Lightweight and energy-saving windward type overhead passenger car air conditioner

An overhead, passenger car technology, applied in vehicle parts, air handling equipment, heating/cooling equipment, etc., can solve the problems of high manufacturing cost, high labor intensity, and difficult assembly, and achieves lower production costs, improved production efficiency, and reduced production costs. Effect of Welding Volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The specific implementations of the light-weight and energy-saving windward-mounted passenger car air conditioner of the present invention will be further described below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following implementations. In addition, statement: the "direction" in the description of the following specific embodiments is explained by the direction of the structure in the drawings of the description, not necessarily the direction in actual operation.

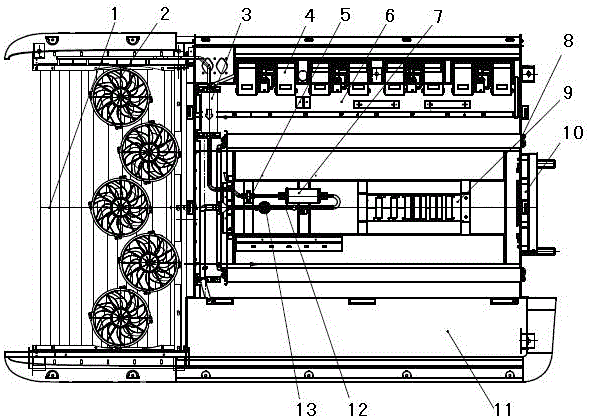

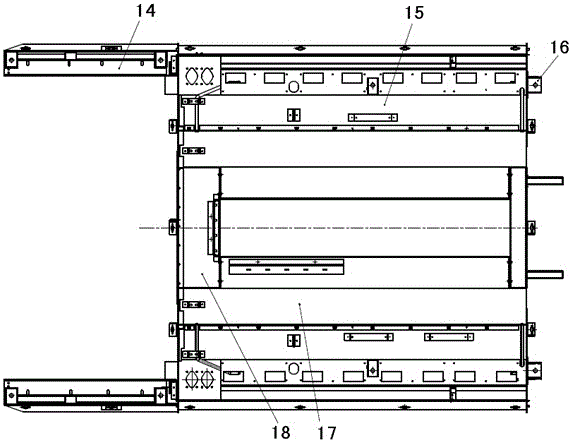

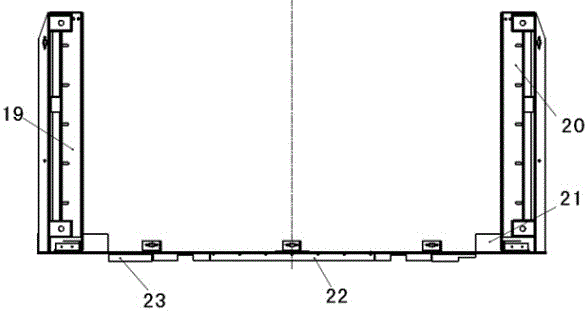

[0066] see figure 1 . A light-weight, energy-saving, windward-mounted air conditioner for passenger cars, comprising a condenser core assembly 1, a condensing fan 2, a liquid receiver 3, an evaporating fan 4, a stop valve 5, a bottom shell assembly 6, a dryer 7, and an evaporator Core assembly 8, electric control box and wiring harness 9, fresh air mechanism 10, air conditioning pipeline 12 and expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com