Barrier film and laminated packaging material comprising the film and packaging container made therefrom

A packaging material and barrier layer technology, which is applied in the field of liquid food packaging, manufacturing the packaging material, and packaging containers, can solve the problem of high manufacturing cost of the barrier film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The polyester contained in the barrier layer may be obtained by condensation reaction between furandicarboxylic acid or its dimethyl ester and diols such as ethylene glycol, 1,3-propanediol (trimethylene glycol) , 2-methyl-1,3-propanediol, 1,4-butanediol, diethylene glycol, neopentyl glycol, tetramethylcyclobutanediol or isosorbide.

[0026] Preferred polyesters are polyethylene furandicarboxylate (PEF) and polytrimethylene furandicarboxylate (PTF), the latter also known as polytrimethylene furandicarboxylate (PPF). These polymers may comprise further monomers, preferably selected from those above.

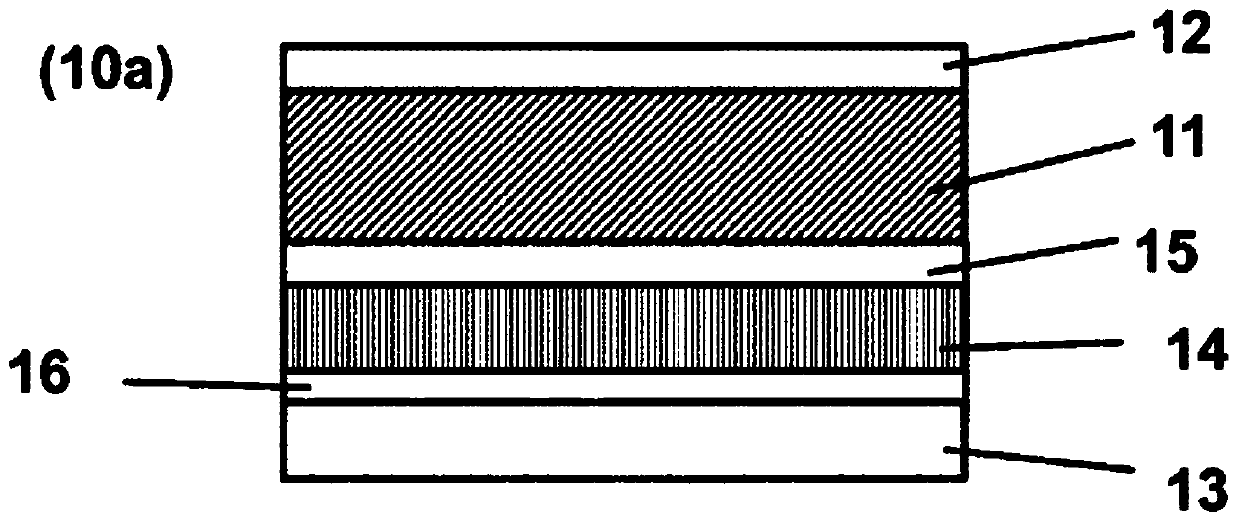

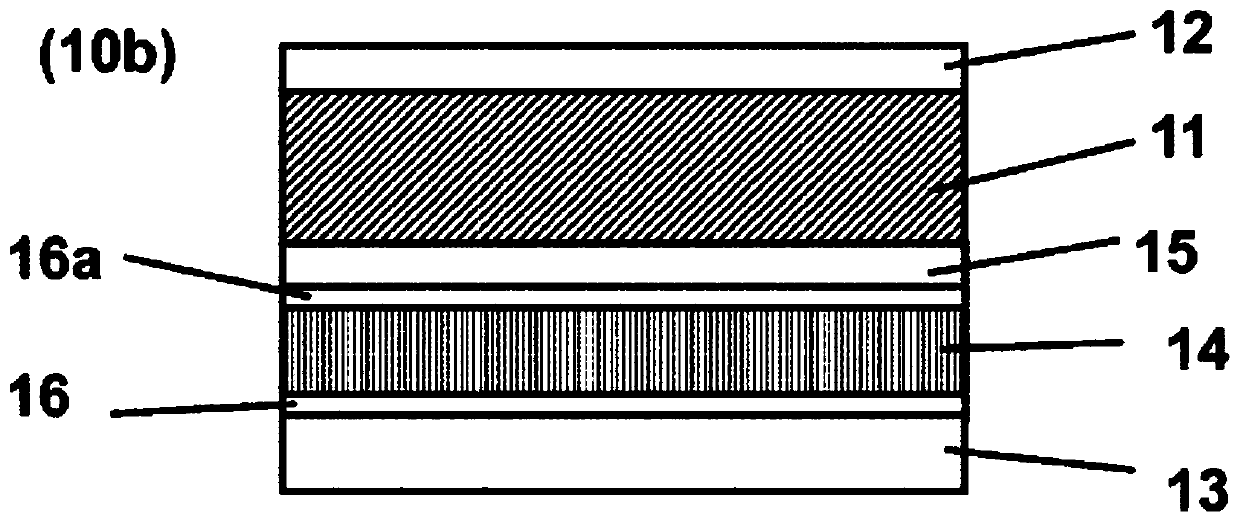

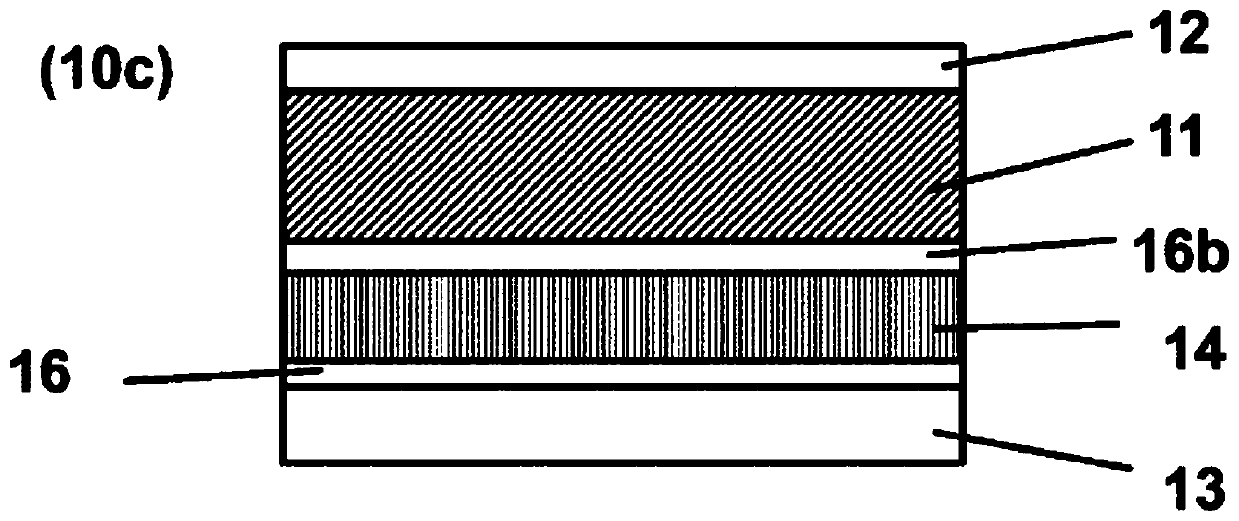

[0027]Barrier layers comprising such polyesters may be applied to the laminated packaging material according to the invention in the form of preformed oriented films, such as blown films or cast oriented films. Both types of films are produced by extruding a molten polyester composition into a film sheet, which is subsequently stretched into a relatively thin but stable fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com