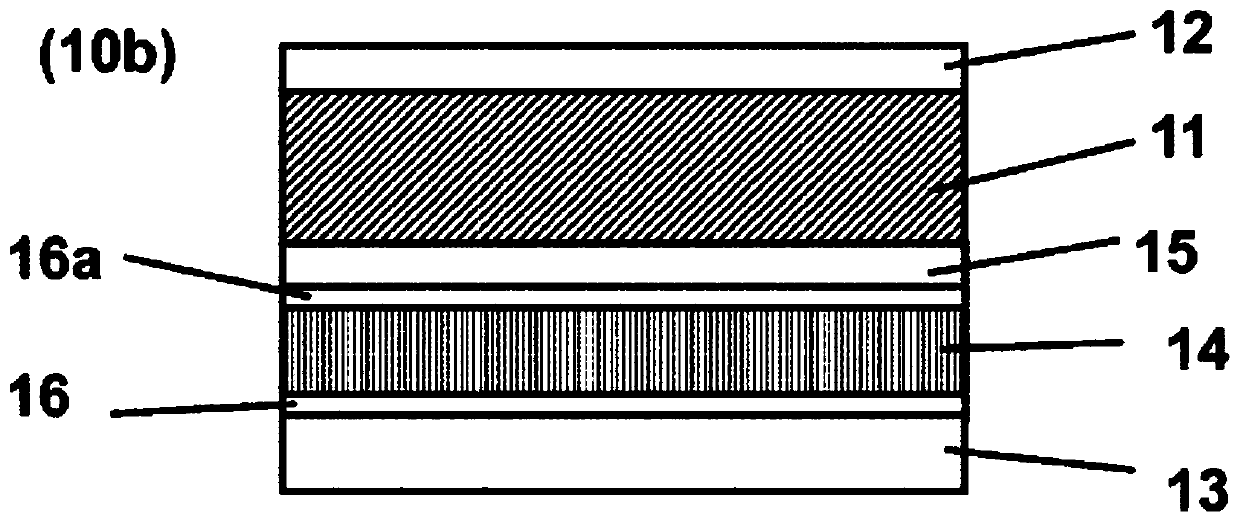

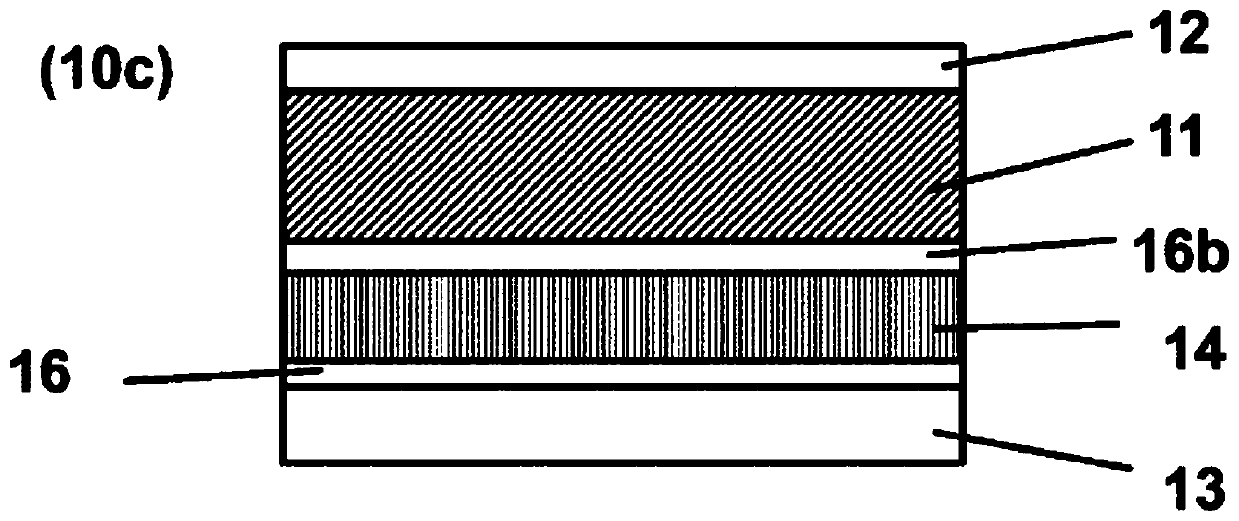

Barrier film and laminated packaging material comprising the film and packaging container made therefrom

ActiveCN111511542AGood packaging integrityGood food preservation performanceSynthetic resin layered productsCellulosic plastic layered productsCellulosePolymer science

The present invention relates to laminated packaging materials comprising a bulk layer of paper or paperboard or other cellulose-based material, and outer- and innermost liquid tight, heat sealable thermoplastic polymer layers, and a barrier layer, and to a method of manufacturing such laminated materials, in particular intended for liquid food packaging. The invention further relates to a packaging container comprising the laminated packaging material.

Owner:TETRA LAVAL HLDG & FINANCE SA

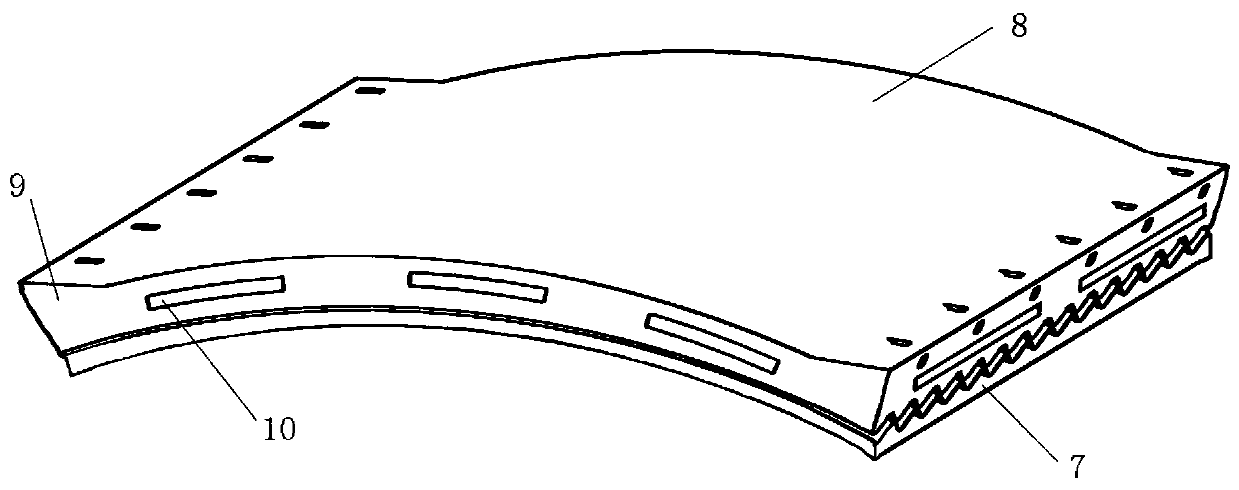

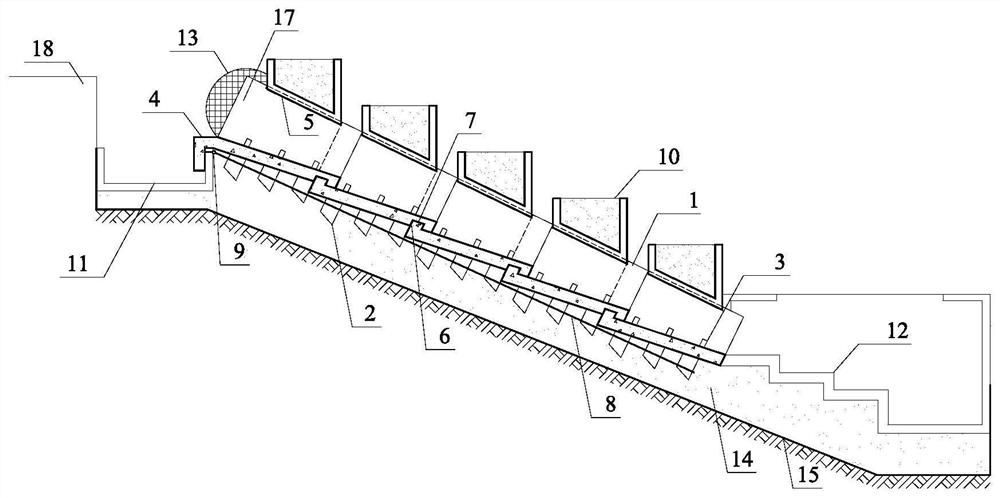

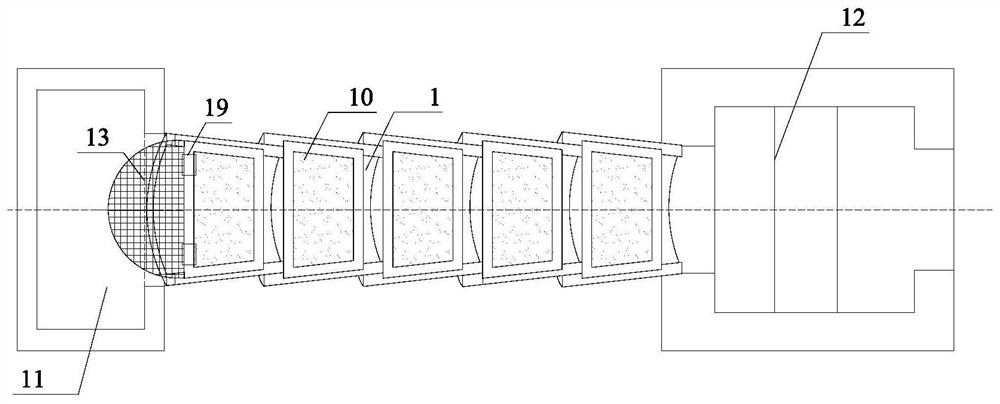

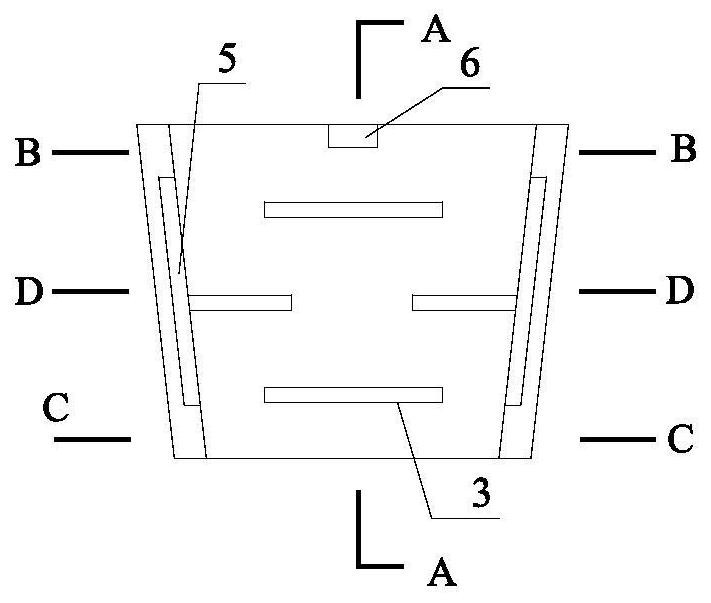

Method for treating operating tunnel leakage with water diversion plate

The invention relates to a method for treating operating tunnel leakage with a water diversion plate. The method comprises the steps of determining the size of the water diversion plate according to the water leakage condition, obtaining two grooves on the two sides of the leaked position through cutting, installing the water diversion plate on the grooves, continuing to lay the water diversion plate on the inner wall of a tunnel, sealing the water diversion plate and the inner wall of the tunnel, and spraying a waterproof coating onto the outer side of the water diversion plate to form a water diversion pipeline so that water can be guided to side ditches of the tunnel. The ultrathin water diversion plate is prefabricated, the plate is extremely thin, a groove is shallow and narrow, weight is low, material consumption is low, and the influence on the appearance of the tunnel after installation is small. The water diversion technology of the ultrathin water diversion plate is convenient to implement, drilling and grouting are not needed, it is only needed to arrange a water diversion plate circuit outside the tunnel, construction is convenient and quick, and disturbance of the tunnel is light. The ultrathin water diversion plate is made of resin or glass fiber, is high in durability, and can serve as a tunnel surface drainage system to be used for a long time so as to improve the drainage capacity of the tunnel.

Owner:SHANDONG UNIV

High-waterproof anti-leakage sealing rubber material and preparation method thereof

The invention discloses a high waterproof and anti-leakage sealing rubber material, which is composed of the following raw materials in parts by weight: succinic anhydride 1-2, anti-aging agent rd1-2, 2-aminoethyl heptadecenyl imidazole Phenyl 1‑2, butadiene rubber 120‑140, attapulgite powder 10‑12, abietyl alcohol 2‑4, vulcanizing agent PM0.7‑1, bone char 3‑4, dibutyl maleate 4‑5 , sodium metasilicate 1‑3, accelerator TT1‑2, N, N‑diethylaniline 0.5‑1, potassium hydrogen tartrate 1‑2, vanadium acetylacetonate 0.5‑1, lithium hydroxide 0.1‑0.2, waterproofing aid Agent 3‑4; the present invention adopts hexahydrophthalic anhydride to cross-link modified stearic acid, and then carry out surface treatment by 1H, 1H, 2H, 2H perfluorodecyltriethoxysilane to obtain highly water-resistant The auxiliary agent can effectively improve the hydrophobicity of the finished material and prevent rubber aging and corrosion. The rubber material of the present invention has strong leakage resistance, and is especially suitable for use in underground water pipes, ships and other fields, with long service life and weather resistance Good sex.

Owner:宁波远欣石化有限公司

Underground construction deformation joint waterproof structure and construction method thereof

PendingCN108978731ASimple waterproof structureReliable functionArtificial islandsProtective foundationJoint spacesPrecast concrete

The invention discloses an underground construction deformation joint waterproof structure and a construction method thereof. The waterproof structure comprises a deformation joint, and an expansion cavity formed in the position 30 to 70 mm away from the top of the deformation joint, and the interior of the expansion cavity and deformation joint space above the expansion cavity are filled with a seal material with the waterproof effect; the construction method comprises the steps that firstly, a frame of a precast concrete wall is built, an expansion cavity mold in the corresponding shape is made, and the position of the preset expansion cavity is marked in the position, 30 to 70 mm away from the top o the deformation joint, in the reserved deformation joint; secondly, the expansion cavitymold is placed on the marked deformation joint and is used for supporting so as to form the expansion cavity; thirdly, concrete is poured into the frame for prefabrication molding, and after curing solidification, the expansion cavity mold and the frame are removed; fourthly, the position, below the expansion cavity, in a deformation joint hole is filled with a flexible filler, and a seal material with the waterproof effect is poured into the expansion cavity and the deformation joint space above the expansion cavity. The structure is simple, the function is reliable, the construction methodis simple, operation is easy, and the cost is low.

Owner:ZHENGZHOU UNIV

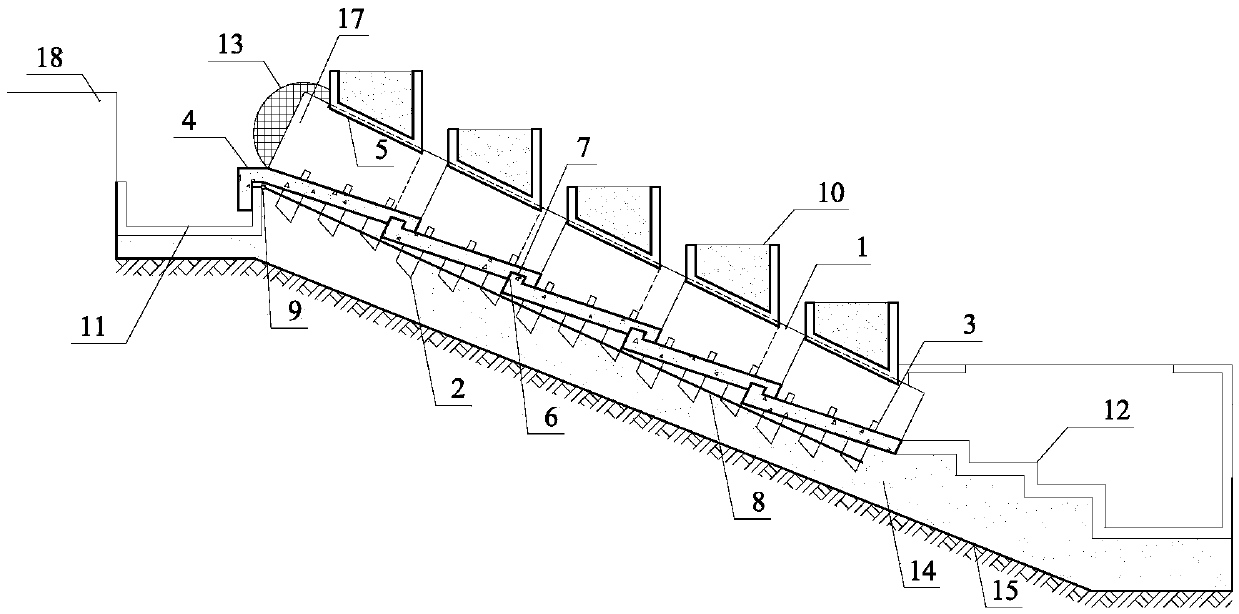

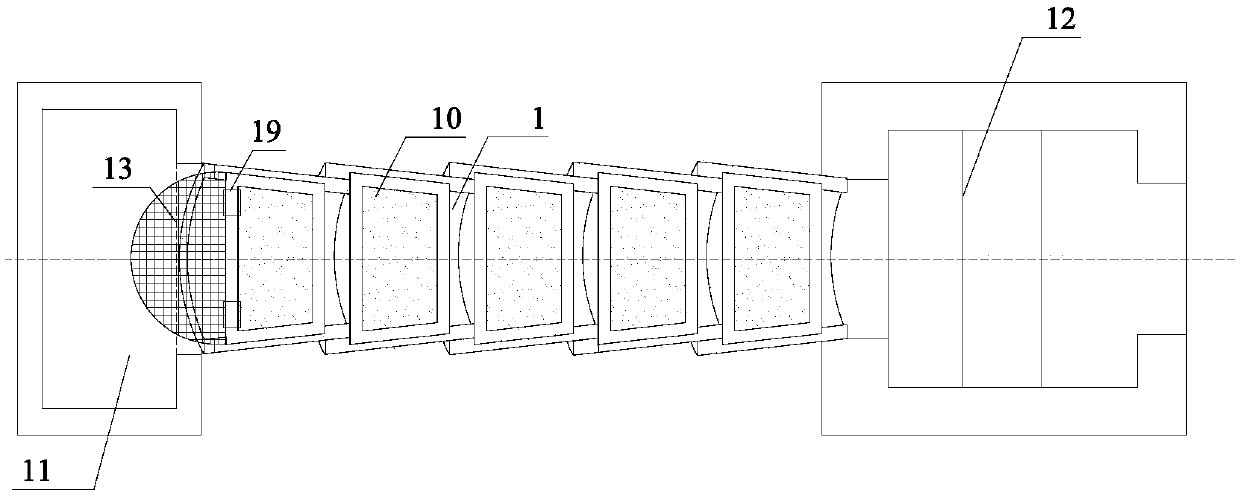

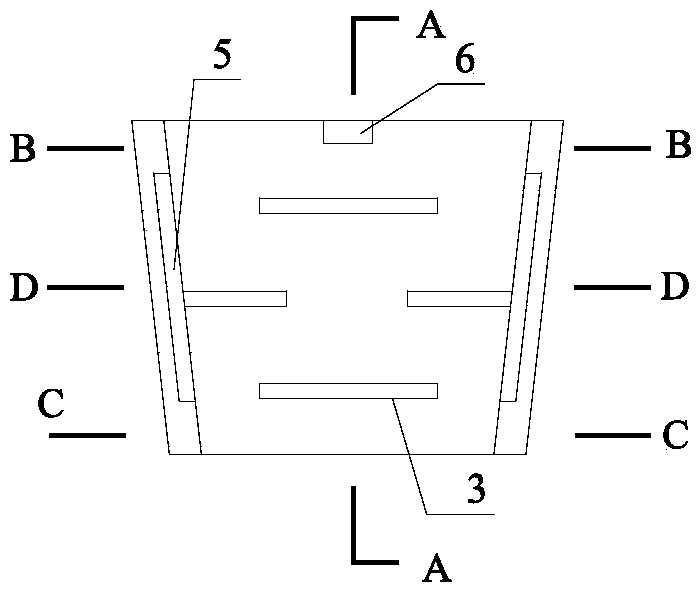

Construction method of ecological prefabricated reinforced-concrete torrent channel drainage system

ActiveCN109577456AOvercome inconsistent specificationsOvercoming the easy settlement and deformation of the rush troughSewerage structuresPaving gutters/kerbsEcological environmentWater leakage

The invention relates to a construction method of an ecological prefabricated reinforced-concrete torrent channel drainage system. The construction method mainly includes prefabricating a torrent channel, prefabricating grass planting mould boxes, constructing channels, mounting force-eliminating steps, mounting standard prefabricated sections of the torrent channel, mounting a prefabricated sump,mounting the grass planting mould boxes and mounting a spherical detachable filter screen. The prefabricated sections of the torrent channel are fastened together in a 'stacking type' way and are integrally bundled together by a steel cable, the two ends of the steel cable are drawn onto pre-embedded pull rings of the prefabricated sump, and the grass planting mould boxes are embedded into the tops of the prefabricated sections of the torrent channel. The torrent channel drainage system based on the prefabricated design concept has the advantages of convenience and rapidness in mounting, highconstruction speed, ecological environment protection and the like; damage, such as hollow-out and scouring, of drained water to roadbeds due to the problems such as water seepage, water leakage andsettlement deformation of brickwork-type torrent channels is avoided, and good economic and technical benefits are achieved.

Owner:杭州昂创科技有限公司

Waterproof system and construction method for toilet

ActiveCN106978856BEasy to fixPrevent leakageSills/thresholdBuilding insulationsFloor slabEngineering

The invention relates to the field of building decoration and provides a bathroom waterproof system which is simple in structure can convenient to construct and can effectively prevent water molecules in a bathroom from leaking outward and a construction method. The technical problems that in the prior art, the leakage proof effect of the bathroom is poor, the situation that a floor, a door sleeve and the like in a dry area mould and decay is quite prone to occurring, and the attractive degree of overall decoration is reduced are solved. The bathroom waterproof system comprises a bathroom floor base layer and a dry area floor base layer connected with the bathroom floor base layer. Ground decoration paving layers are laid on the surfaces of the bathroom floor base layer and the dry area floor base layer correspondingly. An elastic water retaining plate and the lower end of an elastic water retaining strip are arranged between the bathroom floor base layer and the corresponding ground decoration paving layer in a clamped mode, wherein the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected on the bottom face of a doorsill plate in a closed mode, and the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected with a cement mortar retaining strip in an airtight mode. The cement mortar retaining strip divides the corresponding floor decoration paving layer into a bathing area and a rest area.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

Underground continuous wall construction method of city-across pipeline

ActiveCN101343868BImprove integrityImprove stabilityBulkheads/pilesSlurry wallArchitectural engineering

The invention provides an inter-city pipeline underground continuous wall construction method. Through the adoption of the method in the construction, the integrity of the underground continuous wall is good, the verticality is high, the anti-penetration performance is good, the wall body can be successfully sealed, the pollution to the surrounding environment is less, and the underground structures can be better protected. The inter-city pipeline underground continuous wall construction method comprises the following steps: the pipeline is dug, examined and reinforced; wall guiding construction is performed in the pipeline scope; groove building construction is performed, which comprises: firstly, soil masses at both sides of the pipeline are dug with a groove milling machine; secondly, a guiding track frame is arranged along one side of the pipeline; thirdly, a reversible cutting machine is placed in the track guiding frame; and fourthly, the soil masses under the pipeline are laterally milled with the reversible cutting machine; after the groove is milled, a reinforcement cage is hanged in; and the concrete is poured into the pipe.

Owner:SHANGHAI CONSTRUCTION GROUP

Anti-leakage waterborne epoxy coating and preparation method thereof

InactiveCN108517169AImprove toughnessGood uniformity and stabilityEpoxy resin coatingsEpoxyPolyethylene glycol

The invention discloses anti-leakage waterborne epoxy coating which is prepared from the following raw materials in parts by weight: 0.8 to 1 of fatty acid diethanol amide, 0.1 to 0.2 of nonyl phenol,1 to 2 of oleic acid polyoxyethylene ester, 2 to 3 of calcium ricinoleate, 0.7 to 1 of naphthenic soap, 1 to 2 of zinc dialkyl dithiophosphate, 4 to 6 of magnesium silicate, 6 to 8 of hydroxyethyl cellulose, 4 to 7 of polyethylene glycol adipate and 100 to 120 of epoxy resin E51. The coating disclosed by the invention has the advantages of good uniform stability, strong leakage resistance and excellent comprehensive performance.

Owner:胡佳佳

Anti-leakage repair-enhanced building coating

The invention relates to an anti-leakage repair-enhanced building coating which is prepared by adopting the following steps of: mixing and uniformly stirring 30-42 percent of 800-mesh silicate dry powder, 1-2 percent of KFA, 1-2 percent of plasticizer, 1-2 percent of air entraining agent and 54-65 percent of 20-40-mesh quartz sand to prepare a mixture; then adding water accounting for 15-25 percent of the gross weight into the mixture, uniformly stirring, and settling for 30 minutes to prepare the anti-leakage repair-enhanced building coating. The anti-leakage repair-enhanced building coating has the advantages of stronger coagulability, cementability, anticorrosive property, excellent anti-leakage performance, simple construction, advanced process and strong freezing and thawing resistance, is particularly suitable for being used in extremely cold regions and can be used for the leak stoppage, the seepage prevention, the reinforcement and the corrosion prevention of roads, bridges, oceans, sewage treatment and concrete structures, such as tunnels, large reservoir dams, and the like without other various additives, thereby lowering the cost of the additives and the construction difficulty, improving the engineering quality and the use durability of concrete and avoiding the mutual exclusive reaction.

Owner:夏凤君

A kind of environmental protection waterproof coating

ActiveCN104119734BImprove waterproof performanceStrong leakage resistanceCoatingsSodium metasilicateEmulsion

The invention discloses an environmentally friendly waterproof coating, which is composed of the following raw materials in parts by weight: styrene-acrylic emulsion 62-70, pyromellitic dianhydride 0.4-1, guaiacol 1-2, mannitol 1 ‑2, potassium titanate 0.1‑0.2, fluorapatite 6‑10, talc powder 4‑6, 1,2‑dimethylimidazole 1‑2, dioctyl azelate 2‑3, sodium metasilicate 1‑2, Polypropylene Glycol Diglycidyl Ether 0.5‑1, Diethanolamide Cocoate 0.5‑1, Hydroxyethylidene Diphosphonic Acid 0.3‑0.6, Coating Aid 5‑7, Deionized Water 10‑16, this The invented waterproof coating has good waterproof effect, strong leakage resistance, excellent aging resistance, strong adhesion, good material extensibility, good construction performance, safety and environmental protection, and no toxic and side effects.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

A kind of slag Portland cement and production method thereof

The invention relates to a portland blast furnace slag cement and a preparation method thereof. The portland blast furnace slag cement is prepared from the following raw materials by weight percent: 12%-30% of at least one of slag, coal gangue, boiling slag, liquid slag, cinerite, kiln dust and crushed tile, 10%-42% of mineral waste residue, steel slag or silicomanganese slag, 0-12% of limestone, 2%-8% of gypsum, 0-10% of zeolite, 0-17% of boiling slag, 0-10% of coal ash, and 10%-50% of silicate series cement. The preparation method comprises steps of putting the slag, mineral waste residue, gypsum, zeolite, boiling slag, and coal ash into a pulverizer to be smashed, grinding by a ball mill to achieve the fineness of 0.08mm, sieving by a square hole sieve with 2% left, and then mixing with the silicate series cement. The portland blast furnace slag cement has the advantages of having a simple preparation method, needing no cement clinker, guaranteeing the strength and stability of the cement, fully using industrial residue resources like slag and mineral waste residue, lowering production cost, and reducing the pollution of industrial residue to the environment.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE

Construction method of prefabricated septic tank

InactiveCN110589963AGood structural stabilityStrong leakage resistanceTreatment with anaerobic digestion processesBiological sludge treatmentStructural stabilityShop drawing

The invention discloses a construction method of a prefabricated septic tank. The construction method of the prefabricated septic tank comprises the following steps: determining a construction position and the position of an inspection well; carrying out field leveling cleaning, and excavating a foundation ditch for mounting a septic tank; mixing concrete with water in proportion, and then enabling the mixture to be in a wet state, leveling the bottom of the foundation ditch, laying a broken stone hardcore on the bottom, and laying a concrete layer on the upper surface of the broken stone hardcore; then building a frame of the septic tank on the surface of the concrete layer, and meanwhile prefabricating a cover plate; pouring prepared concrete into an inner partition plate of the frame, standing for 8-14 hours, and then sequentially disassembling a fixing rack, the frame and the inner partition plate; mounting a connecting pipeline according to a construction drawing, and covering theseptic tank with the cover plate after a water closing test is qualified; and carrying out sealing, earthwork backfilling and tamping, and finally checking. The construction method of the prefabricated septic tank is good in structural stability, high in seepage resistance, small in engineering quantity, short in period and convenient to construct, and mounting can be implemented along with excavation.

Owner:广东建宇建筑科技有限公司

A prefabricated hybrid structure assembly toilet and its manufacturing method

ActiveCN108612345BGuaranteed Quality ControlReduce construction difficultiesWallsSpecial buildingFloor slabArchitectural engineering

Owner:重庆宜府住工科技有限公司

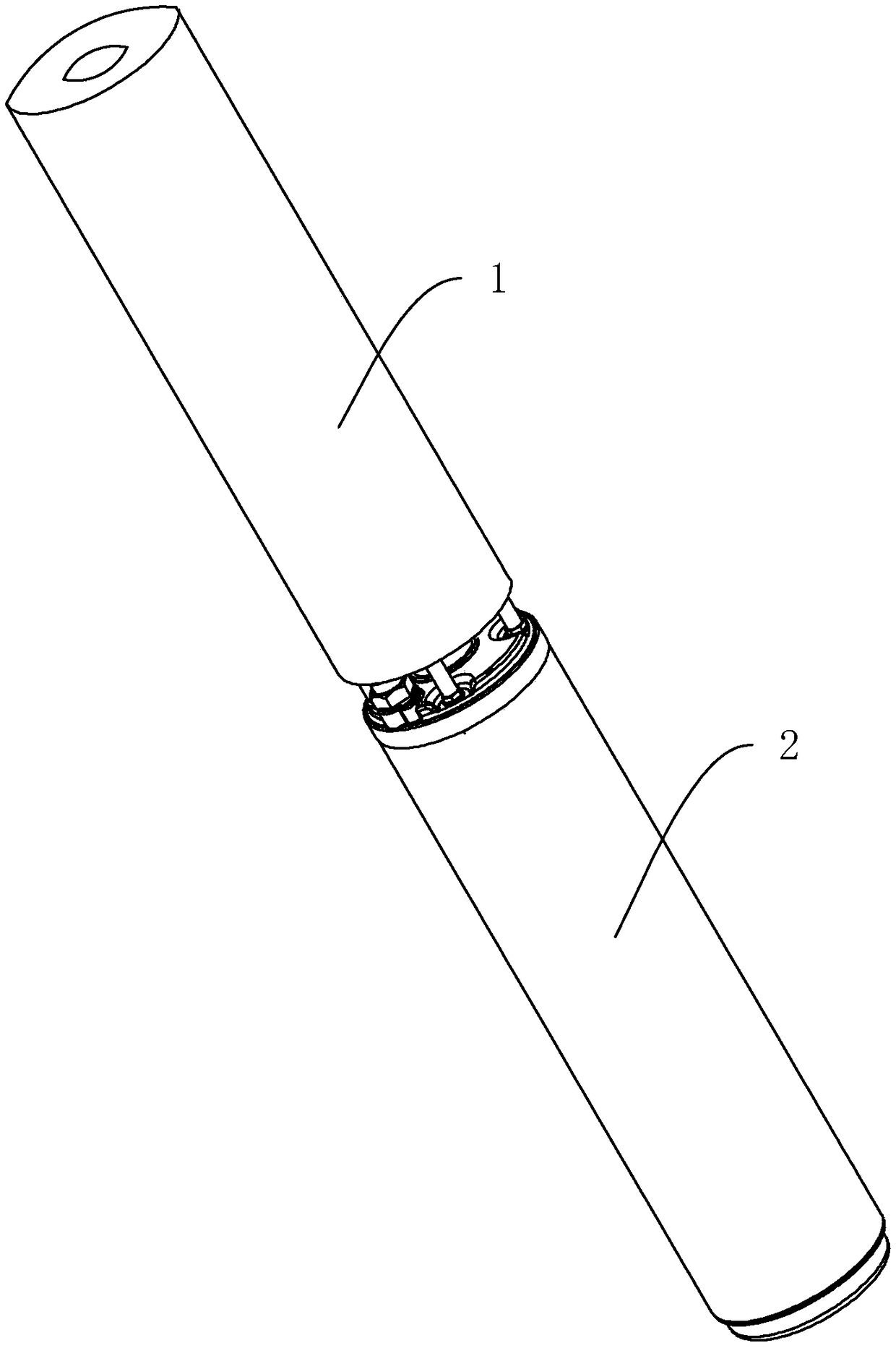

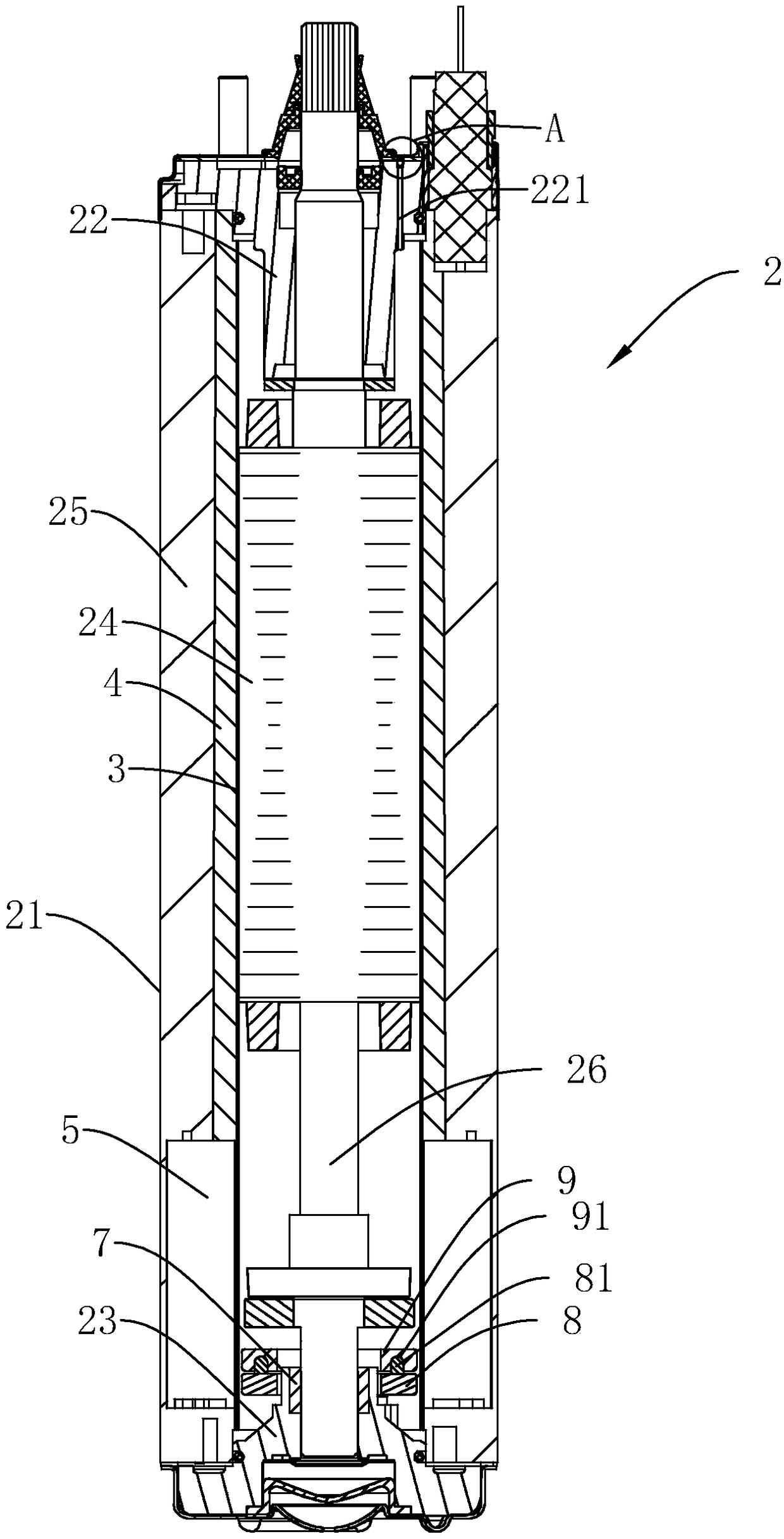

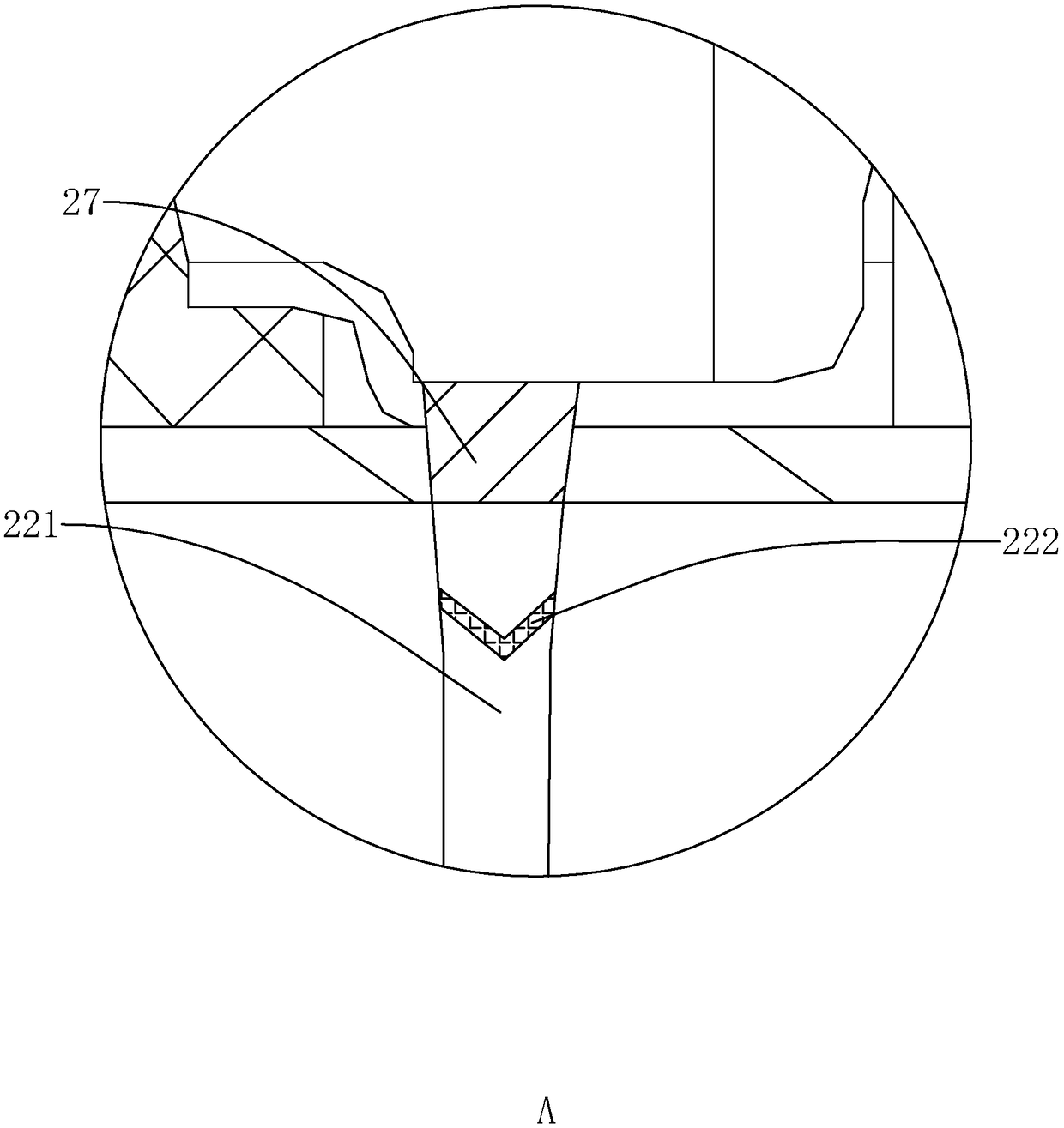

Deep well pump with efficient waterproof motor and production technology thereof

PendingCN108799146AStrong leakage resistanceImprove compactnessPump componentsPump installationsEpoxyStator coil

The invention discloses a deep well pump with an efficient waterproof motor and a production technology of the deep well pump with the efficient waterproof motor. The deep well pump with the efficientwaterproof motor is characterized by comprising a pump body and a motor, wherein the motor comprises a motor barrel, the motor barrel is provided with an upper bearing seat, a lower bearing seat, a rotor and a stator coil, an output shaft is arranged in the middle of the rotor in a penetrating manner, the rotor is sleeved with a shielding sleeve, the two ends of the shielding sleeve are fixedly connected with the upper bearing seat and the lower bearing seat, epoxy resin is poured between the shielding sleeve and the stator coil, and the stator coil is wrapped inside the epoxy resin. The production technology of the deep well pump comprises the steps that after the upper bearing seat, the stator coil, the shielding sleeve, the rotor and a capacitor are installed, the epoxy resin is heatedat different times for different times and poured into the motor barrel three times so as to wrap the stator coil. The epoxy resin has the characteristics of high anti-leakage performance and high compactness, so that water entering the motor can be isolated from the stator coil beneficially, and it is effectively avoided that the water makes contact with the stator coil; and in this way, the waterproof effect in the motor is improved, and motor damage is reduced.

Owner:日达泵业有限公司

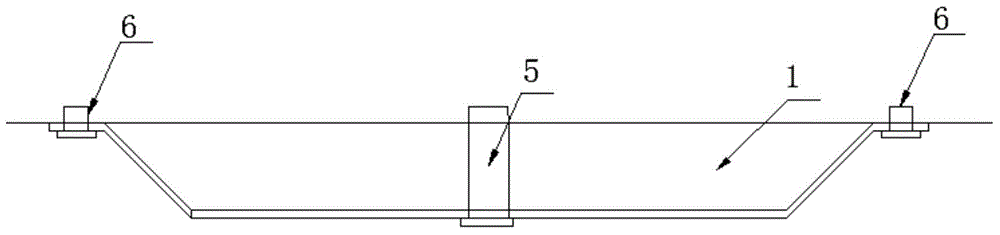

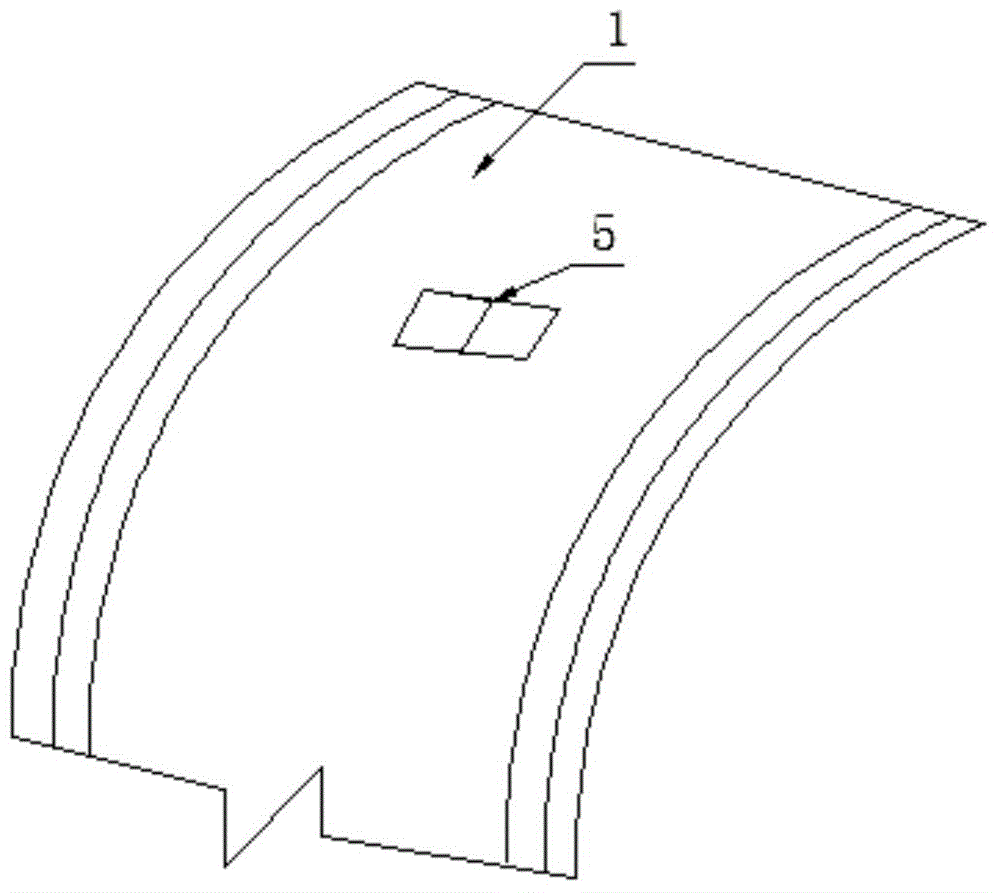

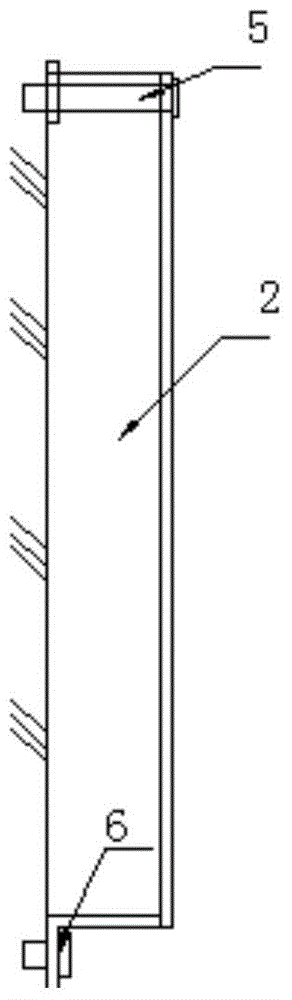

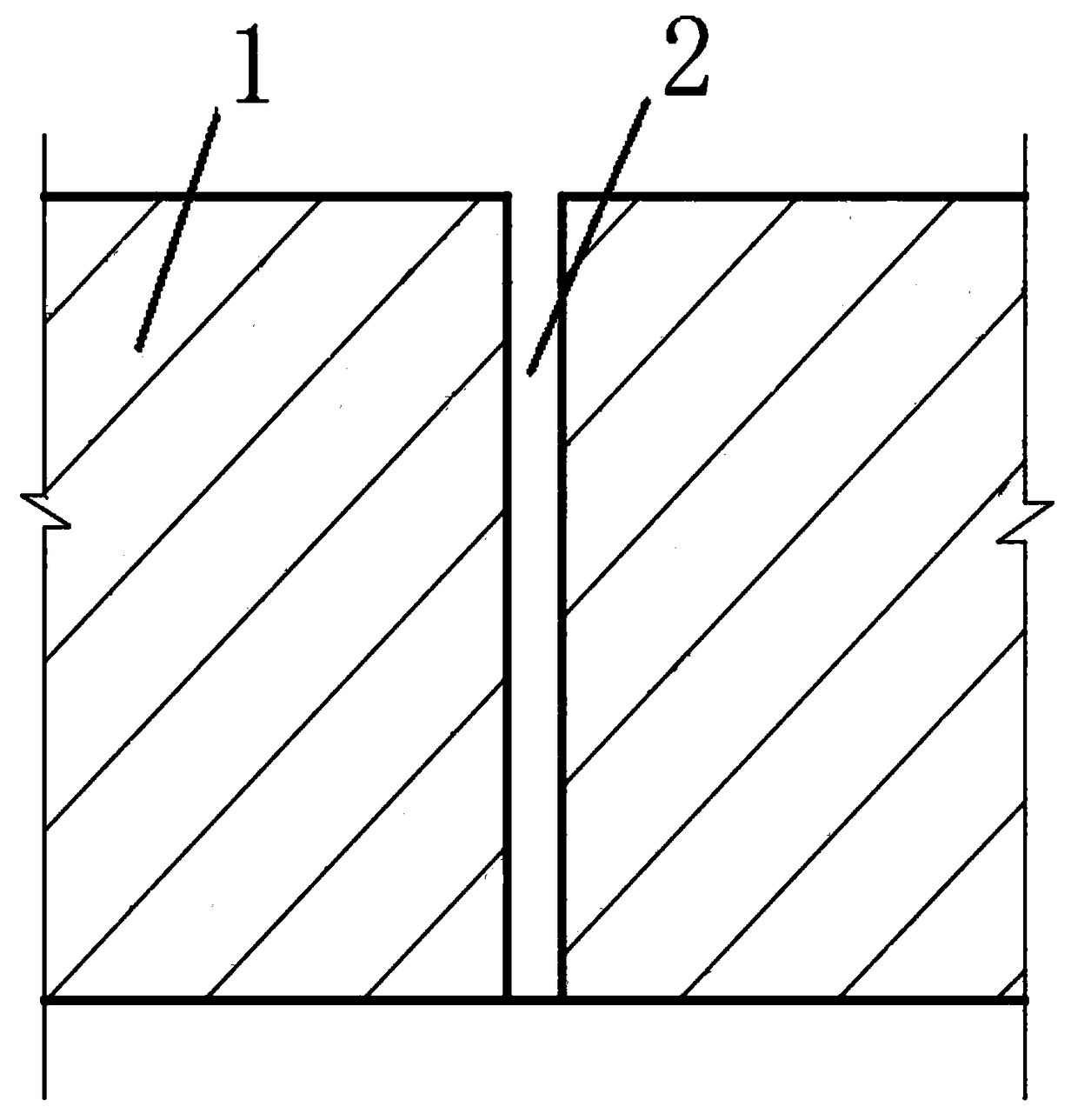

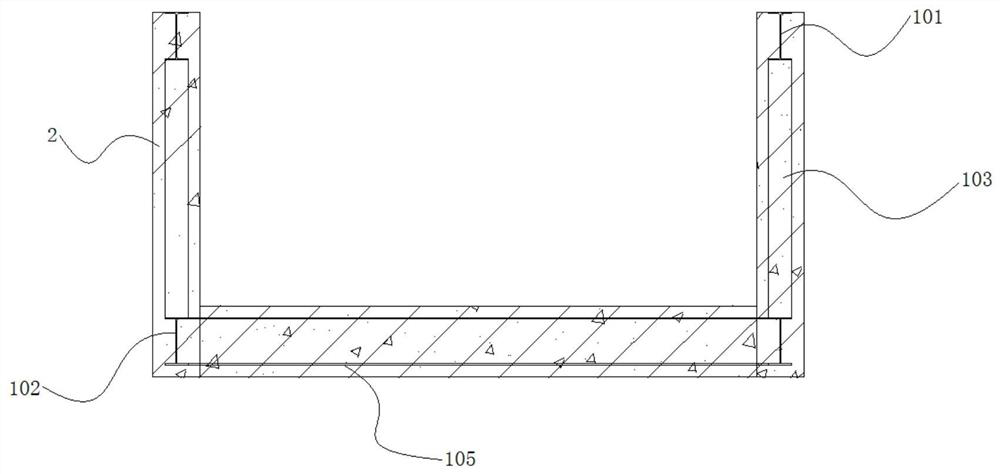

Prefabricated corrugated steel concrete composite pipe gallery

ActiveCN108286267BFast constructionGuarantee product qualityArtificial islandsUnderwater structuresReinforced concreteSheet steel

The invention discloses an assembled corrugated steel concrete combined comprehensive pipe rack, belongs to the field of civil engineering, and aims at solving the problems that the existing concretepipe rack field workload is large, and the construction time is long. The assembled corrugated steel concrete combined comprehensive pipe rack comprises two lateral shallow arches, a plurality of upper side shallow arches, a prefabricated bottom plate, prefabricated partition pieces and prefabricated longitudinal beams. The lateral shallow arches and the upper side shallow arches are formed in themanner that reinforced concrete is poured to the outer surfaces of corrugated steel plate arches. The lateral shallow arches are arranged on the left side and the right side of the prefabricated bottom plate correspondingly. The prefabricated longitudinal beams are arranged on the top faces of the prefabricated partition pieces. A plurality of bins are formed through division of the multiple prefabricated partition pieces, and the upper portion of each bin is covered with the corresponding upper side shallow arch. The steel-concrete combined system is adopted in the shallow arches in the comprehensive pipe rack, a pouring template is arranged, the concrete template erecting workload is reduced, and the components are obtained through industrialized production and prefabrication; and compared with traditional cast-in-place concrete comprehensive pipe racks, the production quality can be sufficiently guaranteed, and the construction speed is greatly increased.

Owner:HARBIN INST OF TECH

Construction method of ecological prefabricated reinforced concrete rapid trough drainage system

ActiveCN109577456BStrong connectionStrong resistance to deformationSewerage structuresPaving gutters/kerbsEnvironmental resource managementReinforced concrete

The invention relates to a construction method of an ecological prefabricated reinforced-concrete torrent channel drainage system. The construction method mainly includes prefabricating a torrent channel, prefabricating grass planting mould boxes, constructing channels, mounting force-eliminating steps, mounting standard prefabricated sections of the torrent channel, mounting a prefabricated sump,mounting the grass planting mould boxes and mounting a spherical detachable filter screen. The prefabricated sections of the torrent channel are fastened together in a 'stacking type' way and are integrally bundled together by a steel cable, the two ends of the steel cable are drawn onto pre-embedded pull rings of the prefabricated sump, and the grass planting mould boxes are embedded into the tops of the prefabricated sections of the torrent channel. The torrent channel drainage system based on the prefabricated design concept has the advantages of convenience and rapidness in mounting, highconstruction speed, ecological environment protection and the like; damage, such as hollow-out and scouring, of drained water to roadbeds due to the problems such as water seepage, water leakage andsettlement deformation of brickwork-type torrent channels is avoided, and good economic and technical benefits are achieved.

Owner:杭州昂创科技有限公司

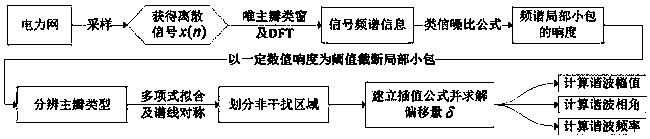

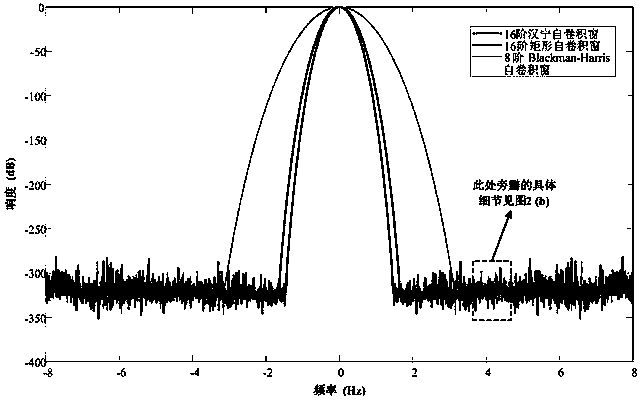

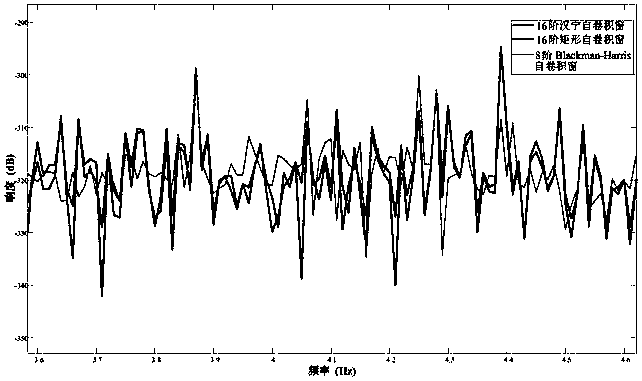

Interharmonic detection method based on polynomial fitting and non-interference area division

ActiveCN108427031BIdentify interferenceInterference AccurateSpectral/fourier analysisFrequency spectrumTransformer

The invention relates to a polynomial fitting and non-interference area division-based interharmonic detection method. The method comprises the steps that an electric power signal is converted into asecondary side dispersion signal through a power transformer; frequency spectrum information of the signal is obtained by means of a specific window function and discrete Fourier transform; sensitivity, relative to a peak value, of a spectral line near a spectrum packet is worked out by adopting a similar signal-to-noise ratio formula; the sensitivity of a certain numerical value serves as a threshold value to cut a packet, the truncation length serves as the basis to distinguish the main lobe type; then the symmetric axis of a spectral line at one side is built through polynomial fitting, thespectral line is symmetrized to the other side, and a non-interference area is marked out; finally, an interpolation formula is built according to the spectral line in the non-interference area, andthe offset is solved. By taking the offset as the basis, parameters such as the amplitude, the frequency and the phase angle of a harmonic wave can be worked out. Accordingly, whether or not main lobejamming occurs in the frequency domain of the signal can be distinguished, and on the condition that main lobe jamming occurs, the area which is not disturbed or disturbed less can be effectively marked out.

Owner:CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com