LED lamp production process and LED lamp welding jig

A technology of LED lamps and welding fixtures, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency, slow heat transfer, difficult to move, etc., to improve product quality, easy molding, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

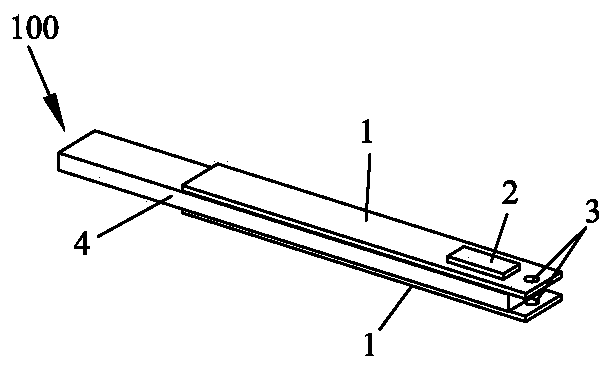

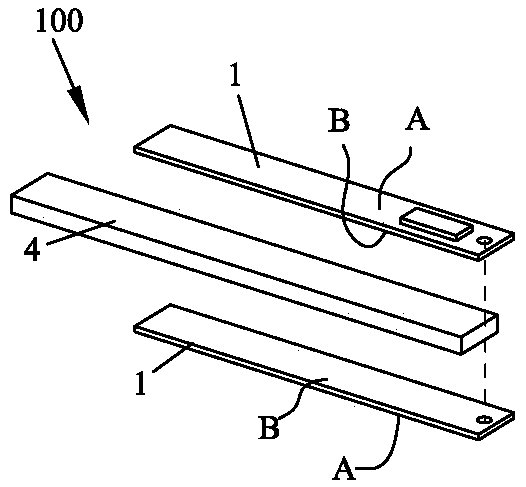

[0053] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the LED lamp 100 of the preferred embodiment of the present invention, which is a super heat dissipation LED lamp, which can be used in the fields of household environment lighting, automobile lamps, street lamps and the like.

[0054]Wherein, the structure of the LED lamp 100 includes two PCB components and a heat pipe 4 interposed therebetween. The PCB assembly is composed of a PCB 1 and a light-emitting element 2. The PCB 1 has a side A and a side B. The light-emitting element 2 is patch-welded on the A-side of the PCB 1, and the B-side is welded on the heat pipe 4. In this embodiment, the light-emitting element 2 is composed of a plurality of patch-type LED lamp beads. The heat pipe 4 is a vacuum copper pipe. The head end of the PCB 1 protrudes from the front end of the heat pipe 4 , and a positioning hole 3 is provided on the head end of the PCB 1 . The PCB1 is shorter than the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com