Reinforced concrete hollow prefabricated component plate

A reinforced concrete slab and reinforced concrete technology, which is applied to building components, floor slabs, structural elements, etc., can solve problems such as poor crack resistance, weak connection force, and easy cracking, and achieve strong leakage resistance, strong connection force, and anti-corrosion good cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

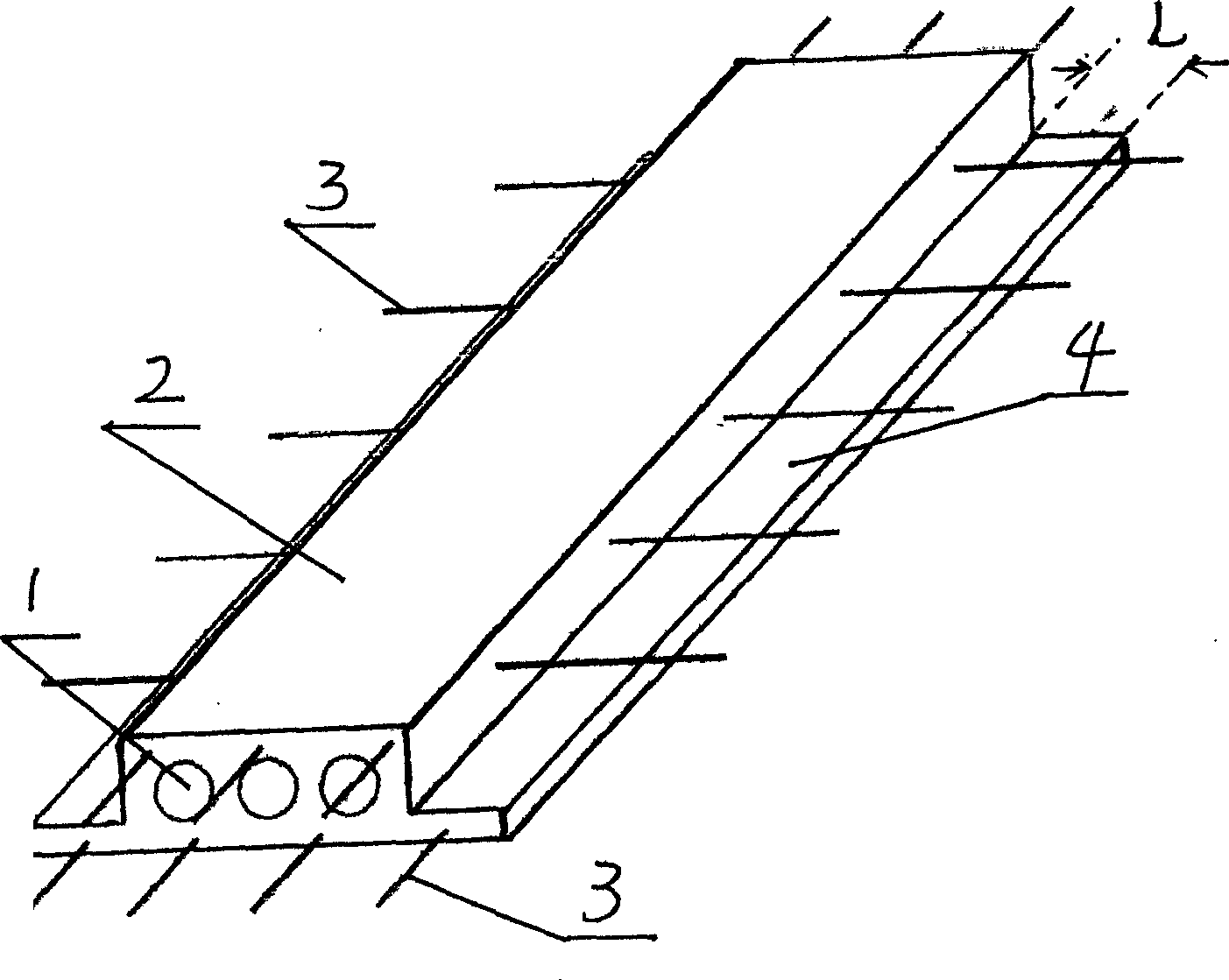

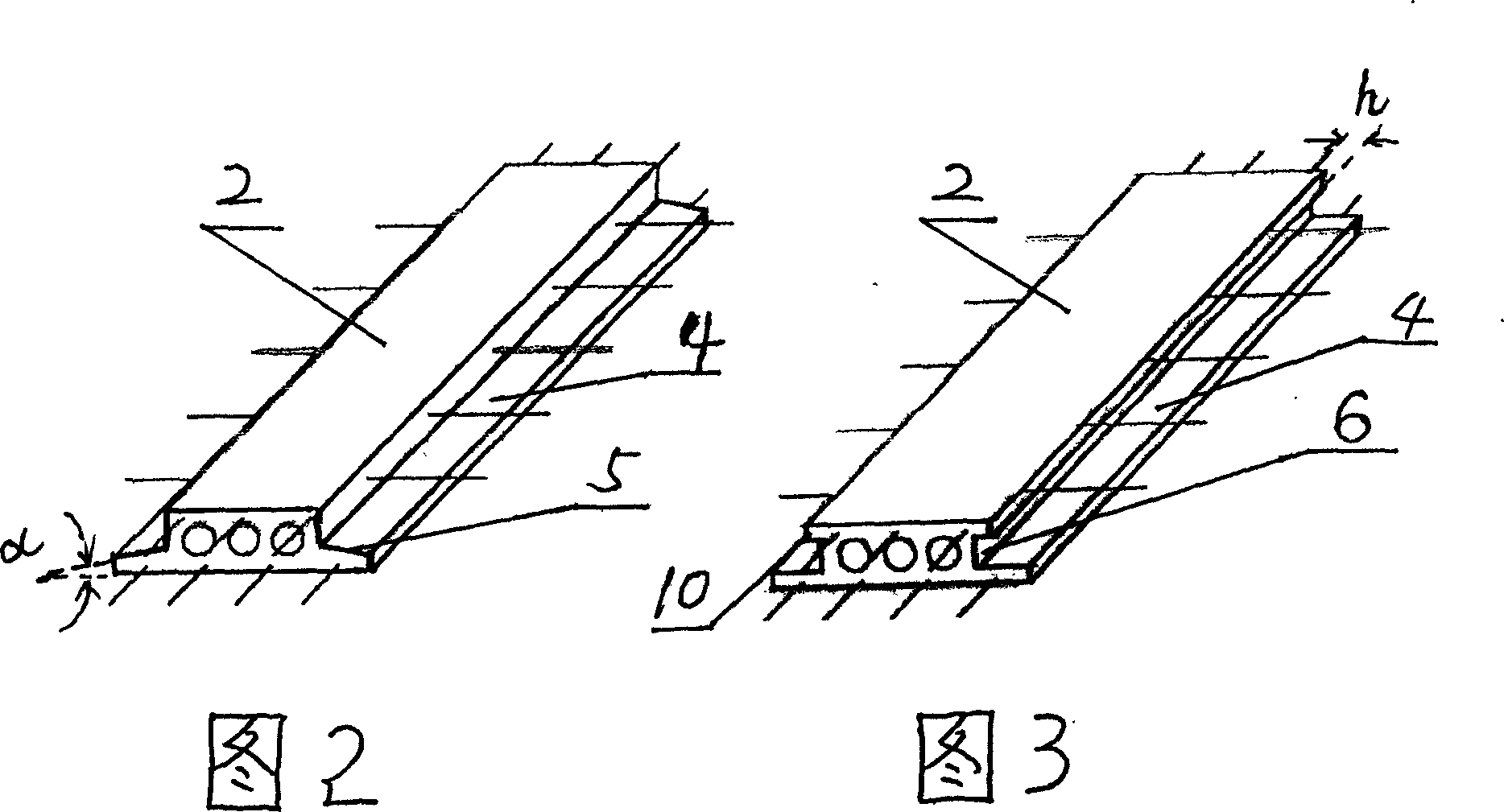

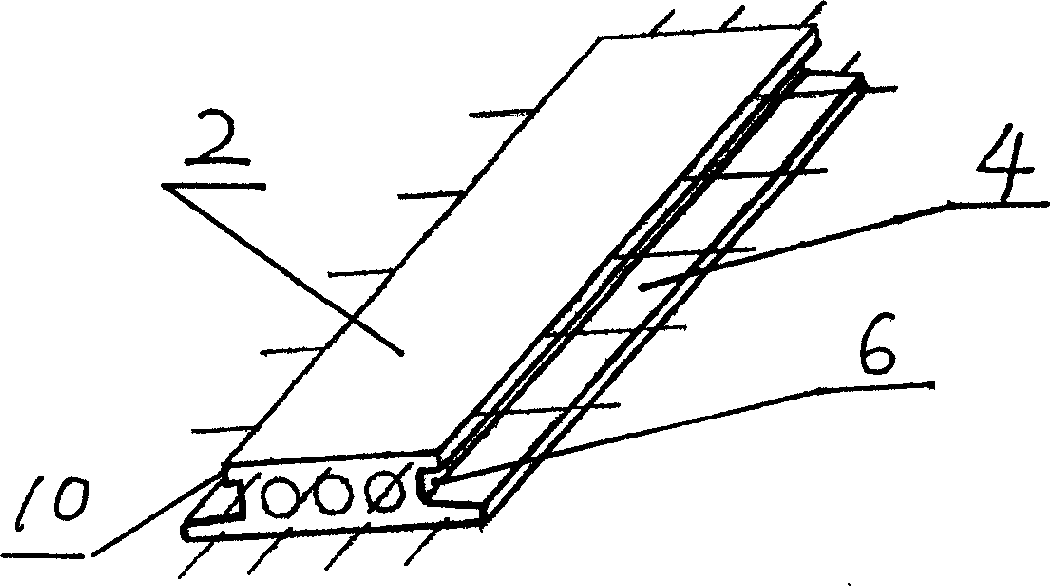

[0012] refer to figure 1 , Figure 2, Figure 3, Figure 4 , Figure 5 , Image 6 , the reinforced concrete hollow prefabricated member board includes a reinforced concrete board body 2, a through hole 1 is opened in the middle, and lower protruding blocks 4 are arranged on both sides of the reinforced concrete board body 2, and the width of the lower protruding block 4 is L≥ 3.5 cm, which can not only function as a template, but also stagger the upper and lower joints. There are connecting steel bars 3 on both sides of the board body 2. The upper plane 5 of the lower protruding block 4 can be parallel to the bottom plane, or it can form an angle α (α≤45 degrees), so that the lower protruding block 4 has a shape with a thick inside and a thin outside, which not only increases the bending resistance of the lower protruding block 4 force, without affecting the thickness of the cast-in-place concrete 7 at the joint. There are also upper protruding blocks 10 on the tops of both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com