Method for efficient synthesis of 2-chloro-4-fluoro-5-nitrotrichlorotoluene

A technology of nitrobenzotrichloride and fluorobenzotrichloride, which is applied in the field of efficient synthesis of 2-chloro-4-fluoro-5-nitrobenzotrichloride, can solve problems such as high cost and incomplete nitration reaction, and achieve Effects of increasing mass fraction, enhancing nitrification ability, and enhancing digestion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

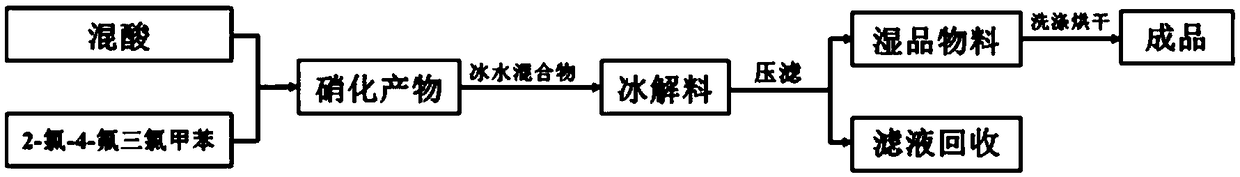

Method used

Image

Examples

Embodiment 1

[0024] Get 25.0g (0.10mol) 2-chloro-4-fluorobenzotrichlorotoluene liquid and place in 50mL dropping funnel, the concentrated sulfuric acid that 26.0g mass concentration is 98% and the concentrated nitric acid that 26.0g mass concentration is 98% forms Pour the mixed acid into a 100mL four-necked flask. Under the condition of stirring, open the dropper to slowly add the 2-chloro-4-fluorobenzotrichlorotoluene liquid into the four-necked flask. The dropping time is 1.5h, and the reaction temperature is 0°C. After the dropwise addition, keep warm for 10 minutes, then put the nitrating material into 250g (13.89mol) of ice-water mixture, filter with circulating water vacuum pump, wash and dry to obtain egg yellow 2-chloro-4-fluoro-5-nitrotri Chlorotoluene solid 28.77g, the filtrate and washing water that are sucked out are reclaimed, to recycle. The product yield calculated by weighing is 98.23%, and the product purity is 92.50%.

Embodiment 2

[0026] Get 25.0g (0.10mol) 2-chloro-4-fluorobenzotrichlorotoluene liquid and place in 50mL dropping funnel, the concentrated sulfuric acid that 26.0g mass concentration is 98% and the concentrated nitric acid that 26.0g mass concentration is 98% forms Pour the mixed acid into a 100mL four-necked flask, and under the condition of stirring, open the dropper to slowly add the 2-chloro-4-fluorobenzotrichlorotoluene liquid into the four-necked flask, the dropping time is 1.5h, and the reaction temperature is -2°C , keep warm for 10min after the dropwise addition, then put the nitrating material into 200g (11.12mol) ice-water mixture, carry out suction filtration with a circulating water vacuum pump, wash, and dry to obtain egg yellow 2-chloro-4-fluoro-5-nitro Trichlorotoluene solid 28.70g, the filtrate and washing water that are sucked out are reclaimed, to recycle. The product yield calculated by weighing is 98.01%, and the product purity is 92.32%.

Embodiment 3

[0028] Get 25.0g (0.1mol) of 2-chloro-4-fluorobenzotrichlorotoluene liquid and place it in a 50mL dropping funnel, and use 26.0g mass concentration of 98% concentrated sulfuric acid and 26.0g mass concentration of 98% concentrated nitric acid to form Pour the mixed acid into a 100mL four-necked flask. Under the condition of stirring, open the dropper to slowly add the 2-chloro-4-fluorobenzotrichloride liquid into the four-necked flask. The dropping time is 1.5h, and the reaction temperature is 2°C. After the dropwise addition, keep warm for 10 minutes, then put the nitrating material into 200g (11.12mol) of ice-water mixture, filter with circulating water vacuum pump, wash and dry to obtain egg yellow 2-chloro-4-fluoro-5-nitro Trichlorotoluene solid 29.00g, the filtrate and washing water filtered out by suction are recovered for recycling. The product yield calculated by weighing is 98.17%, and the product purity is 91.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com