Underground continuous wall construction method of city-across pipeline

A technology of underground diaphragm wall and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., and can solve the problem that the closure of underground diaphragm wall structure affects the stability of foundation pit, and the closure of underground diaphragm wall structure cannot be guaranteed. The stability coefficient is not high, and the effects of avoiding pipeline relocation, low construction risk and strong anti-leakage ability are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

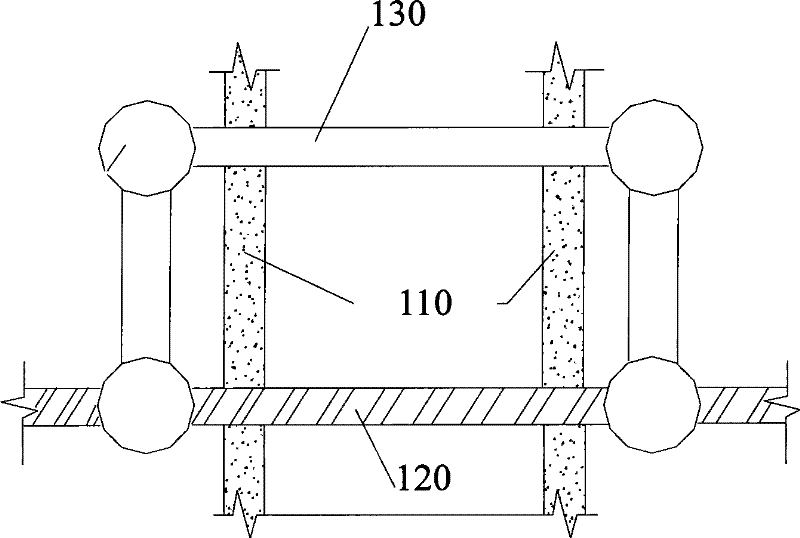

Image

Examples

Embodiment Construction

[0020] In order to make the purpose and features of the present invention more obvious and understandable, the present invention will be further described by giving preferred embodiments and in conjunction with the accompanying drawings.

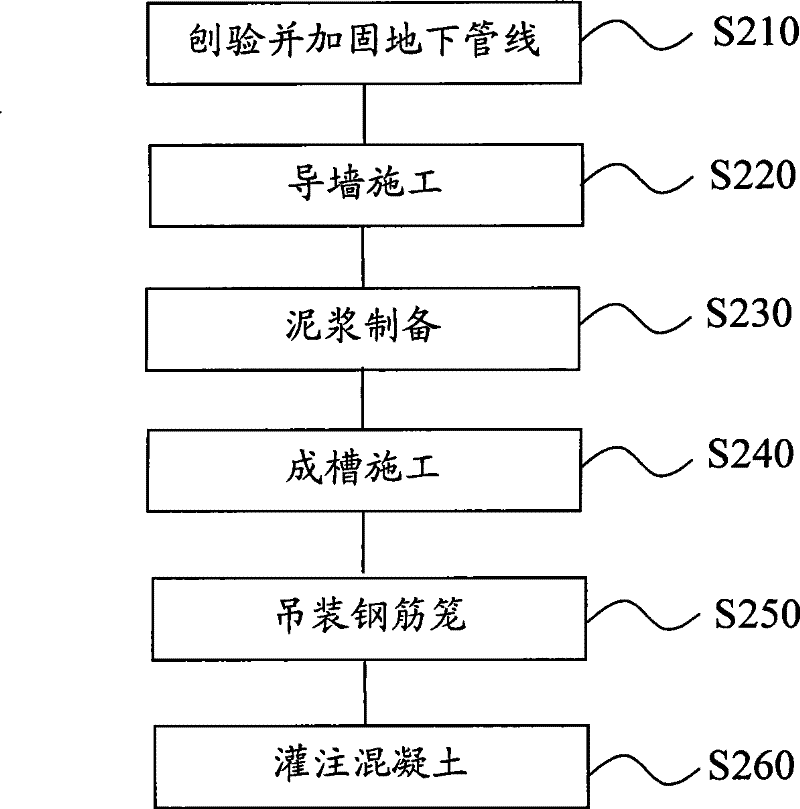

[0021] See figure 2 The flow chart of the construction method provided for an embodiment of the present invention

[0022] Step S210: Examine and strengthen the underground pipelines. Where there are pipelines, add steel pipes or section steels to reinforce and protect the pipelines at a place 50cm below the pipelines. It will not be damaged during construction.

[0023] Step S220: guide wall construction. When excavating the guide wall, in order to facilitate the protection of underground pipelines and adjust the position of the steel cage after lowering, the width of the guide wall should be increased appropriately. For example, when excavating a deep groove with a width of 120cm and a depth of 120-200cm, the depth should be adjusted ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com