Coating composition, printed packaging laminate, method for manufacturing of the packaging laminate and packaging container

A technology for packaging containers and compositions, applied to coating compositions, capable of solving problems such as insufficient adhesion, spots, and reduced image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

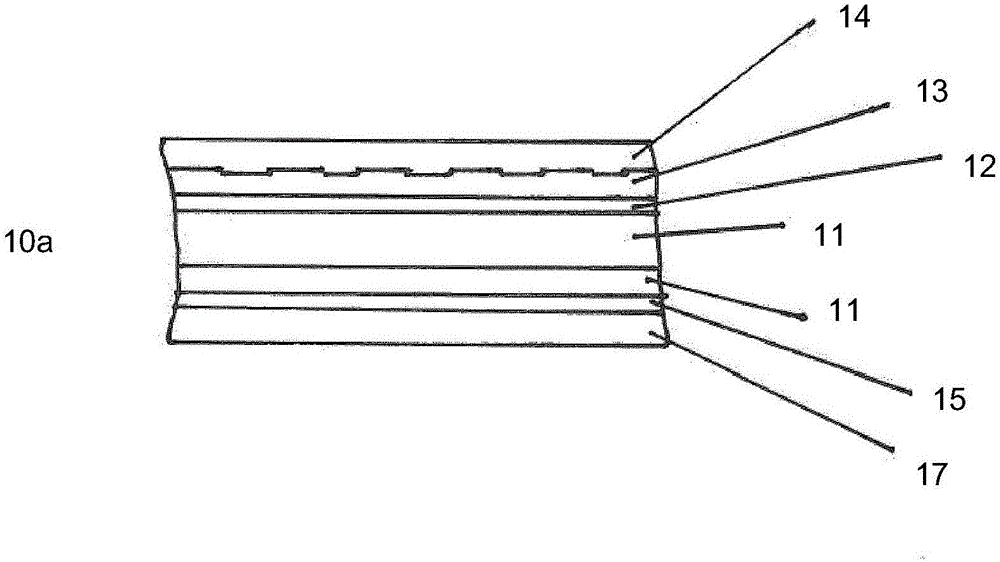

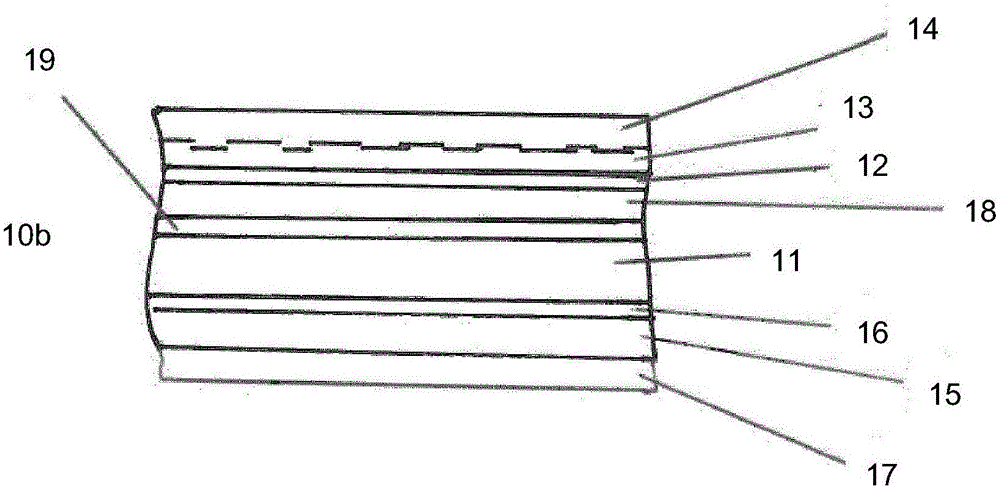

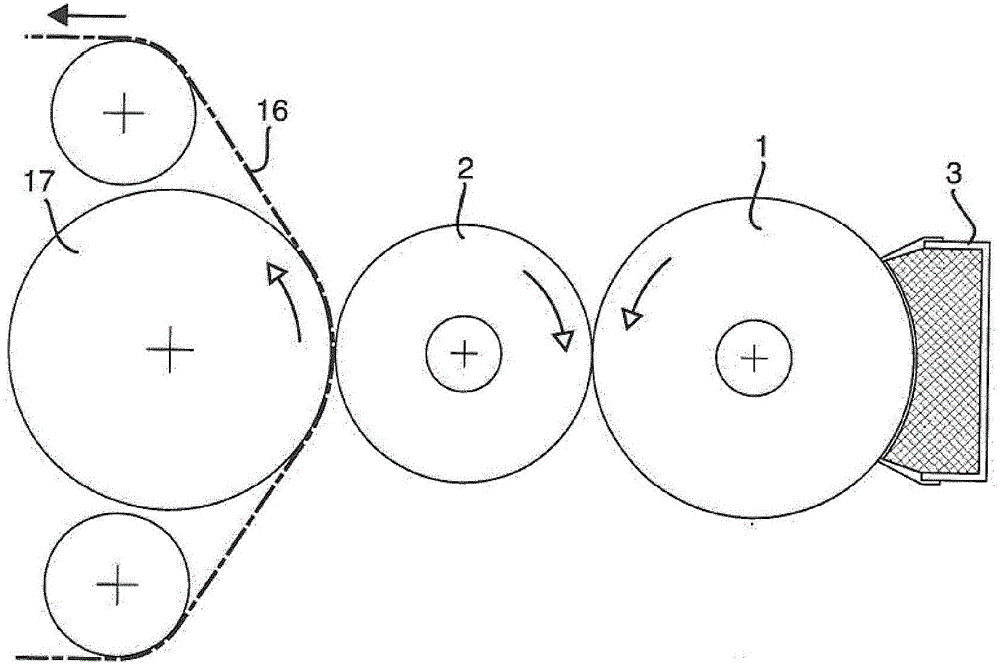

[0032] Thus, the laminated packaging material for food packaging according to the invention comprises a substrate layer on its surface intended to be directed towards the outside of a packaging container made of the packaging material on its first side surface, A precoat for receiving a printed decorative layer of an aqueous pigment-based inkjet printing ink, a pigmented inkjet printed decorative layer, and an outermost thermoplastic polymer layer further laminated to said printed decorative layer are applied in this order to Thereon, wherein the precoat composition comprises a water-soluble polyvalent cationic salt and the salt concentration applied on the substrate surface is 0.02 g / m 2 to 0.1g / m 2 , preferably from 0.02g / m 2 to 0.05g / m 2 dry coating weight.

[0033] According to one embodiment of the invention, said substrate is paper or paperboard constituting the core layer of said laminated packaging material.

[0034] According to a further embodiment, the precoat c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com