Secant pile construction cold joint treatment structure and method

A technology of occlusal piles and cold joints, which is used in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems affecting the integrity of foundation pit, anti-leakage, anti-seepage and anti-leakage performance to be strengthened, delaying occlusal piles Construction and other problems, to achieve the effect of strong anti-leakage ability, high overall stability, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

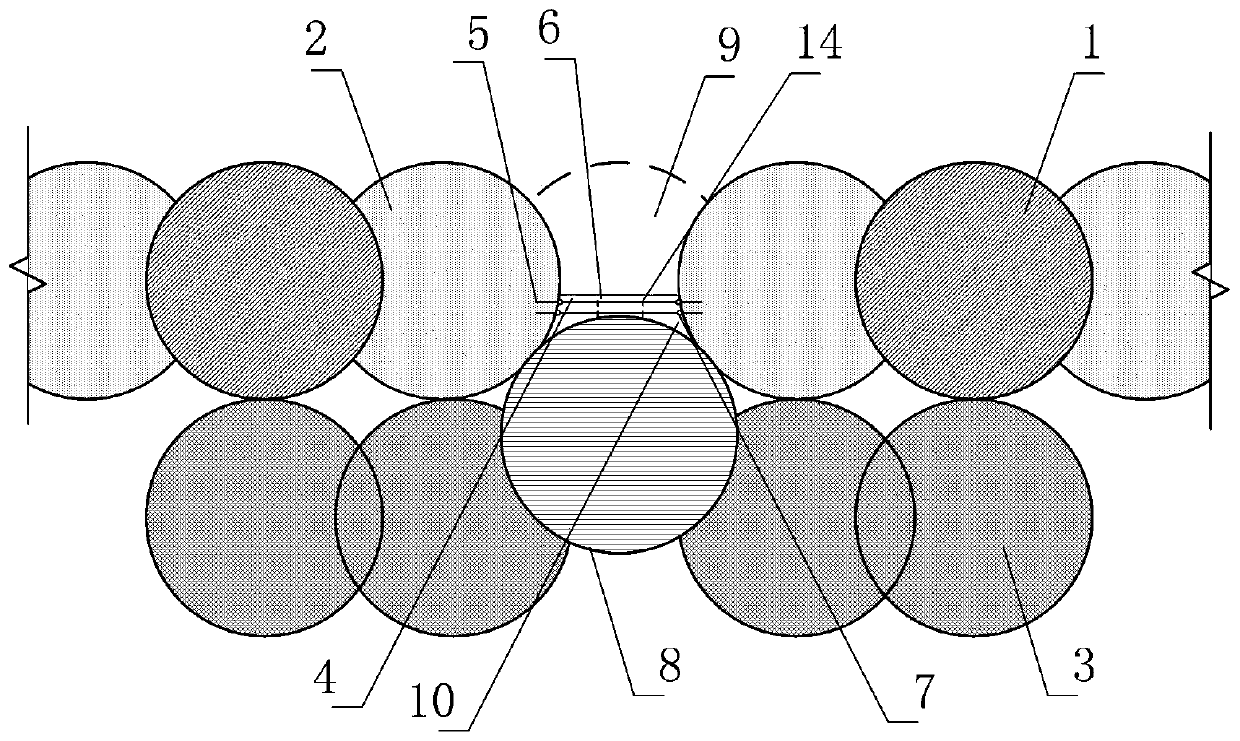

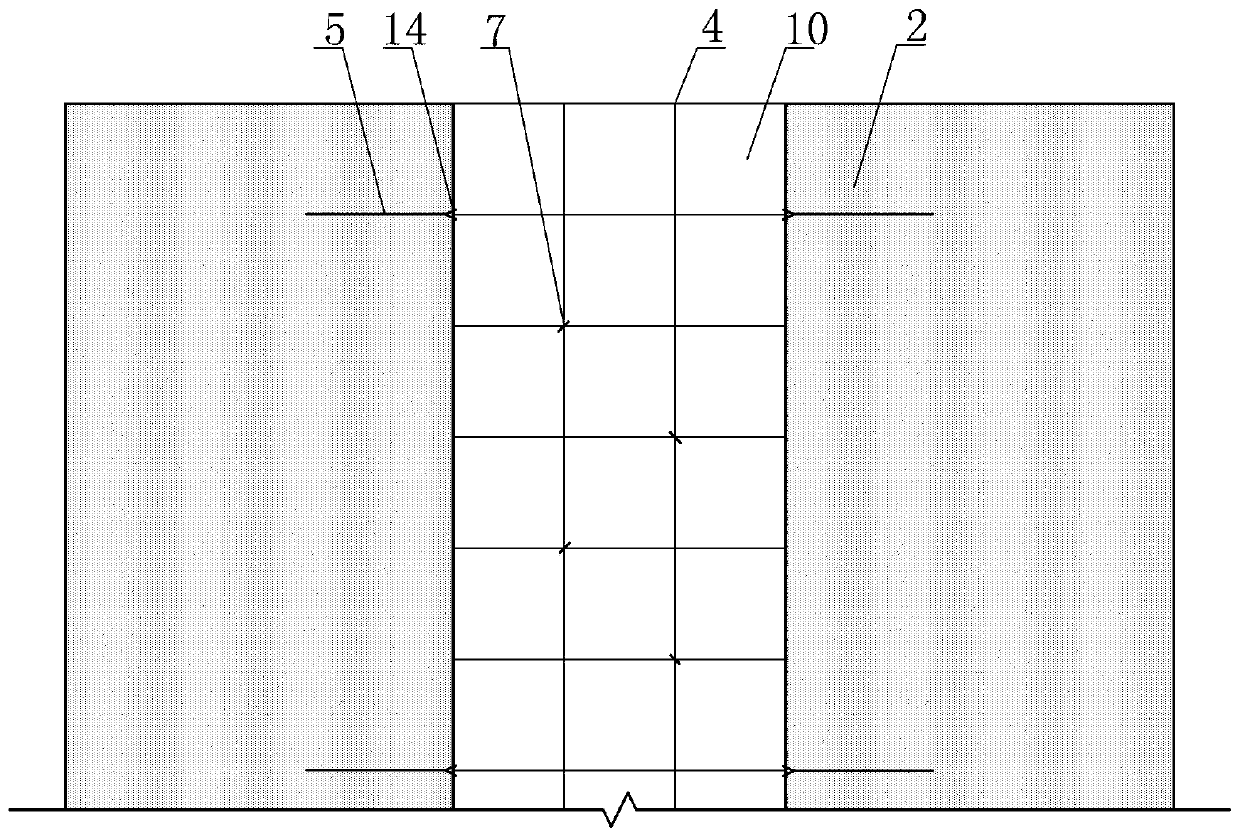

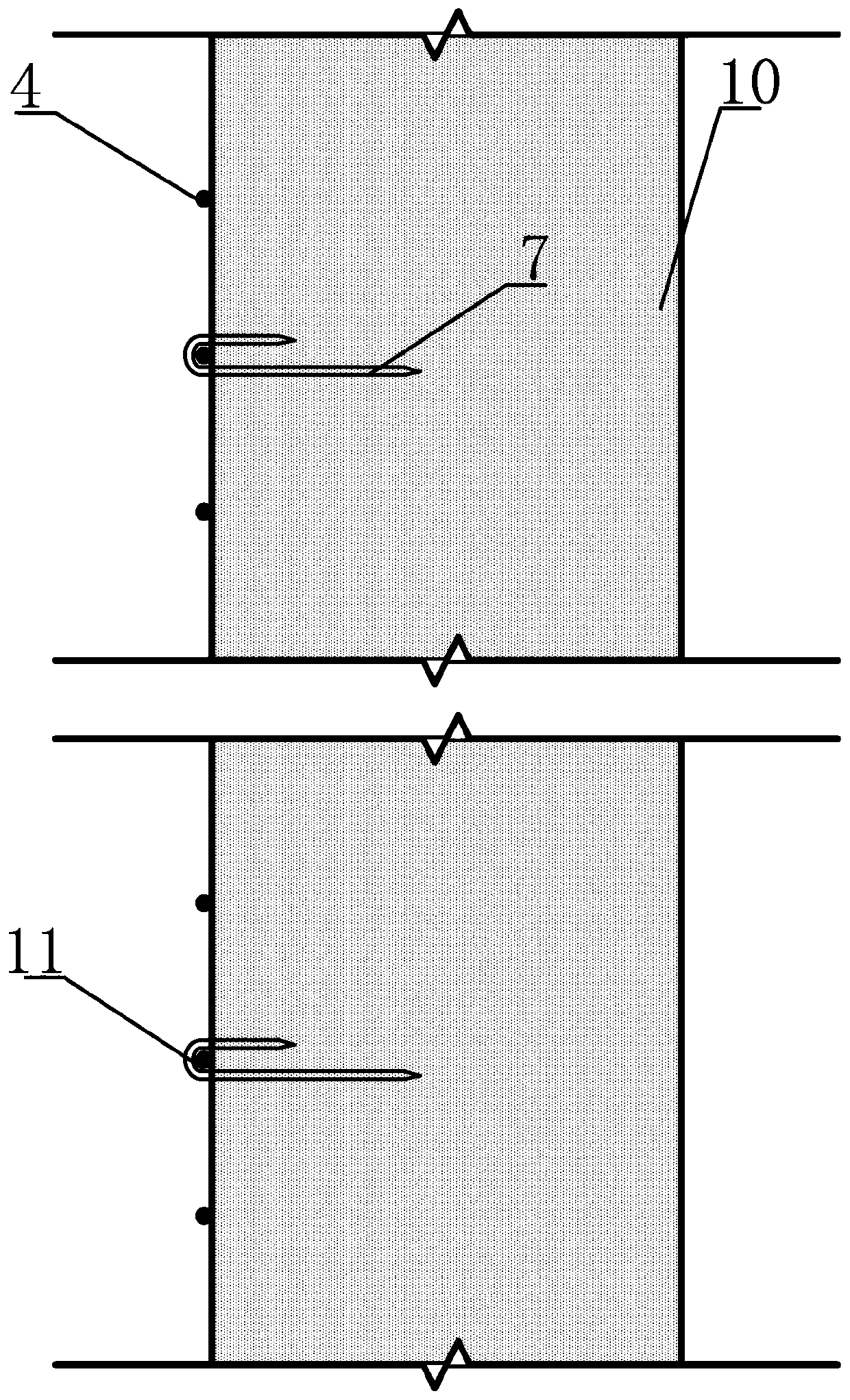

Embodiment 1

[0028] The cold joint treatment structure of the occlusal pile construction described in this embodiment includes the occlusal pile 1, the occlusal pile 2, the rotary grouting pile 3, the steel mesh 4, the C18 ribbed steel bar 5, the concrete layer 6, and the Y-shaped connection Pieces 7, Reinforced piles 8, Soil between occlusal plain piles 10, Steel mesh nodes 11, Glue for planting bars 12, Y-shaped connectors and ribbed steel welds 13, U-shaped connectors 14; C18 belt The ribbed reinforcement 5 is welded to the bottom of the Y-shaped connector 7, and the welding point is the Y-shaped connector and the ribbed reinforcement welding point 13; the occlusal pile 2 is used to plant reinforcement glue 12 to plant reinforcement C18 with ribbed reinforcement 5 and steel mesh The longitudinal bars 15 of the steel mesh and the transverse bars 16 of the steel mesh are connected by welding or binding to form the steel mesh 4, and the connection point between the longitudinal bars 15 of t...

Embodiment 2

[0032]In this embodiment, the structure described in Example 1 is used in the construction process of a certain subway station. The main structure of the occlusal pile construction cold joint treatment structure includes 1000mm occlusal pile 硂 pile 1, 1000mm occlusal pile plain pile 2, and 1000 mm rotary spray pile 3 , 8mm@200×200mm steel mesh sheet 4, C18 ribbed steel bar 5, 200mm thick C20 shotcrete layer 6, Y-shaped connector 7, 1000mm reinforced stone pile 8, 1000mm unconstructed stone pile 9, occlusal plain pile Inter-soil 10, steel mesh node 11, planting glue 12, Y-shaped connector and C18 ribbed steel welding spot 13, U-shaped connector 14, steel mesh longitudinal reinforcement 15, steel mesh transverse reinforcement 16; Y The outer two ends of the type connector 7 are provided with crotch hooks, and the bottoms of the two crotch hooks are welded and connected. Made of light round steel bars; the U-shaped ends of the U-shaped connector 14 have lengths of 200mm and 100mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com