Decorative sheet for building decoration

A technology of architectural decoration and decorative panels, which is applied in the fields of architecture, building construction, sustainable waste treatment, etc. It can solve the problems of magnesite board moisture absorption and halogen return, short service life, easy aging, etc., and achieve a smooth surface and ensure Long service life and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

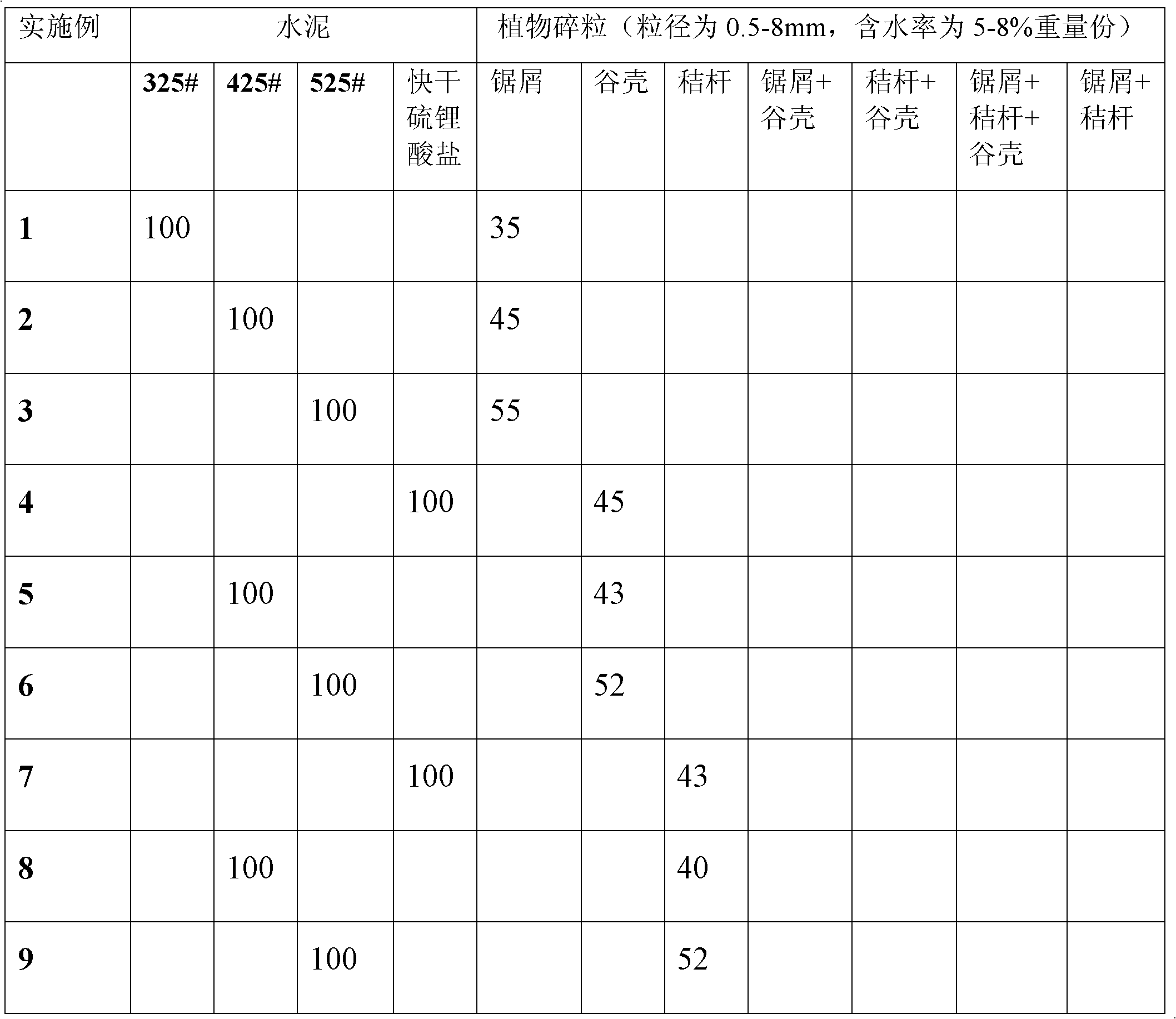

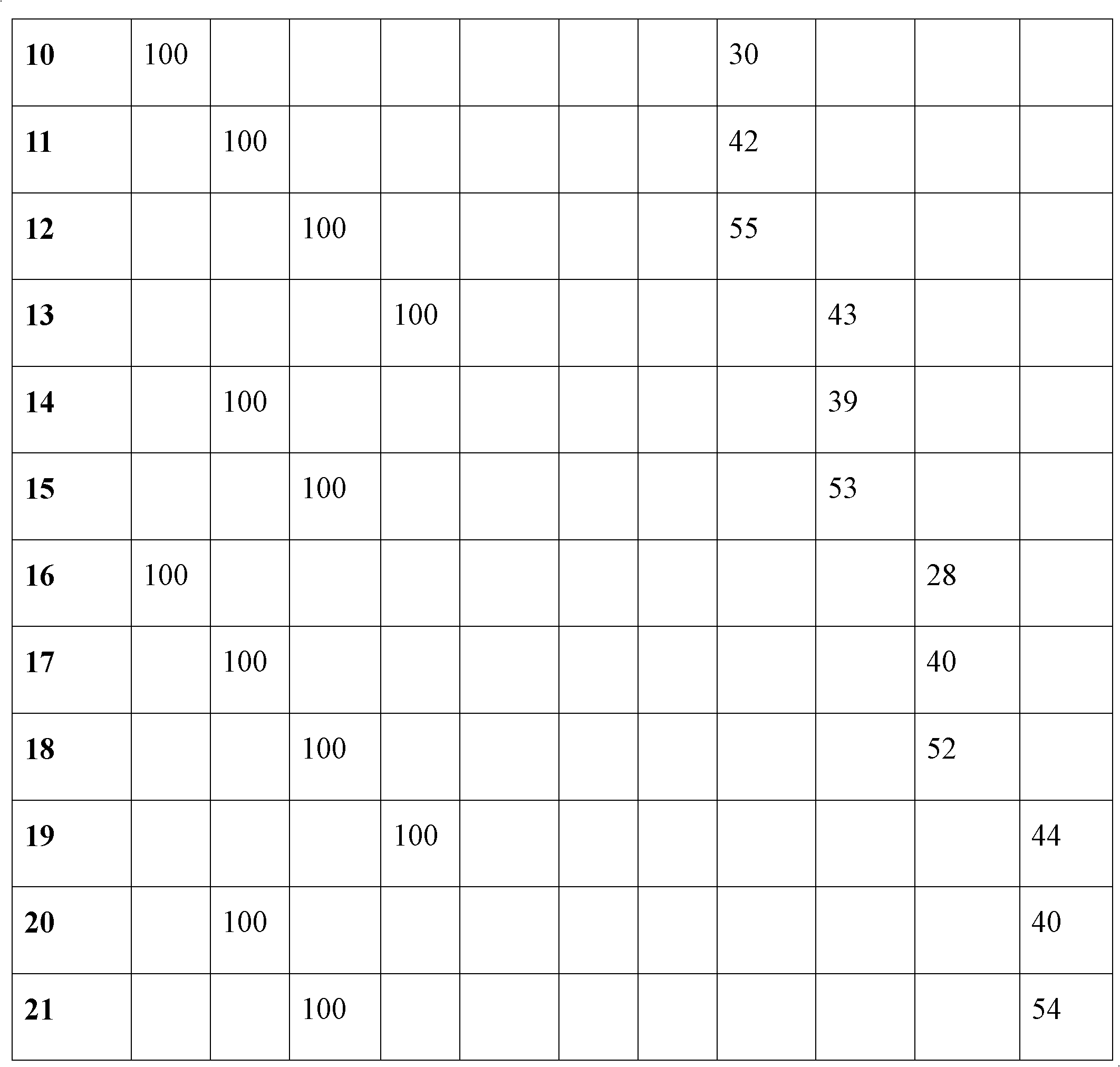

[0013] Unit: kilogram

[0014]

[0015]

[0016] Get the cement of arbitrary proportioning in the example 1-21, plant crumb, add water and stir and mix evenly with a mixer, the weight portion of water is 80-100 parts. Lay non-woven fabric (this layer of non-woven fabric can also be used) and alkali-resistant glass fiber grid cloth or alkali-resistant glass fiber cloth on the bottom formwork used as a pallet, and put the cement and plant debris mixture that is stirred evenly. On the alkali-resistant glass fiber mesh cloth or alkali-resistant glass fiber cloth, it is sent to the first pressing roller, and the first pressing roller puts another layer of alkali-resistant glass fiber mesh cloth or alkali-resistant glass fiber cloth and non-woven fabric Press on the top of the cement and plant crushed mixture, start the vibrator at the same time, enter the second pressure roller for re-pressing, it will be formed after exiting the machine, and it will be cured and shaped in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com