Construction method of ecological prefabricated reinforced concrete rapid trough drainage system

A reinforced concrete and prefabricated assembly technology, applied in waterway systems, sewer systems, drainage structures, etc., can solve problems such as reducing water flow energy, subgrade settlement deformation, and insufficient mortar, and achieves reduction of water flow energy and anti-leakage. Strong ability, reducing the effect of erosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

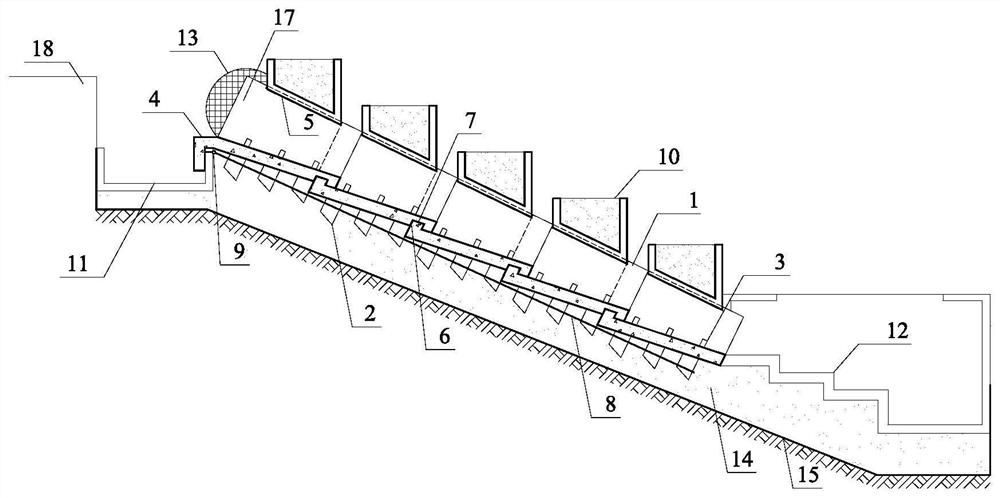

[0038]The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples. The construction method of the drainage system of the rapid flow trough of the subgrade slope of a highway, the slope of the subgrade slope is β, and the construction method of the ecological prefabricated reinforced concrete rapid trough drainage system is adopted.

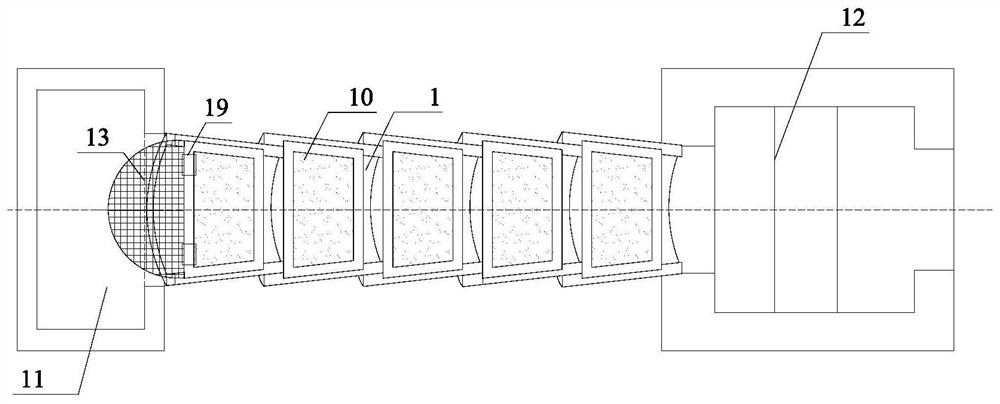

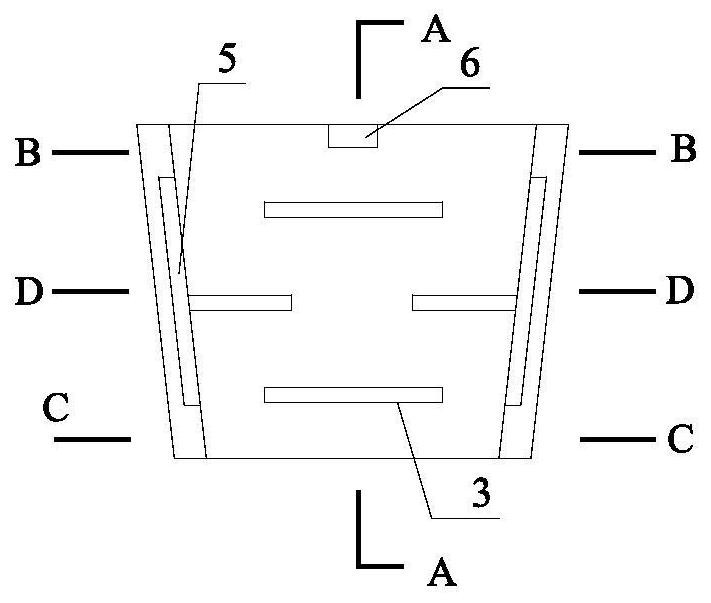

[0039] combined with figure 1 with figure 2 As shown, the eco-type prefabricated reinforced concrete rapid trough drainage system involved in the present invention includes a standard prefabricated section 1 of the rapid trough, a non-standard prefabricated section 17 of the rapid trough, a steel cable 8, a prefabricated sump 11, a stilling step 12, grass planting Mold box 10, spherical detachable filter screen 13, crushed stone cushion 14, waterproof geotextile 15; one end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com