Socket structure for plastic steel twined piles

A plastic-steel winding pipe and plastic-steel technology, which is applied in the direction of pipeline connection layout, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of sewage leakage, installation difficulties, and loose steel belt buckles, etc., to achieve fast installation and connection, and easy The effect of installation connection, strong sealing and leakage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

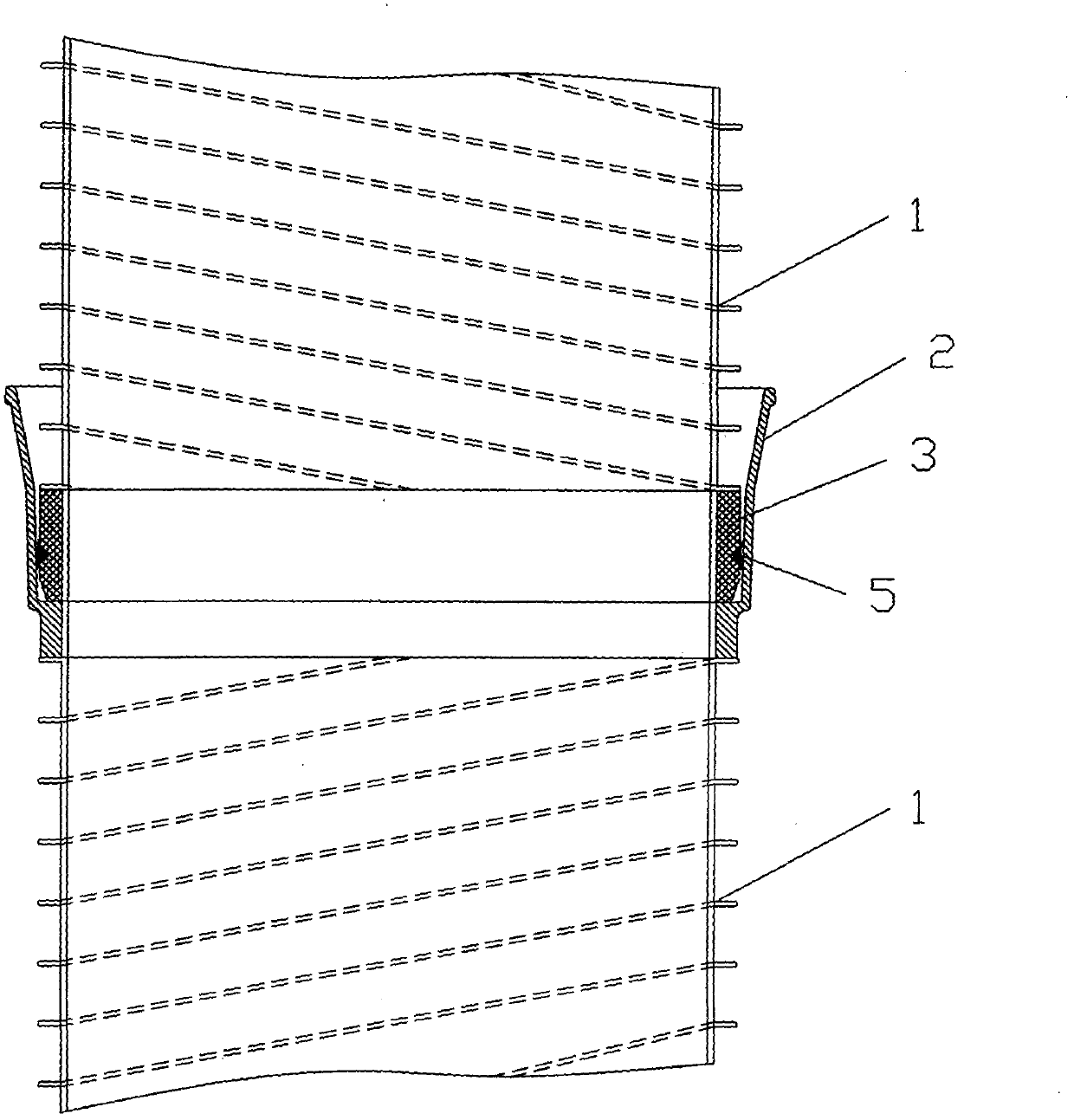

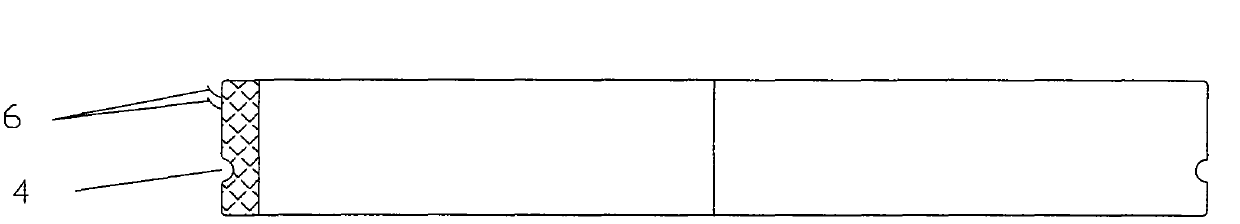

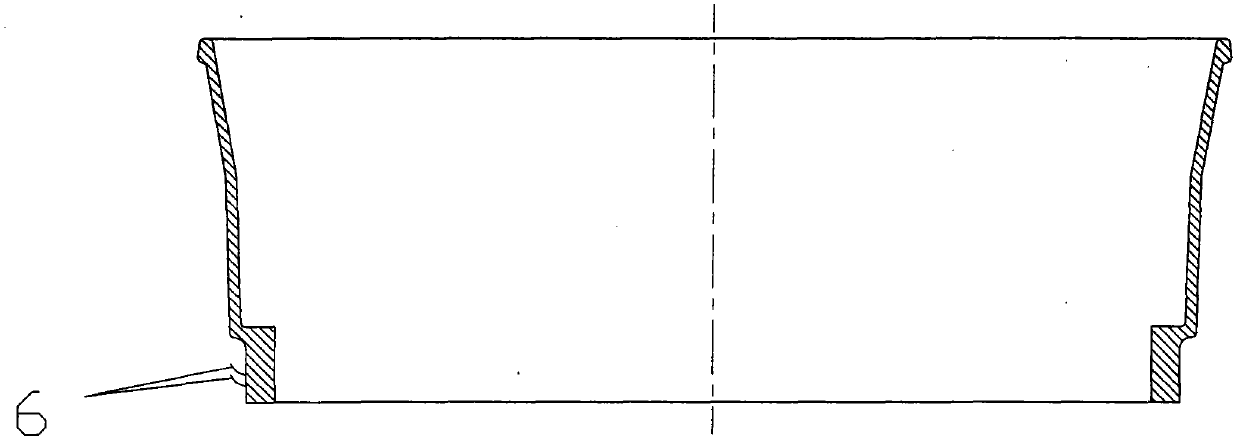

[0015] Such as figure 1 As shown, a plastic-steel winding pipe socket structure includes two sections of plastic-steel winding pipe 1 with spiral outer surfaces. 2 is a stepped type, the small-diameter section of the electric melting jacket 2 is placed on the periphery of one end of one end of the plastic-steel and plastic-steel winding pipe 1, and the electric melting sleeve 3 is put on the periphery of the other end of the plastic-steel winding pipe 1. The electric heating sleeve 3 is in the shape of a ring, and the electric heating sleeve 3 is arranged in the large-diameter section sleeve of the electric heating sleeve 2 . In order to strengthen the tightness and leakage resistance between the two sections of plastic-steel winding pipe 1 (that is, to strengthen the tightness and leakage resistance between the electric heating sleeve 2 and the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com