Method for treating operating tunnel leakage with water diversion plate

A water deflector and tunnel technology, applied in drainage, mining equipment, earth-moving drilling, etc., can solve problems such as large water leakage in operating tunnels, and achieve the effects of shortening repair time, less consumables, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

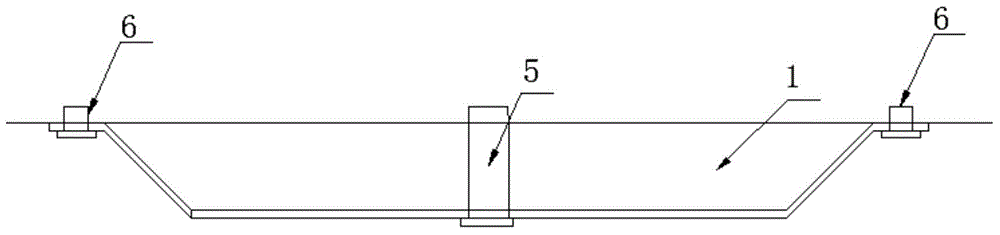

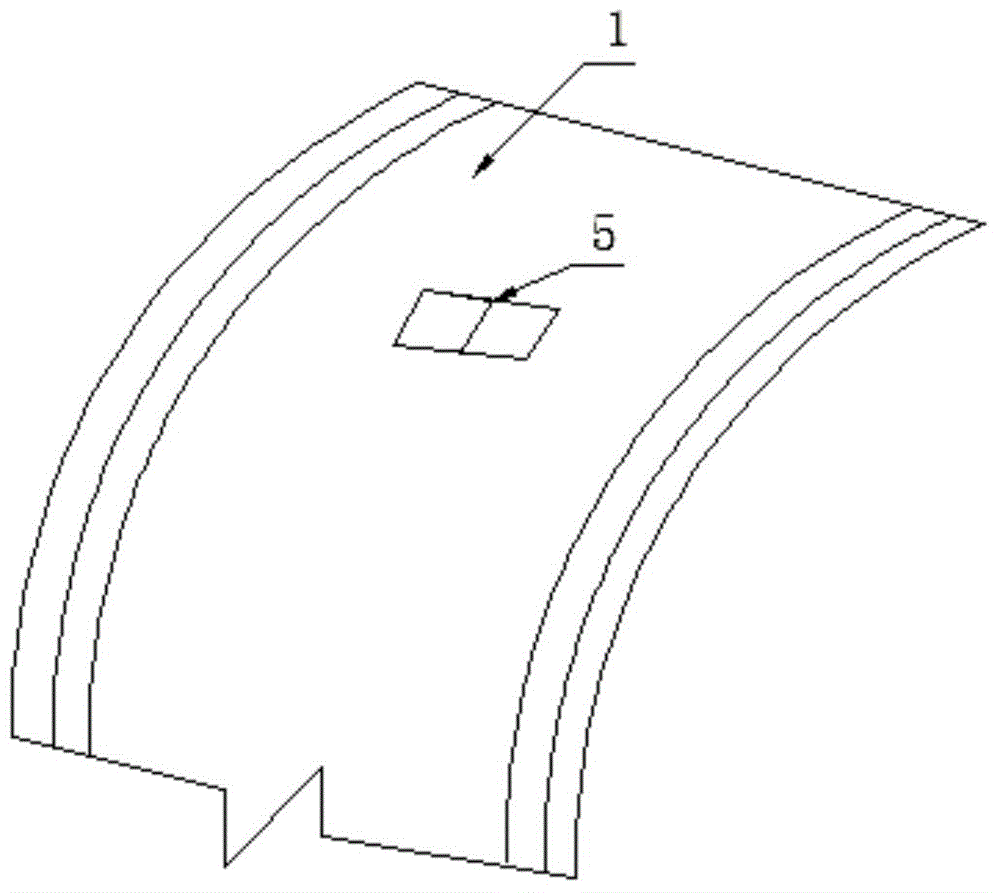

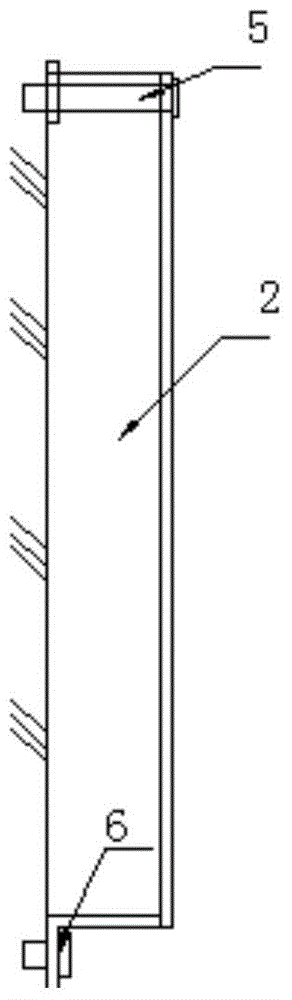

[0035] When there is water leakage in the operating tunnel, it can first be investigated and dealt with on-site to determine the severity of the leakage problem and record it. According to the requirements of the specification, the disease situation is graded and treated, and the diseased part is marked with ink and relevant key information is marked on the diseased part. Rinse and clean the diseased part with high-pressure water, and cut out two grooves with a depth of about 5mm on both sides of the leak point, and insert the two wings of the water guide plate here, and make an arched guide according to actual requirements. Water structure 1 (such as figure 1 and figure 2 shown), horizontal water guide structure 2 (such as image 3 and Figure 4 shown), longitudinal water guide structure 3 (such as Figure 5 and Image 6 shown) and side ditch water guide structure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com