Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce the amount of sulfuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel production technique of xylose

ActiveCN101392009AReduce the amount of sulfuric acidAvoid environmental pollutionSugar derivativesSugar derivatives preparationRegenerative processXylose

The invention discloses a new manufacturing technique of a xylose and relates to a technique for manufacturing the xylose. The technique adopts the technology of electrodialysis recycling sulphuric acid, a bag adopted by a nanofiltration concentration device and a special nanofiltration separation system concentrates the liquid in the technique for manufacturing the xylose at normal temperature, therefore water and other impurities can be removed from the product; the manufacturing technique comprises: 1. pretreatment, 2. hydrolyzation, 3. decoloration, 4. electrodialysis, 5. ion exchange, 6. nanofiltration, 7. concentration, 8. ferment, 9. crystallization, 10. centrifugation, and 11. drying, then the high purity xylose is obtained. The new manufacturing technique of the xylose can not only recycle 50 percent sulphuric acid in the hydrolyze liquid, but also can recycle waste acid and spent caustic produced in the regenerative process of duolite, therefore the dosage of sulphuric acid can be saved and the environment pollution is avoided. The technique solves the problems of scale formation in device in the neutralizing deacidification technique, large usage of duolite in deacidification technique, large usage of devices, large investment, large consumption of acid and alkali, high costs and the like; thus improving the device utilization rate and the service life, decreasing the ash and the acid contents in the hydrolyze liquid, improving the quality of the hydrolyze liquid and enhancing the product quality and separating efficiency.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

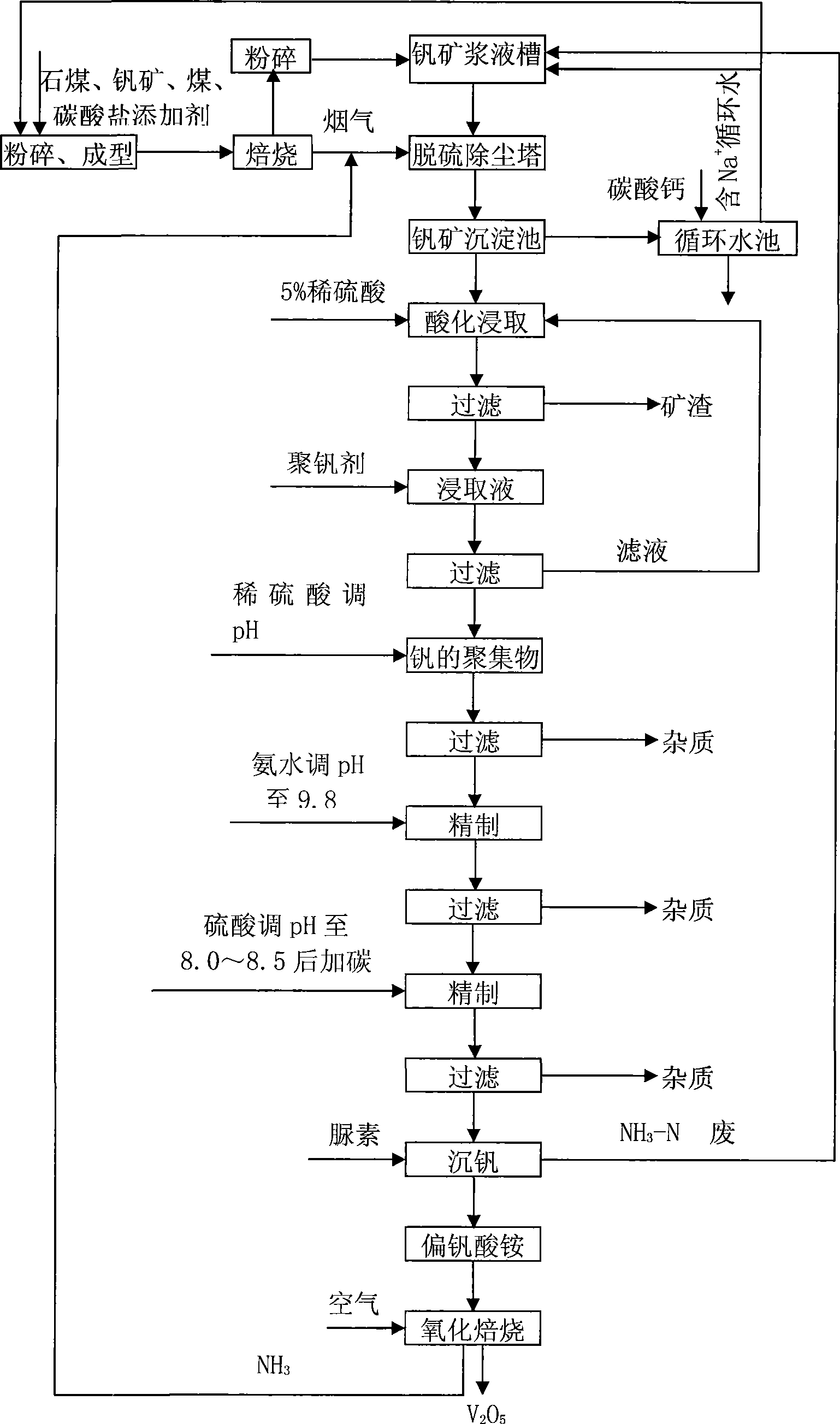

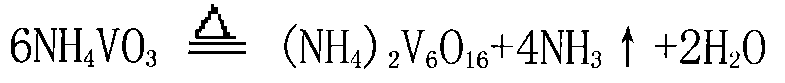

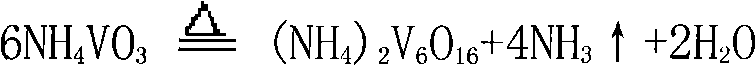

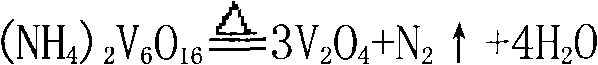

Desulphurization and vanadium extraction technique for calcinated vanadium ore

InactiveCN101503762ANo pollution in the processEliminate pollutionProcess efficiency improvementResource utilizationSodium salt

The invention provides a process for primary desulfurization and secondary vanadium purification of roasted vanadium ores. The process takes sodium salts which do not contain chlorine ions as a roasting additive of vanadium ores and molds the vanadium ores; and the roasted sodium-containing vanadium ores are used for reclaiming SO2 gas generated in the roasting process at first, and diluted acid is used for immersion and vanadium purification. The maximum characteristic of the process is that the sodium-containing vanadium ores are taken as alkaline desulfurized substances and circulated into a desulfurizing tower; Na ions in the vanadium ores are recycled in the form of intermediate carriers; when the concentration of the Na ions in a circulating absorption liquid reaches a certain value, the recovery rate of the SO2 gas generated in the roasting process can be improved and the amount of sulfuric acid in the procedure of immersion in the diluted acid and vanadium purification can be reduced; and sodium salt wastewater can be taken as the roasting additive of the vanadium ores instead of the sodium salts which do not contain the chlorine ions, so that the problem of severe environmental pollution of a large quantity of sodium salt wastewater and the SO2 gas produced in the conventional technological line is solved, and the process is a novel environment-friendly stone-like coal vanadium purification process having the advantages of utilization of waste materials to produce waste materials, high resource utilization rate, low production cost, small environmental pollution and even non pollution.

Owner:HUNAN UNIV

Method for separating and reclaiming arsenic and iron from acidic waste liquid containing arsenic acid and ferric sulfate

ActiveCN101168450AReduce the amount of vulcanizing agent and sulfuric acidReduce processing costsIron oxides/hydroxidesCalcium/strontium/barium sulfatesArsenateChemistry

The invention relates to a method for separating and recovering arsenic and iron from acidic waste liquid containing arsenic acid and ferric sulfate, which belongs to the treatment and comprehensive recovery method of industrial waste water. The method is composed of four operation steps of reduction operation, vulcanization operation, neutralization operation and sulfate precipitation operation. Among them, the reduction operation is to reduce the pentavalent arsenic in the waste liquid to trivalent arsenic, and the ferric iron is reduced to ferrous iron; the sulfidation operation is to make the arsenic form arsenic sulfide precipitation, separate and obtain the arsenic-containing precipitate and the arsenic-removing liquid; the neutralization operation is The iron in it is precipitated in the form of ferric hydroxide, and the iron-containing precipitate and the iron-removing liquid are separated; the sulfate precipitation operation is to add lime to the iron-removing liquid, so that the sulfate in it produces calcium sulfate and hydroxide precipitation, and separates Calcium sulfate-containing precipitate and water are obtained, and the water is returned to the production system for recycling as production water. The advantage is that the amount of vulcanizing agent and sulfuric acid used in the vulcanization operation is greatly reduced, thereby reducing the cost of waste liquid treatment, which is beneficial to environmental protection and has strong practicability.

Owner:CHINA NAT GOLD GROUP CORP TECH CENT +1

Method for extracting beryllium oxide from low-grade beryllium ore

InactiveCN102168184AIncrease concentrationLow firing temperatureProcess efficiency improvementKeroseneSlag

The invention discloses a method for extracting beryllium oxide from low-grade beryllium ore. The method is characterized by comprising the following steps of: grinding the low-grade beryllium ore, pelletizing, drying, roasting, and crushing to obtain a roasted material; adding concentrated sulfuric acid, stirring, leaching, and separating to obtain acidified liquid and acidified slag; adding the acidified liquid into the other roasted material, and stirring and leaching to obtain primary steep and primary leaching residue; adding concentrated sulfuric acid into the primary leaching residue, adding water, and stirring and leaching to obtain secondary steep and secondary leaching residue, wherein the acidified liquid is replaced by the secondary steep for recycling; extracting the primary steep by adopting an extracting agent in a volume ratio of phosphors extracting agents: alkanol: kerosene of (25-45):(5-1):(50-70) to obtain a beryllium-loaded organic phase and raffinate; washing the beryllium-loaded organic phase by adopting solution of oxalic acid, and performing back extraction by using solution of NaOH to obtain a blank organic phase and stripping solution; and regulating the concentration of hydroxyl ions in the stripping solution to ensure that beryllium is hydrolyzed and precipitated, and calcining a precipitate to obtain the beryllium oxide. The method is easy to operate, the cost is low, the beryllium oxide with the content of over 97 percent is obtained, and the recovery rate of the beryllium is about 80 percent. The method is suitable for extracting the beryllium oxide from low-grade beryllium ore with low BeO content and high CaF2 content.

Owner:广东省资源综合利用研究所

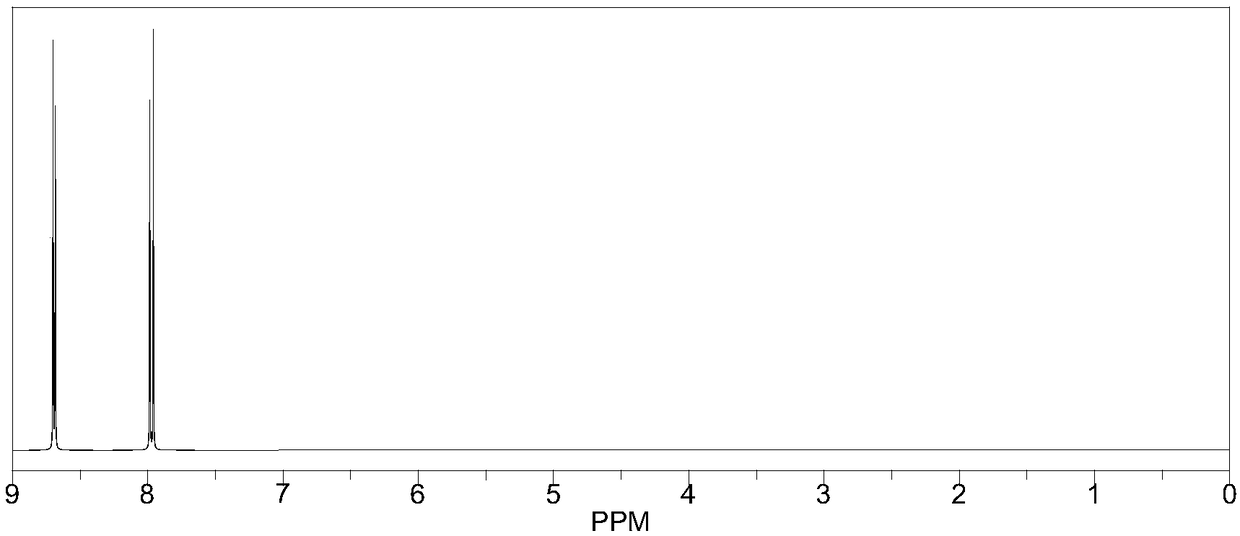

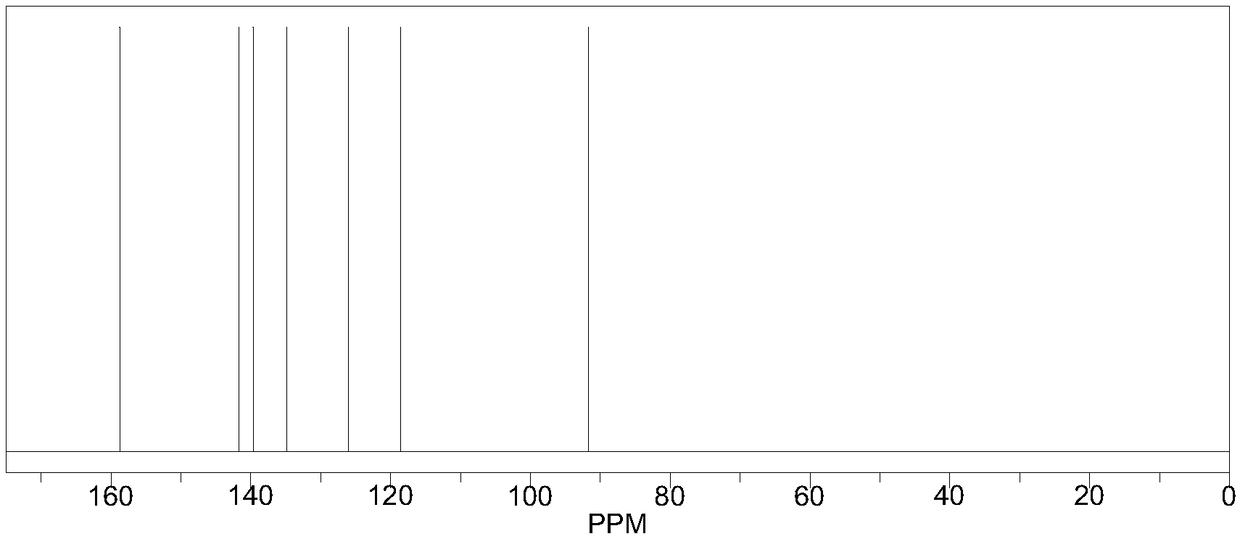

Method for producing 1,5(1,8)-dinitro-anthraquinones

ActiveCN101423477AEmission reductionSimple processNitro compound preparationNitrationPollutant emissions

The invention relates to a method for producing 1, 5(1, 8)-binitro anthraquinone. The method comprises the following steps: putting anthraquinone in concentrated nitric acid, stirring and cooling the mixture, dripping sulphuric acid at a temperature of between 20 DEG C below zero and 15 DEG C, and making the mixture react for 2 hours continuously at the temperature of between 20 DEG C below zero and 15 DEG C after the dripping is finished, wherein the weight ratio of the concentrated nitric acid to the anthraquinone is between 5 to 1 and 30 to 1, and the weight ratio of the concentrated sulphuric acid to the anthraquinone is between 1 to 1 and 2 to 1; and then gradually heating the reaction mixture to between 60 and 65 DEG C, making the mixture react for 2 hours continuously, and finally adding the reaction mixture into cold water to separate out solid, filtering the solid, washing the solid by water and then drying the solid to obtain the binitro anthraquinone, wherein total content of 1,5-binitro anthraquinone and 1, 8-binitro anthraquinone is not lower than 88 percent. The method has the remarkable advantages that the method has normal-pressure reaction and simple process, can use batch process and continuous method for production, and uses general chemical equipment, and uses little sulphuric acid, and reduces discharge of pollutant. The total content of the 1, 5(1, 8)-binitro anthraquinone in nitration reaction surpasses that of the prior advanced art.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

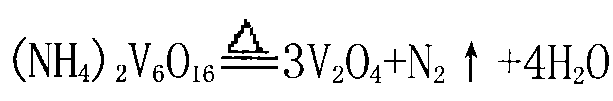

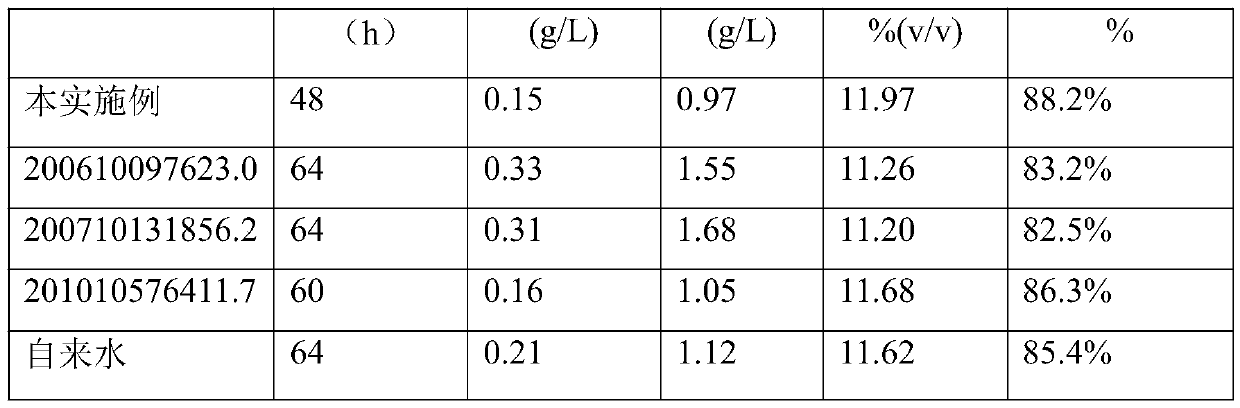

Method for pretreating ethyl alcohol produced from corn straws

InactiveCN104878055AReduce the amount of sulfuric acidImprove preprocessing effectBiofuelsFermentationChemistryMoisture

The invention discloses a method for pretreating ethyl alcohol produced from corn straws. The method comprises the following steps: taking corn straws as a raw material, pulverizing the corn straws, and conducting air drying to obtain corn straw powder; balancing moisture in the corn straw powder, adding water and acid liquor, conducting slightly acidic medium pressure steam explosion pretreatment, after hydrolysis reaction is finished, conducting centrifugal separation on the exploded sample and hydrolysate, and separately collecting a sample a and a hydrolysate I; balancing moisture in the corn straw powder, conducting neutral steam explosion pretreatment, after hydrolysis reaction is finished, conducting centrifugal separation on the exploded sample and hydrolysate, and separately collecting a sample b and a hydrolysate II; washing the sample a and the sample b subjected to prehydrolysis to be clean, and mixing so as to obtain a cellulose substrate used for follow-up enzymolysis fermentation. According to the method, a scientific overall process is provided, the pretreated sample obtains excellent application effects on the aspect of ethyl alcohol preparation through enzyme hydrolysis, and certain technical guidance is provided for the engineering application of converting the corn straws into the biological ethyl alcohol.

Owner:SOUTH CHINA UNIV OF TECH

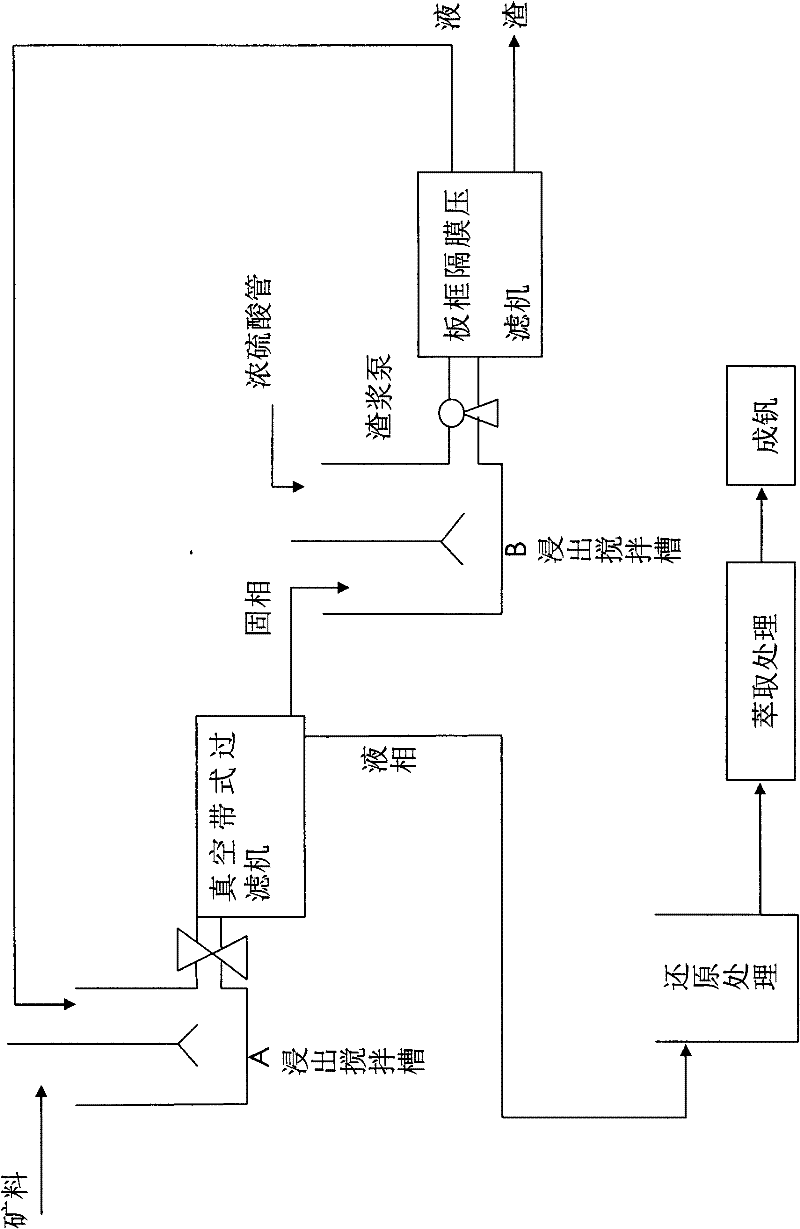

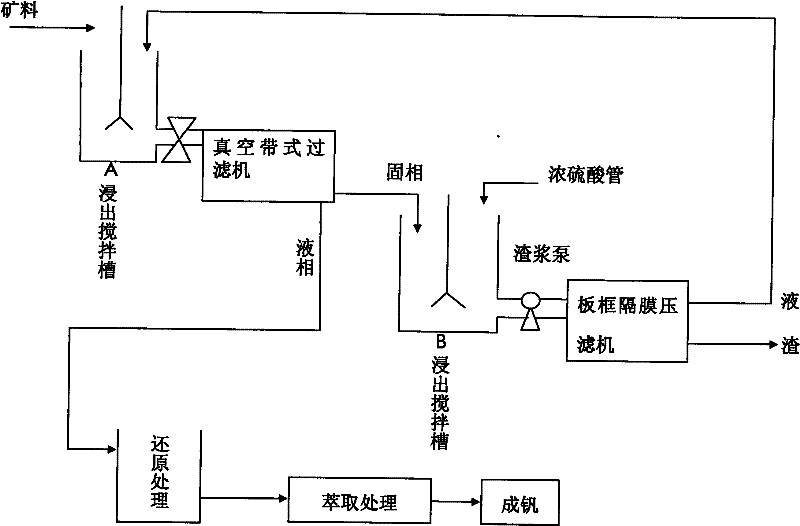

Circulating graded leaching method of stone coal acid-leaching vanadium extraction sulfuric acid

InactiveCN102251103AReduce the amount of sulfuric acidReduce residual acid concentrationProcess efficiency improvementSolid phasesLeaching rate

The invention relates to a circulating graded leaching method of stone coal acid-leaching vanadium extraction sulfuric acid, which comprises steps as follows: two leaching agitator tanks A and B are adopted, and a liquid phase which is separated after minerals are subjected to acid leaching treatment by the leaching agitator tank A is directly used for reduction and extraction treatment; the separated solid phase enters the leaching agitator tank B, and is subjected to further acid leaching treatment; and the separated leaching solution B returns to the leaching agitator tank A so as to soak the newly added minerals. Compared with the existing acid-leaching vanadium extraction method, the invention reduces the consumption of sulfuric acid in the stone coal leaching process, lowers the concentration of spent acid in the leaching solution A, does not need to add alkali for neutralization in the post processing, and can not cause new environmental protection problem; and the leaching rate is higher than 90%.

Owner:BAOJING TIANRUI VANADIUM

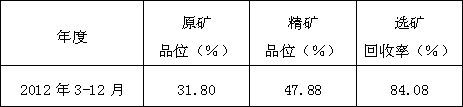

Beneficiation method of recovering sulfur from copper sulfide ore flotation tailings

ActiveCN103157558AReduce the amount of sulfuric acidImprove grade and recoveryFlotationMaceralCopper sulfide

The invention belongs to the field of mineral processing, relates to a beneficiation method, and particularly relates to a method of sorting copper sulfide ore flotation tailings. The method comprises the following steps: A, the tailings with copper and sulfur separated are dewatered through a thickener, wherein the content of the sulfur in the tailings is more than 20%, and the concentration of the tailings is 10-15%, and after the tailings are dewatered, the concentration of a bottom current is improved to 20-25%; B, the bottom current of the A step enters a whirlcone to grade, and the concentration of sinking sand of the whirlcone is improved to 30-40%, the whirlcone overflows, the concentration of the tailings is 10%, the content of the sulfur is 15%, the tailings are discharged to a tailings pond or are concentrated back to the step A; and C, the concentration of the sinking sand in the step B is 30-40%, the content of the sulfur is 25-35%, the sinking sand enters to a flotation system, acid is added in the sinking sand and are mixed with a pH value of 6.5-7.5, after flotation reagents are added, final sulfur concentrate is obtained after one-time rough concentration, one-time scavenging and two-time choiceness. Compared with the prior technology, the beneficiation method of recovering the sulfur from the copper sulfide ore flotation tailings has the advantages of being stable in technological process, small in dosage of sulfuric acid and high in grade of sulfur concentrate and recovery rate.

Owner:JIANGXI COPPER

Treatment method of smelting waste liquor

InactiveCN102001761AReduce the cost of acid treatmentAchieving zero emissionsWater contaminantsWaste water treatment from metallurgical processLiquid wasteCyanide

The invention relates to a treatment method of smelting waste liquor, in particular to a method for treating the heavy metal ion in the smelting waste liquor by the precipitation of high-alkaline and high-cyanide barren liquor generated in the cyaniding extraction process of gold and silver. The method is characterized by comprising the steps of: adding the smelting waste liquor in cyaniding barren liquor, wherein the pH value is 2-3; standing for precipitation to obtain precipitate and supernatant, wherein most of the heavy metal is precipitated in cyanide complex form and the impurity removal rate of the heavy metal in the supernatant is above 95%; adding cyaniding barren liquor to the supernatant to adjust the pH value to 8-9; precipitating and filtering part of the alkaline heavy metal ion; taking the supernatant after twice impurity removal by precipitation and filtration as refilling water for the cyaniding process; and returning to the cyaniding process for cyclic utilization. By adopting the method, the investment is not increased; the cyaniding barren liquor is used for treating the smelting waste liquor, and through controlling the pH value, the cyaniding barren liquor and the smelting waste liquor interact, thereby recycling the heavy metal ion in the waste liquor without increasing the treatment investment, realizing the zero discharging of the smelting waste liquor, treating the cyaniding barren liquor, reducing the sulfuric acid amount in the acidizing treatment of the barren liquor, and lowering the acidizing treatment cost of the cyaniding barren liquor.

Owner:山东金洲矿业集团有限公司

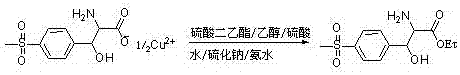

Synthetic method for p-methyl phenyl serine ethyl ester

ActiveCN106905203AMoisture suppressionImprove the conversion rate of esterificationOrganic chemistryOrganic compound preparationWastewaterEthyl ester

The invention provides a synthetic method for p-methyl phenyl serine ethyl ester. The method comprises the following steps: adding diethyl sulfate, ethanol, sulfuric acid and p-diphenylserine copper salt in a reaction vessel, performing a backflow reaction, monitoring the esterification conversion rate at 95-99% and completing the reaction; cooling the mother liquor after insulation and press filtration and crystallizing the material, performing pumping filtration after cooling to -5-0 DEG C, dissolving an obtained filter cake with water and removing copper by sodium sulfide, performing ammoniacal liquor analysis to obtain the product. The method has the advantages that average yield can reach 95%, product purity can reach more than 98%, waste water is little, and the method is environmentally friendly.

Owner:SUZHOU KAIYUAN MINSHENG SCI & TECH CORP

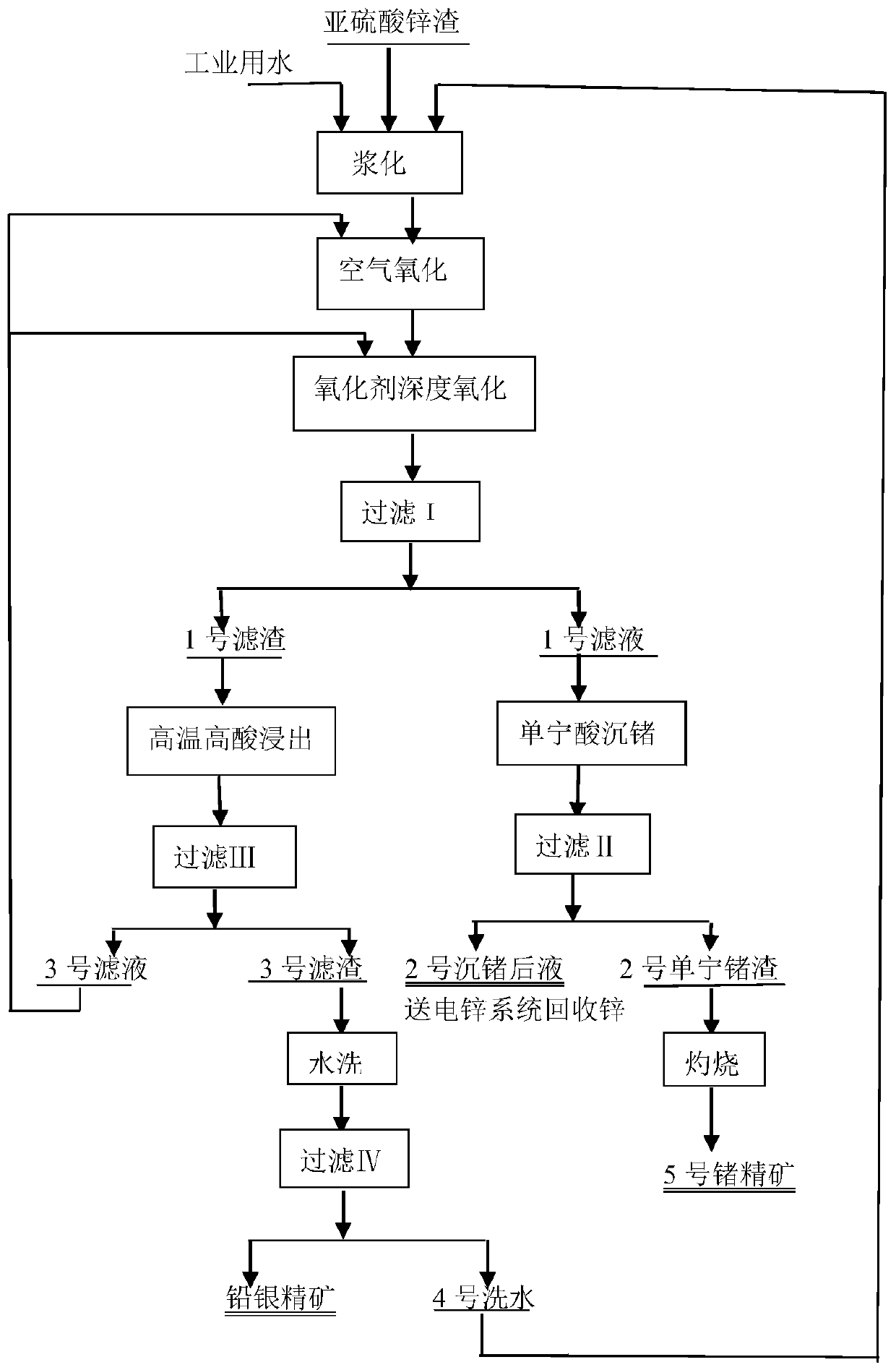

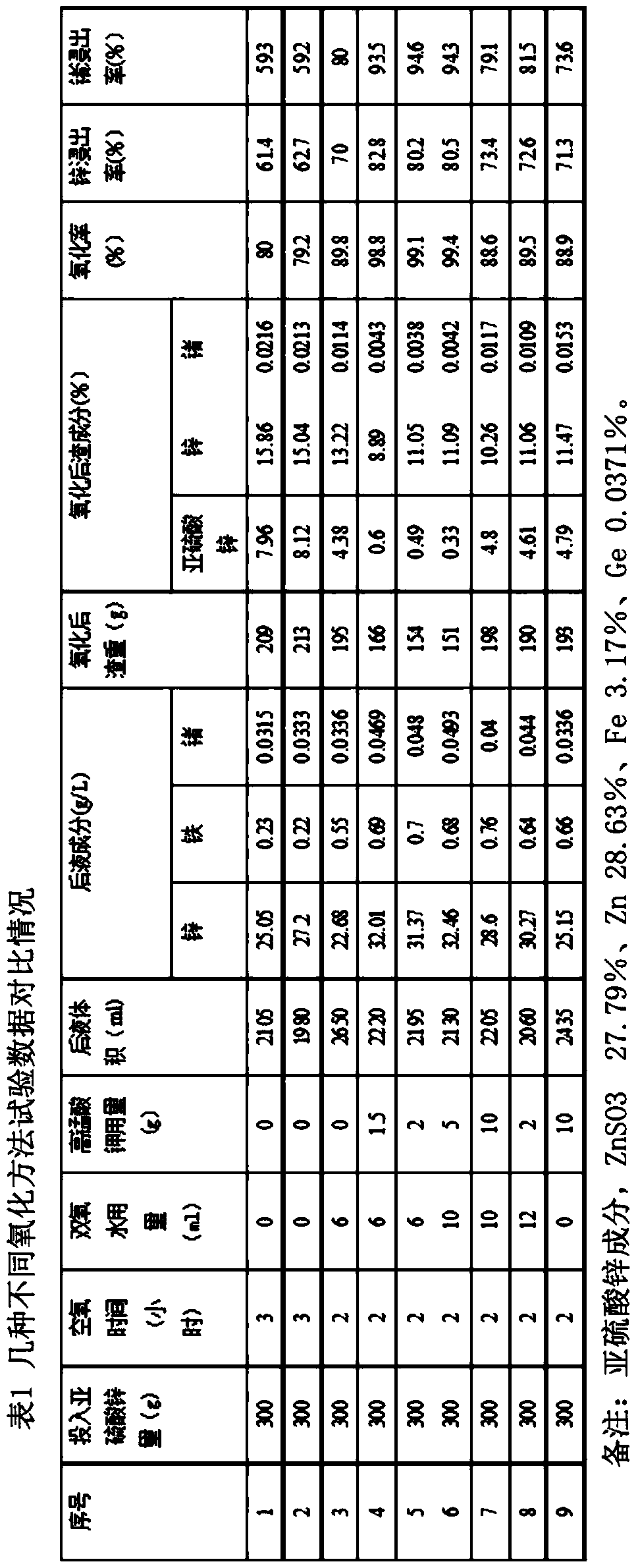

Method for deep oxidation and harmless treatment of zinc sulfite slag for comprehensive recovery of valuable metal

PendingCN111235392AAir Oxidation Process BriefOxidation Process BriefProcess efficiency improvementSlagHydrometallurgy

The invention discloses a method for deep oxidation and harmless comprehensive recovery processing of zinc sulfite slag. The method comprises the following steps: zinc oxide powder produced by a zincvolatilizezing kiln is directly pulpified to absorb low-concentration sulfur dioxide flue gas generated by the zinc volatilizezing kiln to obtain zinc sulfite slag as the raw material, the zinc sulfite slag is first pulpified and then subjected to air oxidation, then, a mixing oxidizing agent is added for deep oxidation, heating and warming are carried out, finally filtering is carried out to obtain germanium-containing zinc sulfate solution and zinc oxide slag, germanium-containing zinc sulfate solution and zinc oxide slag are the raw materials of zinc hydrometallurgy, wherein zinc sulfate solution contains high content of germanium and low contents of zinc and ferric iron, germanium can be directly recycled to obtain high-grade germanium concentrate, acid leaching is carried out on zincoxide slag to recycle zinc and produce lead and silver concentrate to recycle lead and silver.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

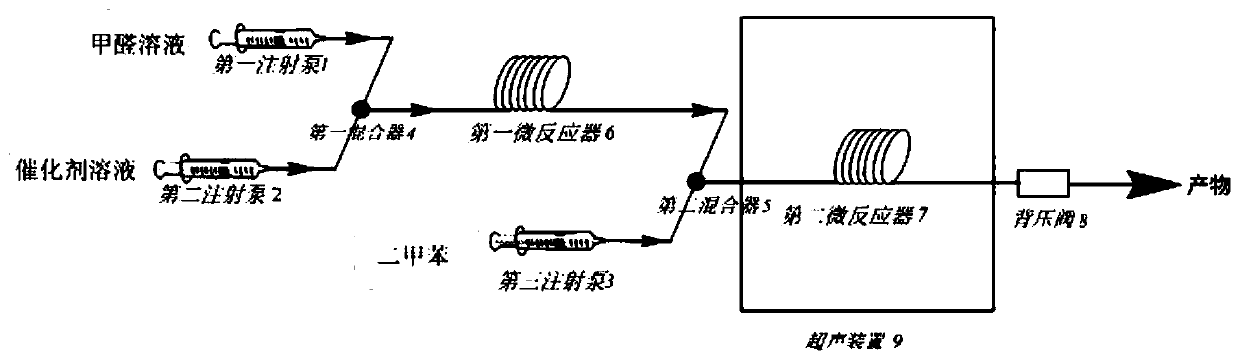

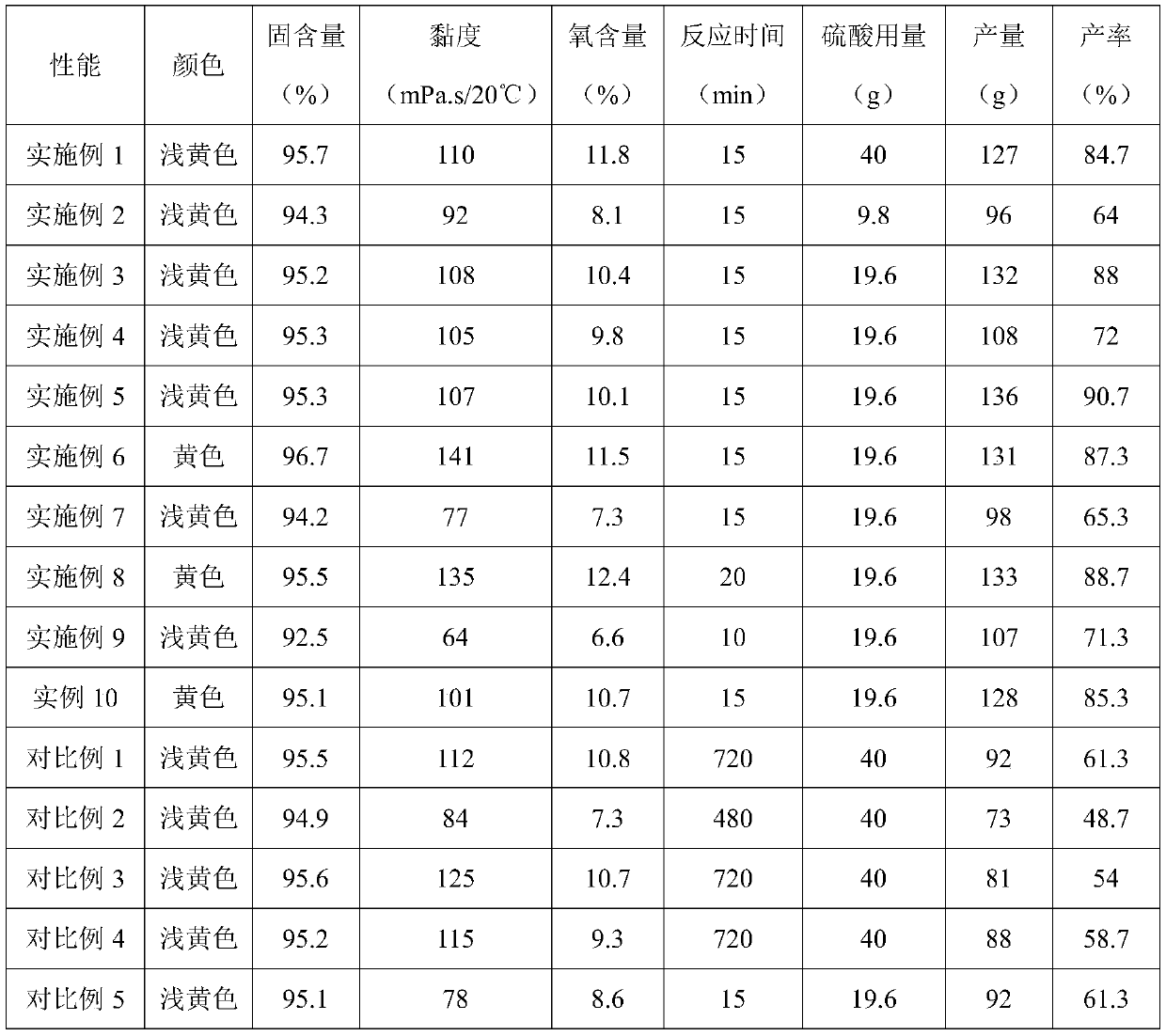

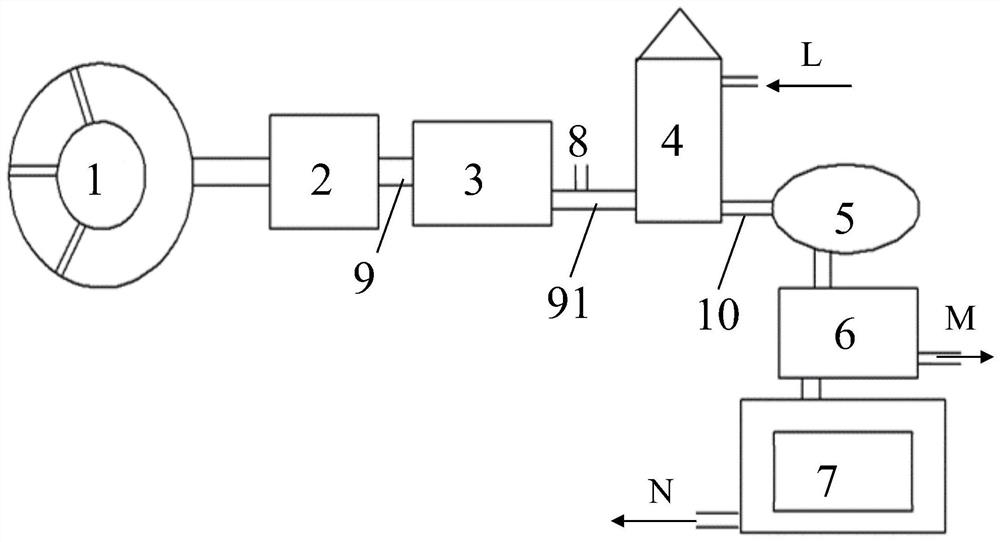

Micro-reaction device and method for preparing xylene formaldehyde resin by using micro-reaction device

InactiveCN110918021AWell mixedIncrease profitChemical/physical/physico-chemical microreactorsXylylenePtru catalyst

The invention provides a micro-reaction device and a method for preparing xylene formaldehyde resin. The method comprises the following steps: simultaneously pumping a formaldehyde aqueous solution and a catalyst aqueous solution into a first mixer of the micro-reaction device for mixing, then generating a reaction product in a first micro-reactor, mixing the reaction product with xylene in a second mixer, carrying out ultrasonic treatment and heating reaction in a second micro-reactor, carrying out water washing or alkali washing to remove a water layer and then carrying out rotary evaporation to obtain the product. Compared with the existing preparation method, the method has the advantages that the use amount of sulfuric acid is greatly reduced and corrosion to equipment and pollution of reaction waste liquid to the environment are reduced; the formaldehyde solution and the xylene are subjected to ultrasonic treatment and can be sufficiently emulsified to form microemulsion so thattwo-phase reaction raw materials are in more sufficient contact and the mass and heat transfer efficiency is greatly improved; meanwhile, the reaction system can bear certain pressure so that volatilization of the formaldehyde solution is reduced, the utilization rate of the formaldehyde is greatly increased and the product yield can be increased by 30%-40% relative to that in a reaction kettle.

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

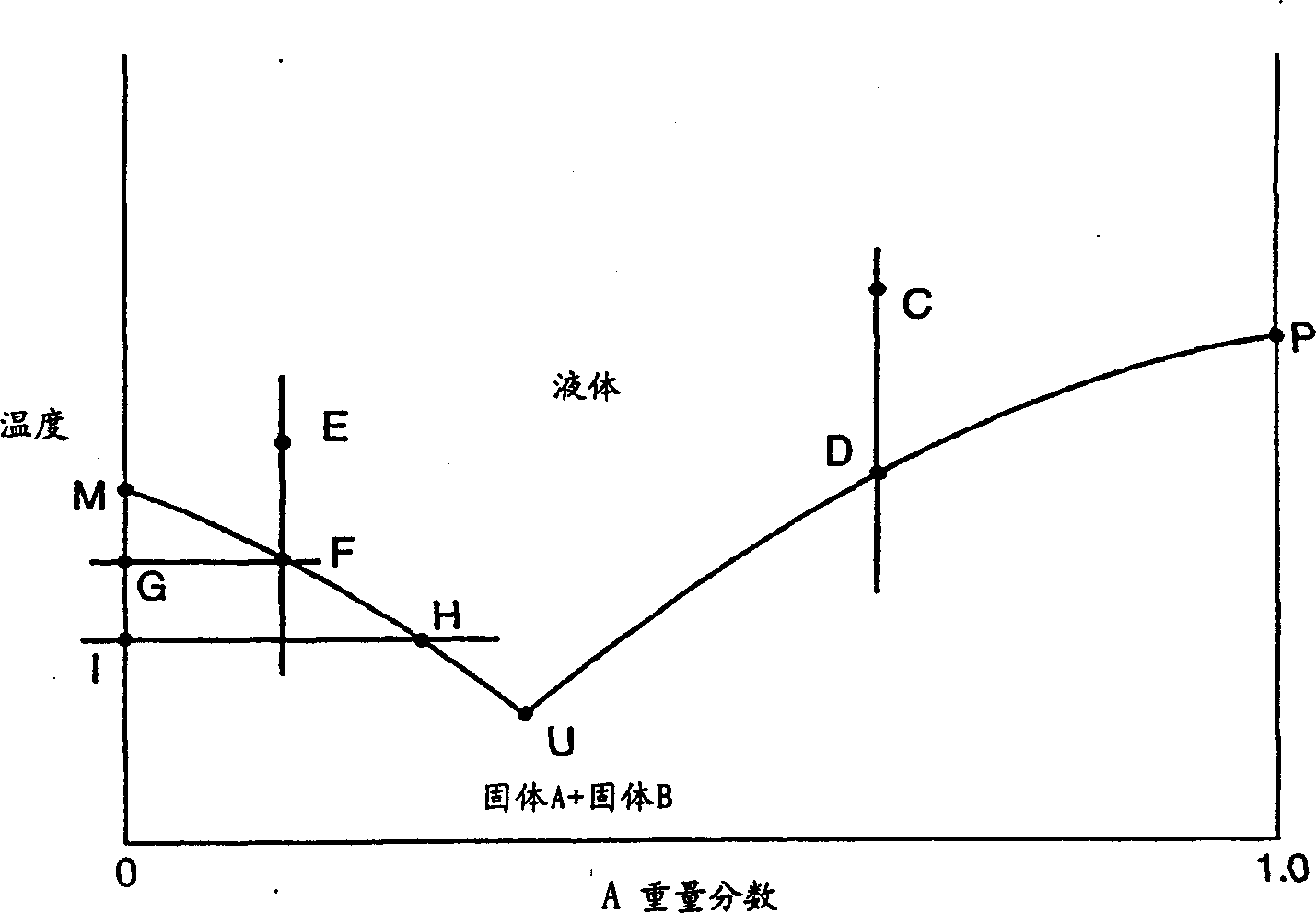

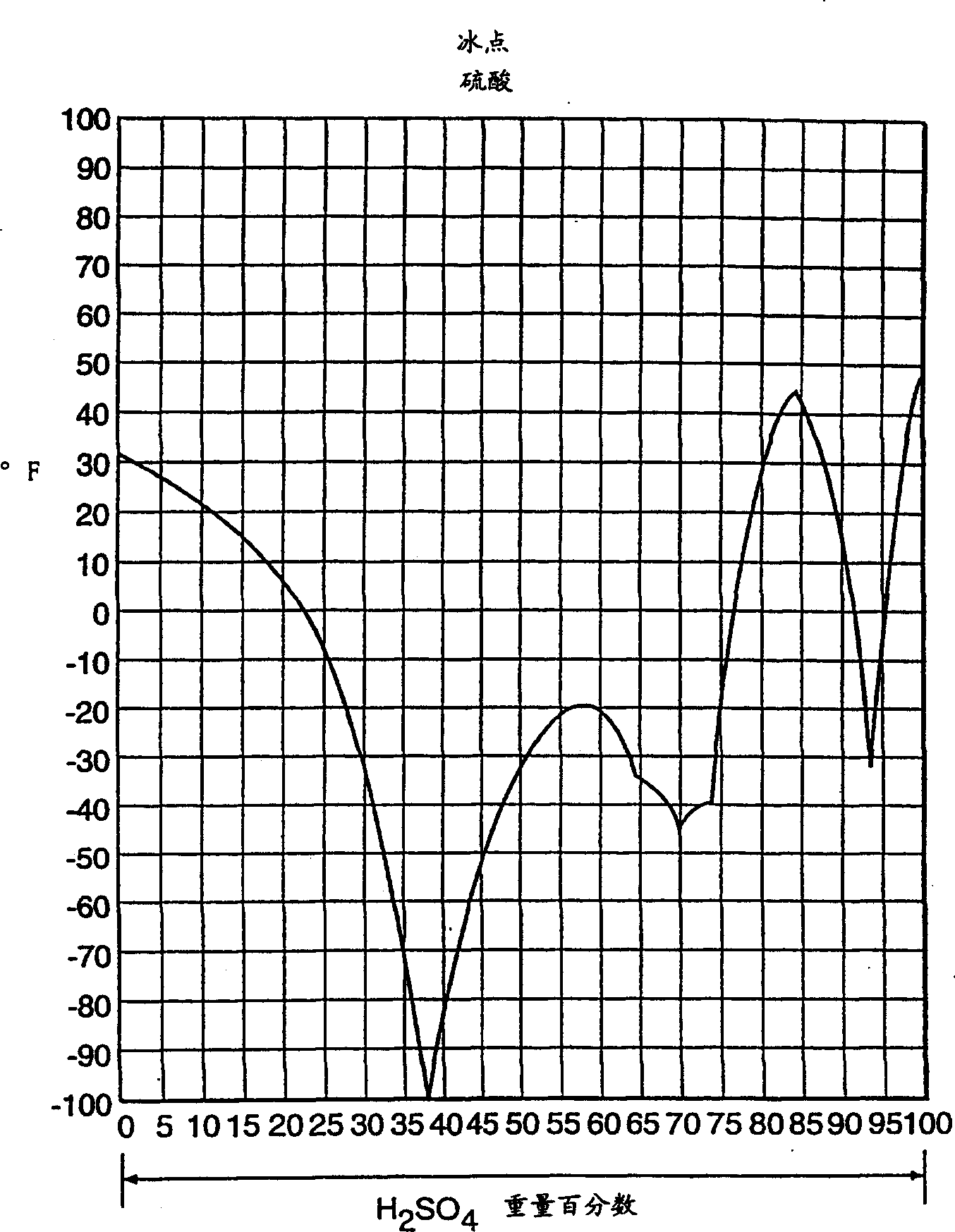

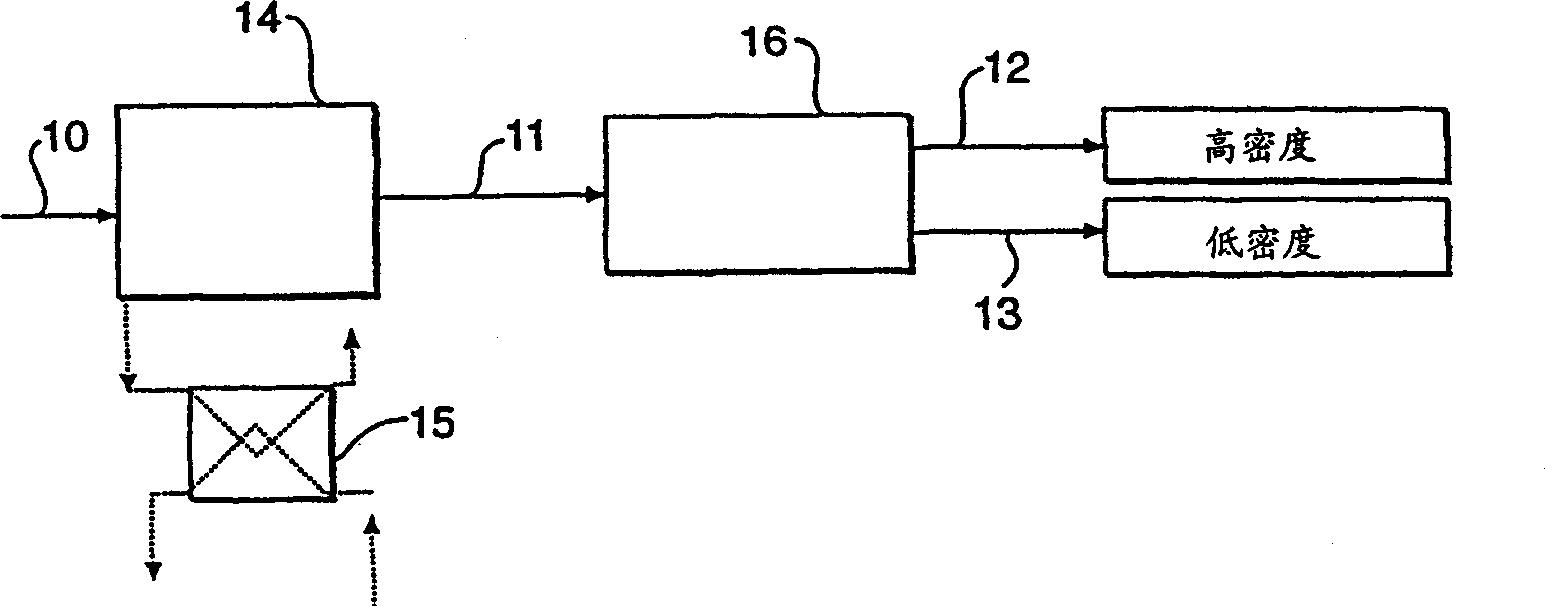

Waste acid recovery

InactiveCN1292766ALow costSolving problems in disposal of sulfuric acidWater/sewage treatment by centrifugal separationProductsSlurrySpent acid

A process for purifying a sulfuric acid solution such as by cooling a sulfuric acid solution to at or near its freezing point to form a slurry of a solid phase and a liquid phase. The slurry has an acid-rich region and an acid-poor region. The acid-rich region is separated from the acid-poor region on the basis of density.

Owner:WATERWORKS INT

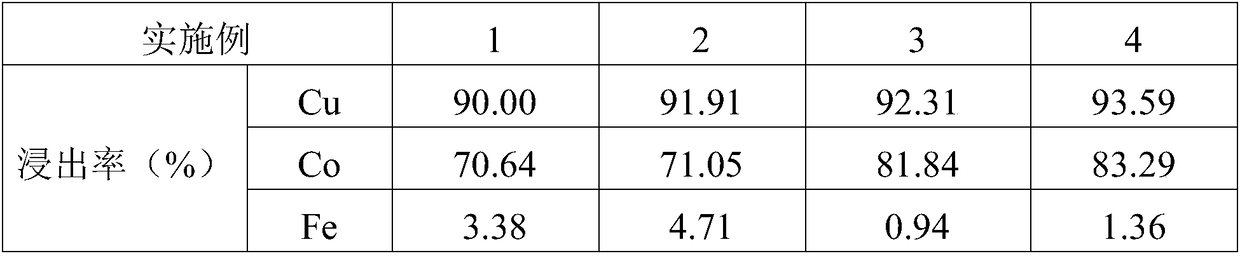

Method for recovering copper and cobalt from copper furnace slag

InactiveCN108285982AAvoid explosion riskReduce the amount of sulfuric acidProcess efficiency improvementIron sulfateSlag

The invention provides a method for recovering copper and cobalt from copper furnace slag. The method comprises the following steps: after the copper furnace slag is finely grinded, water is added toprepare pulp; sulfuric acid is added in the pulp for stirring and preimpregnation; the preimpregnated pulp is added in a high-pressure kettle, and oxygen is introduced in the high-pressure kettle forheating, stirring and oxygen pressure leaching; and the pulp after oxygen pressure leaching is taken out from the high-pressure kettle for filtration and washing to obtain leaching liquid, washing water and leaching slag. The method consumes metal iron in the copper furnace slag beforehand through preimpregnation to prevent the explosion risk caused by excessive hydrogen generated in the high-pressure reaction kettle; and meanwhile, most iron is remained in a slag phase in a form of ferric oxide in the oxygen pressure leaching process without entering solution in a form of iron sulfate, so that the use level of sulfuric acid is greatly reduced, the recovery cost is low, and the method can be widely applied to the field of recovery of the copper furnace slag.

Owner:CHINA ENFI ENGINEERING CORPORATION

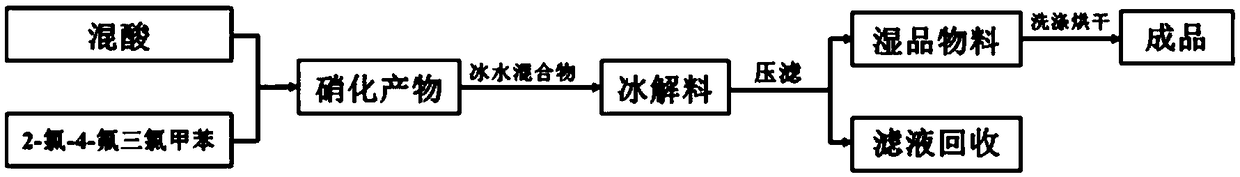

Method for efficient synthesis of 2-chloro-4-fluoro-5-nitrotrichlorotoluene

InactiveCN109265349AImprove nitrification capacityReduce the amount of sulfuric acidNitro compound preparationQuenchingSulfuric acid

The invention discloses a method for efficient synthesis of 2-chloro-4-fluoro-5-nitrotrichlorotoluene. The method comprises the following steps of (1) a nitrification reaction, wherein concentration sulfuric acid with the mass concentration of 98% and concentrated nitric acid with the mass concentration of 98 % are mixed according to the mass ratio of 1:1 to prepare mixed acid, and 2-chloro-4-fluorotrichlorotoluene is added dropwise into the mixed acid under the condition of stirring to carry out the nitration reaction; (2) quenching of the reaction, wherein a nitrified material obtained afterthe nitrification reaction is put into an ice-water mixture for stirring to quench the reaction; (3) preparation of a dry product, wherein after the reaction is quenched, a circulating water vacuum pump is adopted for suction filtration, and then washing and drying are conducted to obtain the dry product of 2-chloro-4-fluoro-5-nitrotrichlorotoluene; (4) recycling, wherein a filtrate obtained after the suction filtration and washing water are recovered for recycling. The method can improve the production efficiency, the color of the finished product is pure, and the yield and purity of the product are also high and are both 90% or above.

Owner:宿州学院

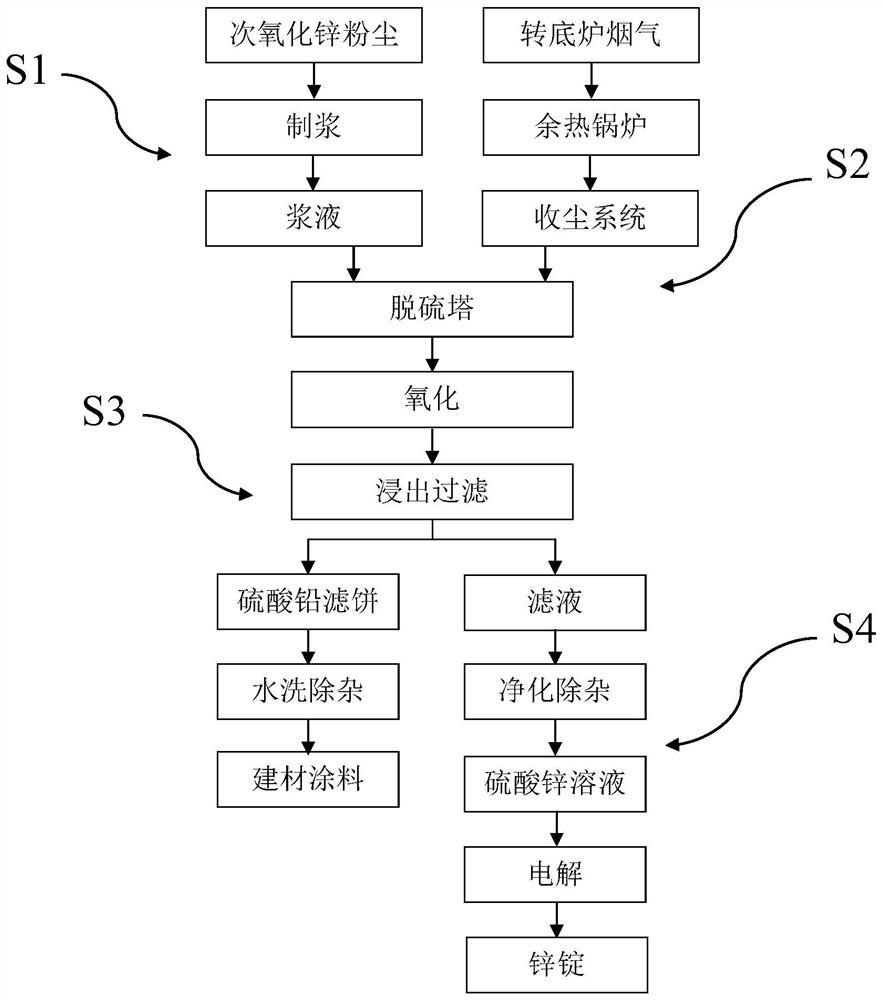

Treatment method and device for secondary zinc oxide dust

PendingCN111850309AImprove qualityAchieve fixationPhotography auxillary processesDispersed particle separationSulfate zincElectrolysis

The invention discloses a treatment method and device for secondary zinc oxide dust. The treatment method comprises the following steps that S1, the secondary zinc oxide dust and water are mixed to prepare slurry, and the pH is adjusted to be 4.3-6.5; S2, rotary hearth furnace flue gas and the slurry are fed into a desulfurizing tower to be desulfurized, and a mixed solution and desulfurized gas are obtained; S3, the mixed solution is fed into an oxidation pond, air is introduced for oxidation treatment, then dilute sulphuric acid is added, and filtrate and a lead sulfate filter cake are obtained after filtering; and S4, the pH of the filtrate is adjusted to be 1.2-1.4, zinc powder is added, a zinc sulfate solution is obtained, and a zinc ingot is obtained after the zinc sulfate solution is electrolyzed. According to the treatment method, the secondary zinc oxide dust is adopted as an absorbent to fix SO2 in the flue gas, then metal zinc is obtained through the processes of oxidation,filtering, purification, electrodeposition and the like, the cost of secondary zinc oxide zinc extraction and flue gas treatment can be reduced, the problem that a desulfurized product is difficult totreat is solved, and the resource utilization of secondary zinc oxide is achieved.

Owner:宝武集团环境资源科技有限公司

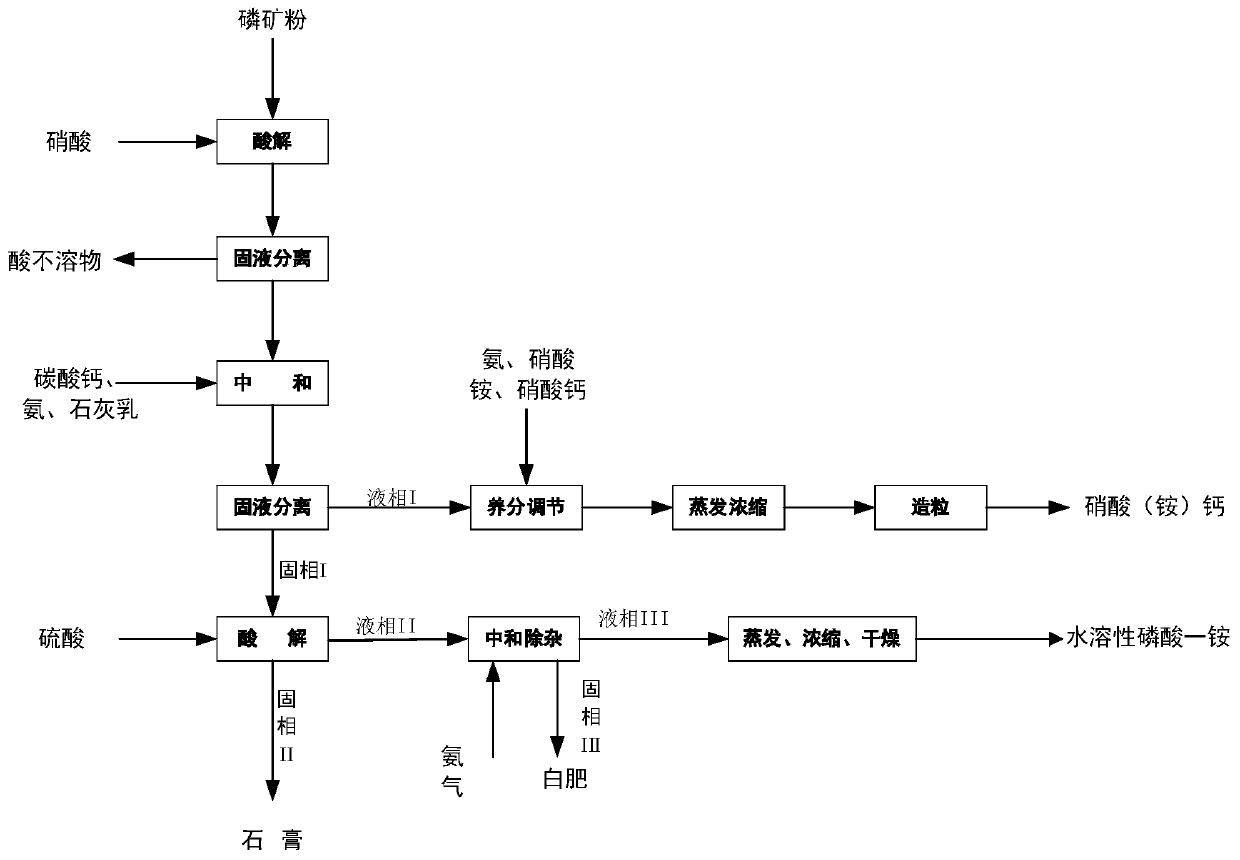

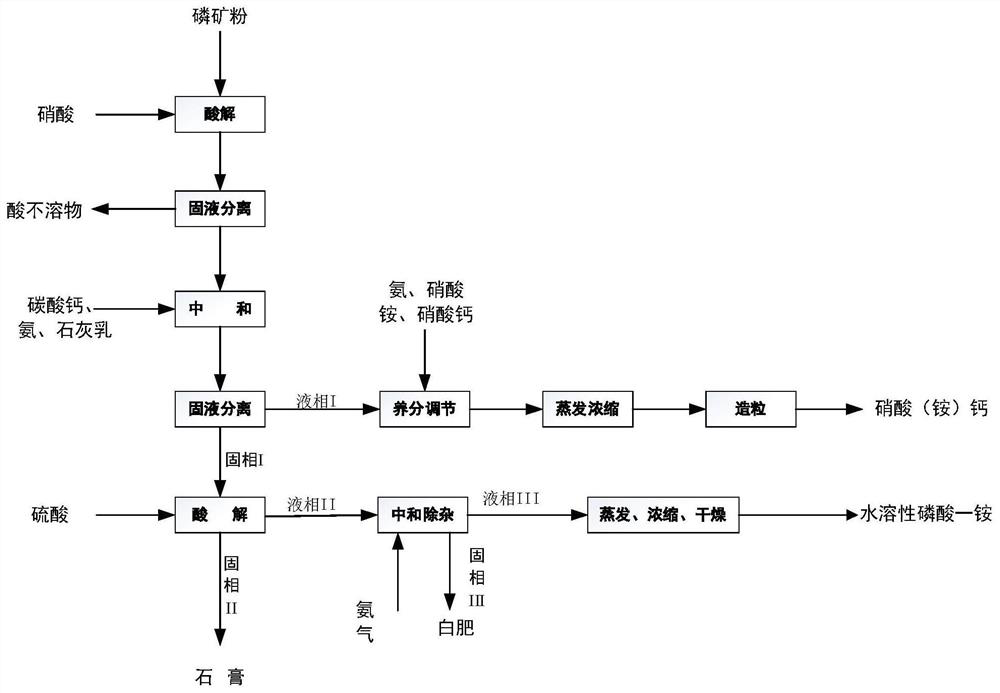

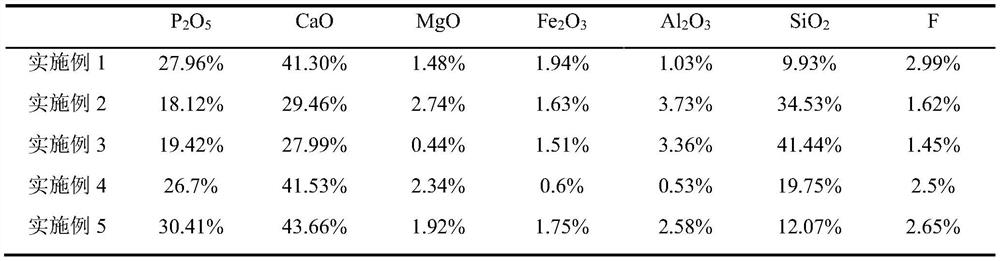

Production method of water-soluble monoammonium phosphate

ActiveCN111533099AIncrease profitHigh purityPhosphatesAlkali orthophosphate fertiliserFluid phasePhosphoric acid

The invention relates to a production method of water-soluble monoammonium phosphate, and belongs to the technical field of phosphorite clean processing and utilization. The method comprises the following steps: a. mixing nitric acid and phosphorite, reacting at 30-70 DEG C for 0.5-2 hours, and carrying out solid-liquid separation to obtain an acidolysis solution; b, neutralizing the acidolysis solution until the pH value is 6.5-8, and carrying out solid-liquid separation to obtain a solid phase I and a liquid phase I; c, mixing the solid phase I with a sulfuric acid solution, reacting at 30-70 DEG C for 0.3-2 hours, and performing solid-liquid separation to obtain a solid phase II and a liquid phase II; neutralizing the liquid phase II until the pH value is 4.0-4.5, and carrying out solid-liquid separation to obtain a solid phase III and a liquid phase III, wherein the liquid phase III is processed to obtain the water-soluble monoammonium phosphate. According to the method, phosphorusand calcium in phosphorite are completely separated, the utilization rate of calcium, phosphorus and other elements is greatly increased, and water-soluble monoammonium phosphate can be directly produced.

Owner:SICHUAN UNIV

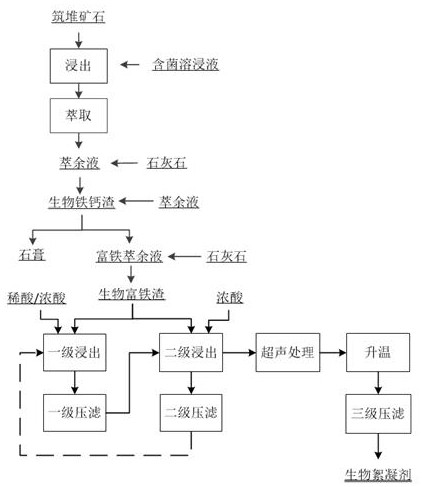

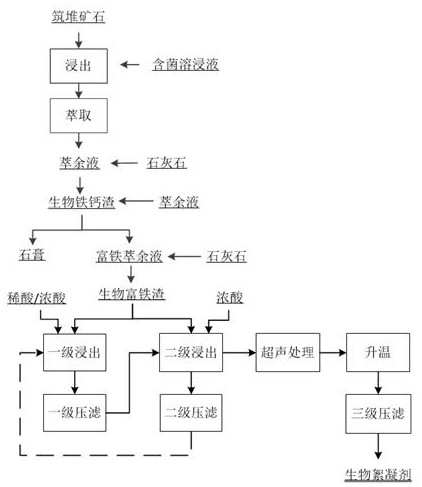

A method for preparing biological flocculant by using biological iron-calcium slag in biological heap leaching

ActiveCN113968610BRaise the ratio of iron to calciumLower calcium levelsSolid solvent extractionWater/sewage treatment by flocculation/precipitationPregnant leach solutionFiltration

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

A kind of production method of water-soluble monoammonium phosphate

ActiveCN111533099BIncrease profitHigh purityPhosphatesAlkali orthophosphate fertiliserFluid phasePhosphoric acid

The invention relates to a production method of water-soluble monoammonium phosphate, which belongs to the technical field of clean processing and utilization of phosphate rock. A method for producing water-soluble monoammonium phosphate, comprising the following steps: a. mixing nitric acid and rock phosphate, reacting at 30-70°C for 0.5-2 hours, and separating solid and liquid to obtain an acidolysis solution; b. and until the pH is 6.5-8, solid-liquid separation, solid phase I and liquid phase I are obtained; c, solid phase I and sulfuric acid solution are mixed, 30-70 ° C for 0.3-2h, solid-liquid separation, solid phase II and Liquid phase II; neutralize the liquid phase II until the pH is 4.0-4.5, and then separate the solid and liquid to obtain solid phase III and liquid phase III; wherein, the liquid phase III is water-soluble monoammonium phosphate after processing. The method of the invention completely separates phosphorus and calcium in the phosphate rock, greatly improves the utilization rate of elements such as calcium and phosphorus, and can directly produce water-soluble monoammonium phosphate.

Owner:SICHUAN UNIV

Method for producing 1,5(1,8)-dinitro-anthraquinones

ActiveCN101423477BEmission reductionSimple processNitro compound preparationNitrationPollutant emissions

The invention relates to a method for producing 1, 5(1, 8)-binitro anthraquinone. The method comprises the following steps: putting anthraquinone in concentrated nitric acid, stirring and cooling the mixture, dripping sulphuric acid at a temperature of between 20 DEG C below zero and 15 DEG C, and making the mixture react for 2 hours continuously at the temperature of between 20 DEG C below zero and 15 DEG C after the dripping is finished, wherein the weight ratio of the concentrated nitric acid to the anthraquinone is between 5 to 1 and 30 to 1, and the weight ratio of the concentrated sulphuric acid to the anthraquinone is between 1 to 1 and 2 to 1; and then gradually heating the reaction mixture to between 60 and 65 DEG C, making the mixture react for 2 hours continuously, and finally adding the reaction mixture into cold water to separate out solid, filtering the solid, washing the solid by water and then drying the solid to obtain the binitro anthraquinone, wherein total content of 1,5-binitro anthraquinone and 1, 8-binitro anthraquinone is not lower than 88 percent. The method has the remarkable advantages that the method has normal-pressure reaction and simple process, canuse batch process and continuous method for production, and uses general chemical equipment, and uses little sulphuric acid, and reduces discharge of pollutant. The total content of the 1, 5(1, 8)-binitro anthraquinone in nitration reaction surpasses that of the prior advanced art.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

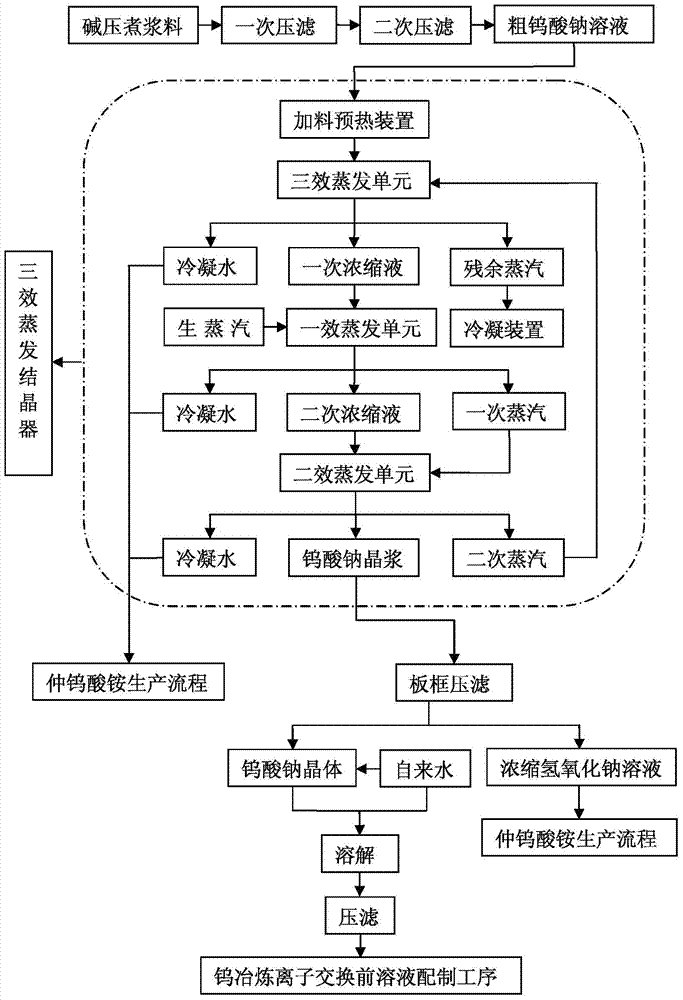

Method for recovering excess sodium hydroxide in tungsten smelting crude sodium tungstate solution

ActiveCN103523800BImprove recycling efficiencyPrevent crystallizationProcess efficiency improvementAlkali metal oxides/hydroxidesFiltrationEvaporation

The invention discloses a method for recovering excess sodium hydroxide in a tungsten smelting crude sodium tungstate solution. The method comprises the steps of mixing a tungsten ore raw material and water according to the volume ratio of 10: 3, then adding into a ball mill for ball milling to obtain tungsten ore slurry, adding a sodium hydroxide solution into the tungsten ore slurry to perform alkali autoclaving to obtain alkali autoclaved slurry, and performing pressure filtration on the alkali autoclaved slurry twice so as to obtain a crude sodium tungstate solution; pumping the crude sodium tungstate solution into a feeding and preheating device; enabling sodium tungstate crystal slurry obtained by separation after the well preheated crude sodium tungstate solution sequentially passes through a three-effect evaporation unit, a one-effect evaporation unit and a two-effect evaporation unit for evaporation and crystallization to enter a plate frame for pressure filtration so as to obtain a concentrated odium hydroxide solution and sodium tungstate crystals. The method disclosed by the invention has the advantages of high degree of automation, convenience in operation and capabilities of greatly reducing energy consumption, reducing later-stage wastewater neutralization control burden, reducing labor cost, reducing labor intensity and being easy to implement, and is in line with the national policies of reducing cost, increasing efficiency, saving energy and reducing emission.

Owner:CNMC GUANGXI PGMA

Method for preparing biological flocculant by using biological iron-calcium slag in heap biological leaching

ActiveCN113968610ARaise the ratio of iron to calciumLower calcium levelsSolid solvent extractionWater/sewage treatment by flocculation/precipitationPregnant leach solutionSlag

The invention discloses a method for preparing a biological flocculant by using biological iron-calcium slag in heap biological leaching. Iron in the biological iron-calcium slag is leached and concentrated by using the biological iron-calcium slag generated in a low-grade copper ore hydrometallurgy heap biological leaching process. The method includes the following three main steps: (1) pre-separation of iron and calcium: mixing the biological iron-calcium slag with raffinate in proportion to obtain iron-rich raffinate, and then adding limestone for neutralization to obtain biological iron-rich slag; (2) multi-stage countercurrent leaching: carrying out circulating countercurrent leaching on the biological iron-rich slag in the system through two-stage serial leaching tanks; and (3) colloid destabilization and separation: sequentially carrying out ultrasonic destabilization and high-temperature viscosity reduction on the mixed solution, and then carrying out filter pressing to obtain the biological flocculant. The production cost is low, the iron concentration in the leachate is larger than 100 g / L, the flocculant can be used as a biological flocculant, the problem of accumulation of biological iron-calcium residues of enterprises is solved, the environmental protection risk and pressure are reduced, and meanwhile economic benefits are created for the enterprises.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

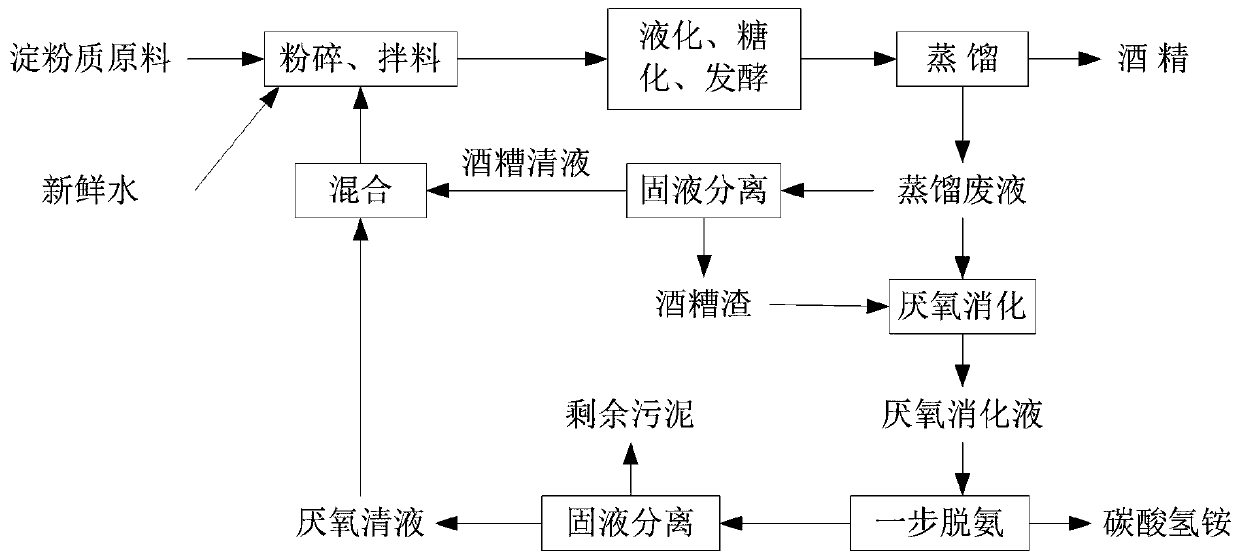

A kind of alcohol production method based on comprehensive utilization of waste water

ActiveCN106591379BSmall footprintExempt from aerobic digestion treatmentTreatment with anaerobic digestion processesMultistage water/sewage treatmentAmmoniacal nitrogenDistillation

The invention discloses an alcohol production method based on comprehensive utilization of waste water and belongs to the technical field of a waste water treatment and alcohol fermentation industry. The alcohol production method comprises carrying out one-step deamination treatment on an anaerobic digestion liquid, then carrying out solid-liquid separation to obtain an anaerobic clear liquid, and mixing the anaerobic clear liquid and a grain stillage clear liquid to obtain a liquid for material blending, wherein a ratio of the anaerobic clear liquid to the liquid for material blending is 60-99%. The one-step deamination treatment process comprises distilling an anaerobic digestion solution through water vapor in a distillation column with multiple layers of column plates or a filler, and removing a part of ammonia nitrogen and alkalinity of the anaerobic digestion solution through thermodynamic effects of water vapor. Through further deamination treatment on the anaerobic digestion solution, ammonia nitrogen accumulation in anaerobic digestion solution recycle is eliminated. The method has low energy consumption, less investment and simple operation, and is very suitable for industrial application.

Owner:JIANGNAN UNIV

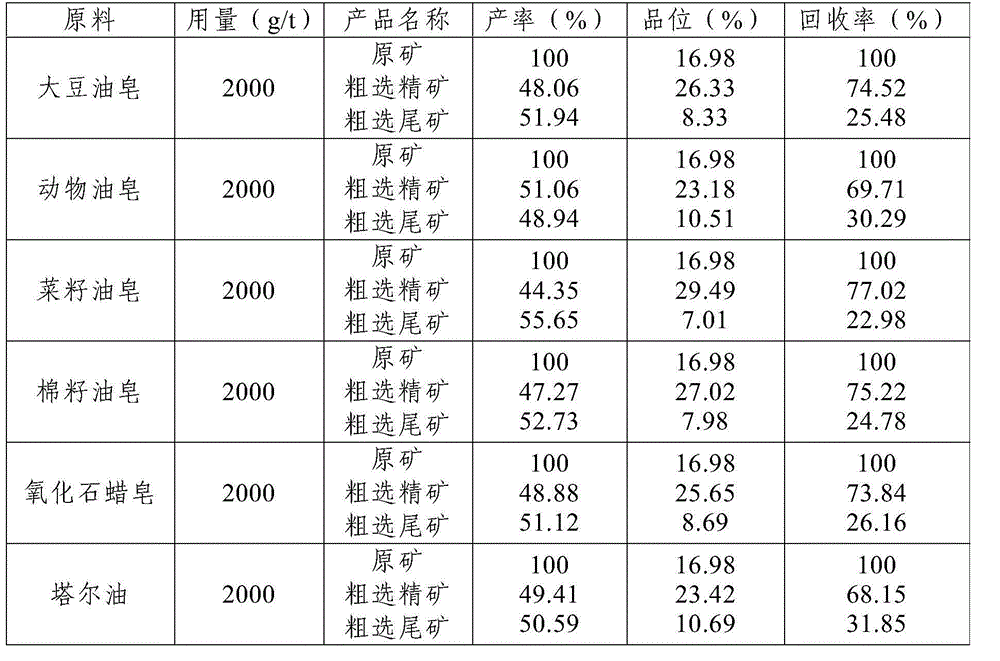

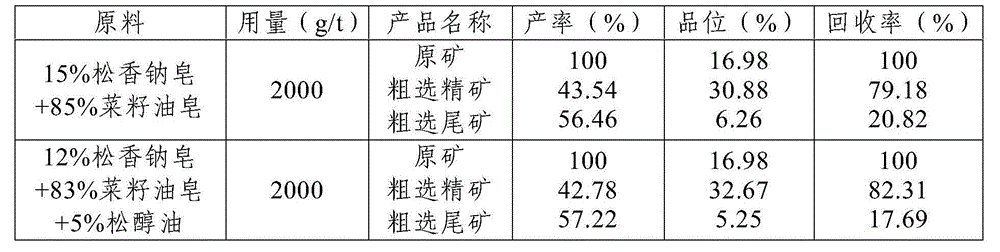

Environment-friendly ilmenite collecting agent and preparation method thereof

ActiveCN104069950BStrong harvesting abilityEnhanced harvesting capacityFlotationToxic materialFatty alcohol

The invention discloses an environment-friendly ilmenite collecting agent. The environment-friendly ilmenite collecting agent is composed of, by mass, 35% to 65% of colza oil soap, 10% to 30% of rosin soda soap, 3% to 8% of terpenic oil, 1% to 5% of fatty alcohol-polyoxyethylene ether sodium sulfate, 0.5% to 3% of coconut fatty acid diethanol amide and the balance water. In addition, the invention further discloses a preparation method of the collecting agent. Compared with a traditional collecting agent containing arsenium and other toxic substances, the environment-friendly ilmenite collecting agent is safe, environmentally friendly, abundant in raw material source, low in cost, small in use amount, high in selectivity, capable of reducing the use amount of regulators such as sulfuric acid, and beneficial for protecting the environment and further reducing production cost. After the environment-friendly ilmenite collecting agent is unceasingly used by mine enterprises, it is verified that under the condition that the floating raw ore grade is 16.33%, good indexes including the concentrate grade of 48.16% or above, the work recovery rate of 83.23% or above and the tailings grade of 3.24% or below can be achieved.

Owner:河南天鸿新材料科技有限公司

Desulphurization and vanadium extraction technique for calcinated vanadium ore

InactiveCN101503762BEliminate pollutionImprove pollutionProcess efficiency improvementResource utilizationSodium salt

Owner:HUNAN UNIV

A kind of synthetic method of p-thymphenyl phenylserine ethyl ester

ActiveCN106905203BMoisture suppressionImprove the conversion rate of esterificationOrganic chemistryOrganic compound preparationWastewaterEthyl ester

The invention provides a synthetic method for p-methyl phenyl serine ethyl ester. The method comprises the following steps: adding diethyl sulfate, ethanol, sulfuric acid and p-diphenylserine copper salt in a reaction vessel, performing a backflow reaction, monitoring the esterification conversion rate at 95-99% and completing the reaction; cooling the mother liquor after insulation and press filtration and crystallizing the material, performing pumping filtration after cooling to -5-0 DEG C, dissolving an obtained filter cake with water and removing copper by sodium sulfide, performing ammoniacal liquor analysis to obtain the product. The method has the advantages that average yield can reach 95%, product purity can reach more than 98%, waste water is little, and the method is environmentally friendly.

Owner:SUZHOU KAIYUAN MINSHENG SCI & TECH CORP

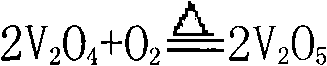

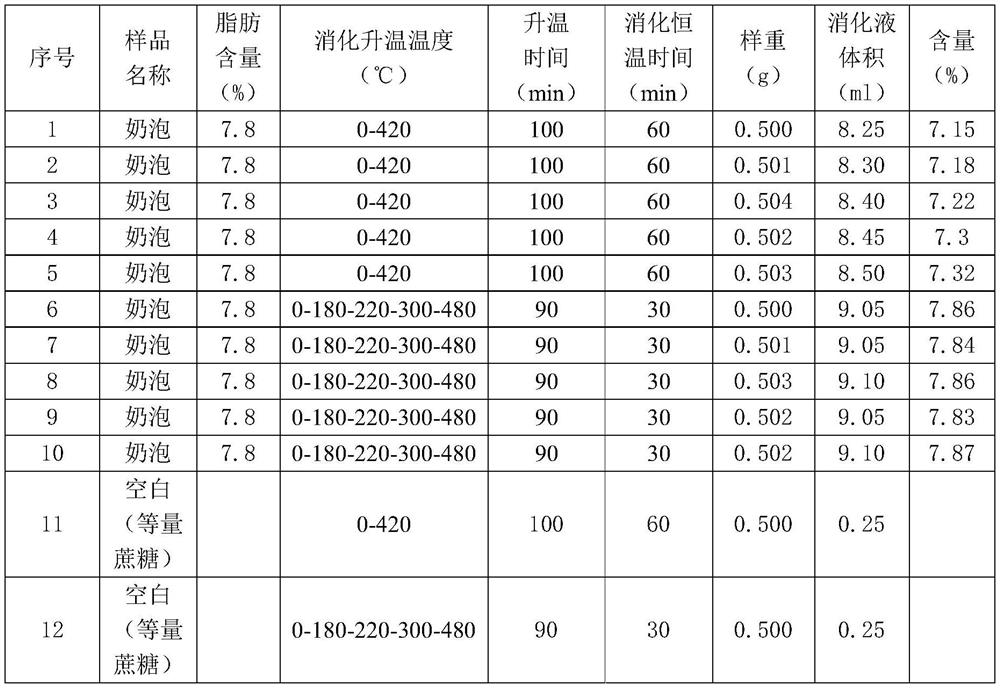

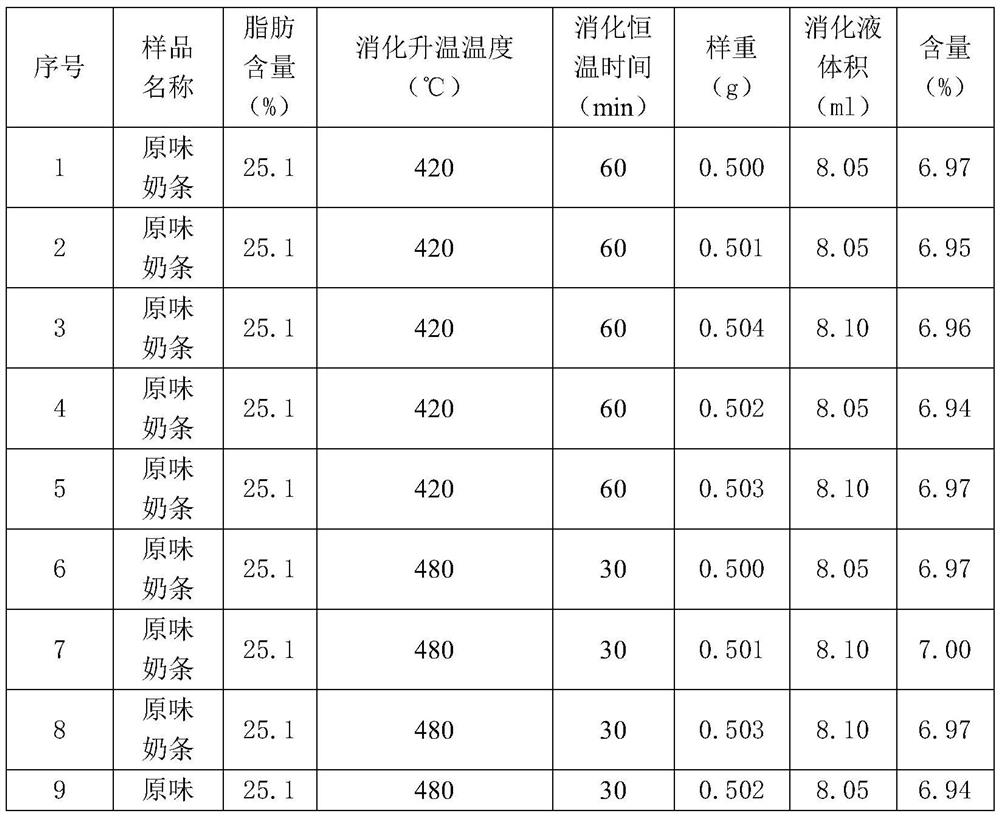

Protein detection method for staged accurate temperature control milk-containing product

PendingCN111796054AAvoid formingSlow release rateChemical analysis using titrationPreparing sample for investigationBiotechnologyProtein detection

The invention discloses a protein detection method for a staged accurate temperature control milk-containing product. The protein detection method comprises the steps of (1) weighing a sample; (2) carrying out a digestion reaction in a digestion furnace to prepare a digestion liquid; and (3) detecting the protein content in the digestion fluid by using an automatic Kjeldahl apparatus. The method has the advantages that by precisely controlling the heating rate in stages, on one hand, foam formation can be avoided, so that the detection result is more accurate, on the other hand, the release speed of the concentrated sulfuric acid is reduced, the product carbonization is more complete, the detection accuracy is further improved, meanwhile, sufficient time is provided for thoroughly dilutingthe concentrated sulfuric acid, and the environmental pollution risk is reduced; according to the invention, the staged heating temperature is set, so that the fat can be completely released, the product end point digestion color can be rapidly achieved, the digestion end point can be completely achieved with the detection method provided by the invention after the simultaneous use for 2 h, and the digestion end point can be achieved only by continuously prolonging different digestion time according to various characteristics of the actual product in the existing standard detection method; the detection result is more accurate, the detection efficiency is high, and safety and environmental protection are achieved.

Owner:内蒙古草原红牛生物科技有限公司

Method for extracting beryllium oxide from low-grade beryllium ore

InactiveCN102168184BIncrease concentrationLow firing temperatureProcess efficiency improvementKeroseneSlag

The invention discloses a method for extracting beryllium oxide from low-grade beryllium ore. The method is characterized by comprising the following steps of: grinding the low-grade beryllium ore, pelletizing, drying, roasting, and crushing to obtain a roasted material; adding concentrated sulfuric acid, stirring, leaching, and separating to obtain acidified liquid and acidified slag; adding theacidified liquid into the other roasted material, and stirring and leaching to obtain primary steep and primary leaching residue; adding concentrated sulfuric acid into the primary leaching residue, adding water, and stirring and leaching to obtain secondary steep and secondary leaching residue, wherein the acidified liquid is replaced by the secondary steep for recycling; extracting the primary steep by adopting an extracting agent in a volume ratio of phosphors extracting agents: alkanol: kerosene of (25-45):(5-1):(50-70) to obtain a beryllium-loaded organic phase and raffinate; washing theberyllium-loaded organic phase by adopting solution of oxalic acid, and performing back extraction by using solution of NaOH to obtain a blank organic phase and stripping solution; and regulating theconcentration of hydroxyl ions in the stripping solution to ensure that beryllium is hydrolyzed and precipitated, and calcining a precipitate to obtain the beryllium oxide. The method is easy to operate, the cost is low, the beryllium oxide with the content of over 97 percent is obtained, and the recovery rate of the beryllium is about 80 percent. The method is suitable for extracting the beryllium oxide from low-grade beryllium ore with low BeO content and high CaF2 content.

Owner:广东省资源综合利用研究所

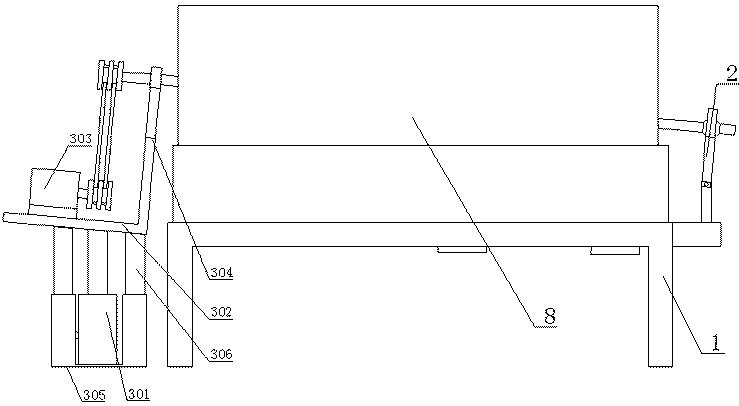

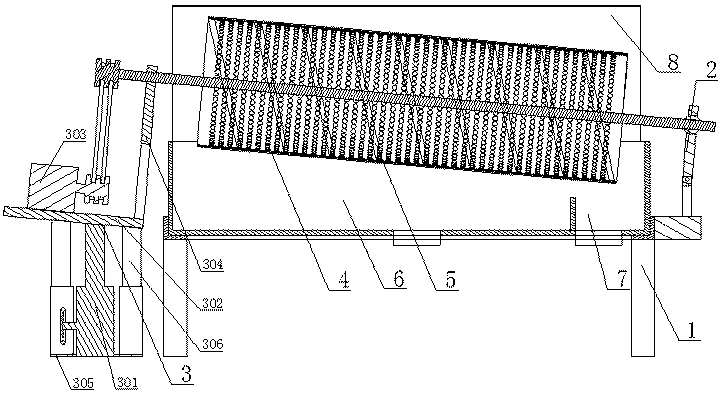

Apparatus and method for separating black liquor from saponified product

ActiveCN106049151AReduce the amount of sulfuric acidSave the consumption of sulfuric acid in productionPulp liquor regenerationBlack liquorFiltration

The invention relates to an apparatus and a method for separating a black liquor from a saponified product. The apparatus comprises: a rack; a first support seat, wherein the first support seat and the first end of the rack form a hinged connection; a lifting bracket connected to the second end of the rack or positioned at the outer side of the second end; a screening roller, wherein both ends of the rotation shaft are respectively and rotatably connected to the first support seat and the lifting bracket; a filtration screen attached on the inner ring surface of the screening roller; a diversion baffle connected to the inner ring surface of the screening roller and the filtration screen; and a first collection groove connected to the rack and a second collection groove connected to the rack, wherein the lifting bracket comprises a lifting mechanism, a support platform, a transmission motor connected to the support platform, and a second support seat. The separation process comprises that the transmission motor is started to make the screening roller rotate, a saponified product is continuously added into the material inlet end of the screening roller, the liquid permeating the filtering screen enters the first collection groove, the concentrated saponified product enters the second collection groove, the liquid in the first collection groove is reused, and the saponified product in the second collection groove is sent to the subsequent saponified product processing step so as to be used.

Owner:湖南双阳高科化工有限公司

Method for preparing high-purity titanium dioxide from titanium-containing blast furnace slag

ActiveCN112047377AImprove acid hydrolysis conversion rateReduce the amount of sulfuric acidTitanium dioxideTitanium oxidePhysical chemistry

The invention discloses a method for preparing high-purity titanium dioxide from titanium-containing blast furnace slag, and belongs to the technical field of chemical material preparation. The methodcomprises the following steps: by taking the titanium-containing blast furnace slag as a raw material, firstly, preparing an impurity-containing titanyl sulfate solution by a sulfuric acid enhanced acidolysis method; separating impurities and titanium-containing components by using a selective hydrothermal deposition method to prepare a metatitanic acid precursor; and calcining the metatitanic acid precursor, controlling the calcination temperature to regulate the crystal form of the product to obtain anatase or rutile high-purity titanium dioxide with the purity of more than or equal to 98%,The total yield of the titanium dioxide is more than or equal to 85%. The method is mainly characterized in that efficient conversion and comprehensive impurity removal of the low-grade titanium-containing blast furnace slag are realized by utilizing an enhanced acidolysis and selective hydrothermal precipitation method, the method has the outstanding characteristics of short process flow, high product purity, high titanium yield, low acid consumption and the like, and a new way is provided for industrial application of the titanium-containing blast furnace slag.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com