Underground continuous wall construction method crossing city pipelines

A technology of underground diaphragm wall and construction method, applied in sheet pile wall, infrastructure engineering, construction and other directions, can solve the problems of difficulty in hoisting the steel cage, affect the stability, inaccuracy, etc., to avoid pipeline relocation, anti-leakage, etc. The effect of strong ability and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose and features of the present invention more obvious and understandable, the present invention will be further described by giving preferred embodiments and in conjunction with the accompanying drawings.

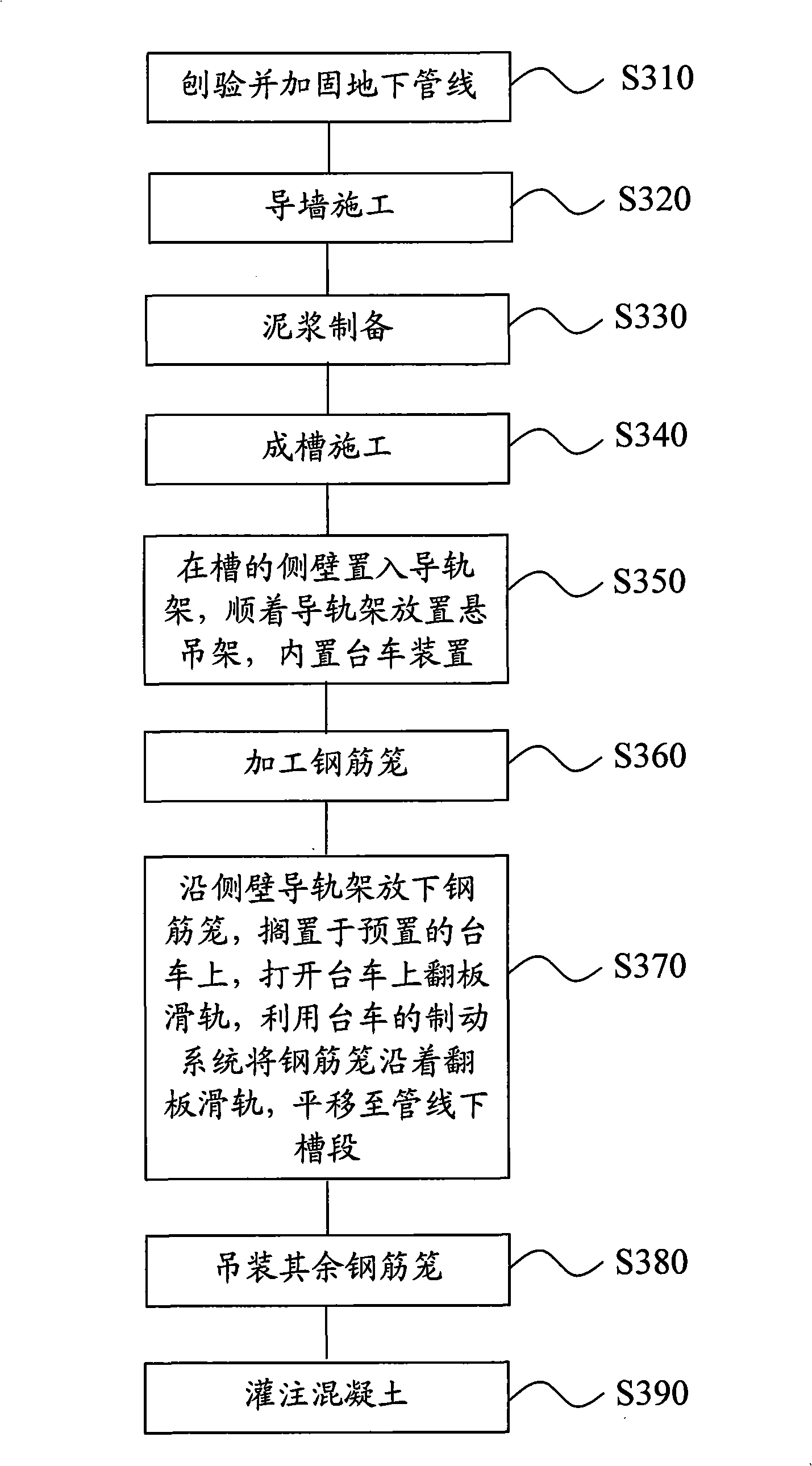

[0017] See image 3 It is a flow chart of the construction method provided by an embodiment of the present invention.

[0018] Step S310: Examine and strengthen the underground pipelines. Where there are pipelines, steel pipes or section steel can be added to reinforce and protect the pipelines at a place 50cm below the pipelines. It will not be damaged during construction.

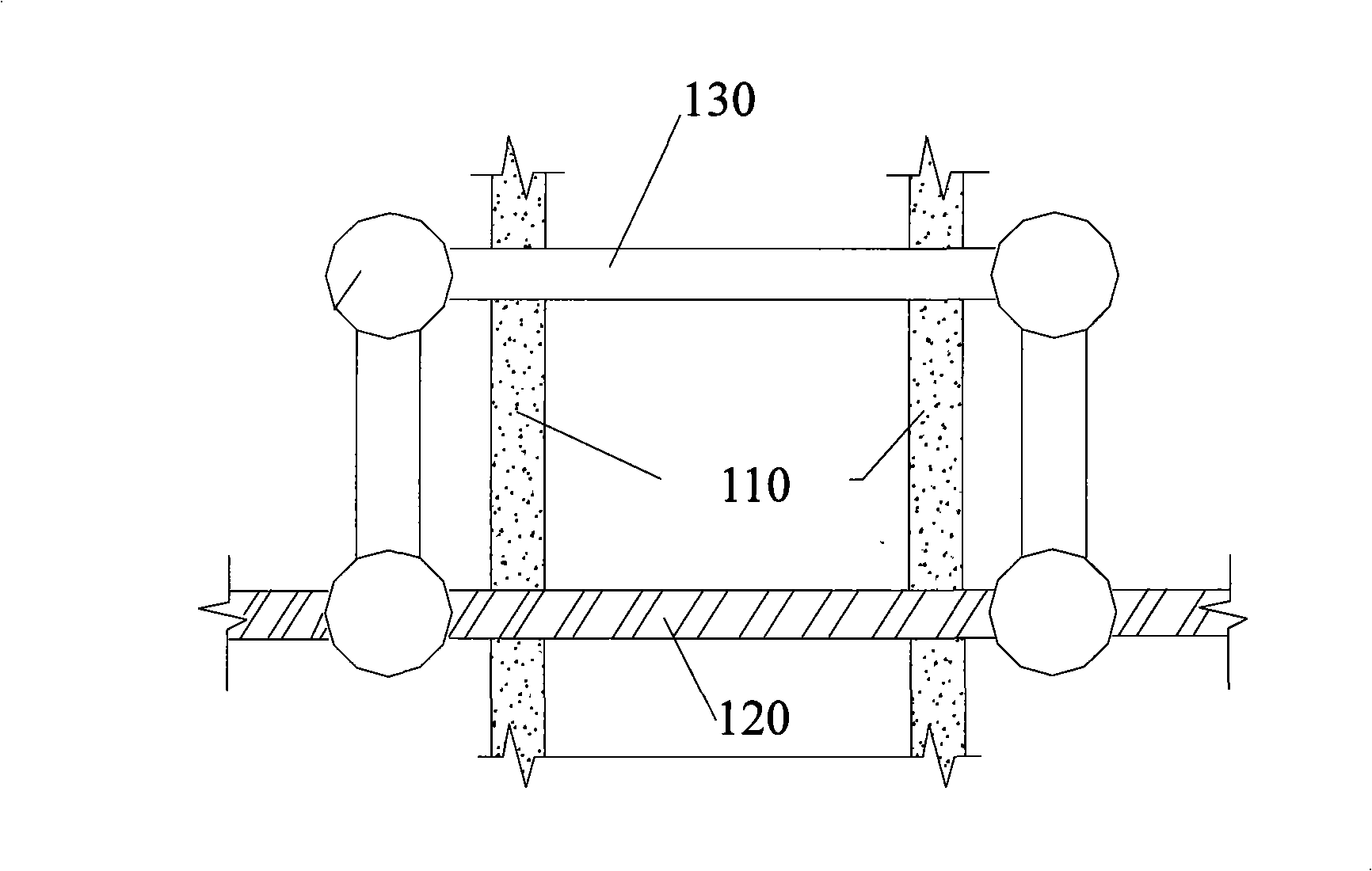

[0019] Step S320: guide wall construction. When excavating the guide wall, in order to facilitate the protection of underground pipelines and adjust the position of the steel cage after lowering, the width of the guide wall should be increased appropriately. For example, when excavating a deep groove with a width of 120cm and a depth of 120-200cm, the depth should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com